#environmental compliance

Text

Water and Wastewater Treatment Equipment Market, Analyzing Market Forces, Technological Advancements, and Environmental Impacts

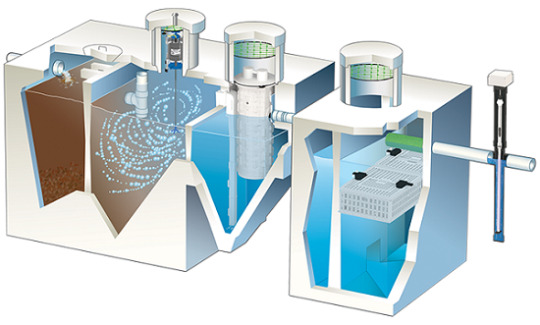

The global water and wastewater treatment equipment market size is anticipated to reach USD 90.0 billion by 2030, registering a CAGR of 4.6% over the forecast period, according to a new report by Grand View Research, Inc. The market is driven by increasing demand for clean and safe water in both developed and emerging economies. This is due to growing concerns over water pollution and scarcity, and the need for effective wastewater management.

Water And Wastewater Treatment Equipment Market Report Highlights

Asia Pacific accounted for the largest revenue share of the global market in 2023, accounting for 35.1%, and is expected to maintain its dominance throughout the forecast period. This can be attributed to the presence of a strong consumer base that has led to significant demand for water and wastewater treatment equipment

By application, the municipal segment dominated the market with a revenue share of 66.0% in 2023. The increasing initiatives undertaken by governments, strict environmental regulations, and increasing awareness regarding water treatment are some of the factors contributing to the growth of the municipal segment over the forecast period

By process, the tertiary treatment segment dominated the market with a revenue share of 44.2% in 2023. Some of the drivers for the increasing demand for tertiary wastewater treatment are environmental protection, water scarcity, and the increasing demand for clean water. As these issues continue to be major concerns across the world, the demand for tertiary wastewater treatment is expected to grow over the forecast period

Major key players frequently engage in mergers & acquisitions and new product launches to maintain their market shares. For instance, in March 2022, Pentair plc, announced the definitive agreement to acquire Manitowoc Ice. The move was taken by the company to enhance its commercial water solutions platform and cater to the demand from the food service industry

For More Details or Sample Copy please visit link @: Water And Wastewater Treatment Equipment Market Report

Furthermore, the demand for decentralized wastewater treatment systems is expected to increase over the projected period, as these systems offer several advantages such as low operating costs, high treatment efficiency, and easy maintenance. Several companies are focusing on developing innovative decentralized wastewater treatment systems that can be easily installed in residential and commercial buildings.

Population growth, urbanization, increasing industrialization, and the need for clean water for various purposes such as drinking, agriculture, and industrial processes all drive demand for water and wastewater treatment equipment. Government regulations aimed at protecting the environment and ensuring public health also have an impact on the demand for water and wastewater treatment equipment.

The market players are constantly undertaking strategic initiatives such as mergers, acquisitions, partnerships, and new product launches to gain a competitive advantage. For instance, Ceco Environmental, a provider of air pollution control solutions, announced the acquisition of Compass Water Solutions, a provider of water and wastewater treatment equipment. The acquisition will enable Ceco Environmental to integrate Compass Water Solutions’ critical engineered solutions with its industrial water capabilities.

WaterAndWastewaterTreatmentEquipmentMarket #WaterAndWastewaterTreatmentEquipment #WaterTreatment #WastewaterManagement #EnvironmentalEngineering #SustainableTechnology #CleanWaterSolutions #IndustrialWaterTreatment #WaterPurification #GreenInfrastructure #InnovationInWaterManagement #WaterQualityControl #WastewaterRecycling #MarketTrends #EnvironmentalCompliance #SmartWaterTechnologies #RegulatoryFrameworks #EcoFriendlySolutions #EmergingTechnologies #ResourceRecovery

#Water and Wastewater Treatment Equipment Market#Water and Wastewater Treatment Equipment#Water Treatment#Waste water Management#Environmental Engineering#Sustainable Technology#Clean Water Solutions#Industrial Water Treatment#Water Purification#Global Market Analysis#Green Infrastructure#Innovation In Water Management#Water Quality Control#Waste-water Recycling#Environmental Compliance#Smart Water Technologies#Regulatory Frameworks#Eco-Friendly Solutions#Emerging Technologies#Resource Recovery

0 notes

Text

What is environmental, social and governance (ESG)?

Environmental, social and governance (ESG) is a framework used to assess an organization business practices and performance on various sustainability and ethical issues. It also provides a way to measure business risks and opportunities in those areas.

In capital markets, some investors use ESG criteria to evaluate companies and help determine their investment plans, a practice known as ESG investing.While sustainability, ethics and corporate governance are generally considered to be non-financial performance indicators, the role of an ESG program is to ensure accountability and the implementation of systems and processes to manage a company's impact, such as its carbon footprint.

