#tensiometer

Text

Understanding Beam Loads: A Comprehensive Overview

In structural engineering, analyzing the different types of loads on a beam is fundamental to ensuring the safety and stability of structures. The loads applied to a beam can vary in nature, and engineers must consider these variations for accurate design and assessment. Here, we explore the various types of loads on a beam and delve into the crucial role of Crane Safe Load Indicators (SLIs), especially in urban environments like Delhi.

Types of Loads on a Beam:

Point Load:

A concentrated force applied at a specific point on the beam. This could represent a single heavy object or a support point.

Uniformly Distributed Load (UDL):

This load is spread evenly along the length of the beam, creating a uniform force per unit length. Examples include the weight of a floor or roof.

Uniformly Varying Load (UVL):

Also known as a triangular load, the intensity of this force varies uniformly along the length of the beam. It creates a triangular shape on load diagrams.

Concentrated Moment:

Unlike a point load, which applies force vertically, a concentrated moment applies a twisting force at a specific point on the beam. This is crucial for assessing the beam's resistance to torsional forces.

Understanding these loads is essential for designing structures that can withstand the forces they are likely to encounter during their lifecycle.

Importance of Crane Safe Load Indicators (SLIs) in Delhi:

In bustling urban environments like Delhi, where construction and infrastructure development are ongoing, the use of cranes is widespread. Crane Safe Load Indicators (SLIs) play a pivotal role in ensuring the safety and efficiency of crane operations.

Preventing Overloading:

The primary function of a Crane Safe Load Indicator is to prevent overloading. Overloading a crane can lead to structural failure, posing a severe risk to personnel, equipment, and surrounding structures. In Delhi, where densely populated areas coexist with construction sites, preventing overloading is of paramount importance to avoid accidents and ensure public safety.

Real-Time Monitoring:

Crane SLIs provide real-time monitoring of the load being lifted. This includes information about the load's magnitude, position, and distribution. Real-time data is crucial for crane operators to make informed decisions, especially when working in dynamic construction environments.

Enhancing Operator Awareness:

Safe Load Indicators in Delhi enhance operator awareness by providing visual and audible alarms when the load approaches or exceeds safe working limits. This helps operators take immediate corrective actions, ensuring that the crane operates within its specified capacity.

Structural Integrity:

Overloading a crane not only poses risks to the crane and its operators but can also lead to structural damage to the building or infrastructure being constructed. Crane SLIs contribute to maintaining the structural integrity of both the crane and the surrounding structures.

Legal Compliance:

In Delhi, adherence to safety regulations is a legal requirement for construction projects. Crane Safe Load Indicators help construction companies and crane operators comply with safety standards, reducing the risk of legal complications and liabilities.

Efficient Operations:

By providing precise load information, SLIs contribute to the efficient operation of cranes. Operators can optimize lifting operations, reduce downtime, and enhance overall productivity on construction sites in Delhi's fast-paced environment.

Training and Certification:

Crane SLIs facilitate training and certification processes for crane operators. Ensuring that operators are well-trained and certified on the use of Safe Load Indicators in Delhi contributes to the overall safety culture in the construction industry.

In conclusion, the different types of loads on a beam represent the complexities of structural engineering. Understanding and appropriately addressing these loads are essential for constructing safe and resilient structures. In urban landscapes like Delhi, where construction activities are omnipresent, the role of Crane Safe Load Indicators cannot be overstated. These indicators not only prevent accidents and overloading but also contribute to the overall safety, efficiency, and compliance of crane operations in dynamic and densely populated environments.

0 notes

Text

I wonder what kind of tools other mechanics/craftsmen fetishize.

What does the carpenter lust after at night?

What kind of tools do car mechanics keep in their special little hardcases they take home at the end of the day?

3 notes

·

View notes

Link

0 notes

Link

0 notes

Text

#Tensiometer Market Size#Industry Analysis By Segmentations#Top Key Players#Trends#Future Development & Forecast

0 notes

Text

What are the soil moisture measuring instruments

Overview

The development of precision agriculture and the global need to conserve water determine the need for rational soil treatment. It requires the use of more or less sophisticated soil environmental monitoring systems equipped with different types of sensors. The state of soil water in particular is the most challenging. With the development of the Agricultural Internet of Things. Different soil moisture measurement instruments can be developed according to different application scenarios. Now let’s see what kinds of instruments are available to measure soil moisture content.

