#Bitumen

Text

Kroelian SANDYGAST & PALOSSAND (Ground/Poison)

They can be found on the northern shores of Kroel, in a zone known for their constant oil spills, where many other pokemons affected by this oil live and have adapted

They are based on Oil Sands, also known as "Tar sands" or "Bituminous sands", Oil rigs and Drilling towers

#pokemon#fakemon#fake pokemon#palossand#sandygast#regional form#regional variant#regional evolution#ground type#ground pokemon#ground fakemon#poison pokemon#poison type#poison fakemon#oil#sand#oil sands#tar#petroleum#bitumen#oil spill#oil rig

1K notes

·

View notes

Text

Neanderthals were master innovators, dare we say, even engineers! Researchers have discovered stone tools from 120,000 to 40,000 years ago with complex adhesive handles, showcasing advanced creativity and even some basic chemistry. This changes our understanding of Neanderthal technology and challenges our perceptions of their prehistoric intelligence.

30 notes

·

View notes

Note

Bitumen ❤️

Hi! Thanks for the ask <3

I can't believe it's been almost a year since I updated this one. Bitumen is my secret favorite because I love necromancer!Harry so so much, and the plot is just absurd.

It was important to note that emotions were below someone as magically and psychologically advanced as the Dark Lord Voldemort. He was a god among men—literally, as he wielded power most could not fathom, and he was utterly, unquestionably immortal. No one was better than him at anything.

Except fucking Necromancy, apparently.

He was not bitter. He was not jealous. He was pleased to have someone in his service who could provide a useful service. And such fortuitous timing, too, given that the best plan of action to terrify the world into submission required Necromancy. It was too bloody perfect. Clearly, fate held Voldemort in its favor, and had granted Harry Potter as a gift.

14 notes

·

View notes

Text

A piece of wilfully aged “Diesel Sneeze”, 2020

121 notes

·

View notes

Photo

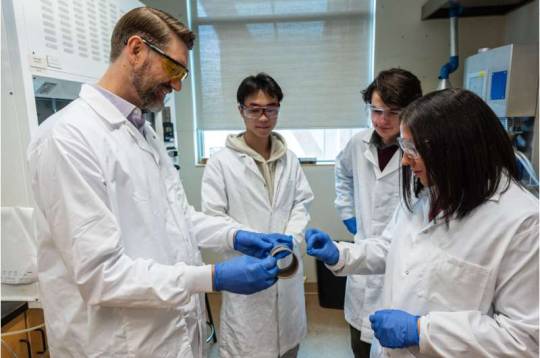

Researchers turn black bitumen into green carbon fibers

Bitumen, the sticky product from Alberta's oil sands, is normally burned as fuel or gets a second life as asphalt pavement.

But what if it could be turned into something more valuable, like the carbon fibers that make aircraft and hockey sticks light and durable, and electric cars safer and more efficient?

UBC materials engineer Dr. Yasmine Abdin and her colleagues, Dr. Frank Ko in the faculty of applied science and Dr. Scott Renneckar in the faculty of forestry, have developed a way to convert bitumen into commercial-grade carbon fibers.

Their solution, described recently in the journal Advances in Natural Sciences: Nanoscience and Nanotechnology, uses melt spinning to produce two sizes of fibers cleanly and economically. Projected cost is $12 per kilo, compared to commercial carbon fibers that normally cost $33 per kilo.

Read more.

12 notes

·

View notes

Text

Application of bitumen in building

Bitumen has numerous applications in the construction industry, primarily serving as an adhesive and waterproofing material. Its versatile properties make it indispensable in various building-related functions. Here are some key applications of bitumen in construction:

1. Roofing and Waterproofing:

Bitumen 60/70 is extensively used in roofing systems to provide waterproof membranes for flat roofs. Traditional bitumen roofing membranes consist of layers of bitumen sprayed with aggregate, with a carrier fabric made of polyester or glass in between. Polymer-modified bitumen sheets have become the standard for flat roof waterproofing. Bituminous roofing membranes can also be recycled easily, enhancing their sustainability.

2. Wall Sealing:

Bitumen 60/70 plays a crucial role in sealing walls, providing protection against water and moisture intrusion. It is applied to substrates such as bathrooms and toilets, which are constantly exposed to moisture, to prevent water penetration and safeguard the underlying structures.

