#biodegradable art

Text

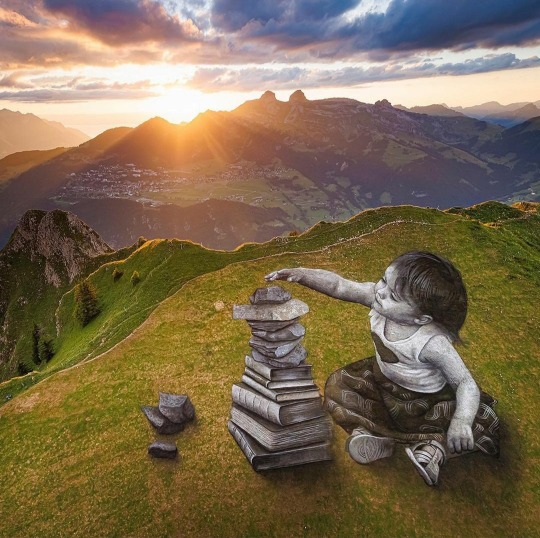

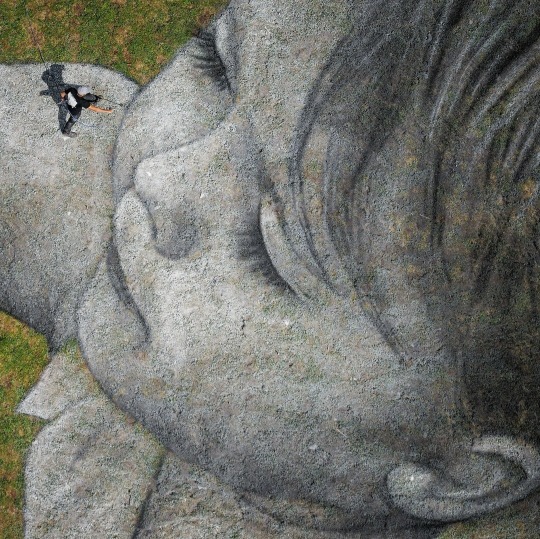

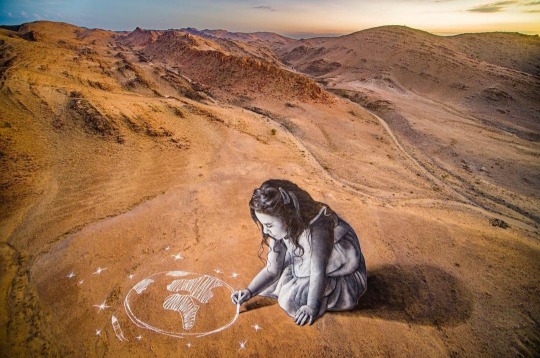

Saype, born Guillaume Legros, is a French artist living in Bulle, Switzerland. A self-taught artist, Saype’s giant biodegradable artworks adorn fields, are best seen by drones and last only days. The artist is represented by MTArt Agency since 2018. Beginning his career as a young graffiti artist, Saype’s work quickly gained recognition and became highly sought after, resulting in him landing his first gallery exhibition at age 16. Saype is a pioneer of the land art movement, focusing upon large scale biodegradable paintings with strong social messages.

Using 100% biodegradable paint composed of water, chalk, coal and casein, Saype’s ephemeral land artwork disappears after a month due to regrowth of the grass it is painted upon, the weather and the passage of visitors. With each project he completes, his recognition grows, capturing the attention of those on social media as well as landing extensive global media coverage. Career highlight for Saype have included gaining thanks from the Swiss President, Doris Leuthard, for the social vision of his art, in 2017, and following that in 2018, the publication of his book, ‘Green Art’, which highlights the innovative qualities of the biodegradable paint Saype has created.

1K notes

·

View notes

Text

Scarlett Yang CSM 2021 Graduate collection, Biodegradable dress made from algae.

#scarlett yang#art#nature#landscape#aesthetic#portrait#contemporary art#painting#abstract#architecture#haute couture#hautefashion#biodegradable#green fashion

861 notes

·

View notes

Text

Artist: @saype_artiste • @art_dailydose

"Massive artworks that are visible from the sky, lasts for a few weeks before vanishing naturally.

This contemporary artist famous for his huge nature paintings made with a biodegradable paint he created.

He is a pioneer in the art of painting on grass and uses a special environmentally friendly paint made of water, chalk, charcoal, and casein."

12 notes

·

View notes

Text

doodles of myself as i got a new haircut

(man i drew these like 3 days ago but hey)

(massive improvement from my last haircut which was an awkward grown out buzz cut)

#my art#dont ask abt the biodegradable thing#actually you can but I'm not explaining straight up on my blog so that counts out everyone as nobody has the balls to dm their mutuals#more irl moxxie lore zamn#self portrait

4 notes

·

View notes

Text

Time for a new ref for the boy!