Introduction of soil moisture measurement instruments

Soil moisture sensors contribute to good irrigation management. Good irrigation management can provide better crops, use fewer inputs, and improve profitability. Soil moisture sensors help irrigators understand what is happening in crop root zones. The soil moisture sensors commonly used in soil moisture monitoring and irrigation soil moisture monitoring are FDR and TDR, namely frequency domain and time domain. FDR frequency domain reflector is a kind of instrument used to measure soil moisture. It has the advantages of simple and safe, fast and accurate, fixed point continuous, automation, wide range and less calibration.

Soil tensiometer is to measure the suction pressure at the porous tip of the tensiometer. Water is drawn out of or into the nozzle, depending on the amount of water available. This creates a suction that represents the force the plant needs to extract water from the soil. Measurements can be made by manually reading a vacuum gauge or automatically reading using a logging pressure sensor. To maintain the tensimeter, check the bubbles and refill the fluid used to create a vacuum in the tensimeter.

Soil moisture measurement instruments have been widely used in water-saving agricultural irrigation, greenhouse, flowers and vegetables, grassland and pasture, soil speed measurement, plant culture, scientific experiments and other fields. Through the soil temperature and humidity sensor can easily grasp the soil moisture changes. Thus better completion of crop growth to help.

0 notes

Text

you really find yourself at a disadvantage when you're in med school and you don't have any close relative who's a doctor because suddenly your assignment asks you to use a tensiometer and like... bestie where exactly do i get one??

2 notes

·

View notes

Text

Liquid Surface Tension Meter In-Depth Profiling With Key Players and Recent Developments, Forecast Period: 2021-2031

Liquid surface tension meter is a measuring instrument used to measure the surface tension of liquids and/or the interfacial tension between two immiscible liquids. Surface tension is defined as the attraction of like molecules on a liquid’s surface. Surface tension is also sometimes called capillary force or interfacial tension. Surface tension is the property by which liquid surfaces tend to shrink into the minimum surface area possible. At the liquid–air interface, surface tension is generated due to the greater attraction of liquid molecules to each other than to the molecules in the air. The interface boundary is formed by the difference in attractions between liquids and gases. The resultant effect is an inward force at the surface of the liquid that causes the liquid to behave as if the surface is covered with a stretched elastic membrane. Surface tension of a liquid surface is created by cohesion which is the interaction of like molecules with each other. Measurement of surface tension is actually a measurement of the balancing forces between two surfaces which are responsible for creating the surface tension. The surface tension may be liquid to air, liquid to solid, liquid to liquid, or other combinations. Surface tension is an important parameter that controls a liquid’s ability to influence certain properties of a system such as the ability to wet a solid surface. Modern methods of surface tension measurement include the digital goniometer/ tensiometer method, which measures surface contact angle and capillary pressure between two fluids. Measurement of surface contact angle helps to define the exact interface surface. Contact angle meter is used to measure the contact angle of a liquid to a solid. This is called the wettability of liquid to solid. The contact angle meter is capable of measuring the contact angle of various liquids to various materials. The instrument plays a very important role in the petroleum, printing and dyeing, pharmaceutical, spraying, mineral processing and other industries. Various type of liquid surface tension meters is available to determine surface tension of liquids such as oils, coatings, lacquers, adhesives and others.

Top impacting factors: Market Scenario Analysis, Trends, Drivers and Impact Analysis

Liquid surface tension meters are used across various industries in various applications. Liquid surface tension meters are employed in various industries including the global manufacturing and construction industries for monitoring processes such as electroplating and cleaning operations. Surface tension meters also help to determine the powder wettability, absorption, surface heterogeneity, density among other important parameters of various products. Liquid surface tension meters are also extensively used in the petroleum industry. However, high cost of equipment is likely to challenge the market growth. The opportunity for growth for the global liquid surface tension meter market come from the growing global petroleum industry as demand for petroleum products that are used for various uses continue to grow worldwide.

Growth of global construction and manufacturing industry

Surface tension meters are used for monitoring various industrial production processes like the cleaning of parts or electroplating process. They are also used for monitoring the detergent concentration that is used in the cleaning or electroplating processes. Surface tension meters also help to determine the powder wettability, absorption, surface heterogeneity, density among other important parameters of various products. The surface tension of a solvent is an important parameter that helps to determine the effectiveness of wetting, spreading, foaming and emulsification of various products. Surface tension meters are required for various applications like to determine the surface tension of liquids like coatings, lacquers or adhesives. These are products that are used commonly in the global construction, manufacturing, and other industries. With the growth of the global construction and manufacturing sectors, the global liquid surface tension meter market is also expected to grow as measurement of surface tension is such an important and integral process in many applications in these industrial processes.

