#cobots

Text

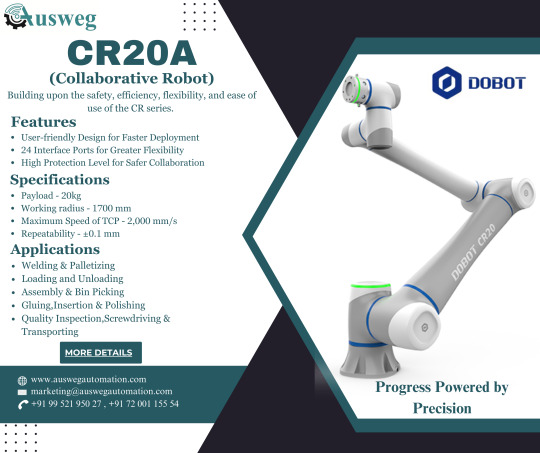

DOBOT CR20A

Performance Unleashed With High Payload and Wide Radius

www.auswegautomation.com

[email protected]

+91 99 521 950 27, +91 72 001 155 54

#cobots#collabrativerobots#automation#industry40#robotics#manufacturing#ai#roboticstechno#digitaltransformation#innovation#techtrends#futureofwork#smartfactory#industrialautomation#productivity#workplacesafety#efficiency#humanrobotcollabration#roboticsindustry#advancedmanufacturing

2 notes

·

View notes

Text

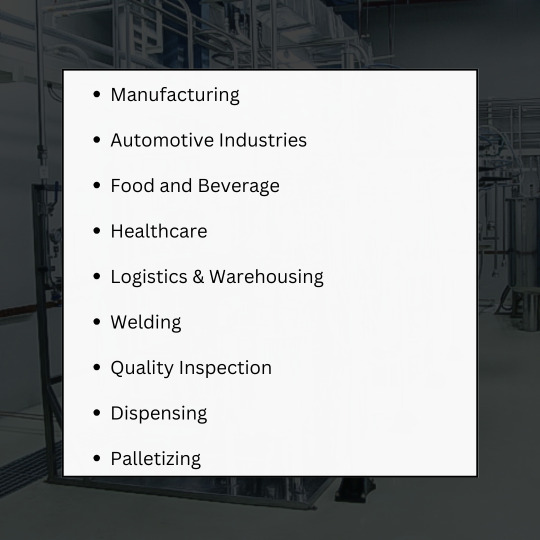

Applications Of Cobots | Patvin Engineering

Cobots offered by Patvin can be used for various applications such as manufacturing, welding, dispensing, palletizing, quality inspection, and many more.

To know more about cobots, check out our dedicated blog.

0 notes

Text

Svaya Robotics: Engineering the Future of Collaborative Workspaces

Svaya Robotics: Crafting the Next Generation of Safe Cobots

In an era where the integration of robotics into the fabric of industrial production is becoming increasingly paramount, Svaya Robotics Pvt. Ltd. emerges as a vanguard, pioneering the development of the next generation of safe collaborative robots, or cobots. These innovations are not just revolutionizing manufacturing processes but are also redefining the dynamics of human-robot interaction, making it safer, more efficient, and incredibly productive.

A Vision for Safer, Collaborative Workspaces

At the core of Svaya Robotics' mission is a commitment to safety and collaboration. Traditional robots, designed for efficiency and speed, often required extensive safety measures, including cages and barriers, to protect human workers. This not only limited the robots' flexibility and utility but also kept them isolated from the human workforce. Svaya Robotics disrupts this paradigm by designing cobots that can safely work alongside humans, sharing workspace and tasks without the need for physical barriers. This approach fosters a harmonious environment where robots complement human efforts, enhancing productivity without compromising safety.

Engineering Excellence for Unparalleled Safety

Safety is an integral component of Svaya Robotics' design philosophy. Each cobot is engineered with built-in dual-channel redundant safety systems, ensuring that they can operate in close proximity to human workers without posing risks. This redundancy is crucial, as it provides an additional layer of protection, ensuring that even if one safety system fails, the other can take over, maintaining a safe operational environment at all times.

