#Luxury Folding Carton Market by Type

Text

Sustainable Solutions: Biodegradable Materials Transforming Box Packaging

Box packaging isn't just about protection and practicality; it's a critical component of brand identity and consumer perception. As we navigate through the myriad options available in the packaging world, it's essential to stand out with designs that not only captivate but also communicate your brand's essence. Here, we delve into the art and science of box packaging designs, offering insights and tips to elevate your packaging game.

Introduction to Box Packaging Designs

The first impression can make or break a product. In today's market, where competition is fierce, the packaging is your silent salesman. It's not just about holding a product; it's about communicating a brand story, values, and promise. The evolution of box packaging designs reflects changing consumer behaviors, technological advancements, and a growing emphasis on sustainability.

Get More Information @ https://saypan.in/our-services/

Types of Box Packaging

Box packaging comes in various shapes and sizes, each serving different purposes and industries. Folding cartons offer versatility and cost-effectiveness for lightweight items. Rigid boxes, with their sturdy construction, exude luxury and protection. Corrugated boxes, known for their strength and durability, are ideal for shipping and handling.

Design Elements in Box Packaging

A compelling box design marries form and function. Color psychology plays a pivotal role in evoking emotions and driving consumer behavior. Typography and readability ensure that the product communicates effectively with potential buyers. Imagery and branding elements like logos and slogans solidify brand identity and recall.

Sustainable Box Packaging Solutions

As environmental concerns rise, sustainable packaging solutions have become a priority for brands and consumers alike. Innovations in biodegradable materials and designs that encourage reuse not only minimize environmental impact but also resonate with eco-conscious consumers.

Innovative Box Packaging Trends

The packaging industry is constantly evolving, with trends like smart packaging solutions that enhance user experience through technology, and minimalist designs that focus on simplicity and clarity, leading the way.

Box Packaging Design Process

The journey from concept to creation involves several stages. It starts with conceptualization and sketching, followed by prototyping and testing, ensuring that the final product is not only visually appealing but also functional and user-friendly.

The Role of Technology in Packaging

Technology has revolutionized packaging design. 3D printing allows for rapid prototyping and customization, while Augmented Reality (AR) offers an interactive experience, making packaging a gateway to the digital world.

Box Packaging for Different Industries

Packaging needs vary significantly across industries. Food and beverage packaging emphasizes freshness and safety, while cosmetics and beauty products focus on aesthetics and brand prestige.

Custom Box Packaging Solutions

The demand for personalization has led to the rise of custom packaging solutions. Personalized packaging, tailored to individual preferences or occasions, creates a unique unboxing experience, strengthening the emotional connection between the brand and its consumers.

Cost Considerations in Packaging Design

Designing effective packaging involves balancing aesthetic appeal with cost. Understanding the trade-offs between material choices, production methods, and economies of scale can help brands manage costs without compromising on quality.

The Future of Box Packaging Designs

The future of packaging is ripe with possibilities. Predictions include further advancements in sustainability, technology integration, and personalization, shaping how brands interact with consumers through packaging.

Conclusion

In the realm of box packaging designs, creativity knows no bounds. From enhancing brand perception to meeting sustainability goals, the packaging serves as a crucial touchpoint that can significantly influence consumer decisions. By embracing innovation, prioritizing sustainability, and focusing on the user experience, brands can craft packaging designs that not only stand out on the shelf but also resonate with their audience on a deeper level.

Saypan, the premier box packaging designs company in Pune, has set a new standard in the industry with its innovative, sustainable, and impactful packaging solutions. By understanding the critical role packaging plays in branding and consumer perception, Saypan crafts designs that not only protect the product but also tell a story and connect with consumers on a deeper level. As packaging design continues to evolve, Saypan remains at the forefront, ready to meet the challenges of the future with creativity, sustainability, and excellence.

Contact us

Phone : +91 96657 20007, +91 87672 11111

Email : [email protected]

Website: https://saypan.in/

Follow us :

Facebook

Instagram

linkedin

0 notes

Text

Corrugated Types Used in the Packaging Sector

Because cardboard may be used in many ways daily, many varieties are available on the market. Cardboard may have good thermodynamic qualities and be a material that is both lightweight and very strong, depending on its thickness, shape, and form.

This post will examine the most popular varieties of cardboard box manufacturers sector and discuss their widespread usage and dependability.

Also Read: Suppliers of Carton Boxes and Their Impact on Contemporary Packaging

Different Cardboard Box Types

The several kinds of boxes and the terms used interchangeably in the packing business to describe them—rigid boxes, folding cartons, set-up boxes, corrugated boxes, cardboard boxes, paperboard boxes, and so forth—confound many people. There are three main box types in the packaging industry. They are all made of paper pulp in varying thicknesses.

Fundamental Kinds of Boxes

Carton Folding

Among the most common box types seen in stores are folding cartons, also called paperboard cartons or paper packaging boxes. This is a folding carton; it resembles a milk or cereal box.

Stiff Boxes

Since they do not fold or collapse, rigid boxes—also called set-up boxes—are more resilient than folding cartons. They are often (though not always) used to luxury goods that are thought to be of superior quality. They are also used when the contents need extra support since they are hefty. A stiff box may be compared to the packaging of an iPhone.

Plywood Boxes

When relocating, brown cardboard boxes called corrugated boxes—also called corrugated board, mixed board, or corrugated fiberboard—are often used to pack and store belongings.

Honeycomb box manufacturers typically consist of three layers. A curved or fluted layer sits between two smooth exterior surfaces. The longevity of this paper product is found in its perforated layer.

Various Cardboard Packaging Types

Your needs will determine how many different kinds of cardboard packaging you need. The following list includes many types of cardboard packaging:

One-Faced Board

The single-face board is the most prevalent kind of cardboard packaging that you will encounter. This is only corrugated cardboard minus the second piece on the opposite side of the fluted layer. It is common practice to pack items in a single box in this manner to ensure that they do not break or clash while in transportation.

Single-Wall Board

This is the typical corrugated cardboard for shipping boxes and other cardboard packaging. It features one line of fluting in the centre and two flat walls. This cardboard may be robust even with only one flute layer, so boxes often utilise it.

Double-Wall Board

Naturally, the double-wall board adds fluting between the two outermost layers. Doing this strengthens the board, giving the items kept within even more protection.

Conclusion

Making the best choices for package design requires understanding the function of cardboard in packaging.

#corrugated box supplier#carton box supplier#corrugated packaging manufacturer#corrugated box manufacturers

0 notes

Text

Packaging boxes

Packaging boxes

Packaging boxes play a crucial role in protecting and presenting products during transportation, storage, and display. When it comes to packaging boxes, there are various types, materials, and design considerations to take into account. Here are some key points to consider when dealing with packaging boxes:

Box Types:

Folding Cartons: These are typically used for retail packaging and are made of paperboard.