Not a whole lot to say! Zeal's wings are finally fully grown in, and he's getting a lot better at using them. For a while he was pretty clumsy but he's had about a month and a half in-game to get used to them (we did a lot of overland travel recently that took ages).

His horns are also turning gold - the more (Divine Soul) Sorcerer levels he takes, the more his inner Celestial blood takes root. The wings are a wonderful culmination of him accepting (for the most part) the Fiendish side of him, but he's a bit worried about them looking menacing. He's been able to temporarily change their color using Transmute Sorcery Points though, and it's giving him ideas.

I really wanted to see what he'd look like with a smaller profile so I drew them folded as well - they're not TOTALLY 1 for 1 on volume but it's all I can be bothered with right now. Zeal's general footprint has grown so much which... is so fucking funny considering he's the twink. He's the largest creature by far in the group now purely on square footage.

#tiefling#dungeons and dragons#wings#digital art#character design#asharts#aiben#zeal#he gets that glitter magic EVERYWHERE#its like real glitter#impossible to get rid of#it 'biodegrades' after a while but yaknow#im v proud of my boy#the black wings look sick as hell but its not aesthetically RIGHT for him#we'll get there#for now enjoy ref of boy

41 notes

·

View notes

Text

Villars-sur-Ollon, Switzerland

A biodegradable land art painting entitled The Sun Has an Appointment with the Moon’ by the French-Swiss artist Saype, near the summit of the Grand Chamossaire mountain, above the alpine resort of Villars-sur-Ollon

Photograph: Laurent Gilliéron/EPA

#laurent gillieron#photographer#epa#villars-sur-ollon#switzerland#biodegradable land art#the sun has an appointment with the moon#french-swiss artist#saype#artist#art#grand chamossaire mountain

5 notes

·

View notes

Note

hello! i finally watch the lego elves episode Down a Dark Path. i saw your post about it, why do you think they purged everything?

Most likely explanation is that LEGO overlooked the content for the theme when redesigning and restructuring the website. Why bother carrying over tertiary content for a theme that's been retired?

Then again, the character profiles, set listings (marked as retired), and YouTube episode links are still present. It's just the activity sheets, comics, and DaDP that are gone. There really isn't any way of knowing for sure what LEGO's thought process behind it was unless you're on one of the creative or executive teams

#lego elves#secrets of elvendale#i really wish lego would bring back elves#no hate to LEGO Friends or anything#but good god that theme is SO tired man#give girls a cool fantasy theme like the boys have#only thing girls have now is disney product#lego barbie#and craft jewelry you can find in the art section three aisles down#i have a whole rant video idea locked and loaded for this topic#though lego is working on fully biodegradable bricks#so maybe they'll bring elves back with the ecofriendly bricks as a ~naturey~ theme#sure would be more interesting than turtle rescue set number 50 from friends

7 notes

·

View notes

Text

Fire Goddess Quilled Novelty Earrings

#firecore#flame#inspired by nature#jewelry#jewellery#earrings#artisan#craftmanship#oneofakind#art nouveau#made by me#yellow aesthetic#fire aesthetic#handcrafted#biodegradable#recyclable#rongful#custommade#novelty#etsy#etsy shop#etsy small business#etsy seller#sun aesthetic#a e s t h e t i c#aesthetic vibes#aesthetic#sunrise#suncore#fire goddess

4 notes

·

View notes

Text

Q&A: A blueprint for sustainable innovation

New Post has been published on https://thedigitalinsider.com/qa-a-blueprint-for-sustainable-innovation/

Q&A: A blueprint for sustainable innovation

Atacama Biomaterials is a startup combining architecture, machine learning, and chemical engineering to create eco-friendly materials with multiple applications. Passionate about sustainable innovation, its co-founder Paloma Gonzalez-Rojas SM ’15, PhD ’21 highlights here how MIT has supported the project through several of its entrepreneurship initiatives, and reflects on the role of design in building a holistic vision for an expanding business.

Q: What role do you see your startup playing in the sustainable materials space?

A: Atacama Biomaterials is a venture dedicated to advancing sustainable materials through state-of-the-art technology. With my co-founder Jose Tomas Dominguez, we have been working on developing our technology since 2019. We initially started the company in 2020 under another name and received Sandbox funds the next year. In 2021, we went through The Engine’s accelerator, Blueprint, and changed our name to Atacama Biomaterials in 2022 during the MITdesignX program.

This technology we have developed allows us to create our own data and material library using artificial intelligence and machine learning, and serves as a platform applicable to various industries horizontally — biofuels, biological drugs, and even mining. Vertically, we produce inexpensive, regionally sourced, and environmentally friendly bio-based polymers and packaging — that is, naturally compostable plastics as a flagship product, along with AI products.

Q: What motivated you to venture into biomaterials and found Atacama?