3. Floor and Wall Insulation:

Bitumen 80/100 insulation is widely employed for building waterproofing, both horizontally and vertically. It effectively prevents water penetration into floorboards and walls, offering reliable protection. Bitumen's chemical and physical properties make it easy to work with and highly durable.

4. Sound Insulation:

Bitumen's sound-absorbing properties find applications beyond construction. It helps reduce noise transmission, such as the sound of footsteps under floor coverings. Special tar mats in cars and elevators utilize Bitumen 80/100 for sound insulation.

5. Electrical Cable Insulation:

Bitumen's low electrical conductivity makes it suitable for use as an insulating material for electrical cables. It helps protect the cables and prevent electrical hazards.

6. Other Uses:

Bitumen 80/100 & bitumen 60/70 finds application in various other areas, such as the paper industry and the manufacturing of paints and varnishes. Its thermal insulation properties are beneficial in different contexts.

From an ecological standpoint, bitumen is highly regarded for its long lifespan. It remains a popular construction material, with significant demand both domestically and in international markets. The producer of bitumen in Iran exports a large percentage of its production to other countries such as Singapore, Dubai, Panama.

In residential construction, plastic-modified bitumen (KMB) coatings are commonly used for insulation. They compete with bitumen-free FPD (Flexible Polymer Disc) seals, which are easier to apply and offer faster repair options.

Overall, the applications of bitumen in the construction industry are extensive, ranging from roofing and waterproofing to sound insulation and electrical cable insulation. Its versatility and durability make it a valuable material in various building-related functions.

Important Considerations Before Using Bitumen:

1. Surface Preparation:

Before applying bitumen, it is crucial to ensure that the surface is clean, dry, and free from any contaminants. Even the presence of dust, dirt, or grease can hinder the adhesion of the bitumen coating and compromise the effectiveness of the seal. Additionally, the surface should be free from frost. If there are old incompatible coatings, they must be removed. In the case of older buildings, previous applications of bituminous paints may not provide a suitable surface for polymer-modified bitumen (PMB) coatings.

2. Repairing Cracks and Unevenness:

Prior to applying bitumen, any cracks or unevenness on the surface should be repaired using appropriate materials like repair mortar or leveling compounds. This ensures a smooth and uniform surface, promoting better adhesion and a more effective seal.

3. Additional Preparatory Measures:

In some cases, additional preparatory measures may be necessary. One option is to use a layer of synthetic resin on the coarse-pored bed or to apply a sealing slurry. A sealing slurry is a waterproof mixture of cement and plastic that allows water vapor to pass through. The advantage of using a sealing slurry is that it can adhere well to old bituminous coatings, providing an ideal substrate for applying a thick new bituminous coating.

By following these steps and ensuring proper surface preparation, you can optimize the adhesion and effectiveness of bitumen coatings in various applications.

What are the suitable means for repairing cracks and unevenness on the surface before applying bitumen?

There are several suitable means for repairing cracks and unevenness on the surface before applying bitumen. The choice of repair method depends on the severity of the damage and the specific requirements of the project. Here are some common methods for repairing cracks and unevenness:

1. Crack Fillers and Sealants:

For smaller cracks, crack fillers or sealants can be used. These materials, such as asphalt-based crack fillers or specialized concrete crack sealants, are designed to fill and seal cracks, preventing water infiltration and further damage. They are typically applied using a caulk gun or trowel.

2. Repair Mortar:

Repair mortars are suitable for filling larger cracks, holes, or areas of unevenness. These mortars are made from a blend of cement, sand, and additives to enhance adhesion and strength. They can be mixed with water to create a workable paste and then applied to the damaged areas using a trowel or other appropriate tools. Repair mortars are commonly used for repairing concrete surfaces.

3. Leveling Compounds:

Leveling compounds, also known as self-leveling underlayments or floor levelers, are used to create a smooth and level surface. These compounds are typically made from a blend of cement, fine aggregates, and additives. They have a fluid consistency that allows them to flow and self-level over uneven areas. Leveling compounds are commonly used to repair uneven concrete or subfloor surfaces before applying flooring materials.