Corrugated Boxes: Ideal for shipping and transportation due to their strength and durability.

Rigid Boxes: Sturdy and often used for luxury or high-end products.

Materials:

Cardboard: Commonly used for folding cartons and is versatile in terms of design.

Corrugated Board: Comprising three layers (an inside liner, an outside liner, and a fluting medium), it provides strength and protection.

Kraft Paper: A strong, durable material commonly used for corrugated boxes.

Design and Customization:

Consider the size and shape of your product to ensure a proper fit.

Branding: Incorporate your brand elements, logo, and colors for brand recognition.

Printing: High-quality printing enhances the visual appeal of the box.

Die-cutting: Allows for unique shapes and openings.

Box Inserts:

Use inserts to secure and protect the product inside the box. Inserts can be made of foam, molded pulp, or other materials depending on the product.

Sustainability:

Consider using eco-friendly materials and designs to minimize environmental impact.

Use recycled or biodegradable materials.

Regulations and Compliance:

Ensure that your packaging complies with relevant regulations and standards.

Include necessary product information, barcodes, and labels.

Testing:

Perform quality and durability tests to ensure the packaging can withstand transportation and handling.

Cost Considerations:

Balancing quality and cost is important. Choose materials and designs that meet your budget constraints.

Supplier Selection:

Choose a reliable and experienced packaging supplier to ensure consistent quality and timely delivery.

Shipping and Storage:

Consider how the packaging will impact shipping costs and storage space.

Remember, the right packaging not only protects your product but also serves as a marketing tool, influencing the customer's perception of your brand.

0 notes

Text

Packaging Choices: Rigid Set-up Boxes vs. Folding Cartons

When planning to bring a new product to market, the packaging is a critical point in consumer response. Not only should the product be presented with outstanding design elements that attract the eye, the box must be able to withstand the stresses of packing and shipping without damage to box, surface, or product. The choice between rigid set-up boxes and folding cartons is just one of a multitude of crucial decisions that are part of planning a new product launch, or the process of updating an existing brand.

RIGID SET-UP BOXES

Rigid set-up boxes are crafted from thicker material called ship board that get wrapped with a light printed sheet. They require no erecting/folding type When planning to bring a new product to market, the packaging is a critical point in consumer response. Not only should the product be presented with outstanding design elements that attract the eye, the box must be able to withstand the stresses of packing and shipping without damage to box, surface, or product. assembly, making product fulfillment time less than a traditional folding carton solution. A rigid set-up box provides an unmistakable impression of quality, particularly when the box has been designed with appealing graphics, special finishes and textures, or other attractive design elements.

Consumers respond to quality packaging, and rigid set-up boxes are a powerful way to present a product, particularly when the box design has design elements such as textures, foil stamping, or embossing. Although these boxes cost more to produce and carry higher shipping costs due to the larger required space, the end result of a custom-designed box is a critical selling point for the product. Bottom line – consumers appreciate quality, and the box design and structure clearly communicate the quality of the product within.

Folding cartons have the advantage of being shipped flat – saving the cost of shipping when compared to shipping rigid boxes. These cartons are produced with fewer processes, and at lower cost. The boxes, manufactured from paper or plastic, require set-up (erecting) after shipping, quickly taking shape, and are pre-glued for rapid construction. Folding cartons can be designed in almost limitless range of shapes, sizes, designs, and substrates.

THE EYE OF THE BEHOLDER: CREATING AN IMPRESSION OF QUALITY

The critical point in any folding carton is whether the design stands out on the shelf and attracts the eye of the consumer. Every detail matters, from texture, to graphics, to shape, size, color, and clear branding. With the help of a professional packaging design team, luxury or decorative folding cartons can be produced to suit your brand perfectly. With the right design, shape, and custom features and finishes, your product can be far more attractive to consumers browsing the shelves.

THE BEST OF BOTH WORLDS: FOLDING CARTONS THAT PERFORM

A skilled folding carton manufacturer can create a folding carton that can “stand in” for a rigid set-up box successfully, giving the appearance of high quality and costing far less to produce. At West Pac Pkg Inc, our team of professionals can help you design a folding carton that provides the luxury appeal of a rigid box, but without the higher cost of production and shipping. We cover the full spectrum of industries, including health and beauty, entertainment, spirits, foodand beverage and more.

Our team has the expertise, experience, and deep skillset needed to produce rigid set-up boxes or folding cartons that are truly above and beyond the ordinary in quality and design.

West Pac Pkg, Inc is one of the leading Custom Setup Boxes PackagingManufacturer in California. Contact us today for design sample!

0 notes

Text

Child Resistant Packaging Market to Reach a Valuation of ~ US$ 40.1 Bn by 2031

Transparency Market Research offers key market acumens of global child resistant packaging market in its newly published report, which includes global industry survey, share, growth, size, trends, along with forecast for 2021-2031. In terms of global revenue, the child resistant packaging market is anticipated to register growth at a CAGR of 5.9% during the upcoming decade, of which TMR provides a detailed analysis of lucrative growth opportunities in the child resistant packaging market report.

Get a Sample of This Report for Industrial Insights and business Intelligence - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=15368

The child resistance locking pouches are made from plastic material, which has a feature that makes it difficult for a child to open it. Child resistance locking pouches are used to prevent accidental exposure to toxic or harmful content. The child resistant locking pouches are opaque and have a high barrier packaging option, which make it popular among various end-use industries such as food & beverages, personal care, pharmaceuticals, etc.

Sterile medical packaging includes various types of packaging such as caps and closure, dropper, blister and clamshells, joint container tubes, bags and pouches, cartons, and many others that are used for the specific type of packaging.

Advancement in Healthcare Sector Generating Demand for Safer and More Efficient Products

The last few decades were a period of global economic crisis and witnessed a growth in the number of drugs packaging. As a consequence, various pharmaceutical products have been compelled to review their strategies. As a result, a major shift in focus was observed in healthcare, focusing on the use of products that are child resistant. Therefore, pharmaceutical companies are focusing on the use of child resistant packaging products at relatively economical cost, which can respond to the growing demand for the adoption of various product type.

Get a glimpse of the in-depth analysis through our Report Brochure https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=15368

Product Innovations among Child Resistant Packaging Manufacturers

Key market players are aiming to expand their product offerings and presence in untapped market. For instance, companies that excel in offering small sized packaging will likely opt for other sizes and technologies, similar to those who hold market share in a single location will look for mergers or acquisitions, which allow them into newer markets.

On October 2021, Berry M&H launched a child resistant certified bottle and closure combination, which will provide safe and secure packaging for a range of applications that include healthcare and household cleaning products. The child resistance protection is certified according to ISO standards. The company says the bottle range was tested and approved to BS EN ISO 8317:2015.

