#Electronics calibration services

Text

Calibration of Gas Analyzer

2 notes

·

View notes

Text

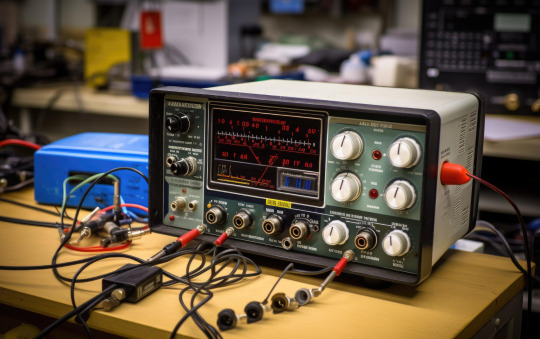

Electrical and Electronics Calibration Services In Singapore for Different Industries

In Singapore, where industries such as manufacturing, healthcare, telecommunications, and aerospace thrive, the need for precise and reliable measurement instruments is paramount. Calibration services encompass a wide array of equipment, including voltmeters, oscilloscopes, temperature sensors, pressure gauges, and more. These instruments are subject to gradual wear and environmental factors that can affect their accuracy over time. Regular calibration ensures that measurements remain within acceptable tolerances, preventing inaccuracies that could lead to faulty products, compromised processes, or safety hazards.

Electrical and electronics calibration services are indispensable in Singapore's industrial landscape. They ensure that measurement instruments function accurately, meeting both internal quality benchmarks and external regulatory requirements. By upholding precision and compliance, calibration services contribute significantly to the nation's economic growth and technological advancement.

Electrical and electronics calibration services in Singapore offer a range of benefits. They enhance product quality, reduce production costs, improve process efficiency, and contribute to a safer working environment. By relying on accredited calibration laboratories, businesses can demonstrate their commitment to precision, consistency, and compliance, thus fostering customer trust and industry reputation.

If you are looking for Electrical and Electronics Calibration Services Singapore, you will have some better options to fulfill your requirement by going online –a convenient way to save you time and provide you with some better opportunities of fulfilling your requirement.

Check all details and get the right solutions according to your specific needs.

0 notes

Text

Effortless Temperature Monitoring with Wireless Data Logger

Discover the cutting-edge technology of temperature data logger wireless systems, enabling seamless real-time monitoring and recording of temperature variations. Experience the convenience of remote access, accurate data collection, and dependable performance for diverse applications like healthcare, cold chain management, and industrial processes.

#temperature data collecting devices#data logger calibration service#temperature data collecting services#electronic temperature data logger#temperature data logger calibration

0 notes

Note

What kinda dinky ass cybernetics did they give Veers in A Little Help from my Friends??!

The short answer? This kind:

The long and rambling answer with all the meta and thought I've put into this but never written down until now? Follow me under the cut, Friend, and let's talk (cw for medical stuff, discussions of amputation)

First, let me preface this with the fact that I am neither a medical professional nor someone with any personal experience with traumatic limb loss and/or physical disabilities. I am, however, a service technician for very complicated and expensive pieces of lab equipment, and a lot of that bleeds into the mechanical aspects of Veers' cybernetic limbs. I have done a fair bit of research for this fic, and I'll try to throw my sources on this if I can find them again.

A meta perspective:

Longtime readers will know I have a certain type of fic that I gravitate towards (@madelgard lovingly described it as “romantic medical despair”), and one of the this I like to explore is 'what if there was more to healthcare in Star Wars than just “magic healing goo” and “robot limbs that behave exactly like human limbs in every way” (and whatever Andor was doing with the MedSpike I guess). In particular, I've never been fond of the way that characters (with the exception of Vader, but we'll get to him) don't really deal with the disabling and the traumatic aspects of losing a limb, and I wanted to explore that in a fic. Since Veers loses a leg in Legends and is seriously injured in canon, he seemed the perfect candidate for this sort of angsty fic (he also didn't want a cybernetic prosthetic in legends because of the 'stigma' apparently, which sounds fake but I took to mean that he and cybernetics didn't work well together).

For this sort of speculative science, I like to base it in as much real science as possible, and then extrapolate based on the rules of the universe I'm working in. In this case, I wanted to figure out how the prosthetics should work, so they I could break them in realistic ways that made sense for the story I wanted to tell. There were two major considerations for designing the prosthetics and how they work:

What do they need to do to fulfill the same role as biological limbs? Range of motion is an obvious consideration, but balance, physical sensation, and temperature regulation (1) are all essential things provided by a flesh and blood limb that a modern day prosthetic may or may not provide. Veers' case is further complicated by the fact that he has a bilateral (both legs) trans-femoral (mid thigh) amputation – in modern times, he would likely go through several iterations of prosthetic before he got the final versions with jointed knees at his full height (2)

How are they going to do this? While bionic limbs have come a long way in the past few years (3), science fiction gives us a lot of leeway here on things like “weight” and “battery life”. Even so, they aren't one to one analogs, and I think there's a lot of potential for angst, especially regarding the direct interface with the patient's nervous system.