A: I’m from Chile, a country with a beautiful, rich geography and nature where we can see all the problems stemming from industry, waste management, and pollution. We named our company Atacama Biomaterials because the Atacama Desert in Chile — one of the places where you can best see the stars in the world — is becoming a plastic dump, as many other places on Earth. I care deeply about sustainability, and I have an emotional attachment to stop these problems. Considering that manufacturing accounts for 29 percent of global carbon emissions, it is clear that sustainability has a role in how we define technology and entrepreneurship, as well as a socio-economic dimension.

When I first came to MIT, it was to develop software in the Department of Architecture’s Design and Computation Group, with MIT professors Svafa Gronfeldt as co-advisor and Regina Barzilay as committee member. During my PhD, I studied machine-learning methods simulating pedestrian motion to understand how people move in space. In my work, I would use lots of plastics for 3D printing and I couldn’t stop thinking about sustainability and climate change, so I reached out to material science and mechanical engineering professors to look into biopolymers and degradable bio-based materials. This is how I met my co-founder, as we were both working with MIT Professor Neil Gershenfeld. Together, we were part of one of the first teams in the world to 3D print wood fibers, which is difficult — it’s slow and expensive — and quickly pivoted to sustainable packaging.

I then won a fellowship from MCSC [the MIT Climate and Sustainability Consortium], which gave me freedom to explore further, and I eventually got a postdoc in MIT chemical engineering, guided by MIT Professor Gregory Rutledge, a polymer physicist. This was unexpected in my career path. Winning Nucleate Eco Track 2022 and the MITdesignX Innovation Award in 2022 profiled Atacama Biomaterials as one of the rising startups in Boston’s biotechnology and climate-tech scene.

Q: What is your process to develop new biomaterials?

A: My PhD research, coupled with my background in material development and molecular dynamics, sparked the realization that principles I studied simulating pedestrian motion could also apply to molecular engineering. This connection may seem unconventional, but for me, it was a natural progression. Early in my career, I developed an intuition for materials, understanding their mechanics and physics.

Using my experience and skills, and leveraging machine learning as a technology jump, I applied a similar conceptual framework to simulate the trajectories of molecules and find potential applications in biomaterials. Making that parallel and shift was amazing. It allowed me to optimize a state-of-the-art molecular dynamic software to run twice as fast as more traditional technologies through my algorithm presented at the International Conference of Machine Learning this year. This is very important, because this kind of simulation usually takes a week, so narrowing it down to two days has major implications for scientists and industry, in material science, chemical engineering, computer science and related fields. Such work greatly influenced the foundation of Atacama Biomaterials, where we developed our own AI to deploy our materials. In an effort to mitigate the environmental impact of manufacturing, Atacama is targeting a 16.7 percent reduction in carbon dioxide emissions associated with the manufacturing process of its polymers, through the use of renewable energy.

Another thing is that I was trained as an architect in Chile, and my degree had a design component. I think design allows me to understand problems at a very high level, and how things interconnect. It contributed to developing a holistic vision for Atacama, because it allowed me to jump from one technology or discipline to another and understand broader applications on a conceptual level. Our design approach also meant that sustainability came to the center of our work from the very beginning, not just a plus or an added cost.

Q: What was the role of MITdesignX in Atacama’s development?

A: I have known Svafa Grönfeldt, MITdesignX’s faculty director, for almost six years. She was the co-advisor of my PhD, and we had a mentor-mentee relationship. I admire the fact that she created a space for people interested in business and entrepreneurship to grow within the Department of Architecture. She and Executive Director Gilad Rosenzweig gave us fantastic advice, and we received significant support from mentors. For example, Daniel Tsai helped us with intellectual property, including a crucial patent for Atacama. And we’re still in touch with the rest of the cohort. I really like this “design your company” approach, which I find quite unique, because it gives us the opportunity to reflect on who we want to be as designers, technologists, and entrepreneurs. Studying user insights also allowed us to understand the broad applicability of our research, and align our vision with market demands, ultimately shaping Atacama into a company with a holistic perspective on sustainable material development.

Q: How does Atacama approach scaling, and what are the immediate next steps for the company?

A: When I think about accomplishing our vision, I feel really inspired by my 3-year-old daughter. I want her to experience a world with trees and wildlife when she’s 100 years old, and I hope Atacama will contribute to such a future.

Going back to the designer’s perspective, we designed the whole process holistically, from feedstock to material development, incorporating AI and advanced manufacturing. Having proved that there is a demand for the materials we are developing, and having tested our products, manufacturing process, and technology in critical environments, we are now ready to scale. Our level of technology-readiness is comparable to the one used by NASA (level 4).

