Text

Digital workforce make company able to cope up with the challenges in market. Such as

Consumer’s taste and preference : in this competitive market, too many companies offer same kind of product and because of that the variety for consumer’s has been increase. So company can give product which consumer like the most in market with through flexible production capacity.

Launch New Product :company can not survive with only one type of product in market because other competitors provide many options of such product. So if company want to launch new product in market according to market trend, manufacturer don’t need to change machines and tools. It just need some changes in programming in software and production line enable to work on new different product.

Increase total working hours : this can be major challenge for many manufacturer sue to such reasons. The aim to have digital workforce in manufacturing Is to make things automated, and if machines operate by itself then total working hours will increase. Because machine don’t take any leave. Machine can operate for 24 hours a day.

2 notes

·

View notes

Text

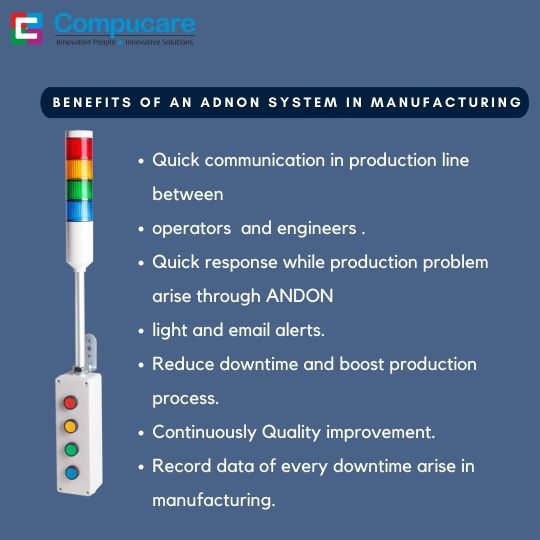

How ANDON system sends notification?

There are three ways:

1) ANDON light

This is the most common method where three LED lights i.e. red, yellow and green are used as a indicator.

RED – Problem arise - It indicates that an action needs to be taken to solve problem

YELLOW - Problem Found – e It indicates that problem is found and will be fixed

GREEN - Smooth Production – The production line problem is resolved and is running smoothly

2) SMS and Email alert

Second way is where ANDON system automatically sends Email/SMS about the issue to authoritative operator and engineer. Thus, time wasted in confirming through verbal communication with each other is saved.

3) Sound alert

Here, whenever a problem arises the ANDON system gets activated and it gives loud sound alert to indicate a operator that something is wrong and attention is needed.

ANDON system is one of the best systems which can reduce the downtime for sure. This automation is small in size but help your business to be more efficient in production

0 notes

Text

Types of Industrial Automation System

0 notes

Photo

These are the locations in india where major industries are operating in india.

0 notes

Text

What is Production Monitoring System?

Production monitoring system refers to the technique which design to measure overall production efficiency in production line. This system provide real time performance data which are accurate. This can be possible with the help of Industrial Internet of things (IIoT) and this is automatic system where process from collecting data to transfer data is automated.

Data collected from various production line from floor and display it on production monitoring system with overall efficiency. also there is system to automatically transfer notification and data to autorotative engineers, workers and managers of company. So if any problem arise on production floor then everyone get inform within a second. And immediate actions can be taken.

0 notes

Photo

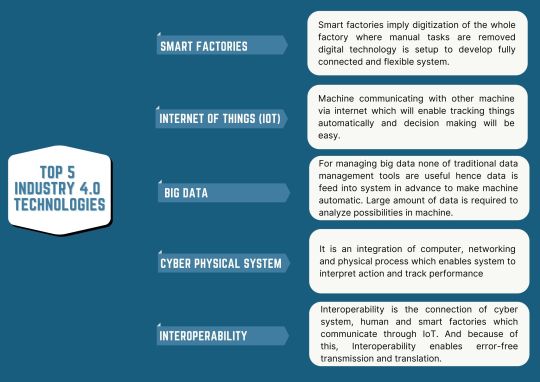

Industrial development shows how industries adopt technology and improving by changing operation style. from industry 1.0 to industry 4.0 industries are more advanced and make operations more easy. But this advancement is not solely happened, this development is possible with above these technologies.

0 notes

Text

Biometric Time attendance system

Time attendance system directly affect discipline of any organization. It need to maintain properly. Because it effect more on your professional life. Time attendance with the help of technology make things easy to maintain. Biometric time attendance system is the modern way to manage. Biometric Time Attendance is easy to use. It is very essential tool for specially HR of the organization. Because he/she has to manage things like leave management, salary, regularity of an employee etc. if HR do all this things manually then it’s going to be very confusing and faulty. But Biometric Time Attendance make things easy for HR because it save all things as it connected with software. So Biometric Time Attendance is very importance accessory of every offices. And Compucare India Pvt. Ltd. has been in the forefront of providing the latest Biometric/RFId based time attendance solution with its efficient Time Office Software.

0 notes

Text

Industry 4.0 for Women

Industry 4.0 is now emerging technology like Cloud, IoT, 5G ,AI, etc. Along with it, the opportunities for women has also opened the door. Most of the telecom are focusing on making their sector a gender inclusive. Like, Vodafone recruits 50-60% of women from all levels of education at every location. So industry 4.0 is can actually fill the skill gap and make the line true “Skill India” through give chance to develop everyone. Compucare India Pvt. Ltd. believe in fill this gap.

0 notes

Link

ANDON system is a part off an industry 4.0 and very useful during manufacturing any product as it directly link with the production machinery and help to identify any problem arise in machinery. in this situation, ANDON light quickly give signals to whole production assembly line. and within a second, operators and engineers who are working on that production line notify the situation and start to resolve it.

ANDON can be done automatically and manually, in manually when any operator press ANDON button or any handle , then light blink with specific sound.

ANDON system is the best example of industry 4.0. and it is going to be mandatory in most of the manufacturing companies.

for more understanding, go through this link and see this video.

0 notes

Photo

This if future of production and maintenance process in manufacturing industry. ANDON system make it easy to understand the problem arise in manufacturing process. This small system in manufacturing plant improve the communication between operators and engineers related to manufacturing process. Compucare will Make this system for your companny

1 note

·

View note