#Construction Health#Safety & Environment Audit#Environmental and Social Due Diligence Services#Environment Services#Environmental Compliance#environmental services company in chandigarh

0 notes

Text

#At Refrigerant Center INC#we specialize in providing comprehensive refrigerant solutions tailored to meet the diverse needs of our clients. With a deep understanding#Ventilation#and Air Conditioning) industry and its evolving regulatory landscape#we are committed to offering environmentally responsible refrigerant products and services.#Our company prides itself on being a trusted partner for businesses operating in various sectors#including commercial#industrial#and residential. Whether you're a facility manager#HVAC contractor#or equipment manufacturer#we have the expertise and resources to fulfill your refrigerant requirements efficiently and affordably.#Key Services and Products:#Refrigerant Sales: We offer a wide range of refrigerant products#including traditional HFCs (Hydrofluorocarbons)#low-GWP (Global Warming Potential) alternatives like HFOs (Hydrofluoroolefins)#and natural refrigerants such as CO2 and ammonia. Our extensive inventory ensures that clients can find the right refrigerant for their spe#Refrigerant Reclamation: Recognizing the importance of sustainability#we provide refrigerant reclamation services aimed at recovering#purifying#and reprocessing used refrigerants. Through our state-of-the-art reclamation facilities#we help clients minimize environmental impact while maximizing cost savings.#Regulatory Compliance Assistance: Navigating the complex regulatory landscape surrounding refrigerants can be challenging. Our team stays u#national#and international regulations#including EPA (Environmental Protection Agency) regulations in the United States.#Technical Support: We understand that proper handling and usage of refrigerants are critical for the safety and efficiency of HVAC systems.#training#and educational resources to assist clients in handling refrigerants safely and effectively.#Customized Solutions: Every client has unique requirements

2 notes

·

View notes

Text

AIDGC: Pioneering Safety in Handling Dangerous Goods

In a world where hazardous materials play an integral role in various industries, safety must remain a top priority. The Australian Institute of Dangerous Goods Consultants (AIDGC) is at the forefront of revolutionizing how businesses handle dangerous goods. Their unique approach to promoting safety, compliance, and education sets them apart as industry leaders. Let’s explore how AIDGC is making a difference and fostering a culture of responsibility in handling dangerous goods.

Unmatched Expertise:

AIDGC’s team of seasoned consultants brings unparalleled expertise to the table. With years of hands-on experience and in-depth knowledge of regulations, they offer reliable guidance to businesses dealing with dangerous goods. From chemicals to flammable substances, AIDGC’s consultants know the intricacies of each industry, ensuring the safe handling and transportation of hazardous materials.

Tailored Solutions for Every Business:

Recognizing that one size doesn’t fit all, AIDGC provides customized solutions for businesses of all sizes and industries. Their approach is flexible, addressing unique challenges and specific needs. AIDGC works closely with clients to develop comprehensive safety strategies, enhancing their risk management practices and promoting a safety-first culture.

Proactive Safety Training:

Preventing accidents starts with education. AIDGC conducts cutting-edge training programs that empower employees with the knowledge and skills to handle dangerous goods responsibly. From theoretical understanding to practical simulations, the training equips personnel to react appropriately during emergencies, minimizing potential risks.

Embracing Innovation:

AIDGC embraces technological advancements to optimize safety measures further. They keep themselves updated on the latest industry trends and incorporate innovative solutions into their consultancy services. By leveraging modern technology, AIDGC ensures businesses stay ahead of the curve in hazardous materials management.

Sustainable Practices:

Safety and sustainability go hand in hand. AIDGC emphasizes the importance of environmentally responsible practices in handling dangerous goods. Their consultants work with businesses to adopt eco-friendly approaches, reducing their impact on the environment and contributing to a greener future.

Conclusion:

When it comes to handling dangerous goods, AIDGC stands as a beacon of expertise and innovation. Their unique approach to safety, tailored solutions, proactive training, and commitment to sustainability have earned them a reputation as pioneers in the industry. Collaborating with AIDGC empowers businesses to navigate hazardous materials responsibly, safeguarding their employees, communities, and the planet. By choosing AIDGC, you choose a safer and more sustainable future for your business and the world.

#AIDGC#Compliance#Dangerous Goods Consultants#Environmentally Responsible#Expertise#Greener Future#Handling Dangerous Goods#Hazardous Materials Management#Hazardous Materials safety#Innovative Solutions#Proactive Safety Training#Regulations#Risk Management#Safety in Handling Hazardous Materials#Safety Strategies#Safety-first Culture#Sustainable Practices#Tailored Solutions#Technological Advancements

3 notes

·

View notes

Text

Thanks to a multiyear, multimillion dollar cleanup, what was once a toxic junkyard has become a flower- and fauna-filled zone at Cuyahoga Valley National Park in Ohio. Many national parks contain environments that have been remediated and reclaimed. Photograph By Chris Davis, National Park Service

It Was a Toxic Wasteland. Now It’s a National Park.

After a $50 million cleanup, flowers and wildlife replace chemicals and rusting cars in one corner of Ohio’s Cuyahoga Valley National Park.

— By Shannon Bohle | May 2, 2022

A junkyard that once held rusting cars and thousands of barrels of oozing toxic chemicals just got added to a national park. The former Krejci dump, a 45-acre parcel that operated from 1948 to 1980, opened to the public in December as part of a 200-acre addition to Cuyahoga Valley National Park, a 33,000-acre swath that winds between Cleveland and Akron, Ohio.