On November 2021, diamond packaging made an announcement of winning three awards in the 2021 North American paperboard packaging competition. Diamond Lockbox folding cartons are an upscale, certified child-resistant (CR) packaging solution for medical or recreational marijuana products, luxurious enough to rival high-end cosmetic brands.

On December 2021, berry global introduced a lightweight and recyclable closure for sauce bottles providing more convenience for consumers. The company has also introduced a range of child-resistant certified bottles and closures combinations for applications such as cleaning agents and DIY projects. The new design offers strength and durability in the same way with consistent and reliable performance.

Enquire Before Buying - https://www.transparencymarketresearch.com/sample/sample.php?flag=EB&rep_id=15368

Growth in Demand for Reusable Packaging Solutions

To cope with growing regulatory pressure and reduce transportation costs, service providers are focusing on use of reusable packaging rather than one-way (disposable) systems

Reusable packaging reduces usage of refrigerants and insulation materials that are linked with ozone depletion and global warming. Use of reusable insulated containers for multiple transportation is also significantly cost effective.

How Child Resistant Packaging Market Recover After Covid 19 https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=15368

Child Resistant Packaging Market: Competition Landscape

Key market players in the child resistant packaging market are focusing on strategic expansions and acquisitions to maintain their supremacy across the regions and eyeing lucrative growth offered by emerging markets

The Tier Structure is formed based on segmental revenues earned by the sales of sterile medical packaging by the company. According to the tier structure, Constantia Flexibles Group GmbH, Amcor Limited, Berry Global, and WestRock Company are major manufacturers included in tier 1. In addition, Placon Corporation Inc., Bemis Company, Inc, Gerresheimer AG, Bilcare Limited, and Global Closure Systems are included in tier 2. Moreover, KushCo Holdings Inc,. Winpak Ltd and other manufacturers are included in tier 3.

On January 2020, Origin Pharma Packaging has launched a piece of packaging dedicated to the medicinal cannabis industry, which is the newly designed child-resistant jar. These products/medicines have to be packaged safely, as they will be entering a domestic environment where children may be present.

In April 2019, ProAmpac LLC announced the expansion in its product line for child resistant pouch portfolio to cater the increasing demand for child resistant packaging

More Trending Reports by Transparency Market Research –

Aseptic Paper Packaging for Flat Top Carton Market https://www.transparencymarketresearch.com/aseptic-paper-packaging-flat-top-carton-market.html

Robotic Carton Loading Machine Market https://www.transparencymarketresearch.com/robotic-carton-loading-machine-market.html

Carton Erecting Machines Market

https://www.transparencymarketresearch.com/carton-erecting-machines-market.html

Carton Closing Machines Market https://www.transparencymarketresearch.com/carton-closing-machines-market.html

Half Slotted Carton Market https://www.transparencymarketresearch.com/half-slotted-carton-market.html

About Transparency Market Research

Transparency Market Research is a global market research reports company providing business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyze information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

For More Research Insights on Leading Industries, Visit our YouTube channel - https://www.youtube.com/channel/UC8e-z-g23-TdDMuODiL8BKQ

Contact Us:

Rohit Bhisey

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Blog: https://tmrblog.com

Email: [email protected]

0 notes

Text

Find Luxury Rigid Boxes in Endless Packaging Options from The Yebo Group

In the packaging industry, rigid boxes are also commonly known as the Set-Up boxes, helping to deliver standard packing types, and are mostly associated with luxury products. Such one-of-a-kind rigid boxes are typically four times thicker in contrast to the folding cardboard boxes, wherein they are not printed straightway. In essence, such Custom Rigid Boxes are encased with paper that can be simple or deluxe, as per the personalized needs of the clients. PakFactory, the most prominent custom box supplier comes with high-end tailor-made cartons that help to safeguard the products while making the storage and shipping secure.

Why Should The Clients Choose The Custom Packaging Options

1. Extremely Proficient Packaging Specialist

Delivering highly specialized and customized services, the packaging experts of the Yebo Group perceive the objectives of the clients and recommend tailor-made project solutions. The most dependable custom packaging services bring forth end-to-end user-friendly solutions for the clients through their professionally qualified and steadfast packaging specialists delivering unmatched packing experiences for the end consumers.

2. Professionally Crafted Robust Rigid Boxes with Luxury Packing

Rendering flawless product un-boxing insights, the Yebo Group helps to perfectly enhance the brand’s prominence. In this context, the packaging engineers’ devises distinct customized printed rigid boxes that are thoroughly customized and quantified for befitting the specific products efficiently. Such highly functional rigid packaging boxes, including luxury packing, are composed of premium quality materials, and bring forth limitless personalization for fulfilling the client’s expectations.

3. Comprehensive and Accessible Logistics with a Global Packaging Network

These customized packaging options furnished by the Yebo Group help the customers to save on inventory expenses. Bestowing end-to-end supply chain solutions, the adept freight team along with the shipping partners delivers the packages through the air or any other specific delivery schedules. Besides, the clients can also obtain easier access to the global supply chain platform, and also conveniently browse the most advanced packaging variants and designs created worldwide.

4. Simpler Endless Packaging with Loyal Support from Packing Mavens

The Yebo Group also offers complete freedom to the clients in selecting the choicest packaging options from an assorted range of layouts and structures. With cutting-edge packaging strategies, improved product-centric packing can be utilized. Moreover, this reputed Custom Rigid Boxes packaging store comes with an exhaustive range of paperboard packaged boxes that syncs in befitting structural designs of cartons, along with using in-house fine art creativity.

In the process, the packaging specialists assist the customers with their custom packing needs, amplifying their box wrapping experiences. Moreover, this packaging specialist also offers exclusive consultation to potential clients, delivering innovative concepts and customized designs of product packaging, and un-boxing experiences, thus negating the hassles of the customers.

5. Optimally Scalable and Efficient Platform with Cost-Effectiveness

The Yebo Group furnishes an end-to-end synchronized platform of standardized and customized orders that are automatically administered and distributed with the help of real-time production and supply chain management. Besides, they also offer user-friendly Luxury Rigid Boxes packaging solutions along with premiums of a data drive system of vast packaging network, and fully accessible to reasonable production and logistics prices. Therefore, such a completely automated platform helps to minimize the needless expenses in sales and marketing, client service, order administration, and supply chain network. Their adept packaging experts help the customers to generate enhanced profits via the eco-friendly business model.

6. Rigorous Quality Control

Moreover, clients can rest assured of obtaining premium quality products and services from the packaging mavens of the Yebo Group. Likewise, all the orders are processed through a stringent 20-point inspection, sustaining the highest quality control standard, and effectively analyzed for any defacements based upon ultramodern pattern recognition technology, assuring the packaging is error-free.