The cobots are equipped with advanced sensors and machine vision technology that enable them to be highly perceptive of their surroundings. This allows them to detect human presence and make real-time adjustments to their operations to avoid accidents, ensuring a safe collaboration space. Moreover, the intuitive design of these robots means that they can be easily controlled and programmed by the workforce, empowering employees to work alongside these machines seamlessly.

Full-Stack Technology for a Seamless Experience

Svaya Robotics stands out not just for its focus on safety but also for its comprehensive approach to robotics. By developing a full-stack technology platform, the company ensures that its cobots are equipped with the latest advancements in AI and machine learning, digital twinning, and human-robot interaction. This holistic approach enables the robots to perform a wide array of tasks with precision and reliability, from assembly and packaging to more complex processes like welding and gluing.

The integration of digital twin technology is particularly noteworthy. By creating a virtual replica of the physical robot and its operations, Svaya Robotics allows for real-time monitoring and control, enhancing the efficiency and flexibility of manufacturing processes. This virtual control layer not only improves operational visibility but also enables predictive maintenance, reducing downtime and extending the lifespan of the cobots.

Empowering Industries with Versatile Applications

The versatility of Svaya Robotics' cobots is a key factor in their appeal. Designed to be adaptable, these robots can be fitted with a variety of end-effectors, allowing them to undertake different tasks with ease. This versatility, combined with the ability to seamlessly integrate into existing ecosystems through compatibility with various industrial communication protocols, makes these cobots an invaluable asset for businesses looking to enhance their productivity and adaptability.

From assembly lines to quality control, Svaya Robotics' cobots are transforming industries by providing solutions that are not only safe and efficient but also flexible enough to meet the changing demands of the market. Their ability to work safely alongside humans opens up new possibilities for collaborative robots workflows, where the strengths of both humans and robots are leveraged to achieve optimal results.

Towards a Collaborative Future

Svaya Robotics is at the forefront of a significant shift in industrial manufacturing, where the focus is moving from automation for efficiency's sake to automation that enhances human capabilities. By crafting the next generation of safe cobots, the company is not just contributing to the evolution of robotics but is also helping shape a future where human-robot collaboration is the norm, not the exception.

This future, envisioned and brought to life by Svaya Robotics, is one where businesses can thrive in an environment that is both productive and safe. It's a future where the barriers between humans and robots are broken down, leading to workplaces that are more flexible, innovative, and efficient.

In conclusion, Svaya Robotics is not just developing robots; it's pioneering a new era of industrial production. Through its commitment to safety, versatility, and innovation, the company is crafting the next generation of cobots that promise to transform the manufacturing landscape. As we look towards this future, it's clear that the collaborative workflows enabled by these advancements will unlock new levels of productivity and creativity, heralding a new age of industrial harmony.

#cobots#robotics#technology#artificial intelligence#collaborative robots#manufacturing robots#business#industrial robot manufacturers#automationrobotics#industrial automation

0 notes

Text

The metaverse is expected to witness a number of noteworthy developments in 2023 that will change people's interactions with digital environments. The rise in popularity of immersive virtual reality (VR) experiences is one notable development. Users can now interact in metaverse situations with a heightened sensation of presence, blurring the boundaries between the real and virtual worlds, as VR technology becomes more widely available and sophisticated. Applications for anything from social events and group workspaces to learning and entertainment platforms have exploded as a result, providing us with a peek into a time when virtual experiences will be effortlessly incorporated into our everyday lives.

Additionally, the metaverse is witnessing a surge in decentralized and blockchain-based applications. NFTs (Non-Fungible Tokens) have gained traction as a means of establishing ownership and authenticity of digital assets within the metaverse. This has sparked a creative economy, where artists, developers, and content creators can monetize their digital creations. Moreover, blockchain technology is facilitating secure transactions, enabling virtual worlds to have their own economies and ecosystems. This shift towards decentralization not only empowers users but also fosters a sense of community-driven governance within the metaverse, setting the stage for a more inclusive and user-centric digital landscape.