As the prosthetics are mechanical devices, they would be prone to wear and tear just like anything else. Where biological flesh heals and regenerates (usually) over time, self-healing prosthetics are not necessarily achievable or practical, and so certain components (batteries, soles of the feet, synthetic skin, etc) would need to be replaced as time passes. Additionally, if we are operating under the assumption that the limb is fully articulated, it would likely have a control system or on-board computer of some sort – and in my experience, those need to be calibrated on a regular basis, both to account for electronic noise, and any kind of drift in the sensors/drive motors/other components. The only issue is that instead of flashing an LED to find dead pixels on a camera or scanning a range of values to look for the highest signal output on a detector, there's a human person on the other end of the interface. So instead of 'what value gives me the best reading across my mass spectrum' it's 'what value of nerve signal provides the best connection', and unfortunately for Veers, that translates as “pain” (is this a slightly unrealistic approach to this? Maybe. But we do at least see the droid in ESB testing Luke's level of sensation in his hand at the end of the movie, and apparently no one in Star Wars has heard of 'sedating the patient while we attach a new hand' so I feel like it's not out of the realm of possibility)

(1) I had initially thought that Veers would be more frequently cold after losing both his legs, but after reading these two papers, it seems he would have the opposite problem, due to a lack of surface area. This means not only do we have to consider the thermal properties of the materials the prosthetics are made of, but also their ability to effectively distribute body heat when necessary.

(2) I found these two articles about the recovery of a woman with similar injuries to those I've given Veers in this verse very helpful for looking at potential timelines, pitfalls, and the process he might be looking at

(3) this article gives a very good overview of the current state of things and how these limbs interface with the human they are attached to. The process for Direct nerveinterfacing described here is most analogous to how I imagine cybernetic limbs would work in Star Wars, although they are obviously much more advanced

In Universe:

With all of that being said, why do Veers' legs suck specifically? Why does Jerjerrod spend so much time complaining about them?

Well, it all comes down to our favourite asthmatic sith cyborg: while I imagine limb loss is actually fairly uncommon in the GFFA (Skywalkers notwithstanding, blasters and explosives are typically energy weapons, and imo are more likely to cause burns etc than traumatic amputation), the Executor absolutely has to have at least one cybernetics expert on board, to tend to its resident cyborg. However, Vader and Veers differ in a few very fundamental ways, and if said expert is only used to treating Vader and no one else, I would imagine this means that Veers winds up with prosthetics that serve the function of getting him back in the field, but aren't actually designed for him (not to mention the fact that the Imperial Healthcare System probably isn't super focused on Patient Health and Safety, and not getting into the cost aspect of this – Veers is valuable enough to build prosthetics for, but is he valuable enough for top of the line durable materials when he almost died in battle once already and canonically keeps getting sent on suicide missions? Probably not).

The Force. In at least some iterations, Vader relies extensively on the Force to do even basic things such as “moving his heavy limbs” and “not being in excruciating pain all the time” - I seem to recall reading that Palpatine uses Vader's suit to ensure his apprentice is too distracted by pain to have the energy to overthrow him, and that the only part of Vader that wasn't in pain all the time was his original bionic hand from AotC. If Veers, who isn't Force sensitive, has prosthetics designed in a similar way to Vader's suit but no way to compensate for it, it's going to take a hell of a toll on him. Also, if Vader hasn't strangled the doctor for hurting him yet, then Veers is probably just making shit up (or so a doctor or medical droid might assume)

Lifestyle. Veers is physically fit and does a lot of different activities with his legs (yes including “wrestling” Tiaan) – he travels to different planets and terrains with different gravities, he runs, he jumps, he plays sports – whereas Vader... doesn't. This contributes to what the prosthetics actually need to be designed to withstand (Veers isn't going to be doing spacewalks with only his prosthetics, but he's also not going to want to walk stiff-legged and menacingly all the time). Additionally, if your system is calibrated to a specific height/weight/body temp/whatever, that's going to change slightly over time – but its going to change a lot more in Veers; Vader has a self -contained air supply with scrubbers for removing pathogens, a feeding tube, and minimal muscle mass that would change those parameters that the calibrations would be accounting for, but Veers might, say, decide to take up a new sport, or get the flu for three weeks, or anything else that could change his body dramatically enough to upset the equilibrium between him and his prosthetics.

I also wanted to do something with phantom pain and how it affects people who have lost limbs, plus play with the idea of how having something wired directly into the nervous system might have lasting consequences, which is where the ONCP comes from. Symptom and treatment-wise, I've loosely based it on thalamic pain syndrome (as suggested to me by the lovely @pianopadawan), although the underlying cause is very different.

If you've read though all that, thank you for coming to my lecture. Tune in next time for 'how long does it take for a Star Destroyer to restart the reactor from cold' and/or 'lets talk about mental healthcare or lack thereof in the Imperial Navy'

17 notes

·

View notes

Text

MacBook Pro A1989 13" Repair Service #Nehru Place

Conquering MacBook Pro A1989 13" Display Anomalies with Expertise:~~

Our seasoned technicians understand the intricate dynamics of the A1989 13" display, and their expertise is at the forefront of our solution. Whether the flickering is a result of cable wear, hinge stress, or internal friction, our approach goes beyond the surface, addressing the root causes with finesse. We prioritize clarity, precision, and a commitment to delivering a flicker-free display that meets the standards of your MacBook Pro.

By choosing our MacBook Pro A1989 13" Flickering Solution, you're not just opting for a fix; you're embracing a journey led by expertise. Our comprehensive strategies encompass cable inspections, hinge adjustments, and targeted solutions, ensuring a holistic resolution to the anomalies affecting your MacBook Pro display.

Factors Contributing to MacBook Pro A1989 Screen Flickers:~~

The MacBook Pro A1989 is a powerhouse, but users occasionally encounter screen flickering issues that can be both frustrating and disruptive.

Flex Cable Wear: Wear or damage to these cables may lead to intermittent connections, causing screen flickering.

Hinge Stress: Hinge stress may increase friction on flex cables, contributing to flickering issues.