We have proof of concept: a biodegradable and recyclable packaging material which is cost- and energy-efficient as a clean energy enabler in large-scale manufacturing. We have received pre-seed funding, and are sustainably scaling by taking advantage of available resources around the world, like repurposing machinery from the paper industry. As presented in the MIT Industrial Liaison and STEX Program’s recent Sustainability Conference, unlike our competitors, we have cost-parity with current packaging materials, as well as low-energy processes. And we also proved the demand for our products, which was an important milestone. Our next steps involve strategically expanding our manufacturing capabilities and research facilities and we are currently evaluating building a factory in Chile and establishing an R&D lab plus a manufacturing plant in the U.S.

#2022#3-D printing#3d#3D printing#Accounts#Advice#ai#algorithm#Algorithms#Alumni/ae#amazing#amp#applications#approach#architecture#Art#artificial#Artificial Intelligence#background#biodegradable#biofuels#biopolymers#biotechnology#Building#Business#carbon#Carbon dioxide#carbon dioxide emissions#carbon emissions#career

0 notes

Text

Celebrate the joy of birthdays with the cutest pig birthday cards from RossJDesigns!

Let these adorable illustrations fill the special day with laughter and happiness. Send your warmest wishes with our charming pig-themed cards, sure to make any birthday memorable. Spread smiles and make wishes come true!

To gain more insights, click here https://rossjdesigns.com/products/pig-birthday-card-or-print!

#cards#craft#creativity#papercraft#birthdaycards#art#handmadecards#biodegradable#pigbirthdaycard#adorable#pigthemedcards

0 notes

Text

Been a bit. Here's a cat

#Biodegradable fertilize for your garden#Furry#Furry anthro#Furry cat#Furry art#Digital art#Digital painting#Anthro

0 notes

Photo

WalNet, 2023 La souris noix bijou. Longtemps utilisée comme écrin, d’où son nom, la demi coque de la noix bijou reproduit naturellement la forme préhensible d’une souris. Série #cyclé Artefacts numériques biodégradables #filipevilasboas — Introduites par le physicien José Halloy, les “zombies technologies” décrivent ces technologies mortes, énergivores, vouées à l'obsolescence programmée et qui ne tiennent pas compte des limites des ressources planétaires. Le philosophe Alexandre Monnin parle à ce sujet de “communs négatifs” qu’il va aussi falloir gérer, démanteler, déconstruire. Pour sortir de ce modèle intenable, la série “Cyclé” tente d’ouvrir la voie à une conception frugale de l’innovation en limitant autant que faire se peut son impact et ce dès la racine, en utilisant deux leviers : une réduction ou limitation des usages doublée d’une intégration de contenants végétaux déjà produits grâce à l’énergie solaire (photosynthèse) et en bout de chaîne, biodégradables. Si l’histoire des détournements et usages humains de coques végétales s’est en grande partie interrompue avec le développement du plastique, il est aujourd’hui grand temps de la poursuivre. Prototypage en cours avec @la_gouriche [ @ensparissaclay ] #ecoart #ecodesign #art #computermouse #josehalloy #zombietechnologies #technologieszombies #contemporaryart #ecologicalart #alexandremonnin #ecoconception #biomaterials #biodegradable #artetecologie #artwork #artoftheday (à Compost de l’Insurrection) https://www.instagram.com/p/CoI0G30NKlu/?igshid=NGJjMDIxMWI=

#cyclé#filipevilasboas#ecoart#ecodesign#art#computermouse#josehalloy#zombietechnologies#technologieszombies#contemporaryart#ecologicalart#alexandremonnin#ecoconception#biomaterials#biodegradable#artetecologie#artwork#artoftheday

0 notes

Text

Saype / Artist on Instagram

"Massive artworks that are visible from the sky, lasts for a few weeks before vanishing naturally. He is a pioneer in the art of painting on grass and uses a special environmentally friendly paint made of water, chalk, charcoal, and casein."

8 notes

·

View notes

Text

Coming Soon to the SKTtheshop on Facebook and Etsy.

Fully compostable Christmas tree ornaments made from dehydrated citrus fruits and biodegradable embellishments such as pine cones and sea shells. Stay tuned for the drop! The perfect eco solution to a plastic-free Christmas challenge!

#plastic free#zerowaste#biodegradable#dehydrator#citrus fruits#ecofriendly#christmas decorations#arts and crafts#handmade#sustainability#pinecone#tree ornament#forsale#natural#green living#compostable#etsystore#smallbussinessowner

1 note

·

View note

Text

saw a video of someone making resin art of a sea turtle and leaving it on a beach like girl!! do you not see the inherent oxymoron here!!

0 notes

Text

Hatay, Turkey

A giant biodegradable artwork between earthquake-damaged buildings by the French-Swiss artist Guillaume Legros

Photograph: LeSabe/AFP/Getty

#lesabe#photographer#afp via getty images#hatay#turkey#biodegradable artwork#guillaume legros#land art#french-swiss artist

0 notes