Over the past 16 years, this corner of land near the Cuyahoga River was transformed from a Superfund site into a wetland teeming with birds and plants. It’s the most extensive and expensive of the hundreds of ongoing reclamation and rehabilitation projects overseen by the National Park Service (NPS).

Their work turns toxic zones—left behind after coal mining, oil drilling, or hazardous waste dumping—into safe, enjoyable outdoor oases. “Virtually every national park within the system has a contaminated site,” says Veronica Dickerson, a manager at the National Park Service’s Environmental Compliance and Cleanup Division. “People think of bugs, bunnies, and beautiful scenery associated with national parks, but I manage 13 of the messiest projects in the park service.”

Millions of people visit the varied and stunning landscapes of the NPS each year. Few realize that many parks didn’t start out as pristine wilderness. The Grand Canyon once held a uranium mine on its south rim; copper and arsenic extraction sites used to pollute what’s now Joshua Tree National Park. National parks are growing, evolving landscapes that, over time, have been given or acquired new parcels that required remediation.

Today, Cuyahoga Valley National Park’s new acres offer travelers a chance to dip into a revived natural space. Here’s how it went from a wreck to an environmental triumph.

Pollution Inspires a Movement—and an Ohio Park

After the polluted Cuyahoga River caught fire for the 13th time on June 22, 1969, magazines including Time and National Geographic ran articles and photos detailing the area’s ecological crisis. The national outrage that followed catapulted Cleveland to the center of America’s new environmental movement, helping to create the Environmental Protection Agency in 1970 and to pass The Clean Water Act of 1972.

A 1985 photo shows the Krejci dump, a toxic Superfund site that has been rehabilitated and reopened as part of Cuyahoga Valley National Park. Photograph Courtesy of NPS Collection

The Clean Water Act inspired both governmental agencies and volunteer groups to clean out waterways across the U.S. It also spurred the creation of the 33,000-acre Cuyahoga National Recreation Area, which the NPS designated in 1974 to protect and restore one quarter of the length of the Cuyahoga River. It was named a national park in 2000.

The NPS continues to purchase private land adjacent to national parks and recreation areas, removing manmade structures and environmental hazards with the goal of restoring areas to their natural states. That’s what it did in 1985 in the Cuyahoga National Recreation Area, when it acquired the Krejci salvage yard, which had been operated by John Krejci. Sr., and his family for more than 30 years.

From Superfund Site to Wetlands

An Environmental Protection Agency study found that the Krejci dump was contaminated with toxic and hazardous waste including PCBs, benzene, cadmium, and lead.

The U.S. government filed a “Superfund” lawsuit in 1997, a legal action that can hold polluters financially responsible. Fences, signs, and barricades went up, and the long process of reversing the damage began.

A 2006 photo shows the Krejci dump site after toxic soil had been removed. The resulting ravines had to be shored up as part of a $50 to $60 million clean up. Photograph Courtesy of NPS Collection

“The river here was dead. Not like just a few fish, but no fish. It had zero oxygen in places,” says Chris Davis, a Plant Ecologist for Cuyahoga Valley National Park. “Krejci was a ‘biological desert,’ meaning almost nothing could live in the area.”

The EPA administrates Superfund sites, forcing the parties responsible for the pollution to fund cleanups. For the Krejci site, six companies, including Ford and General Motors, shelled out between $50 and $60 million. “The total cost was exorbitant; it was the largest cleanup by far in National Park Service history,” says Davis.

Cleanup and reclamation efforts began shortly after the Superfund case was settled in 2002. Ford paid for and organized the removal of 375,00 tons of contaminated soil in 2002, which required machines to dig to a depth of up to 25 feet. The park service began naturalizing the area in 2012, grading the soil and recreating 3.5 acres of seasonal wetlands and planting native grasses, wildflowers, and sedges.

A Natural Wonderland Reborn

Today, the former Krejci dump is a site of environmental renewal. Located in the central region of the park, it’s a plant- and animal-filled seasonal marshland teeming with wildflowers, Jefferson salamanders, American toads, bald eagles, and woodcocks.

“If someone is interested in habitat restoration, there’s no better place,” says Davis. “This was a toxic wasteland only a few decades ago. To find this diversity of species there today is remarkable.”

Wetlands and seasonal wildflowers now dominate the former Krejci dump site. Photograph By Chris Davis, National Park Service

No official trails, facilities, or bridges exist in the Krejci acres yet. For now, the best way to see the dump-turned-dreamland is by driving along Hines Hill Road between Brandywine Falls and the Boston Mill Visitors Center. A pull-off on the eastern side of the road accesses a small trail into the area; Davis calls it “a nice, quiet place to contemplate nature.”

It’s just one of many restored and reclaimed sites within the national park. Nearly three million people visited it in 2021 to bike and walk along the Ohio & Erie Canal Towpath trail, canoe in the river, or snap photos of Brandywine Falls, a 65-foot-tall waterfall that plunges into a gorge.