Internal Friction: Microscopic damage from internal friction can disrupt stable display connections, leading to flickering.

Overheating: Overheating may lead to malfunctions in electronic components, including those related to display functionality.

Software Issues: Software-related problems may cause intermittent display anomalies, contributing to flickering.

Graphics Card Malfunction: Malfunctions in the GPU may result in visual artifacts, including flickering on the screen.

Incompatible Software or Drivers: Incompatibility issues may lead to flickering as the system struggles to render graphics correctly.

Interference from External Devices: Electromagnetic interference can disrupt the display signal, leading to flickering.

Display Settings and Calibration: Adjustments to brightness, contrast, or color settings might affect display stability.

Hardware Failures: Damaged hardware components may result in flickering and other display issues.

How Our Company Pinpoints Flickering in MacBook Pro A1989 13" Displays:~~

Comprehensive Diagnostics: We commence our process with a comprehensive diagnostic assessment, utilizing cutting-edge tools and software to analyze the display's performance. This step involves a thorough examination of both hardware and software components.

Flex Cable Inspection: One of the primary contributors to flickering is often wear or damage to flex cables. Our experts meticulously inspect these delicate cables, identifying any signs of wear, tears, or compromised connections that may be causing flickering.

Hinge Stress Analysis: Frequent opening and closing of MacBook Pro laptops can cause stress on hinges, potentially affecting the display. We assess the hinge mechanism for any irregularities and make adjustments to minimize stress on flex cables.

Temperature and Overheating Check: Overheating can impact internal components, including those related to the display. Our diagnostics include monitoring temperature levels and ensuring proper cooling mechanisms to prevent overheating-related flickering.

Software and Driver Audits: Software glitches or outdated drivers can contribute to display anomalies. Our team conducts thorough audits of the operating system, display drivers, and related software to identify and rectify any issues causing flickering.

External Interference Analysis: External devices or accessories can introduce electromagnetic interference, affecting the display. We assess the environment and connected peripherals to minimize interference and enhance display stability.

Graphics Card Evaluation: Issues with the graphics processing unit (GPU) can lead to flickering. Our experts scrutinize the GPU's performance, ensuring it functions optimally and addressing any malfunctions that may be contributing to the flickering.

Display Calibration and Settings Adjustment: Incorrect display settings or calibration can cause visual anomalies. We meticulously adjust brightness, contrast, and color settings to optimize the display experience and eliminate flickering.

Documentation and Reporting: Throughout the diagnostic process, our team maintains detailed documentation. This includes findings, identified issues, and the steps taken for resolution. This documentation serves as a reference for transparency and future troubleshooting if needed.

2 notes

·

View notes

Text

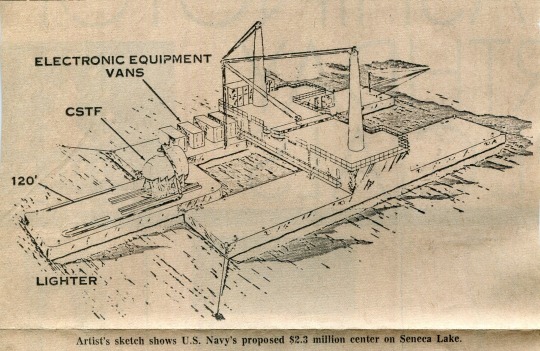

Sounding out the naval barge on Seneca Lake

By Jonathan Monfiletto

The next time you are driving along Seneca Lake, on State Route 414 along the eastern shore or – if you are traveling through Yates County – State Route 14 along the western shore, gaze into the middle of the lake and see if you find an interesting-looking platform floating on the surface. It shouldn’t be too hard to find, but you might wonder just what you are looking at.

This platform is, in fact, a barge anchored in the middle of Seneca Lake off the shore at Dresden. Indeed, the operation is officially known as the Seneca Lake Sonar Test Facility under the auspices of the Naval Sea Systems Command and the Naval Undersea Warfare Center of Newport, Rhode Island. Though it appears only civilian employees work there and no military personnel are stationed there, one could say this facility represents the only presence of the U.S. Navy existing in the Finger Lakes.

According to its website, the Seneca Lake Sonar Test Facility does just that – performing tests and evaluations of equipment to include sonar arrays and systems – and is known for its massive lift and power capabilities. Acoustic testing professionals carry out tests on systems and equipment of all sizes, even an entire sonar suite mounted in its sonar compartment.

Because it is a deep freshwater lake that is open all year, Seneca Lake is the Navy’s primary site for active instrumented calibration and testing. The fairly constant and predictable weather and water conditions of Seneca Lake also make it a choice testing site. It is known for its testing and evaluation of major projects that require relatively deep water with fixed underwater geometry and capabilities for heavy load-handling and electrical power.

Located about a mile and a half from the Dresden shore, the facility consists of two barges – the Systems Measurement Platform and the Remote Calibration Platform – that are the primary measurement and calibration resources. Two equipment-handling barges and numerous transport boats serve the facility, and there are machining and fabrication capabilities on the site to repair or manufacture the equipment and gear being tested.

The facility has been used by the Department of Defense, Department of the Navy, universities, foreign governments, state and local agencies, and private industry. And it has been a part of the Dresden landscape and lakeshore for more than 60 years.

It all began in November 1961, when the original barge – a converted oil tanker measuring 165 feet long and 36 feet long – arrived in Seneca Lake from Miami, via the inland waterway, Hudson River, and Barge Canal. During the heyday of the Cold War, as America furthered its research and development of anti-submarine warfare, the barge was purposed to test advanced sonar equipment designed to detect underwater craft. The barge was a key unit in establishing an anti-submarine acoustics research facility, headed by General Dynamics/Electronics.