Full Report With TOC:-https://www.alliedmarketresearch.com/liquid-surface-tension-meter-market-A09699

0 notes

Text

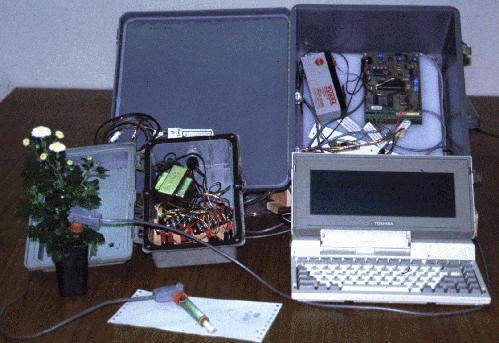

Tensiometer-based irrigation of potted plants (via)

0 notes

Text

"Doctor, we now have all the necessary medical equipment to save lives!"

"But what about cow bell?"

You can download individual items here: Medical Shower, Auxiliary Table, Auxiliary Table 2, Clinic Monitor, Crutches, Grab Bar Right Side, Grab Bars Left Side, Hospital Bed, Screen, Serum Hanger, Tensiometer, Walker, Wall Light, and Wheelchair.Original Creator: kardofe

6/14/23: Based on comments the bed may not be working

0 notes

Text

Understanding Operating Weight and the Role of Crane Small Tensiometers

In the realm of heavy equipment, where precision and safety reign supreme, understanding the concept of operating weight is paramount. Operating weight refers to the total mass of a machine, encompassing not just the equipment itself but also all operational components, fluids, and, if applicable, the weight of the operator. This metric serves as a linchpin in ensuring the safe and efficient use of heavy machinery across various industries.

The Significance of Operating Weight:

1. Safety First:

Operating weight is a cornerstone in the realm of heavy equipment safety. Knowing the exact weight of a machine when fully operational allows operators and project planners to make informed decisions about transportation requirements and the suitability of supporting structures. This knowledge is instrumental in preventing accidents caused by overloading, a situation that can compromise stability and jeopardize the safety of both the equipment and personnel.

2. Efficiency in Planning:

Efficiency in project planning is a direct derivative of understanding operating weight. Project managers can optimize logistics, selecting appropriate lifting and hauling equipment based on the anticipated operating weight. This proactive approach streamlines operations, reduces downtime, and ensures that the right equipment is deployed for the task at hand.

3. Ground and Structural Integrity:

Heavy equipment, by its nature, exerts significant force on the ground and supporting structures. Knowing the operating weight is essential to safeguarding the integrity of the ground surface and structures. This knowledge helps prevent damage to roads, bridges, or any surfaces where heavy equipment operates. Structural engineers rely on accurate operating weight data to assess the impact on buildings and ensure that they can withstand the load without compromising safety.

Introducing Precision with Crane Small Tensiometers:

1. Understanding Small Tensiometers:

In the intricate world of cranes, precision is not just a preference but a necessity. Crane Small Tensiometers play a pivotal role in ensuring that the tension in cables or ropes is maintained within safe and optimal limits during crane operations. These small but powerful devices provide real-time data, allowing operators to make swift adjustments to maintain the right tension levels.

2. Role in Safety Protocols:

Safety is paramount in crane operations, where loads can be immense, and the consequences of failure are severe. A Crane Small Tensiometer acts as an invaluable tool in upholding safety protocols. By continuously monitoring tension, it prevents overloading, one of the primary causes of crane accidents. This not only protects the equipment but, more importantly, safeguards the well-being of operators and those in the vicinity of the crane.

3. Enhancing Equipment Longevity:

Crane Small Tensiometers contribute significantly to the longevity of crane equipment. Proper tension management reduces wear and tear on cables and other components, minimizing the risk of sudden failures. This proactive approach to maintenance ensures that the crane operates optimally over an extended period, reducing downtime and maintenance costs.