4. Patching Mixtures:

Patching mixtures, such as asphalt patching compounds or repair mixes, are specifically designed for repairing asphalt surfaces. They typically contain a combination of asphalt binder, aggregates, and additives. These mixtures can be applied to fill potholes, repair damaged areas, or smooth out unevenness in asphalt surfaces.

5. Resurfacing:

In cases where the damage or unevenness is more extensive, resurfacing the entire surface may be necessary. This involves applying a new layer of bitumen or asphalt mixture over the existing surface to create a smooth and uniform finish. Resurfacing can help address multiple issues, including cracks, potholes, and unevenness.

It's important to follow the manufacturer's instructions and best practices when using any repair materials. Additionally, proper surface preparation, including cleaning and removing loose debris, is essential before applying any repair method.

ATDM CO is a manufacturer and exporter of Bitumen 60/70, offering three different quality grades available in drums, bags, and bulk quantities. Our products are classified into premium, second, and third types, each with varying production costs and facilities. We provide a wide range of options to accommodate different customer needs and volume requirements.

#bitumen#bitumen 60/70#bitumen 80/100#bitumen 60/70 specs#bitumen penetration grade 60/70#bitumen 60/70 specification#bitumen 60 70#atdm co llc.

2 notes

·

View notes

Video

Ballan, Victoria, Australia. 2023-04-02 11:53:56 by stuart murdoch

Via Flickr:

Killing time in Pub carparks. One of several projects, that explore photography as evidence amongst other ideas. Blog | Tumblr | Website | Instagram | Photography links | s2z digital garden | pixelfed.social | glass | grainary | vero | hipstamatic

#IMG_0065#ballan#victoria#australia#carpark#stripes#lines#outdoor#outdoors#car parking bays#barriers#buntings#stops#barrier#cinderbrick#hedge#red hedge#bitumen#leaves#regional#regional victoria#pub#pub carpark#broken cinderblovk#broken#fallen cinder block#all the lines#red#yellow#autumn

4 notes

·

View notes

Text

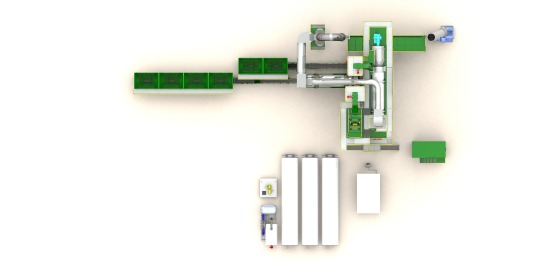

What is Asphalt Recycling Plant?

The use of reclaimed asphalt, or recycling, has become a necessity. Governments increasingly want the reclaimed asphalt from old roads re-used in an effort to be more environmentally friendly. Recycled asphalt also can provide you with cost savings on several fronts.

To use this valuable secondary resource, ZOOMLINE offers the Asphalt Recycling Plants to help your recycling and cost-saving efforts. Regardless of the system you choose, modern ZOOMLINE plant technology will provide a quality recycling process and product.

Asphalt Recycling Plant | Hot & Cold RAP Recycling, RAPpro 100% Recycled Asphalt Hot Mix Plant, Recycled asphalt hot mix plant, RAPpro 100% Recycled Hot Mix Asphalt Production Plant.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#asphalt plant#concrete#heavy equipment#asphaltplant#construction#mobile asphalt drum mix plant#recycling asphalt plant#asphalt recycling plant#recycled asphalt plant#RAP Recycling#recycled asphalt hot mix plant#recycled hot mix asphalt production plant#asphalt production plant

3 notes

·

View notes

Text

call me genderfluid the way i experiment with my pitch drop

#pitch drop experiment#the pitch drop experiment#bitumen#science#queer#lgbtq+#genderfluid#scienceblr#science side of tumblr#mogai#cause i think yall would vibe with this#this joke is funny i pinky promise <3333#just trust me#mythinks

2 notes

·

View notes

Text

@aedrian

See more like this.