The company leased a site at Dresden that provided 180 feet of lakefront – with construction of docking and service facilities to begin soon, according to an October 1961 newspaper article – along with a county road serving the property that would allow access to the facility throughout the year. Seneca Lake was chosen because its 600-foot depth makes it one of the deepest lakes in the country and – with the exception of the Great Lakes – the deepest lake with direct access to the Atlantic Ocean. It also has temperature gradients similar to those in the Atlantic Ocean, meaning sonar tests could be correlated to ocean conditions. The waves on the lake aren’t high enough to interfere with barge operations, and since the lake rarely freezes tests can be conducted throughout the year.

The original barge was equipped with a diesel-driven, 200-kilowatt generator to supply electric power to its electronic equipment, a capacity that was later increased to 400 kilowatts. The barge’s hulls had several ballast tanks, with water pumped out of or into the tanks to raise or lower the height of the deck above water.

Initially, the barge was designed to test then-recently-developed transducers weighing as much as 35 tons. These transducers convert electrical energy into acoustic energy, sending sound signals through the water that bounce off an intended target with an echo that can be recorded and analyzed. For test operations, the barge was to be manned by three engineers working under the direction of a manager.

In 1965, the Navy began leasing the Dresden Marina – with 4.5 acres of land and 900 feet of lakefront – for $20,000 per year with an option to buy the marina for $125,000. As a result of this move, owners of boats and crafts docked at the marina were forced to remove them from the marina and find new facilities to store them. Those with mobile homes located on the hill above the docks also had to vacate the premises. Another result was the Navy expanding its research facilities on Seneca Lake through an investment of $500,000. The improvements included completely fencing in the installation since much of its research work dealing with sound and sonar equipment is classified.

An undated newspaper article – handwritten with “1967,” though the exact date is unclear – indicates the Navy bought the marina a couple of years later for $166,000 and took it over outright. That year, Albert Gatthardt, of the Washington Naval Research Center, spoke before a jointing meeting of the Seneca Falls and Waterloo Rotary Clubs and detailed the history of the Naval Research Laboratory and its recent developments and improvements.

Alternately known as the Seneca Underwater Test and Evaluation Center, the facility was profiled in a July 1968 newspaper article on the occasion of the barge’s conversion from diesel power generated aboard to being powered by an electrical cable from the shore. The change permitted the barge – referred to in the article as DARIUS, though it is unclear what that stands for – to test the largest underwater sonar sound sources.

The following year, the Navy announced a $2.2 million expansion of the research facility on Seneca Lake, making it “the newest, largest, and best underwater research center in the country.” Plans called for using the existing barges plus a new systems measurement platform measuring 195 feet long, 120 feet wide, and 9 and a half feet deep, with a crane capable of lifting 200 tons. The expansion would continue the Navy’s research into sound transmission, travel, and reception underwater, light transmission and reception, underwater radio communications, development of new oceanographic tools and techniques, and underwater tests in the field physics.

As of February 1969, the facility employed eight permanent employees – a number expanded by 10 or 20 visiting technicians, engineers, and scientists. With the expansion anticipated to finish in the summer of 1970, plans called for 15 permanent employees with a capacity for 40 people visiting and working on the site.

By September 1970, work on the expansion had fallen behind but was mostly complete, and the facility continued testing equipment on Seneca Lake. More than 50 years later, the Navy still has a presence in the Finger Lakes, and it is one you can see from the road or the shore.

#history#historyblog#local history#american history#us history#yatescounty#newyork#dresdenny#navy#usnavy

2 notes

·

View notes

Text

V

Quick and tiny bit of fic before work. Getting a feel for Virgil’s opinion of Tony Stark.

So yeah, have a tiny bit more of that Avengers AU you might have thought I had forgotten about :D

-o-o-o-

It was inevitable, really.

Virgil was in Module Two, servicing its grapple systems. Pulling Tony out of his death dive had been amongst the most precise shooting Virgil had managed and he had some ideas how to be more accurate.

And kinder. After all, the only reason Tony was still alive was because of his suit.

Virgil knew what it was like to be hit by a grapple and it wasn’t fun.

“Hey, V!”

Definitely inevitable, as soon as he could walk again.

Keep it polite. “Tony.”

He ignored the man gazing around the inside of the module, eyes taking everything in. “So this is the heart of your flying turtle.”

“No.” Virgil kept working. Maybe if he ignored him, he would go away.

Of course, he didn’t. Instead, there was a sigh and Tony crouched down beside him. “I owe you one. That was some save.”

That did stop Virgil. A thankyou? From Tony Stark? He stared up at the man for a moment. Stark was just so frustrating. At his core he was essentially good, which was why he could wander into the hangars like this and not be vapourised by Kayo on sight.

Actually, that was a lie. She would likely vaporise him anyway which was why Scott had her deployed on the other side of the planet tracking down who it was who tried to blow Tony out of the sky.

They had been lucky Thunderbird Two was nearby, otherwise…

Okay, he had his difficulties with the guy, mostly with what he did to Scott, but he didn’t wish him any ill.

Well, not much.

Maybe a little.

He was so frustrating!

Reaching over, Virgil grabbed his electronic calibrator from the man’s hands. “That’s mine.”

The smirk he got in return was….augh. The man knew how to press buttons to get what he wanted.

Virgil turned away and attempted that ignoring tactic again.