One of the earliest restoration efforts in the Cuyahoga Valley park happened in 1984 when Cleveland- and Akron-area Sierra Club members worked with the NPS to clear out another auto scrapyard. Those efforts led to the popular Beaver Marsh zone in the southern half of the park. Now, it’s among the park’s most-visited spots, where joggers, bikers, or walkers cross a 565-foot-long boardwalk to see dam-building beavers or painted turtles bobbing amid lily pads.

Sierra Club member Peg Bobel remembers that original cleanup. “The visible pollution in the river was just heartbreaking,” she says. “The hands-on, grassroots environmental movement and the national laws being passed worked hand-in-hand.”

— Shannon Bohle is an Ohio technology and science writer whose work has appeared in Nature and the Journal of the Medical Library Association.

#Toxic Wasteland#National Park#Shannon Bohle#Cleveland | Akron | Ohio.#Krejci Dump#Cuyahoga Valley National Park#Cuyahoga River#National Park Service (NPS)#wetlands | Birds 🦅 | Plants 🌱#Veronica Dickerson#National Park Service | Environmental Compliance | Cleanup Division#Pollution#National Geographic#Environmental Protection Agency#Chris Davis | Plant Ecologist | Cuyahoga Valley National Park#EPA Administration#Natural | Wonderland | Reborn#Brandywine Falls | Boston Mill Visitors Center

9 notes

·

View notes

Text

Essential Guide to Packaging Testing: Ensuring Product Integrity

Packaging testing is an indispensable aspect of product development and distribution, aimed at safeguarding the integrity and safety of packaged goods.

Understanding Packaging Testing: Packaging testing is a comprehensive evaluation process that examines the performance, durability, and protective capabilities of packaging materials and designs. It involves subjecting packaging to various simulated conditions and stressors to assess its ability to withstand real-world challenges.

Types of Packaging Tests: There are several types of Packaging Testing, each designed to assess specific aspects of packaging performance. These include mechanical tests to evaluate structural integrity, environmental tests to measure resistance to temperature and humidity, and performance tests to gauge functionality and usability.

Mechanical Testing: Mechanical testing involves subjecting packaging to physical forces and stresses, such as compression, vibration, and impact. These tests simulate the rigors of transportation and handling, helping identify weaknesses in packaging that could lead to product damage or failure.

Environmental Testing: Environmental testing assesses the ability of packaging to withstand exposure to various environmental factors, including temperature fluctuations, moisture, and light. By subjecting packaging to accelerated aging and environmental stressors, these tests evaluate its stability and resistance to degradation.

Get More Insights On This Topic: Packaging Testing

#Packaging Testing#Product Integrity#Quality Assurance#Regulatory Compliance#Environmental Testing#Mechanical Testing#Performance Evaluation#Risk Management#Industry Standards

0 notes

Text

Transforming Compliance Training: The Power of Microlearning

Introduction:

In today's rapidly evolving regulatory landscape, compliance training is more crucial than ever for organizations across industries. However, traditional approaches to compliance training often fall short in engaging employees and ensuring long-term retention of critical information. Enter microlearning – a revolutionary approach to training that delivers short, focused bursts of content to learners. In this article, we'll explore how microlearning is transforming compliance training, its benefits, and best practices for implementation.

The Need for Effective Compliance Training:

Compliance training is a vital component of any organization's risk management strategy. It ensures that employees understand their obligations, adhere to regulatory requirements, and mitigate the risk of legal and financial repercussions. However, traditional compliance training methods, such as lengthy lectures or annual seminars, are often met with low engagement and retention rates. Employees may struggle to retain complex regulatory information, leading to compliance gaps and potential risks for the organization.

Introducing Microlearning for Compliance Training:

Microlearning offers a solution to the challenges of traditional compliance training. By breaking down complex regulatory topics into short, easily digestible modules, microlearning makes learning more accessible, engaging, and effective. Key features of microlearning for compliance training include:

Bite-sized Content: Microlearning delivers content in small, bite-sized modules that focus on specific learning objectives. This approach reduces cognitive overload and enables learners to absorb information more effectively.

Mobile Accessibility: Microlearning platforms are designed to be mobile-friendly, allowing employees to access training content anytime, anywhere, and on any device. This flexibility accommodates busy schedules and enables on-the-go learning.

Interactive Engagement: Microlearning encourages active participation through interactive elements such as quizzes, simulations, and multimedia content. This engagement not only enhances learning retention but also reinforces key concepts.

Personalized Learning Paths: Microlearning platforms often offer personalized learning pathways tailored to individual learner needs and preferences. By analyzing learner data and performance, microlearning platforms deliver targeted training content that meets the unique needs of each employee.

Benefits of Microlearning for Compliance Training:

Microlearning offers numerous benefits for compliance training, including:

Improved Knowledge Retention: The bite-sized nature of microlearning modules facilitates better knowledge retention among employees. By delivering information in short, focused bursts, employees can quickly grasp and retain critical regulatory information.

Enhanced Engagement: Microlearning engages employees through interactive elements and personalized learning experiences. This active engagement increases motivation and promotes a deeper understanding of compliance concepts.

Flexibility and Accessibility: Microlearning platforms are flexible and accessible, allowing employees to access training content whenever and wherever they need it. This accessibility accommodates diverse learning styles and enables continuous learning.