6 notes

·

View notes

Photo

ʙᴇᴡᴀʀᴇ ɪ ʟɪᴠᴇ ʜᴇʀᴇ

*

2022

Madalina Gaceanu

bitumen; zinc wire; photographic print

#bitum#art#sculpture#bitumen#zinc#photographic print#print#beware i live here#madalina#gaceanu#madalinagaceanu#wire#mixedmedia

2 notes

·

View notes

Text

bitumen supplier, Aljabal global holding

When it comes to the construction and infrastructure industries, few materials are as vital as bitumen. Whether it's for road construction, waterproofing, or industrial applications, bitumen plays a crucial role. However, ensuring a consistent and reliable supply of this essential material can be challenging. This is where reputable bitumen suppliers like Aljabal Global Holding step in.

1. Introduction

Bitumen is a versatile material derived from petroleum, known for its adhesive and waterproofing properties. It is commonly used in road construction, roofing, and waterproofing applications. The quality of bitumen directly impacts the durability and performance of various infrastructures.

2. Understanding Bitumen

Bitumen, also known as asphalt, is a sticky, black, and highly viscous liquid or semi-solid form of petroleum. It is composed of complex hydrocarbons and is primarily used in road construction as a binder mixed with aggregate particles.

3. Importance of Bitumen Suppliers

Bitumen suppliers play a crucial role in ensuring a steady supply of quality bitumen to industries worldwide. They source, refine, and distribute bitumen to construction companies, governments, and other stakeholders involved in infrastructure development.

4. Aljabal Global Holding: A Brief Overview

Aljabal Global Holding is a leading bitumen supplier with a reputation for excellence in the industry. With years of experience and a commitment to quality, the company has established itself as a trusted partner for construction projects worldwide.

youtube

5. Services Provided by Aljabal Global Holding

Aljabal Global Holding offers a comprehensive range of services to meet the diverse needs of its clients. From bitumen sourcing and refining to transportation and logistics, the company handles every aspect of the supply chain efficiently.

6. Quality Assurance

One of the key factors that set Aljabal Global Holding apart is its unwavering commitment to quality assurance. The company adheres to stringent quality control measures at every stage of the production process to ensure that its clients receive only the finest bitumen products.

7. Sustainable Practices

In addition to quality, Aljabal Global Holding is also dedicated to sustainable practices. The company prioritizes environmental stewardship and invests in technologies and processes that minimize its ecological footprint.

8. Global Reach

With a network of partners and distributors across the globe, Aljabal Global Holding has a truly global reach. This enables the company to serve clients in various regions efficiently and effectively, regardless of their location.

9. Customer Satisfaction

At Aljabal Global Holding, customer satisfaction is paramount. The company goes above and beyond to understand its clients' needs and deliver tailored solutions that exceed expectations.

10. Competitive Pricing

Despite its commitment to quality and sustainability, Aljabal Global Holding remains competitive in terms of pricing. The company leverages its extensive network and operational efficiency to offer cost-effective solutions to its clients.

11. Case Studies

Numerous successful projects stand as a testament to Aljabal Global Holding's expertise and reliability. From major infrastructure developments to small-scale construction projects, the company has consistently delivered exceptional results.

12. Testimonials

Client testimonials further reinforce Aljabal Global Holding's reputation as a top-tier bitumen supplier. Satisfied clients praise the company's professionalism, reliability, and commitment to excellence.

13. Future Plans and Innovations

Looking ahead, Aljabal Global Holding is committed to continuous improvement and innovation. The company is exploring new technologies and strategies to further enhance its products and services, ensuring that it remains at the forefront of the industry.

14. Conclusion

In conclusion, Aljabal Global Holding stands out as a premier bitumen supplier, offering top-quality products, sustainable practices, and unparalleled customer service. With its global reach and commitment to excellence, the company is poised for continued success in the years to come.

15. FAQs

Q1: What is bitumen, and why is it important?

Bitumen, also known as asphalt, is a viscous material derived from petroleum and is crucial for various industries, including road construction and waterproofing.

Q2: How does Aljabal Global Holding ensure the quality of its bitumen products?

Aljabal Global Holding implements stringent quality control measures throughout the production process to ensure that its bitumen products meet the highest standards.

Q3: Where does Aljabal Global Holding operate?

Aljabal Global Holding operates globally, serving clients in numerous countries across different continents.

Q4: What sets Aljabal Global Holding apart from other bitumen suppliers?