Starting with that amused snort he knew far too well.

-o-o-o-

#thunderbirds are go#thunderbirds#thunderbirds fanfiction#Virgil Tracy#tony stark#avengers au#nuttyfic

11 notes

·

View notes

Text

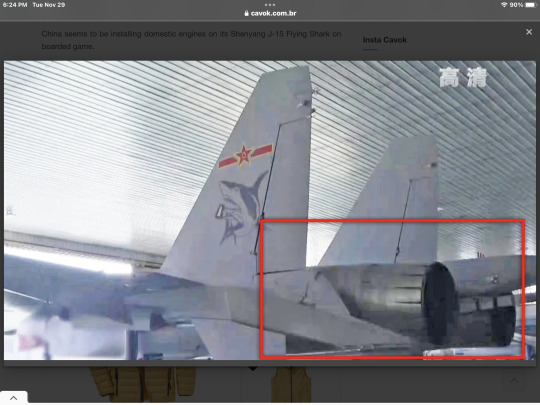

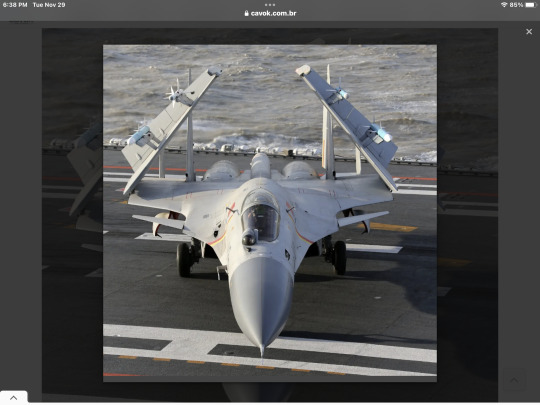

China's J-15 fighters start flying with WS-10 domestic engines

Fernando Valduga By Fernando Valduga 11/29/2022 - 08:29 in Military

China seems to be installing domestic engines on its Shenyang J-15 Flying Shark on boarded game.

Images released on November 17 on the state broadcaster CCTV showed a J-15 of the Navy of the People's Liberation Army (PLAN) with the post-combustion nozzles of the WS-10 Taihang turbofans in calibration in preparation for a test flight at the facilities of the manufacturer Shenyang Aircraft Corp.

The CCTV report was made to mark the 10th anniversary of the first takeoff and landing of the aircraft in Liaoning, China's first aircraft carrier.

This is the first time that a production J-15 has been seen equipped with locally developed engines; there was a time when the WS-10 was seen in a prototype of the J-15 built during the development phase of the aircraft.

youtube

Production copies of the J-15 were previously equipped with Russian AL-31F engines. The jet fighter is the newest modern and native combat aircraft in China's inventory to be equipped with the Russian engine, and follows the installation process in the Chengdu J-10 single-engine that also received the WS-10.

The use of WS-10s in the J-15s in China - and in the J-10s after more than a decade in service - suggests that China is confident with the performance and reliability of the engine type for use in single engines and in the riskiest operations in aircraft carriers.

The WS-10 Taihang is a series of turbofan engines with high thrust and high thrust-to-weight ratio independently developed by China, which is already feeding production examples of the Shenyang J-11B interceptor, the J-16 attack aircraft and the Chengdu J-20 stealth aircraft.

Previous reports suggested that China was struggling to overcome the reliability and performance problems of the WS-10, as the country faced broader problems in the development of national aircraft engines. As a result, China relied on imported Russian engines to power several of its domestic aircraft, including from the J-20 to the Xian Y-20 strategic transport aircraft.

In addition to the domestically developed engine for the J-15, Chinese military observers are eagerly awaiting new information about new aircraft based on aircraft carriers, including an updated and catapult-launched version of the J-15 (based on the Su-33), a stealth aircraft based on state-of-the-art aircraft carriers, a combat jet supposedly called J-35, an early warning aircraft carrier

China is also developing a two-seat J-15 (above) for electronic attack missions on aircraft carriers, similar to the Terrestrial J-16D first seen in 2021.

Tags: Military AviationJ-15 Flying SharkPLAN - People's Liberation Army Navy / People's Liberation Army Navy

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. It has works published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work in the world of aviation.

Related news

HELICOPTERS

South Korea will buy more AH-64E Apache attack helicopters

29/11/2022 - 18:45

Global 6000 for the German Pegasus SIGINT aircraft. (Photo: Bombardier)

MILITARY

Bombardier starts working on the German Pegasus SIGINT aircraft

29/11/2022 - 16:00

MILITARY

Pakistan will send attack helicopter to UN peacekeeping mission in Mali

29/11/2022 - 14:00

MILITARY

Ukraine receives six reconnaissance drones from Luxembourg

29/11/2022 - 13:00

MILITARY

Locally manufactured EFSA radar should extend the service life of Turkish F-16 jets

29/11/2022 - 09:46

AIR ACCIDENTS

USAF pilot pressed the wrong button before ejecting in an accident with F-16CM in March

29/11/2022 - 07:57

home Main Page Editorials INFORMATION events Cooperate Specialities advertise about

Cavok Brazil - Digital Tchê Web Creation

4 notes

·

View notes

Text

Types of Marine Navigation Equipment Used in Marine Vessels

The marine waters are huge and without a proper marine navigation system, there’s a chance of getting lost in the water. The fear of getting stranded in the water can be one of the biggest nightmares for the sailors. There are no roads or defined pathways in the water and thus the chances of getting lost are very prominent.