In Essence

Trusted by 5000+ businesses worldwide, the specialist packaging services of the Yebo Group have diligently delivered thousands of corporate concerns with unique Custom Rigid Boxes and special custom packing solutions that impressed the clients thoroughly.

0 notes

Link

#Luxury Folding Carton Market#Luxury Folding Carton Market Analysis#Luxury Folding Carton Market Analysis in Developed Countries#Luxury Folding Carton Market by Application#Luxury Folding Carton Market by Type#Luxury Folding Carton Market Development#Luxury Folding Carton Market Forecast#Luxury Folding Carton Market Future Innovation

0 notes

Text

RK Printers’ new plant at IMT Faridabad

RK Printers was founded in 1972 by three brothers, KS Malik, Rakesh Malik, and Ramesh Malik. They were among the few printers in Delhi with offset presses for publishing and packaging. The company began and thrived in the industrial sector of Delhi’s Anand Parbat, conveniently positioned and accessible in those days.

[caption id="attachment_68751" align="alignleft" width="300"]

RK Printers at IMT Faridabd.[/caption]

When the second generation of the family joined the company, it quickly recognized the need for more visible space to expand. The search began, and the IMT Faridabad industrial region near Delhi was chosen because of its superior connectivity and infrastructure. However, with the constraints imposed by the Covid-19 lockdowns, it took over two years to establish the new plant at IMT Faridabad. It’s a planned 35,000-square-foot facility with specialized production floors.

“Sustainability is the company’s main focus,” say the nextgen Maliks. Since the brothers consider environmental issues proactively, the intention was to create an environmentally friendly infrastructure when developing the new facility.

30 kW solar power and rainwater harvesting

RK Printers built a 30 kW solar power plant and a rainwater harvesting plant at the new factory to alleviate its carbon footprint. Vikrant Malik, one of the nextgen partners, says, “We believe that the factory and process should be environmentally friendly. Using harvested rainwater and solar panels is an excellent way to reduce the carbon footprint and do our bit to help the environment. Team RK Printers is committed to an extensive recycling program, including everything from paper and inks to the plates we use on our presses. We’re proud of our efforts and continually strive to do whatever we can to protect the environment!”

Speaking about safety, he adds, “The company has installed fire safety measures in the plant. There are 5 to 6 fire extinguisher flasks on every floor, and for every recruit added to the plant, we have given fire hazard and safety training.”

[caption id="attachment_68750" align="alignleft" width="300"]

Boxtech velocity crash lock bottom carton machine.[/caption]

The company currently converts over 1.5 million cartons daily. At the new facility at IMT Faridabad, a pre-owned 6-color Heidelberg offset press with coater, Bobst die cutters, and three new crash lock pasting machines from Boxtech are operational. These substantially boost the company’s earlier production capacity.

The company manufactures 6-color monocartons with UV coating, embossing, and raised UV aqueous coating, along with other special decorative effects. In addition, the firm has widened its reach to new verticals and segments such as pharmaceuticals, cosmetics, foods, and beverages. The USP is to provide its customers with a one-stop solution.

“While many companies specialize in folding carton product boxes, we are a different type of box manufacturer. Our specialty is adding the finishes and textures to printed packaging that attract attention – and that makes the difference in selling the product,” said Malik. RK Printers produces blister cards with HSL and pet coating for cosmetics clients, rigid boxes for the luxury segment, labels, leaflets, danglers, and paper pouches for pharma and personal care mehendi (henna) clients, gift boxes for festivals, corrugated boxes for start-ups, and shipper boxes for exporters. It works with several companies and brands in the pharma, food, beverages, alcohol, agrochemicals, start-ups, and incense segments.

RK Printers plan to enter the European market

The company has invested in the infrastructure, machinery, and accessories to attain the certifications required for exports. The firm also has a contemporary quality control lab with the most up-to-date test equipment capable of performing all necessary tests to confirm the client’s specifications. Malik comments on the company’s plans, “We want to export our products to the European market. We are looking forward to participating in several exhibitions and entering new markets as we now have a robust infrastructure required for exports.”

Passion, creativity, and professionalism drive RK Printer’s growth. To be able to offer these values internationally, the firm produces and promotes novel packaging solutions for its client’s brands. “We leave no stone unturned to provide quality to our customers in India, and we hope that we can deliver the same to the international market as well,” concludes Malik.

0 notes

Text

Get to know Polycart, your premium cardboard packaging will not be the same anymore!

Giving new meanings to packaging, specifically premium cardboard packaging, and catering to all types and sectors of the economy, Polycart is based in Sofia, Bulgaria and it offers packaging solutions to different countries in the EU. Generally at Polycart, items are supplied only after orders, but this company stocks some small quantities of generic products on its shelves for the benefit of its customers. Specializing in paper, carton, plastic and corrugated packaging, Polycart caters to every customer’s needs and the rates of this company are quite reasonable in the European Union.

Further, Polycart works in partnership on a contract basis with other companies in the textile, electronics, jewellery, food, pharmacy, drinks, parts and related industries to offer premium luxury packaging solutions. To sum it up, if it is cardboard, synthetic, self-adhesives, cover and corrugated materials, and printed and plain packaging items you are looking for in the EU and beyond, then you can be assured that Polycart is the best place you should try. We also accept samples of products, like different arrays of premium cardboard packaging that you want us to make for you within your desired price range, for this helps us to meet your needs in the best possible manner.

You have tried our premium cardboard packaging, now know what drives us

In all the years of our functioning, we have understood the importance of our customers, and in serving them, all our departments like Sales, Production, Customer Service, Production, Accounting and Administration etc goes all out in making these customers’ experience with us as enriching as possible and we believe, they are satisfied with our products and services to the utmost. It will be noteworthy to mention that our every staff, from a Customer Service Representative to the Production Supervisor, works tirelessly to see that orders are produced and shipped on schedule and in the way our customers want them, and in all our working quality is never compromised.

If today Polycart is riding on the path of unprecedented success, much of the credit goes to our workforces about whom something has been said before, and this staffs are always imbibed with the belief that in all their workings, along with their benefit, the benefit of the company is a priority. We take pains to ensure a pleasant working environment and good interpersonal communication for these workers and we always hire the best of them, with suitably rewarding outstanding achievements.

Being a company that never compromises on technology, efforts are always made to work with the best and latest equipment and our production facility always adheres to efficient and cost-effective procedures.

Manufacturing standard sized products is not a problem for us but catering to custom orders is our precedence for the real challenges lays in them. If our customers need special papers of different sizes or new features we are all too happy to make these out for them.