Aljabal Global Holding distinguishes itself through its commitment to quality, sustainability, customer satisfaction, and competitive pricing.

Q5: How can I contact Aljabal Global Holding for bitumen supply inquiries?

You can contact Aljabal Global Holding through its official website or by reaching out to its customer service representatives via email or phone.

Address:Office 1010, Floor 10, Grosvenor Business Tower, Barsha Heights Dubai, UAE

Office Tel / fax :

+971 455 4329

WhatsApp and direct mobile:

+971523717966

Youtube Channel

Email:

[email protected]

0 notes

Text

skeleton time

20 notes

·

View notes

Text

Drummed bitumen decanter - Atlas Technologies

The drummed bitumen decanting system featured here can give production of 3.5-4 tons per hour we have bigger models also that can go up to 10 tons per hour.

0 notes

Text

Asphalt Batch Mix Plant Manufacturer

Proc Tech Machineries India Pvt. Ltd. Is an Asphalt Batch Mix Plant Manufacturer in Ahmedabad, Gujarat, India.

Proc Tech Machineries India Pvt. Ltd. specializes in Manufacturing, Exporting, and Supplying a diverse range of products, including Industrial Rotary Dryer, Air Classification Plant, Chilly Processing Plant, Asphalt Drum Mix Plants, RMC Plants, Turmeric Processing Plants, Waste Type Pyrolysis Plant, Jaggery Plant, Coriander Processing Plant, and more.

Working of an asphalt batch plant will include heating and weighing of aggregates, heating and weighing of bitumen, weighing of filler material, and in the end mixing aggregates, bitumen, and filler material to produce hot mix asphalt.

The percentage of each item can vary depending on the mixed material recipe set in the control panel.

The size and percentage of the aggregates will also vary depending on the recipe selected.

Hence FABHIND must manufacture all the vital parts of the plant including the burner, mixer, screen, Drum, filters, feeders, and controls.

Features:

Half-chain drive in the drum for less vibration and trouble-free operation.

Burner is available with different fuel options.

Rugged and proven design.

Dry and wet dust collectors for pollution control.

Fully covered bitumen tanks for maximum heat retention.

Fully covered bitumen tanks for maximum heat retention.

Constant improvement in the design to make it simple and maintenance-free design.

The optional PLC control panel is advanced and maintenance-free.

Factory testing before dispatch.

1260 Degrees Celsius resistant coated cerawool and covered by SS sheet drying drum.

Application:

Cold Aggregate Feeder

Drying Drum

Aggregate Hot Elevator

Drying Drum

Vibrating Screen

Bitumen Tank

Proc Tech Machineries India Pvt. Ltd. Is an Asphalt Batch Mix Plant Manufacturer in Ahmedabad, Gujarat, India, and various locations like Maharashtra, Ahmednagar, Akola, Amravati, Aurangabad, Bhandara, Bhusawal, Buldhana, Chandrapur, Daulatabad, Dhule, Jalgaon, Kalyan, Karli, Kolhapur, Mahabaleshwar, Malegaon, Matheran, Mumbai, Nagpur, Nanded, Nashik, Osmanabad, Pandharpur, Parbhani, Pune, Ratnagiri, Sangli, Satara, Sevagram, Solapur, Thane, Ulhasnagar, Vasai-Virar, Wardha, Yavatmal.

For detailed information or inquiries, please feel free to contact us.

Asphalt Batch Mix Plant Manufacturer

Read the full article

#AirClassificationPlant#AsphaltBatchPlantManufacture#AsphaltBatchPlantManufacturer#AsphaltBatchPlantManufacturerinAhmedabad#AsphaltDrumMixPlants#bitumen#ChillyProcessingPlant#CorianderProcessingPlant#exporting#fillermaterialtoproducehotmixasphalt#Gujarat#heatingandweighingofaggregates#heatingandweighingofbitumen#India#IndustrialRotaryDryer#JaggeryPlant#manufacturing#mixingaggregates#ProcTechMachineriesIndiaPvt.Ltd.#RMCPlants#supplying#TurmericProcessingPlants#WasteTypePyrolysisPlant#weighingoffillermaterial

0 notes

Text

Bitumen Product supplying

Faragam Petro Tech

1 note

·

View note