Marine navigation equipment is critical for every sailor to easily navigate through the endless sea. It’s best to have a prior idea of which direction you need to go to reach your destination within the timeline. To attain proper navigation and make sure you do not get lost, different marine navigation tools are used in marine vessels and boats.

Here are some of the most popular marine navigation systems:

Magnetic Compass: Magnetic compasses are the most traditional and commonly used navigational devices that are used in a boat. A magnetic compass helps sailors to navigate through the waters by showing the directions based on the magnetic field of the earth.

Boat Chartplotter: A boat Chartplotter is a navigation device that integrates GPS data with Electronic Navigation Chart (ENC). It allows ships to know their exact position in the water. It uses a small monitor display that shows the exact location of the ship to the sailor. Boat Chartplotter is an important device that combines modern navigational technologies like GPS, ENC, and AIS to provide the best navigation.

Radar: Radar provides a marine navigation service for identifying the objects in the water. Be it another ship, iceberg, or land obstacles, everything can be detected with the help of radar. All the view of the ship’s surroundings can be seen on a small screen and sailors can navigate safely through the water without colliding into any obstacle.

Autopilot: Autopilot is one of the most up-and-coming technologies for marine navigation. The Autopilot system allows boats and ships to be operated automatically by controlling the steering mechanism of the ship and navigating it on a set path. It helps sailors to easily navigate and identify objects to avoid accidents.

Echo Sounder: Eco sounder is a navigation tool that uses sonar to determine the depth of the water. This equipment can help sailors to be safe in the deeper water. It can also help in navigation but it’s not very effective. Nevertheless, an echo sounder is one of the highly used equipment in boats and ships.

These are some of the vital marine navigation systems that are used in marine vessels, ships, and boats to ensure that they reach their destination safely and do not lose direction in the middle of the waters. Buying the best marine GPS Chartplotter, compass, radar, etc., for your ships is extremely important to ensure the highest productivity and safe navigation.

If you are looking for repair, calibration, or upgrade of your marine navigation system, then you can get in touch with Batterytown Marine. Batterytown Marine’s expert marine electricians provide installation, repair, and maintenance services of major navigation brands like Simrad, Raymarine, Lowrance, Furuno, etc. If you are looking for marine navigation servic

4 notes

·

View notes

Text

Calibration of Luxmeter

1 note

·

View note

Text

Electrical & Electronics Calibration Services In Singapore: Ensuring Precision and Compliance

In today's technologically advanced world, electrical and electronic equipment is the foundation of many industries. Calibration services designed exclusively for the electrical and electronics industry are required to guarantee accuracy and dependability. Singapore is known for its cutting-edge facilities and dedication to perfection and offers a variety of electrical and electronics calibration services Singapore.

In this blog, we will look at the perfection of calibration by the singapore companies.

Calibration of Electronic Equipment for Reliable Performance:-

Electrical and Electronics Calibration Services Singapore are essential for assuring the dependability and performance of electronic equipment. This covers calibrating tools like digital voltmeters, spectrum analyzers, frequency counters, and signal generators. Businesses may reduce errors, find issues, and protect the integrity of their electronic systems by calibrating their electronic equipment regularly. This raises product quality and lowers the chance of downtime, increasing productivity and customer happiness.

Conclusion:-

Singapore's electrical and electronic equipment calibration services are crucial for maintaining accuracy, dependability, and compliance across several industries. Accredited calibration facilities and skilled employees can be used by businesses to guarantee precise electrical measurements and dependable performance of electronic equipment. As a result, regulatory compliance, operational effectiveness, and product quality all increase. Investment in electrical and electronics calibration services Singapore is a sensible move for Singaporean businesses as it demonstrates their dedication to quality and gives them an edge over rivals. Utilizing these calibration services is essential to stay competitive in today's cutthroat market and provide superior electrical and electronic solutions.

0 notes

Text

Efficient Temperature Monitoring

Experience hassle-free temperature monitoring with a smart wireless temperature data logger. These innovative devices provide real-time data collection, remote access, and alerts, ensuring optimal temperature control in various industries, including healthcare, food storage, and logistics.

#temperature data collecting devices#data logger calibration service#temperature data collecting services#temperature data logger calibration#electronic temperature data logger

0 notes

Text

Your Source for Excellence: The World-Class Measuring Instruments of Power Tech Electric

In the realm of industrial operations, precision isn't just desirable—it's essential. Every component, measurement, and process must adhere to the highest standards of accuracy to ensure optimal performance and reliability. At Power Tech Electric, we take immense pride in offering a comprehensive range of top-tier measuring instruments meticulously designed and engineered for precision and durability. Let's delve into our flagship offerings:

Precision Voltage Transformers

Voltage transformers are pivotal components in electrical power systems, responsible for accurately stepping down or stepping up voltage levels for measurement and control purposes. Our precision voltage transformers are crafted with meticulous attention to detail, employing advanced winding techniques and high-quality materials to deliver accurate voltage transformation across a wide range of applications.

High-Performance Current Transformers

Current transformers play a vital role in monitoring and measuring electrical currents in power systems, ensuring the safe and efficient operation of equipment and machinery. Our high-performance current transformers are engineered to deliver precise current measurement, minimal phase angle error, and excellent linearity, making them ideal for demanding industrial environments where accuracy is paramount.

Ultra-Reliable Power Factor Correction Capacitors

Power factor correction capacitors are indispensable for enhancing power factor and energy efficiency in electrical systems, reducing reactive power consumption and minimizing losses. Our ultra-reliable power factor correction capacitors are designed to deliver consistent performance, long-term reliability, and exceptional energy-saving benefits, helping industrial facilities optimize their power usage and reduce operating costs.