In the coming years, we aim to achieve 20% growth each year and bring out more innovation in our production of paper, corrugated, plastic and carbon packaging, and be the best as regards price, service and delivery. We also endeavor to explore new products and markets in these future times, being not satisfied with only products like premium cardboard packaging, thereby bringing into our fold more number of customers.

Polycart LLC

Slavianska 46, BG-2230 Kostinbrod, Bulgaria, EU

Email: [email protected] | Tel: +359 878 421007

0 notes

Text

4ShoppingBags Wholesale Custom Rigid Boxes

Custom Rigid Boxes

Rigid boxes, also known as set-up boxes, are premium packaging that is often associated with luxury products. With most other types of packaging, you must assemble or fold the box prior to placing your product inside. Rigid boxes arrive already formed so there is no additional labor or equipment needed to use the packaging. Simply place your product inside and close the box! So rigid boxes are considered as the best high end packaging choice.

Rigid boxes are made of heavyweight paper boxes (chipboard,greyboard),so rigid boxes are much stronger than folding cartons and are typically four times thicker. Depending on your product and the packaging application, rigid boxes are typically strong enough to survive parcel shipment. Most companies still elect to put the rigid box inside of a shipping bag or over-pack box to protect the graphics.

Many high-end marketing kits are created by combining several different rigid box components along with a book cover. The result is a sturdy kit with excellent graphics that can survive most shipping environments.

Products typically packaged in rigid boxes include cosmetics, medical devices, electronics, candy & confections, candles, jewelry, marketing items, apparel,personal care beauty products and other high-end consumer goods.

Rigid Box Design

Rigid boxes are constructed by cutting and forming a chipboard sheet (sometimes referred to as greyboard sheet), and then wrapping that formed structure with a plain or printed sheet of paper. The result is a robust box with high-end graphics that offers a great presentation and frustration free opening.

Since the box or tray structure is wrapped with a flat printed sheet, all embellishments and capabilities offered by the print industry can also be incorporated into your rigid box.

Want to take your rigid box to the next level? Consider adding lamination to the flat sheet prior to wrapping! Lamination can give your box unique properties such as soft-touch feel, high gloss look, or scuff proof durability.

Rigid boxes can be constructed in many different ways, but they generally consist of two parts: a lid and base. However, the shape, size and function of rigid boxes can vary greatly depending on the product and purpose of the packaging. The base and lid can also be hinged together to give your packaging a different feel and opening experience.

As rigid boxes manufacturer, 4ShoppingBags specialize in manufacturing custom rigid boxes with the best quality and at competitive price. At 4ShoppingBags ,rigid boxes come in any size,shape and style including two piece rigid box,hinged lid rigid box,slipcase,neck box,shoulder box and more.

When you are looking for custom rigid boxes,below information will help you to choose right right boxes to fit your end.

Full Telescope Rigid Boxes

Full telescope rigid boxes are very common. Telescope refers to the way in which the rigid box is assembled. The lid of the box “telescopes” over the base of the box.

Full telescope means the lid fully telescopes the base. A thumb notch can be added to the lid to make opening the box easier.

When opened, the lid detaches from the base leaving you with two components.

This is the reason this style of rigid box also falls under the category of 2-Piece Rigid Box.

Partial Telescope Rigid Boxes

Partial telescope rigid boxes are similar to full telescope rigid boxes. The difference: the lid for the partial telescope rigid box only “telescopes” over part of the base of the box.

A thumb notch is less common in this style of box since its design makes it naturally easier to open. When opened, the lid detaches from the base leaving you with two components.

This is the reason this style of rigid box also falls under the category of 2-Piece Rigid Box.

Shoulder Rigid Boxes

Shoulder rigid boxes are a type of partial telescope rigid box. An additional tray is glued to the inside of the base that protrudes up past the top of the base. The protrusion creates a “neck” and the top edge of the base creates a “shoulder”.

The additional tray can also be placed inside of the lid to give the box a different look while keeping the function the same.

Neck Reveal Shoulder Rigid Boxes

The neck can be extended so that it is visible even when the box is closed. This is often referred to as a “neck reveal” and can give the packaging a unique presentation and branding opportunity since the neck can be printed with the same graphics as the box.

Both of these designs consist of 3 components, and therefore falls under the packaging category of a 3-Piece Rigid Box.

Slipcase

Slipcase is the term used to describe a rigid base tray that slides into a sleeve or another rigid tray that is oriented differently. The result is a box that opens like a drawer.

This type of rigid box can give the custom a unique unboxing experience. The slipcase can also be used to store the product long-term as they are typically very durable and easy to open / close.

Hinged Flip Top Boxes

Hinged rigid boxes have the lid and base of the rigid box hinged together.

The construction consists of a rigid base tray with a flat chipboard sheet attached to the back of the tray. This style is also referred to as a cigar box.

In addition to packaging, this style of rigid box is often used for marketing and sales kits. The inside of the lid can be printed providing marketing real estate or additional space to tell your story.

Hinged Binder Book Boxes

Hinged binder book boxes are comprised of two components: a book cover and a rigid tray.

The rigid tray is glued to the book cover, which gives the box a book / binder look. The spine of the book cover can be attached to the tray or left unattached depending on the desired presentation and function of the packaging.

In addition to packaging, this style of rigid box is often used for marketing and sales kits. The inside of the lid can be printed providing marketing real estate or additional space to tell your story.

0 notes

Text

Some Packaging Types to Consider

It is clear that packaging plays a large role in the perceived value of a product and as a whole, the packaging industry really hasn’t changed too much in the past years, compared to the constant innovations made in portable technology. With all the packaging and Color Box choices available in today’s market, it often becomes difficult to select the most appropriate packaging solution for your product. Let’s take a look at some of the different types of packaging options you can use to enhance your product & customer experience!

Paperboard boxes

Paperboard Gift Box is a paper-based material that is lightweight, yet strong. It can be easily cut and manipulated to create custom shapes and structures. These characteristics make it ideal to be used in personalized packaging. It is made by turning fibrous materials that come from wood or from recycled waste paper into pulp, and then bleaching it. Paperboard packaging comes in various grades, each suitable for different packaging requirements.

SBS (or solid bleached sulfate) paperboard can be used for packing cosmetics, medicines, milk and juice, cosmetics, frozen food and more. Choosing kraft, or CUK (coated unbleached kraft) paperboard packaging is for those who prefer the natural and environmentally-friendly look of recycled paper, which can be used for similar packaging applications. Kraft is often seen to be less resistant to moisture, making it less suitable for food-related products, or frozen-goods packaging. With the right combination of design options, paperboard packaging can look high-end, without high-end pricing.