Cost-effectiveness: Compared to traditional training methods, microlearning offers a more cost-effective solution for compliance training. By reducing the time and resources required for training delivery, organizations can achieve significant cost savings while still providing high-quality training to their employees.

Implementing Microlearning for Compliance Training:

To maximize the effectiveness of microlearning for compliance training, organizations should follow these best practices:

Set Clear Learning Objectives: Define clear learning objectives and desired outcomes for each microlearning module. Focus on key regulatory topics and ensure that training content is relevant and up-to-date.

Create Engaging Content: Use a variety of interactive elements, multimedia content, and real-life scenarios to create engaging and impactful learning experiences. Incorporate storytelling techniques to make training content relatable and memorable.

Provide Ongoing Support: Offer ongoing support and reinforcement to employees throughout the learning process. Provide access to resources, coaching, and feedback to help reinforce learning and address any gaps in understanding.

Measure Learning Outcomes: Use analytics and reporting features provided by microlearning platforms to track employee progress and assess the effectiveness of training initiatives. Use this data to identify areas for improvement and inform future training strategies.

Conclusion:

Microlearning is revolutionizing compliance training by offering a flexible, engaging, and effective solution for organizations looking to ensure regulatory compliance. By delivering bite-sized content, personalized learning experiences, and interactive engagement, microlearning empowers employees to understand and adhere to regulatory requirements. As organizations continue to embrace microlearning for compliance training, they can expect to see improved compliance outcomes, reduced risks, and greater overall business success.

#compliance training#compliance training online#compliance training for employees#compliance courses#hr compliance training#corporate compliance training#compliance officer training#dot compliance training#hr compliance courses#environmental compliance training#staff compliance training#safety and compliance training#safety compliance training#annual compliance training#ethics and compliance training#training for compliance#regulatory and compliance training#compliance safety training#yearly compliance training#compliance training courses#compliance online training#compliance training vendors#compliance training providers#hr compliance training for employees#compliance and risk management courses#compliance training courses for employees#workplace compliance training#business compliance training#lab compliance training#laboratory compliance training

1 note

·

View note

Text

Environmental Engineering Compliance Consulting in Los Angeles

Sierra Engineering provides environmental engineering consulting services to clients and compliance consulting to businesses and organizations in Los Angeles

#Environmental Engineering Consulting in Los Angeles#Environmental Compliance Consulting in Los Angeles

0 notes

Text

Powering the Future: Exploring the Hydrogen Generation Market

As the world transitions towards a low-carbon economy, hydrogen emerges as a versatile and sustainable energy carrier with the potential to revolutionize various sectors, from transportation and industry to power generation and heating. At the heart of this energy revolution lies the hydrogen generation market, which is experiencing rapid growth and innovation driven by the imperative of decarbonization and the pursuit of cleaner energy solutions.

Hydrogen generation technologies encompass a diverse range of methods, including electrolysis, steam methane reforming (SMR), biomass gasification, and solar-driven processes. Each of these methods offers unique advantages and challenges, depending on factors such as cost, efficiency, scalability, and environmental impact.

One of the key drivers of the hydrogen generation market is the increasing focus on renewable hydrogen production. Electrolysis, powered by renewable energy sources such as wind and solar, is emerging as a clean and sustainable method for generating hydrogen without greenhouse gas emissions. As renewable energy costs continue to decline and government incentives support the transition to green hydrogen, the market for renewable hydrogen is poised for significant growth.

Moreover, the expanding application of hydrogen fuel cells in transportation, stationary power, and industrial processes is driving demand for hydrogen as a clean energy carrier. Fuel cell electric vehicles (FCEVs) offer zero-emission transportation solutions with fast refueling and long-range capabilities, making hydrogen an attractive alternative to conventional internal combustion engines and battery-electric vehicles.

Another factor driving market growth is the increasing recognition of hydrogen's potential to address energy storage and grid stability challenges associated with intermittent renewable energy sources. Hydrogen storage and conversion technologies enable the storage of excess renewable energy during periods of low demand and its conversion back to electricity or heat when needed, thus enhancing grid flexibility and resilience.

Furthermore, partnerships and investments across the hydrogen value chain are accelerating the commercialization and deployment of hydrogen technologies. From electrolyzer manufacturers and hydrogen infrastructure developers to energy companies and automakers, stakeholders are collaborating to overcome technical, economic, and regulatory barriers and unlock the full potential of hydrogen as a clean and sustainable energy solution.

In conclusion, the hydrogen generation market is poised for exponential growth as the world transitions towards a low-carbon future. With advancing technologies, expanding applications, and growing investment, hydrogen is set to play a pivotal role in powering the transition to a more sustainable and resilient energy system, driving innovation, economic growth, and environmental stewardship.

#Hydrogen Generation#Renewable Energy#Fuel Cells#Green Technology#Industrial Innovation#sustainability#technology#innovation#augmented reality#environmental sustainability#immersive experiences#additive manufacturing#ai#aiincelltherapy#compliance

0 notes

Text

6 Innovations in the Trucking Industry on the Road to Environmental Sustainability - Technology Org

New Post has been published on https://thedigitalinsider.com/6-innovations-in-the-trucking-industry-on-the-road-to-environmental-sustainability-technology-org/

6 Innovations in the Trucking Industry on the Road to Environmental Sustainability - Technology Org

It’s a pivotal time for the trucking industry when as environmental concerns mount on, stakeholder companies continue to shift gears towards innovations that promise a more sustainable future.