Robust Surge Protection Devices

Surge protection devices are critical for safeguarding sensitive equipment and electronics from transient voltage spikes and surges, which can cause damage and downtime. Our robust surge protection devices are built to withstand the harshest environmental conditions and provide reliable protection against voltage transients, ensuring the uninterrupted operation of industrial machinery, control systems, and communication networks.

Cutting-Edge Power Quality Analyzers

Power quality analyzers are essential tools for monitoring and analyzing electrical parameters such as voltage, current, harmonics, and flicker to identify potential issues and ensure compliance with regulatory standards. Our cutting-edge power quality analyzers offer advanced features, intuitive interfaces, and precise measurement capabilities, empowering industrial users to optimize power quality, troubleshoot problems, and maintain equipment reliability.

Comprehensive Calibration Services

In addition to our premium measuring instruments, we also offer comprehensive calibration services to ensure the accuracy and reliability of your measurement and control instruments. Our ISO/IEC 17025 accredited calibration laboratory is equipped with state-of-the-art standards and equipment, operated by highly trained technicians, enabling us to calibrate a wide range of instruments to the highest industry standards.

Experience Excellence with Power Tech Electric

At Power Tech Electric, we are committed to delivering excellence in every component and service we provide. Whether you require voltage transformers, current transformers, surge protection devices, power quality analyzers, or calibration services, you can trust our world-class measuring instruments to meet your most demanding requirements with unmatched accuracy, reliability, and performance. Experience the difference of precision engineering with Power Tech Electric today.

0 notes

Text

Beneath the Canopy: Unveiling Gas Station Construction Techniques

Gas stations are ubiquitous landmarks in modern society, providing fuel and convenience to millions of motorists every day. However, behind their familiar facades lies a complex process of construction and engineering. From site selection to regulatory compliance, and from foundation construction to canopy installation, every step requires careful planning and execution. In this article, we delve beneath the canopy to unveil the intricate techniques involved in gas station construction.

Introduction

Gas station construction is a multifaceted endeavor that encompasses various stages, each crucial for the successful completion of the project. Whether it's a small neighborhood station or a sprawling truck stop, the principles of construction remain the same.

Site Selection

Selecting the right site is paramount for the success of a gas station. Factors such as proximity to highways, accessibility, and local demographics play a crucial role in determining the viability of a location.

Environmental Considerations

Environmental concerns are an integral part of gas station construction. Measures must be taken to mitigate potential risks such as soil contamination and groundwater pollution.

Regulatory Compliance

Gas station construction is subject to numerous regulations and permits at the local, state, and federal levels. Adhering to these requirements is essential to avoid legal complications and ensure the safety of the facility.

Design and Layout

The design and layout of a gas station are crucial for optimizing traffic flow, maximizing space utilization, and enhancing customer experience. Attention to detail in this phase can significantly impact the station's efficiency and profitability.

Foundation Construction

Building a solid foundation is the cornerstone of gas station construction. Various techniques, such as shallow foundations or deep piling, may be employed depending on the soil conditions and structural requirements.

Underground Infrastructure

The installation of underground infrastructure, including fuel storage tanks, piping, and utility lines, requires precision and adherence to safety standards. Proper planning and execution are essential to prevent leaks and environmental hazards.

Building Construction

Constructing the gas station building involves erecting the structure that houses the retail and administrative areas. Materials selection, structural integrity, and architectural design are key considerations in this phase.

Canopy Installation

The gas station canopy serves as the iconic symbol of a gas station, providing shelter for customers and protection for fuel dispensing equipment. Installing the canopy requires specialized expertise to ensure structural stability and weather resistance.

Fuel Dispensing Systems

The installation and integration of fuel dispensing systems involve connecting pumps, hoses, and electronic controls to deliver fuel safely and efficiently. Proper calibration and maintenance are essential to prevent spills and accidents.

Safety Measures

Safety is paramount throughout the construction process, from site preparation to final inspection. Measures such as site fencing, fire suppression systems, and employee training help mitigate risks and ensure a safe working environment.

Quality Control

Maintaining high-quality construction standards is essential for the long-term viability of a gas station. Regular inspections, quality assurance protocols, and adherence to industry best practices help uphold standards of excellence.

Maintenance Considerations

Once construction is complete, ongoing maintenance is necessary to keep the gas station operating smoothly. Regular inspections, equipment servicing, and infrastructure upgrades are essential for long-term sustainability.

Cost Analysis

Analyzing the cost implications of various construction techniques is essential for project planning and budgeting. Factors such as materials, labor, permits, and environmental remediation must be carefully considered to ensure financial feasibility.

Future Trends

Emerging trends in gas station construction, such as sustainable design, electric vehicle charging stations, and digital payment systems, are shaping the future of the industry. Staying abreast of these developments is crucial for stakeholders seeking to remain competitive in a rapidly evolving market.

In conclusion, gas station construction is a complex undertaking that requires meticulous planning, expert execution, and adherence to safety and regulatory standards. From site selection to maintenance considerations, every aspect plays a vital role in ensuring the success and sustainability of the facility. By understanding the intricacies of gas station construction techniques, stakeholders can navigate the challenges and capitalize on the opportunities inherent in this dynamic industry.

0 notes

Text

Need Soft Starters Repair? Contact Recognised Industrial Electronic Equipment Disaster Recovery Service!

