#manufacturing

Text

do you want my load or should i double it and give it to the next guy

58 notes

·

View notes

Text

this is what we do -

619 notes

·

View notes

Text

dumping the slag

717 notes

·

View notes

Text

expansion of copper tubing

#my posts#gif#hydraulic machine#factory machinery#metal pipe#copper pipe#manufacturing#suggestive#objectophilia#objectum

286 notes

·

View notes

Link

108 notes

·

View notes

Text

We’ve Got It Made: Process X Goes Behind the Scenes to Demystify the Production of Our Favorite Objects and Tools

276 notes

·

View notes

Text

Dyes widely used in the textile, food and pharmaceutical industries pose a pressing threat to plant, animal and human health, as well as natural environments around the world, a new study has found.

Billions of tons of dye-containing wastewater enter water systems every year, and a group of researchers from the UK, China, Korea and Belgium say that new sustainable technologies including new membrane-based nano-scale filtration are needed to solve the issue, adding that legislation is needed to compel industrial producers to eliminate colorants before they reach public sewage systems or waterways.

Published today in Nature Reviews Earth & Environment, the study Environmental impacts and remediation of dye-containing wastewater was written by academics from the University of Bath, the Chinese Academy of Sciences, the Fujian Agriculture and Forestry University, the Korea Institute of Energy Technology (KENTECH), and KU Leuven, Belgium.

The research highlights that currently, up to 80% of dye-containing industrial wastewaters created in low- and middle-income countries are released untreated into waterways or used directly for irrigation. The authors say this poses a wide range of direct and indirect threats to human, animal and plant health

Continue Reading

124 notes

·

View notes

Text

Dreamers and Dogs

The Rail Yards, Albuquerque

#photographers on tumblr#streetphotography#original photographers#my photography#photography#street photography#landscape#contemporary photography#new mexico#art#artists on tumblr#architecture photography#artist on tumblr#locomotive#manufacturing#crane#infrastructure#assembly plant#heavy industry#nm#americaisdead

70 notes

·

View notes

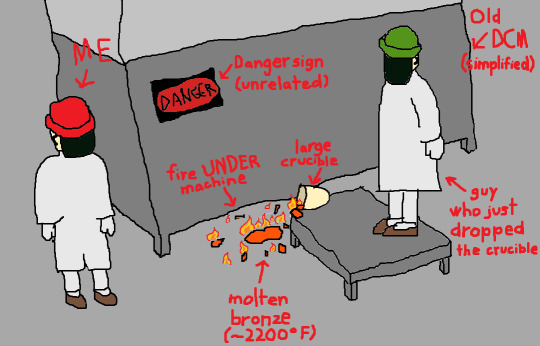

Text

Bit of an issue.

#all the castings came out super good though!#my stuff#art#casting#bronze#manufacturing#paint#this took me a while#I used the mousepad so that might be why#this happened RIGHT AFTER the other guy finished explaining to me the dangers of copper and bronze#in that it will stick to you instead of bouncing off#and you will get severely burned#no one was injured this time though!

108 notes

·

View notes

Note

Why are the clothes you sell so expensive :( I totally understand you need to make a living and all but I don’t think I can drop $50 on one shirt

i totally understand!! and it’s a fair question. thanks to big retailers and, in recent years, fast fashion, most people have been intentionally distanced from the cost and labor that goes into making our clothing (and just about everything else we consume)

basically, when you are making something, the more you make of it, the less it costs to make a single unit of that thing. that may seem counter intuitive, but this is for a couple reasons: 1. the more you make of a single thing, the more streamlined the process becomes and the faster and more skilled workers become at a particular task 2. when you make a lot of something you can buy your materials in bulk, reducing the cost to manufacture a single item 3. when someone places a really really big order for something, they have a lot of bargaining power because if they like what they get, they are likely to return with another large order in the future, and if they put the factory under contract, that is steady, guaranteed work and reliable pay.

i typed this up for a different question recently but it applies here as well so i’ll just copy paste:

of course, if you sell a higher volume, you can not only negotiate a lower PPU (price per unit) based on volume of sales (a factory will make more money from your business if you buy 10,000 shirts for $10/piece than if you buy 1,000 shirts for $12/piece*) but you can also get away with a lower margin because you’re expecting to sell more units to customers. imagine selling 10,000 shirts for $25/ea instead of 1,000 for $35/ea. even with a profit margin of $15/ea instead of $23/ea, you would only need to sell about 1,534 shirts of your 10,000 to make the same net profit and you’d have almost another 8500 shirts you could keep selling.

*these are not real numbers just an example for easy math and to show how stupid manufacturing math is

it’s also much, much cheaper to buy pre-dyed or stock fabric than it is to custom print designs. most large retailers use fabric that has been bulk produced. each of our garments is custom printed because manufacturing bulk custom printed fabric usually STARTS at around 500 yards (way more than we could use for a single design) and a fabric printer starts around $15k and takes up a bunch of room and uses a lot of electricity.

i run a small business with my wife. we do our best to find ethical labor and to pay our employees well, which contribute significantly to our overhead costs. we’re never going to compete price-wise with fast fashion or walmart or even with target. we couldn’t even fathom functioning at 1/100th of their volume. it’s totally understandable that not everyone can afford this or will think it’s “worth” the cost and the things i make are not necessities. i won’t even be offended if people call me overpriced because i know that most people just don’t know what goes into this stuff.

anyway this was long but i hope you found it informative!