Beyond just compliance or good PR, it’s a drive toward efficiency and responsibility that benefits everyone and perhaps the very greater good of humanity.

These six groundbreaking advancements in truck technology are changing the landscape, not only curtailing emissions but also ramping up fuel efficiency.

Let’s take a closer look at these developments steering us toward eco-friendly logistics.

A truck on the road – illustrative photo. Image credit: Gabriel Santos via Unsplash, free license

1. The Rise of Electric Trucks

It’s no secret; electric vehicles are the vanguard in sustainable transportation. Now, this revolution is barrelling into the trucking industry. Pioneers like Tesla and Nikola are unveiling electric trucks that promise zero emissions without sacrificing power or range.

With giants like Daimler also entering the fray, electrification isn’t a distant dream—it’s an unfolding reality on our highways.

Transitioning from diesel to electric could cut down greenhouse gas emissions by a whopping 75 percent over time, demonstrating that the road to sustainability can be as clean as the energy propelling these innovative rigs.

2. Advancing Aerodynamics

Airflow matters. Today’s trucks such as the Peterbilt’s Model 579 are shedding the body builds of the past for sleeker designs that slice through air resistance like a knife through butter.

These advancements in aerodynamics play a crucial role in fuel economy, with manufacturers fine-tuning every curve for optimal performance.

From trailer skirts that reduce drag to futuristic cab shapes, these modifications are not just cosmetic; they’re part of a calculated strategy to burn less fuel and emit fewer pollutants — proving efficiency is as much about shape as it is about what’s under the hood.

3. Harnessing Hybrid Technology

Hybrid engines are another piece of the complex puzzle of sustainable trucking. These powertrains marry the best aspects of internal combustion engines with electric motors, creating a synergy that reduces fuel consumption and CO2 emissions.

Notably, they offer flexibility—enabling long-haul journeys without the range anxiety associated with pure electrics. What’s more, energy-recovery systems capture power typically lost during braking. It’s a smart pivot to hybrids now forming a bridge to fully electric futures, while delivering immediate environmental benefits on our roads today.

4. Alternative Fuels Take the Wheel

Beyond electrification, alternative fuels are revving up the trucking industry’s green transition. Natural gas, biodiesel, and even hydrogen fuel cells are stepping into the spotlight, challenging traditional diesel’s dominance.

These fuels burn cleaner, slashing emissions significantly. Consider liquified natural gas trucks that emit nearly 20% less greenhouse gasses than their diesel counterparts.

It’s a shift that acknowledges not one solution fits all. Rather, a diverse fuel portfolio may be key to achieving environmental sustainability on the freight routes crisscrossing our nation.

5. Smarter Trucks for a Greener Tomorrow

Integrated telematics and features like predictive cruise control are not mere add-ons; they are revolutionizing truck efficiency.

By analyzing terrain and optimizing speed, these smart systems ensure the engine runs only as hard as necessary, minimizing fuel use and emissions. This also extends the lifetime of the truck by a significant margin.

Fleet operators, noting these advantages, often upgrade to smarter trucks or seek pre-owned Peterbilt 579 trucks at fair prices to get these eco-friendly technologies without the steep cost of brand-new models. It’s clear: intelligence on the road is now measured in data points that lead to greener miles ahead.

6. Tire Innovations Rolling Out

Tires are the unsung heroes of fuel efficiency, where even small advancements can yield significant environmental gains. The latest innovations in tire technology focus on low rolling resistance, meaning trucks require less energy to keep the wheels turning.

Manufacturers are not just pumping out new rubber; they’re engineering tires that last longer and perform better under heavy loads.

This means fewer tire changes, reduced waste, and a lighter carbon footprint. For truckers, it’s an investment that pays dividends at the pump and for the planet.

Key Takeaways

Electric trucks are leading the charge in emission-free transport.

Aerodynamic designs directly translate to fuel savings and cleaner operations.

Hybrid technology offers a practical path to reducing reliance on diesel.

Diversifying into alternative fuels can cut greenhouse gas emissions markedly.

Telematics and smart cruising enhance efficiency across truck fleets.

Tire advancements play a critical role in eco-friendly driving without compromising performance.

As the trucking industry shifts into more sustainable gear, these six innovations spotlight a journey where environmental responsibility isn’t just a destination but a continuous drive. The road ahead is greener—and with every technological advance, we move closer to a cleaner horizon.