Soft starters are used in wind and solar energy systems, particularly in applications that need electric motors to control the start-up of motors used in components such as pitch systems, and yaw systems in wind energy; also, in solar water pumps or tracking systems. It is used to lower mechanical stress, prevent abrupt spikes in power consumption, and increase the equipment's dependability and lifespan.

All electrical equipment including inverter repair in hazardous areas needs to be inspected and maintained in addition to starters. Prompt repair of necessary renewable energy systems is essential to maintaining continuous energy production to avoid power fluctuations and component failures.

Process disruptions caused by defective or malfunctioning equipment might result in downtime and higher expenses. For smooth industrial operations, it is crucial to maintain the functionality of Process Control Equipment, which includes VSDs, programmable logic controllers, power supply, and control systems.

Advantages of Contacting Reputable Industrial Electronic Engineering Solutions:

To keep process control equipment operating properly and for industrial electronic repair, businesses should contract with reputable firms.

Efficient fault detection and repair are guaranteed by the use of highly qualified engineers with extensive experience in maintaining and repairing industrial electronic equipment by well-established organisations.

They back their repair services with a warranty, which ensures dependability and excellent craftsmanship. Expert companies ensure that refurbished equipment meets all safety standards for operation in dangerous areas.

In the event of a tragedy, reputable businesses offer full disaster recovery services, which involve painstaking cleaning and refurbishing techniques to restore equipment to manufacturer specifications.

To ensure accurate diagnosis and successful repair without the need for schematics or manuals, they typically invest in signature analysis tools and state-of-the-art testing technologies. This ensures dependable and effective performance following repairs.

Crucial Elements for Preserving Functionality Process Control Tools:

Expert inspections and routine maintenance can weed out any issues, extend the life of the machinery, and cut down on downtime.

Professional engineers assist in routine software updates that ensure system compatibility with new technologies and enhance overall system performance.

Experts at well-established businesses can identify irregularities through ongoing component monitoring early on. This can help companies avoid disastrous breakdowns and quickly replace worn-out parts.

Regular calibration by qualified experts guarantees precise control and accurate measurements while optimising equipment efficiency.

They provide a comprehensive emergency plan that helps lower production losses and speed up troubleshooting if malfunctions are found.

Therefore, contact these renowned services to maintain their machinery and inverters and get the most out of the investments.

Source

0 notes

Text

The Significance Of Calibration Services By FARE Labs.

Introduction:

In the realm of measurement and instrumentation, accuracy and precision are paramount. Calibration services are the cornerstone in ensuring the reliability and integrity of measurement instruments across various industries. FARE Labs, a renowned Calibration Lab, offers comprehensive calibration services to uphold these standards. This article delves into the importance of calibration and highlights how FARE Labs contributes to enhancing measurement accuracy and reliability.

Comprehensive Calibration Testing Services by FARE Labs:

FARE Labs stands as a beacon of precision in the field of calibration services, offering a diverse array of services tailored to meet the stringent requirements of industries ranging from healthcare to manufacturing. With accreditation as per ISO/IEC

17025:2017 by NABL and its recognition by esteemed regulatory bodies like the Food

Safety & Standards Authority of India (FSSAI), Agricultural & Processed Food Products Export Development Authority (APEDA), Export Inspection Council (EIC), Bureau of Indian Standards (BIS), and MOEF & CC attest to its credibility and adherence to stringent quality standards. FARE Labs employs advanced technologies to conduct thorough analyses, ensuring water meets the highest standards for safety and purity.

The major capabilities and competencies of FARE Labs are as follows:

Temperature Calibration:

Accurate temperature measurement is critical in numerous applications, including pharmaceuticals, food processing, and HVAC systems. FARE Labs provides temperature Calibration Services to ensure the accuracy of thermometers, thermocouples, and temperature sensors. This calibration helps industries maintain precise temperature control, ensuring product quality and safety.

Pressure Calibration:

Precision pressure measurement is essential in industries such as aerospace, automotive, and manufacturing. FARE Labs conducts pressure calibration to verify the accuracy of pressure gauges, transmitters, and sensors. This calibration ensures that pressure-sensitive processes operate within specified parameters, preventing costly errors and ensuring safety.

Electrical Calibration:

Electrical instruments and devices play a vital role in numerous industries, from electronics manufacturing to power generation. FARE Labs offers electrical calibration services to calibrate instruments such as multimeters, oscilloscopes, and power analyzers. This calibration ensures the accuracy of electrical measurements, facilitating reliable operation and troubleshooting.

Dimensional Calibration:

Accurate dimensional measurement is crucial in industries such as aerospace, automotive, and engineering. FARE Labs provides dimensional calibration services to calibrate instruments such as calipers, micrometers, and coordinate measuring machines (CMMs). This calibration service ensures precise measurement of length, width, and depth, supporting quality control and compliance with specifications.

Flow Calibration:

Accurate flow measurement is essential in industries such as oil and gas, chemical processing, and water treatment. FARE Labs offers flow calibration services to calibrate flow meters and sensors. This calibration ensures accurate measurement of flow rates, facilitating process optimization and resource conservation.

Conclusion:

FARE Labs, through its unwavering commitment to calibration testing, emerges as a trusted partner in ensuring measurement accuracy and reliability across industries. By conducting comprehensive analyses and adhering to stringent standards, the laboratory enables industries to operate with confidence, knowing that their measurement instruments are calibrated to the highest precision. As industries continue to rely on accurate measurements for quality assurance and compliance, FARE Labs stands ready to provide the analytical expertise and support needed to uphold these standards with precision and excellence.

SOURCE- https://farelabs.com/the-significance-of-calibration-services-by-fare-labs/

0 notes