4. Operational Efficiency:

Efficiency in crane operations hinges on precise tension control. Crane Small Tensiometers provide operators with real-time data, allowing them to adjust tension levels on the fly. This not only enhances safety but also ensures that the crane operates with maximum efficiency, completing tasks in a timely and cost-effective manner.

The Synergy of Operating Weight and Crane Small Tensiometers:

1. Safety Synergy:

Operating weight and Crane Small Tensiometers complement each other in the pursuit of safety. Understanding the operating weight allows for proper planning, ensuring that the crane's lifting capacity is not exceeded. Simultaneously, Small Tensiometers ensure that the applied tension is within safe limits, creating a dual-layered safety net that enhances overall operational safety.

2. Precision in Performance:

The synergy between operating weight knowledge and Small Tensiometers ushers in a new era of precision in heavy equipment operations, particularly in crane usage. This precision is not just about accuracy; it's about optimizing performance, reducing the risk of accidents, and enhancing overall operational efficiency.

3. Future-Forward Approach:

As industries evolve, the need for precision and safety in heavy equipment operations will only intensify. The integration of operating weight considerations and advanced tools like Crane Small Tensiometers represents a future-forward approach. It reflects a commitment to not just meeting operational demands but exceeding them while prioritizing the safety of personnel and the longevity of equipment.

In conclusion, the dynamic interplay of operating weight and Crane Small Tensiometers underscores the evolving landscape of heavy equipment operations. Safety, efficiency, and precision are no longer optional; they are the bedrock upon which successful operations are built. As industries continue to push boundaries, the marriage of these two critical elements will undoubtedly shape the future of heavy equipment usage, ushering in an era where every move is calculated, and every lift is executed with unparalleled precision and safety.

0 notes

Link

0 notes

Text

0 notes

Link

0 notes

Text

Importance of soil moisture sensors in Agriculture | Harisharan Devgan

Soil moisture sensors are important in agriculture because they provide critical information about soil moisture levels. The information is essential for optimizing crop growth and maximizing yields. Some of the key reasons why soil moisture sensors are important in agriculture include:

Water management

Soil moisture sensors can provide accurate and real-time information about soil moisture levels. This help farmers optimize their irrigation practices and reduce water waste. Moreover, it can lead to significant water savings and lower water bills.

Nutrient management

Soil moisture sensors can also use to measure the availability of nutrients in the soil. It also helps farmers optimize their fertilizer applications and reduce waste.

Disease prevention

Maintaining optimal soil moisture levels can help to prevent the growth of fungal and bacterial pathogens that can damage crops. Soil moisture sensors help farmers identify when soil moisture levels are too high or too low, allowing them to adjust irrigation practices accordingly.

Climate adaptation

Soil moisture sensors can used to track changes in soil moisture levels over time, which can help farmers adapt to changing weather patterns and climate conditions.

Different Types of soil moisture sensors

There are several types of soil moisture sensors available, each with its own advantages and limitations. Some of the most common types of soil moisture sensors include:

Tensiometers

Tensiometers are simple and inexpensive devices that measure soil water tension or suction. They have a porous cup connected to a vacuum gauge. It measures the pressure required to extract water from the soil. Tensiometers are often used in conjunction with other sensors to provide a more complete picture of soil water conditions.

Capacitance sensors

They measure the dielectric constant of the soil, which relates to the soil moisture content. These sensors work by measuring the capacitance between two electrodes inserted into the soil. These sensors are relatively inexpensive and easy to use, but they can sometimes affect soil salinity and temperature.

Time-domain reflectometry (TDR) sensors

TDR sensors use electromagnetic waves to measure the dielectric constant of the soil, which relates to the soil moisture content. These sensors work by sending a pulse of energy down a probe inserted into the soil. That measures the time it takes for the energy to reflect. TDR sensors are accurate and used in a wide range of soil types. But they can be expensive and requires specialized equipment.

Electrical resistance sensors

These sensors measure the electrical resistance of the soil, which changes as the soil moisture content changes. These sensors work by sending a small electrical current through two electrodes inserted into the soil. It measures the resistance between them. Electrical resistance sensors are relatively inexpensive and easy to use, but they can affect by soil temperature and salinity.

So, the choice of soil moisture sensor depends on the specific application and the characteristics of the soil.

0 notes

Photo

Yongrow Automatic Digital Wrist Blood Pressure Monitor Sphygmomanometer Tonometer Tensiometer Heart Rate Pulse Meter BP Monitor

0 notes