309 notes

·

View notes

Text

Flexible circuit boards manufacturing (JLCPCB, 2023)

Inkjet print head uses a fiducial camera for registering an FPC panel, and after alignment it prints graphics with UV-cureable epoxy in two passes

#jlcpcb#pcb#fpc#manufacturing#manufacture#factory#electronics#fiducial camera#camera#cv#opencv#computer vision

114 notes

·

View notes

Text

The Keys @ Adafruit

🔑🌈🎨💻⌨️🛠️🎁🔠

Dress up your mechanical keys in your favorite colors, with a wide selection of stylish key caps from Adafruit. Comes in 10 packs for your next mechanical keyboard or NeoKey project.

#Adafruit#Retro#Keyboards#Technology#CustomizeYourKeys#NeoKeyProjects#StyleYourKeyboard#ColorfulCoding#TechWithStyle#KeyboardUpgrade#DIYKeyboard#MechanicalKeys#electronics#manufacturing#nyc#womanowned

931 notes

·

View notes

Text

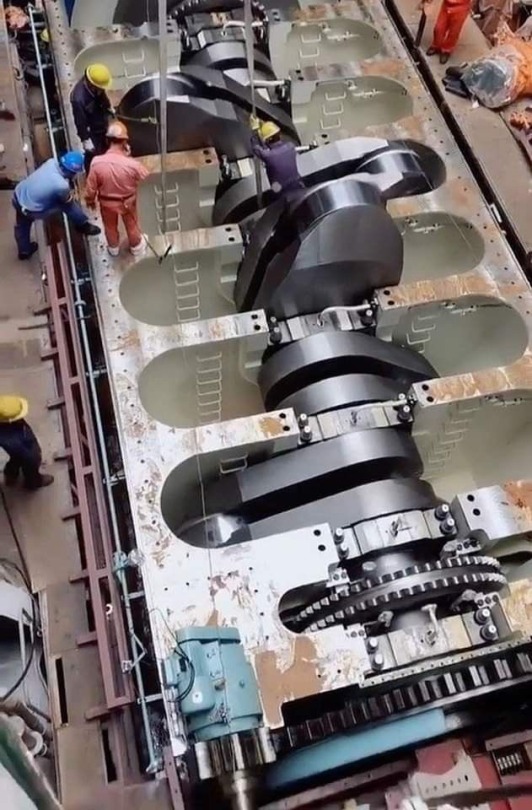

vessel crank

113 notes

·

View notes

Text

Here are some of my character designs from one of my first illustration jobs. A far cry from the sort of work I do now.

56 notes

·

View notes

Text

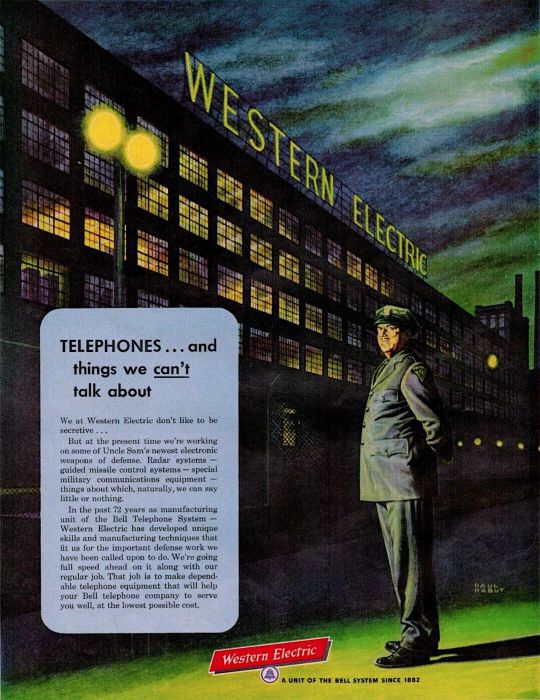

Western Electric Co, 1954

#Bell Telephone#ad#1954#mid century#phone system#advertisement#Paul Rabut#illustration#Uncle Sam#manufacturing#midcentury#vintage#1950s#telephones#national defense#radar systems#military#guided missiles#mid-century

110 notes

·

View notes

Text

Researchers were running the experiment at Sandia when the discovery was made. They only meant to evaluate how cracks formed and spread through a nanoscale piece of platinum using a specialized electron microscope technique they had developed to repeatedly pull on the ends of the metal 200 times per second. Surprisingly, about 40 minutes into the experiment, the damage reversed course. One end of the crack fused back together as if it was retracing its steps, leaving no trace of the former injury. Over time, the crack regrew along a different direction.

87 notes

·

View notes