Corrugated boxes

Corrugated boxes simply refer to what is commonly known as: Cardboard. Corrugated boxes are the ones many probably consider as ‘cardboard’ as it produces the large shipping, shoe & storage boxes. What a lot of people do not realize is that corrugated boxes also come in different types depending on the durability and strength of the Food Packaging Box. Identifying a certain corrugated material, however, is easy. How do you determine the material? Through its corrugated medium (also known as fluting). Identifying a corrugated material is easy. It consists of 3 layers of paper, an outside liner, an inside liner and a corrugated medium (also known as fluting). The corrugated medium that gives it strength and rigidity.

Rigid boxes

I’m sure you’ve always wondered the type of box they used to package iPhones or those luxury retail products such as Rolex, Tiffany & Co and Marc Jacobs. You have a sense that it’s a type of cardboard but still wasn’t sure because of its durable and premium appearance. This type of cardboard material is called a rigid box.

A rigid box is made out of a highly condensed paperboard that is 4 times thicker than the paperboard used in the construction of a standard folding carton. The easiest real-world example of rigid boxes are the Scodix Craft Boxes which holds Apple’s iPhones and iPads, which are 2 piece setup rigid boxes.

Compared to paperboard and corrugated boxes, rigid boxes are definitely among the most expensive box styles. The rigid boxes usually do not require dies that are expensive or massive machinery and are often hand-made. Their non-collapsible nature also gives them a higher volume during shipping, which easily incurs higher shipping fees.

Poly bags

A poly bag, also known as a pouch or a plastic bag, is manufactured out of flexible, thin, plastic film fabric. It is one of the common types of packaging and can carry a wide range of products including food items, flowers, waste, chemicals, magazines, and so on.

Poly bags are durable yet lightweight, reusable and flexible same with Paper Bags. Since poly bags are structurally simple to make, it can be fully customized in design, style & sizes but still remain cost-effective. Plastic recycling is also possible with poly bags, depending on the construction. Most of the poly bags are made with security features, tape attachments, hanging holes, and carrying handles to make sure the products are well secured and visually appealing to the customer.

Young designers might be so focused on the shape, color, and cut of their dress, they may not give much thought to clothing Garments Tags that are added after production. The same goes for consumers; how an item of clothing looks and what it costs tend to be the main concerns for buyers, but clothing labels shouldn’t be ignored so easily. Clothing labels offer important information about the product, information which might just be the difference between an item being purchased or put back on the rack.

One of the most important aspects of clothing labels is the description of the materials the item is made from. Today’s consumers are more environmentally conscious than they’ve ever been, and not all materials are made the same way. With so many materials made from plastic (lycra, polyester, nylon for example), consumers now have a real ethical choice about which clothes to buy.

The world of digital content is changing so rapidly with the rise of mobile, video, AR, VR, big data, little data, that many publishers may forget that print content is evolving too. New technologies in the Book Printing industry are creating opportunities for publishers to streamline their operations, distribute their books faster, and develop new revenue streams. Digital book printing, which encompasses both inkjet and toner applications, allows publishers to take the pulse of the market and adjust their strategy as demand wanes or surges for individual titles. This responsive approach is something that is not possible with offset printing alone, a model where publishers must guess how a book might perform and take on greater risk.

Yet despite the benefits of digital book printing, many publishers, particularly large trade publishers that rely on bestsellers for their income, have been hesitant to adopt. The reasons for this hesitation range from concerns over the quality and cost of digital printing to challenges related to adjusting workflows and infrastructure. While all of these objections have some validity—publishers cannot yet print large, four-color runs affordably on inkjet presses, for example—significant strides have been made in all of these areas. Book manufacturers continue to invest in faster and higher-quality digital printing presses as well as the backend technology that enables publishers to send PDF files to manufacturers who can print the same day—or even immediately.

0 notes

Link

Luxury folding cartons are the type of packaging products that are designed from paper or paperboard products and have the capability to be customized in their shape, sizes to integrate the product as per the need of the consumer. These folding cartons are a combination of flexible and rigid packaging as they can be modified, but are also efficient in protecting the contents from extreme external factors.

0 notes

Text

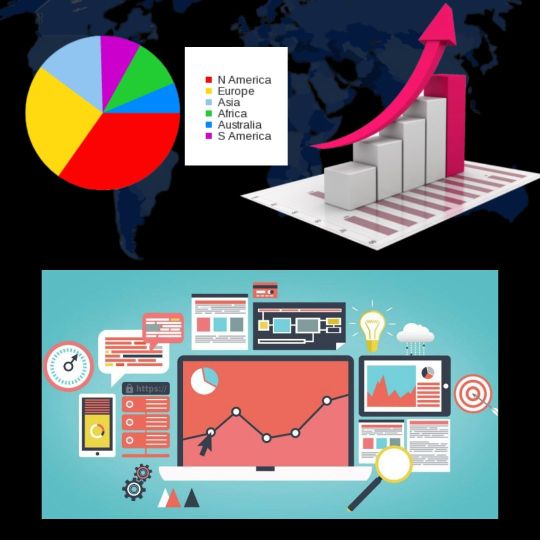

GCC Paper Products Market Size, Growth, Top Key Players, Share, Revenue, and Forecast Report 2021-2026

According to the latest report by IMARC Group, titled “GCC Paper Products Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2021-2026,” the GCC paper products market size reached US$ 10.4 Billion in 2020. Looking forward, IMARC Group expects the GCC paper products market to exhibit moderate growth during 2021-2026. Paper products refer to paper-based materials, including cups, plates and packaging, that are often lined or coated with wax or plastic to prevent the soaking or leaking of the content of the products. Widely available in numerous sizes, colors, forms and textures, these disposables are lightweight, recyclable and easy to handle. They are commonly made from recycled paper, making them easy to decompose to form nutrient-rich compost. Cups and plates made from paper are safe to be used in microwaves for reheating purposes, which has contributed to their escalating use for packaging and serving various foods and beverages, including tea, coffee, soups, soft drinks, sweet corn, and instant noodles, across the food industry. Other product variants, such as copy papers and envelops are also gaining widespread prominence among the students and working professionals.

As the novel coronavirus (COVID-19) crisis takes over the world, we are continuously tracking the changes in the markets, as well as the purchase behaviors of the consumers globally-our estimates about the latest market trends and forecast values after considering the impact of this pandemic. These observations will be integrated into the report.

Request for a free sample copy of this report: https://www.imarcgroup.com/gcc-paper-products-market/requestsample

GCC Paper Products Market Trends:

The market in the GCC region is majorly driven by the increasing utilization of paper products across numerous sectors, including textiles, education, pharmaceuticals, electronics, and food and beverages. Several paper products, such as paper towels, toilet rolls, and tissue papers, are gaining widespread prominence across the domestic and commercial segments on account of the improving living standards and the inflating disposable income levels of the masses. This is also supported by the growing hygiene consciousness among the masses in the GCC region. Moreover, the increasing preference for online shopping among individuals has impelled the demand for eco-friendly packaging solutions, including paper packaging. Supported by an enhanced focus on sustainable development among the masses, this is expected to create a positive outlook for the market. The market is further driven by the escalating demand for online food delivery services in the region, thereby facilitating the uptake of paper cups, plates and packaging. In addition to this, the implementation of plastic ban in various parts of the GCC region, including Oman and Saudi Arabia, is another major growth-inducing factor. The governments of multiple GCC countries are taking favorable initiatives to phase out the usage of traditional plastic bags and products, which, in turn, is expected to boost the sales of paper counterparts.