#aerodynamics#air#anxiety#bridge#Capture#carbon#carbon footprint#Cells#CO2#Companies#compliance#continuous#cosmetic#data#Developments#economy#efficiency#electric trucks#electric vehicles#electrification#emission-free#Emissions#energy#engine#engineering#engines#Environmental#Features#fuel#fuel cells

0 notes

Text

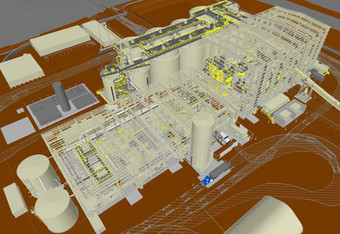

Transforming the Landscape of Bulk Material Management through Structural and Mechanical Design

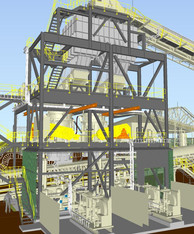

Across the vast expanse of industrial operations, where bulk material management is paramount, Little P.Eng. Engineering has etched a significant mark. The firm's reputation in structural and mechanical design extends beyond just equipment, touching several critical aspects of material management. This article will delve into how Little P.Eng. Engineering is transforming four pivotal sectors: Material Handling Facilities & Building, Bulk Material Transport, Bulk Material Treatment, and Bulk Material Transfer.

Little P.Eng. Engineering is an American / Canadian company that provides economical bulk material handling engineering services that are designed to meet the specific needs of our customers. We have a long history of partnering with supervisors, engineers, planners, and vendors, across a wide variety of industries to provide bulk material handling engineering solutions and systems that improve safety and productivity. Whether you need help designing, installing or maintaining any aspect of your bulk material system, we have the skills and experience to meet your needs.

Our bulk material handling engineering specialists can re-engineer and upgrade existing systems while providing customer solutions and processes. We work with customers through every part of the engineering process to create a one-stop destination for all their needs.

We also work to provide superior customer service that extends well beyond the initial installation or execution of a solution. Our customers can contact us and receive immediate assistance whenever needed for continued support that keeps businesses up and running without having to worry about delays or downtime.

1. Material Handling Facilities & Building

Material handling facilities are the heartbeats of many industries. From mining to agriculture and manufacturing, they facilitate the smooth and efficient movement of bulk materials.

Understanding Infrastructure Needs: Little P.Eng. Engineering begins its design process with a comprehensive study of the client's requirements. The aim is to understand the volume of material to be handled, the rate of throughput, and the kind of materials involved.

Structural Integrity: Buildings designed for material handling need robust foundations. Little P.Eng. ensures that every facility they design can withstand the tremendous loads and stresses associated with bulk material handling.

Optimized Workflow Design: Beyond just structural integrity, Little P.Eng. focuses on creating a streamlined workflow within these buildings. Through the strategic placement of equipment, chutes, conveyors, and storage areas, they ensure that materials move seamlessly, minimizing disruptions and maximizing efficiency.

Innovation at the Forefront: Little P.Eng. is known for incorporating innovative solutions like automated sorting systems, advanced ventilation systems, and sustainable energy solutions, making these facilities both state-of-the-art and environmentally responsible.

2. Bulk Material Transport

Once materials are sourced and sorted, they need to be transported. Little P.Eng. Engineering has a vast portfolio of solutions tailored to this very requirement.

Vehicle Design: Depending on the type of material, the firm designs transport vehicles, whether trucks, railcars, or even conveyor systems. Their designs emphasize both capacity and safety, ensuring that large volumes can be transported without risks.

Infrastructure Design: Little P.Eng. also specializes in designing transport-related infrastructure. This includes everything from loading and unloading docks to advanced conveyor belt systems and even pneumatic transport solutions.

Addressing Challenges: Transporting bulk material is fraught with challenges like spillage, degradation, and contamination. Little P.Eng.'s designs account for these challenges, providing solutions such as sealed transport containers and dust suppression systems.

3. Bulk Material Treatment

Treatment of bulk materials, whether it's refining, purification, or simply grading, is a complex process. Little P.Eng.'s role in this domain is critical.

Treatment Facility Design: Little P.Eng. engineers facilities where bulk materials undergo various treatment processes. Their designs accommodate equipment like crushers, separators, graders, and more, ensuring they operate at optimal capacities.

Safety and Compliance: Treatment processes can sometimes involve chemicals or generate waste. Little P.Eng. prioritizes safety and regulatory compliance, designing facilities that minimize environmental impact and risks to workers.

Energy Efficiency: Many treatment processes are energy-intensive. Recognizing this, Little P.Eng. incorporates energy-saving solutions, from efficient machinery layouts to the use of alternative energy sources, thus driving down operational costs.

4. Bulk Material Transfer

Transferring bulk materials from one point to another, or even from one mode of transport to another, is a task that requires precision and speed.

Transfer Point Design: Little P.Eng. is adept at creating transfer points that minimize material loss. Whether it's transferring grain from a truck to a silo or coal from a railcar to a ship, their designs ensure smooth transitions.

Material Integrity: When transferring materials, there's a risk of contamination or degradation. Little P.Eng. addresses this by designing enclosed transfer systems or integrating rapid sealing mechanisms.

Automation and Technology: In an age of technology, Little P.Eng. leverages advanced automation systems in their transfer point designs. This not only speeds up the transfer process but also reduces human errors.

Little P.Eng.'s Journey to Excellence

At its core, Little P.Eng. Engineering’s success can be attributed to its comprehensive approach. Instead of viewing these four sectors in isolation, they consider them parts of a holistic system. Their designs, thus, seamlessly integrate across the spectrum, from handling facilities to transfer points.