METAVERSE TRENDS

#ai technology#ai chatbot#nlp#chatbot#openai#machine learning#ai generated#chatbots#conversational ai#software engineering#software#automation#apps#information technology#developer#development#cobots#ai image#ai art#ai artwork#artificial intelligence#technology#midjourney#chatgpt#ai#machine language#python#coding#java#code

0 notes

Text

0 notes

Text

Collaborative robots, also known as cobots, are rapidly gaining popularity in the manufacturing industry. These robots are designed to work safely alongside human operators, making them a more flexible and efficient alternative to traditional industrial robots.

There are a number of factors driving the growth of the cobot market. One is the increasing demand for automation in manufacturing. As labor costs rise and competition intensifies, manufacturers are looking for ways to improve productivity and reduce costs. Cobots offer a cost-effective way to automate tasks that would otherwise be performed by human workers.

0 notes

Text

The Impact of Robotics on the Future of Work

Robotics and Automation

The rapid advancement of robotics and automation technologies has raised questions about the future of work and the potential impact on employment. As robots become increasingly sophisticated and capable, it is crucial to understand how they will shape the workforce and what implications this may have for individuals and society as a whole. In this article, we will…

View On WordPress

#Automated Workforce#Automation and Job Displacement#Cobots#Collaborative Robotics#Human robot interaction#Impact of Robotics#Robotics and Automation

0 notes

Link

Collaborative robots, also known as cobots, work alongside people in shared workspaces. Small and Medium Enterprises (SMEs) are the primary drivers of growth, as are investments in manufacturing process automation.

0 notes

Text

Universal Robots giới thiệu các robot hợp tác để tự động hóa sáng tạo

Universal Robots giới thiệu các robot hợp tác để tự động hóa sáng tạo

Universal Robots (UR), công ty dẫn đầu toàn cầu trong thị trường rô bốt cộng tác (cobots) đang phát triển nhanh chóng, đang giới thiệu các giải pháp tự động hóa sáng tạo với chi phí hợp lý để xếp hàng, đóng gói, chọn và đặt hàng tại phiên bản thứ 15 của Propak Việt Nam 2022 đang diễn ra tại Trung tâm Hội chợ & Triển lãm Sài Gòn (SECC), Thành phố Hồ Chí Minh, từ ngày 9 đến 11/11.

(more…)

View On WordPress

0 notes

Text

Empowering the Future: How Svaya Robotics is Revolutionizing Collaborative Manufacturing

Industrial Robot Manufacturers: Shaping the Future of Production

In the ever-evolving landscape of manufacturing, industrial robot manufacturers stand at the forefront of innovation and efficiency. These trailblazers are not just altering the way products are made; they are reshaping the very fabric of the industrial sector, making operations more flexible, productive, and adaptive to changing demand. Among these pioneers, Svaya Robotics Pvt. Ltd. emerges as a beacon of progress, demonstrating how the future of work is a productive interplay between humans and robots.

Svaya Robotics Pvt. Ltd. was established with a vision to bridge the gap between human creativity and robotic precision. This vision is rooted in the belief that when humans and robots work together, they unlock new possibilities for businesses, making operations not just automated but truly collaborative. The company's approach to robotics goes beyond simple mechanization, aiming to create an ecosystem where robots work with and alongside people, enhancing workflows and productivity.

A New Era of Collaborative Robots

At the heart of Svaya Robotics' innovation is the development of collaborative robots, or "cobots," designed to operate in tandem with human workers. These cobots are a testament to the company's commitment to making robotics accessible, convenient, and reliable for deployment in any setting, by anyone, regardless of their prior experience with robotic technology.