Ask Analyst for Instant Discount and Download Full Report with TOC & List of Figure: https://www.imarcgroup.com/gcc-paper-products-market

Key Market Segmentation:

Competitive Landscape With Key Players:

Safeer Luxury Pack

Arkan Mfg Paper Cup Company

Middle East Paper Company (MEPCO)

Al Kifah Paper Products

Al Nawar Corner

Lamina Company Ltd

Golden Paper Cups Mfg. Co. Ltd.

Unipack Containers & Carton Products LLC

Hotpack Packaging LLC

Gulf Carton

Arabian Paper Products Company (APPCO)

Breakup by Cups Type:

Cold Paper Cups.

Hot Paper Cups.

Breakup by Wall Type:

Single wall-paper cups.

Double wall-paper cups.

Breakup by Application:

Tea and Coffee

Chilled food and beverages

Others.

Breakup by Plate Type:

Heavy-duty plates.

Medium-duty plates.

Breakup by Distribution Channel:

Retail

Institutional Segments.

Breakup by Product Type:

Boxes,

Rigid Boxes

Folding Cartons

Paper Bags

Others.

Breakup by Material Type:

Brown

White

Other kraft.

Breakup by Regional Insights:

Saudi Arabia

The UAE

Kuwait

Oman

Bahrain

Qatar.

Key Highlights of the Report:

Market Performance (2015-2020)

Market Outlook (2021- 2026)

Porter’s Five Forces Analysis

Market Drivers and Success Factors

SWOT Analysis

Value Chain

Comprehensive Mapping of the Competitive Landscape

If you need specific information that is not currently within the scope of the report, we can provide it to you as a part of the customization.

Related Report:

Vietnam Pangasius Market Report 2021-2026

Trade Management Market Analysis 2021-2026

Tea Polyphenols Market Forecast 2021-2026

Cardiac Holter Monitor Market Report

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact Us:

IMARC Group

30 N Gould St, Ste R

Sheridan, WY (Wyoming) 82801 USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

Americas:- +1 631 791 1145 | Africa and Europe :- +44-702-409-7331 | Asia: +91-120-433-0800, +91-120-433-0800

0 notes

Text

Sterile Medical Packaging Market in Global Industry: Demands, Insights, Research and Forecast 2021-2028

Sterile medical packaging market will reach an estimated valuation of USD 14.30 billion by 2028, while registering this growth at a rate of 5.0% for the forecast period of 2021 to 2028.

Key Market Competitors: Global Sterile Medical Packaging Market

Few of the major competitors currently working in the sterile medical packaging market are DuPont; Bemis Company, Inc.; DWK Life Sciences; Nelipak Corporation; puracon GmbH; BillerudKorsnäs; ProAmpac; Deufol SE; Abbott; Oliver; Heritage Paper; Ahlstrom-Munksjö; Unicep; GY Packaging; James Alexander Corporation; Sonoco Products Company; BD; ESCO Technologies inc.; Ethox Chemicals, LLC.; Gerresheimer AG; Klöckner Pentaplast; Pfizer Inc.; GS Medical Packaging Inc.; Westfield Medical Ltd; West Pharmaceutical Services, Inc.; Wipak; Sabre Medical; UFP Technologies, Inc.; Amcor Limited; 3M; Placon; Riverside Medical Packaging Company Ltd and Tekni-Plex Inc.

Download PDF Sample report @ https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-sterile-medical-packaging-market

Sterile medical packaging is a packaging method utilized for protection of medical products utilized in the healthcare industry against various environmental factors, contaminants, bacteria, etc. from the point of manufacturing when packaged to the end-point of consumption. This packaging process also involves decontaminating the packaging products and medical products of being sterilized of any contaminants before being used.

Segmentation: Global Sterile Medical Packaging Market

· By Product Type (Thermoformed Trays, Sterile Bottles & Containers, Vials & Ampoules, Blister & Clamshell, IV Containers & Bags, Sterile Lid, Pouches, Die-Cut Baker Cards, Guided Wire Hoops, Sterile Wraps, Others)

· By Sterilization Method (Chemical Sterilization, Radiation Sterilization, High Temperature/Pressure Sterilization)

· By Material Type (Plastics, Paper, Foil, Non-Woven, Foam Sheets, Glass, Metals)

· By Application (Medical Disposable Supplies, Medical Equipment)

· By Geography (North America, South America, Europe, Asia-Pacific, Middle East and Africa)

Competitive Analysis:

Global sterile medical packaging market is highly fragmented and the major players have used various strategies such as new product launches, expansions, agreements, joint ventures, partnerships, acquisitions, and others to increase their footprints in this market. The report includes market shares of sterile medical packaging market for global, Europe, North America, Asia-Pacific, South America and Middle East & Africa.

Market Drivers:

· Growth of geriatric population resulting in high demand for medical devices and surgical equipment, which is expected to drive the growth of sterile medical packaging

· High consumption of medical devices from is expected to drive the market growth

Market Restraints:

· Strict regulations from the authorities regarding the specifications and materials used by the manufacturers in packaging is expected to restrain the market growth

· Consistency in maintenance of medical packaging products and protection of products is also expected to restrain the market growth

Want Full Report? Enquire Here@ https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=global-sterile-medical-packaging-market

Key Insights in the report:

· Complete market analysis and forecasting

· Market definition, understanding the concept of sterile medical packaging

· Market drivers and restraints of the industry

· Market segmentations and market share divided amongst them

· Key players in the market and their analysis

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge Market Research provides appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact:

Data Bridge Market Research

US: +1 888 387 2818

Related Reports:

Elastic Laminates Market

Luxury Folding Carton Market

#Sterile Medical Packaging Market#Sterile Medical Packaging#Sterile Medical Packaging Market Trends#Sterile Medical Packaging Market industry#Sterile Medical Packaging Market News#Sterile Medical Packaging Market Research

0 notes

Text

On-the-go Breakfast Packaging Market Opportunities, Demand and Revenue Forecast

The global on-the-go breakfast packaging market is expected to be a host to an intensely competitive business landscape, reports Transparency Market Research (TMR). Featuring high fragmentation, the global on-the-go breakfast packaging market comprises a large pool of both small- and medium-sized vendors. Established vendors are seen expanding their product portfolios in order to keep their presence dominant in the market.

The emergence of flexible packaging materials and further advances in packaging technology are expected to be key trends leveraged by vendors in the global on-the-go breakfast market in coming years. Meeting the consumer’s need for convenience, sustainability, and safety is likely to play a key role in strategies adopted by vendor in this market.

Want to know the obstructions to your company’s growth in future? Request a brochure @ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=26579

Prominent vendors in the global on-the-go breakfast packaging market are Bemis Co. Inc., Amcor Limited, Tetra Pak International S.A, Sealed Air Corporation, and Coveris Holdings S.A.

According to TMR’s projections, the global on-the-go breakfast packaging market is expected to rise at a healthy 5.1% CAGR over the forecast period from 2017 to 2025. At this rate, the market value deemed worth US$743 mn in 2016 is likely to reach US$1.1 bn by the end of the forecast period.

Plastics, in terms of material type, is predicted to emerge as the leading segment. The segment held 56.1% of the overall market share, and this trend is expected to continue on account of high demand for the material among consumers. With a 5.3% CAGR over the forecast period, Asia Pacific is anticipated to demonstrate highest growth prospects in terms of geographical segmentation. The burgeoning growth the food and beverage industry in the region could be accounted to be responsible for the growth of this regional market.

Changing Lifestyles Provide Impetus to On-the-Go Breakfast Packaging Market

Rapid changes in consumer life and busy day-to-day routines have led to increased demand for a solution for on – the-go packaging. Thanks to a hectic lifestyle, the growing number of homes and the number of working women worldwide, people have restricted time to prepare food. Thus with the increasing implementation of on-go packaging, the food and drink industry has acquired much benefit. The packaging industry is focused towards “on-the-go packaging” solutions to satisfy the increasing demand for packaged and processed foods due to consumer preferences for fast and simple consumption of food while on – the-go. Thus, the urban lifestyles are garnering high demand in the global on-the-go breakfast packaging market.

However, there are few limiations on the development of breakfast packaging market growth. Contamination of the product in particular of processed products is a key restraint. Packaging for on – the-go breakfast makes the use of processed foods easier, which could in turn lead to a large amount of contamination.

Flexible Packaging to Emerge as Key Market Trend

Combining plastic, film, paper, and aluminum foil; flexible packaging offers a wide range of safeguards while at the same time minimizing materials and costs. Due to these benefits, it is still one of the world’s fastest-growing breakfast packaging sectors. Because of the comfort associated with low weight packaging, flexible packaging is the dominant segment in the global on-the-go breakfast packaging market. In the foreseeable future it is expected to remain at the forefront.

Looking for exclusive market insights from business experts? Request a Custom Report

As flexible packaging gains popularity in the food industry, it is expected to be regarded as the prime choice for on – the-go breakfast packaging both domestically and globally. In the worldwide on-the-go breakfast packaging industry in the next few years, a huge preference for flexible packaging from providers and customers will prove to be a lucrative opportunity.

This review is based on TMR’s report titled, “On-the-go Breakfast Packaging Market (Material Type – Plastic (PE, PP, PVC, EVOH, and PET) and Paper; Packaging Type – Rigid Packaging (Rigid Boxes, Bottles and Jars, Cans, and Trays) and Flexible Packaging (Films & Wraps and Pouches & Sachets); Breakfast Products (Cereal Meals, Breakfast Bars, Sandwiches and Burgers, Cakes and Muffins, Sausages and Salamis, Egg Meals, and Milkshakes and Juices) – Global Industry Analysis, Size, Share, Growth, Trends, and Forecast, 2017 – 2025.”

You May Also Like PRNewswire on Luxury Folding Carton Market

0 notes

Text

Boost your Brand through Custom Printed Retail Packaging

Are you a manufacturer of consumer products but are not getting enough customer support? Does your marketing campaign lack zest and zeal? If so, then custom printed retail packaging can prove to be the real deal for you.

As a company, you must have first spent significant amounts in creating the most appropriate products that precisely meet customer requirements. Next, you must have acquired the right marketing team to present the brand and products in the most eye-catching manner. Businesses generally carry out extensive advertising and promotions that position their brand uniquely in the market. However, these marketing tools may not be sufficient in actually alluring customers in purchasing the products from retail stores. A study shows that around 80% of customers make purchase decisions at retail outlets. Packaging plays a vital role in diverting customers’ focus on the products and positively influencing their purchase decisions. Make your products distinguished from the crowd by boxing them in noticeable packaging.

Get customized luxurious boxes for all kinds of products

We offer top-notch packaging boxes for different industries. They include, but not limited to:

Beverages

Cigarettes

Candies

Candles

Cosmetics

CBD

E-commerce

Jewelry

Vape

All branded packaging

The box types offered include auto-lock, chipboard, corrugated, display, dispenser, folding cartons, gable, Kraft Card, one-piece mailer, pillow, product, product sleeves & bellybands, packaging inserts, rigid packaging, shopping bags, tuck boxes, window-cut packaging.

We produce all kinds of custom boxes to suit every requirement. Sellers have the liberty to customize these boxes in any shape, size, or color incorporating various distinct features. Laminations are available in gloss and matte with sandy matte, pattern, and soft-touch options. Rich coatings include gloss AQ, satin, varnish, spot UV, and flood UV. Moreover, one-of-a-kind add-ons such as embossing, debossing, die-cutting, metallic inks, and foil stamping can be utilized to give an individualistic appeal to the packaging boxes and make them shine among rivals.

Other advantages of such packaging

In addition to the uses stated above, such packaging is designed to box products safely preventing damage and mishaps. Manufacturers have to ship items globally and this involves products being subject to all kinds of handling and climatic conditions. This calls for packaging that is strong and durable to withstand all types of weather and sustain prolonged transportation. Moreover, customers demand packaging that is easy to open and can be stored for longer. Special devices like pull tabs and slide-off lids help to make this possible. Also, if you are in the e-commerce industry then there is no better way to box products than through custom printed retail packaging. They are successful in making a positive first impression with customers and help to generate customer loyalty.

We offer these boxes at the best possible price to make them affordable for you. Businesses often run on limited budgets and wish to promote the brand in the most cost-effective manner. Obtaining well-crafted boxes pushes sales upwards without putting a strain on total costs. This also helps to gain a competitive advantage over rivals that can be passed onto the customers as reduced prices.

Get started at once!

Our team of skilled and well-trained customer sales staff assists you through the whole ordering process. You can have all your queries answered promptly through live chat and helpline numbers. Additionally, free shipping and handling, free sample kits, and free review of artwork are also provided to make life easier. Boxes are delivered quickly via fast production turnaround time. All in all, these boxes prove to be a fruitful marketing strategy to publicize your brand and products.

0 notes