The introduction of cobots into the manufacturing sector marks a significant shift from traditional automation. Unlike their predecessors, which were often isolated due to safety concerns, cobots are built to be inherently safe, equipped with dual-channel redundant safety systems. This allows them to be deployed directly alongside human workers without the need for extensive safety barriers or protocols, fostering a more integrated and flexible work environment.

Full-Stack Technology for Unmatched Flexibility

Svaya Robotics distinguishes itself by developing and building all the technology that powers its robots, from the hardware to the software and the algorithmic stack. This full-stack approach enables the company to offer robots that are not only versatile and safe but also equipped with advanced features like built-in sensing and machine vision. These features, powered by artificial intelligence (AI) and machine learning (ML), allow Svaya's robots to perform a wide range of tasks, from assembly and packaging to welding and gluing, in even the most unstructured environments.

The company's digital-twin technology exemplifies its innovative spirit. By bridging the physical and virtual worlds, this technology provides total visibility into robot workflows, enabling virtual control of robots with real-time operational data. This seamless integration of digital and physical domains ensures that businesses can optimize their production processes with unprecedented precision and efficiency.

Empowering Industries with Intuitive Human-Robot Interaction

Svaya Robotics is committed to demystifying robotics for the wider workforce. Its robots feature an intuitive and engaging interface that makes creating, connecting, simulating, and controlling workflows accessible to anyone, regardless of their technical background. This emphasis on simplicity and ease of use ensures that businesses can quickly adapt their production lines to meet changing market demands without the need for specialized training or expertise.

The versatility of Svaya's robots is further enhanced by their ability to integrate with a multitude of third-party end-effectors and communicate across different industrial communication protocols. This interoperability ensures that Svaya's cobots can seamlessly become a part of any ecosystem, enhancing comprehensive automation across production processes.

Shaping the Future of Production

As industrial robot manufacturers like Svaya Robotics continue to innovate, the potential for collaborative robotics in shaping the future of production becomes increasingly clear. By making robotics more accessible and intuitive, Svaya is not just enhancing productivity and efficiency; it is empowering businesses to be more innovative and flexible in the face of evolving market demands.

The journey of Svaya Robotics illustrates a broader trend among industrial robot manufacturers toward creating more collaborative, adaptive, and human-centric manufacturing environments. As these technologies continue to advance, the future of production looks not only more automated but more collaborative, with humans and robots working side by side to achieve greater innovation, quality, and efficiency. In this future, companies like Svaya Robotics play a pivotal role, enabling businesses to harness the full potential of human-robot ecosystems and paving the way for a new era of manufacturing excellence.

#collaborative robots#technology#industrial automation#artificial intelligence#business#cobots#industrial robot manufacturers#manufacturing robots#robotics

0 notes

Photo

🔩 A001 - MaterialHandling & Vision Inspection Kawasaki duAro DualArm

SCARA Robot KawasakiRobot @KawasakiRobot Robotics ... collaborative robots

▸ TAEVision Engineering on Pinterest

Data A001 - Nov 01, 2022

#automation#robot#robotics#materialhandling#vision inspection#Kawasaki#KawasakiRobot#duAro#DualArm#SCARA#collaborative robots#cobots

1 note

·

View note

Photo

Robot- Human Collaboration: #roboticautomation #robots #armrobots #automation #automationsystems #enstein_project #manufacturingindustry #productdesign #prototyping #fabrication #innovation #technology #enstein #industry40 #industrial_automation #industrialdesign #robotics #manufacturingprocess #roboticsengineering #cobots (at Enstein-Robots & Automations Pvt Ltd.) https://www.instagram.com/p/CiwYbo0rDo9/?igshid=NGJjMDIxMWI=

#roboticautomation#robots#armrobots#automation#automationsystems#enstein_project#manufacturingindustry#productdesign#prototyping#fabrication#innovation#technology#enstein#industry40#industrial_automation#industrialdesign#robotics#manufacturingprocess#roboticsengineering#cobots

1 note

·

View note