Client-Centric Approach

Little P.Eng. has always prioritized the unique requirements of its clients. They understand that every industry and even individual businesses within those industries can have varying needs. This client-centric approach has resulted in solutions that aren't just efficient but are also tailored to the specific challenges and objectives of their clientele.

Embracing Future Challenges

As the world continues to evolve, so do the challenges associated with bulk material management. Little P.Eng. Engineering, with its commitment to research, innovation, and adaptability, is well-equipped to tackle these challenges head-on.

With a growing demand for efficiency, safety, and sustainability, industries will find in Little P.Eng. a partner that's not just equipped to meet these demands but one that's committed to exceeding expectations.

In the world of bulk material management, Little P.Eng. Engineering stands tall, not just as a solution provider but as an innovator and trailblazer. Through their expertise in structural and mechanical design across the four critical sectors detailed in this article, they're not just shaping industries but also the very future of bulk material management.

Little P.Eng. Engineering’s Bulk Material Handling Team is a dynamic and diverse group with experience in conveying systems – mechanical and pneumatic; chutes transfers, dust control & collection, etc. Our experience in material handling for the power and manufacturing industries will provide rapid development of realistic concepts, and reliable designs which optimize operating and maintenance cost for your project. Our goal will be to not only deliver successful design to the field but to provide you with the information you need to make informed decisions to meet your objectives.

Industries served through our Bulk Material Handling Engineering Services

Grains

Mining

Mills

Metals

Manufacturing

Maintenance

Fabrication

Agriculture

Packaging

Safety

Fire & Explosion

Ship/Barge Loading & Unloading

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

We offer the following Engineering Services within our Bulk Material Handling Engineering Services :

Discrete Element Modeling (DEM)

Calculation based modeling

Allows for visualizing results

Particle velocity

Forces (shear and normal) and moments (bending and torsional)

Acceleration and material scatter

More than just flow simulation of bulk materials

wear Patterns

Mixing

Center loading

DEM Benefits

Reduced Dust Levels

Reduced Noise

Reduced Chute Plugging

Better Conveyor Tracking (Center Loading)

Reduced Belt Cover Wear

Reduced Chute Wear

Reduced Equipment Wear

Structural Engineering Services

Foundation Design

Concrete Structure Design

Steel Structure Design

Piping Engineering Services

Bulk material handling engineering specifically focuses on the design, processing, and transportation of bulk materials, which can include items such as ores, coal, minerals, and grains, among others. These materials often present unique challenges due to their bulk nature, including issues related to flowability, abrasiveness, corrosiveness, weight, and other specific characteristics. Here are the various aspects of bulk material handling engineering services:

Storage Solutions:

Design and layout of silos, bins, and stockpiles

Assessment of material flow properties to reduce issues like bridging or rat-holing

Conveyor Systems:

Design and optimization of belt, screw, chain, and pneumatic conveyors

Selection of appropriate conveyor belts, idlers, and drives

Loading and Unloading Systems:

Railcar and truck loading/unloading facilities

Ship and barge loading/unloading equipment

Reclaiming Systems:

Design of stacker-reclaimers, bucket wheel reclaimers, and scraper reclaimers

Size Reduction Equipment:

Crushers, grinders, and milling equipment

Sizers and chutes to manage particle sizes

Screening and Sorting:

Vibrating screens, trommels, and sorters

Density separation using jigs or cyclones

Feeding and Metering Equipment:

Feeders for accurate and controlled material flow

Rotary valves, weigh feeders, and volumetric feeders

Material Transfer:

Chutes, hoppers, and gates

Transfer tower and junction house design

Dust Control and Suppression:

Dust collection and filtration systems

Wet suppression and foam suppression systems

Safety and Environmental Considerations:

Explosion and fire protection in dusty environments

Erosion control and spill prevention

Flow Aids and Devices:

Vibrators and air cannons to aid material flow

Flow liners and internal coatings

Bulk Material Testing:

Evaluating flowability, abrasiveness, and other material properties

Moisture content and material density testing

Rail and Marine Infrastructure:

Rail siding design and layout

Port and harbor infrastructure for bulk material export/import

Automation and Controls:

Automated monitoring of material levels in bins and silos

Control systems for conveyor speed, material flow, and routing

Maintenance and Wear Protection:

Wear liners and abrasion-resistant materials

Maintenance strategies and schedules

Bulk Material Transport:

Pipeline transport for slurry and other bulk fluids

Pneumatic transport systems for powders and granules

Economic Analysis:

Cost estimation for bulk material handling projects

Return on investment (ROI) calculations

Regulatory Compliance and Standards:

Ensuring designs meet relevant industry standards

Adherence to safety and environmental regulations

Continuous Improvement and Upgrades:

Evaluation of existing systems for performance enhancement

Retrofitting and upgrading older infrastructure

Consultation and Advisory Services:

Providing expertise on specific bulk material challenges

Assisting with vendor and equipment selection

Given the unique nature and challenges of handling bulk materials, these services are essential to ensure efficient, safe, and economical processing, transportation, and storage. Properly designed and managed systems reduce product loss, minimize environmental impacts, and ensure safety while optimizing costs.

Tags:

Little P.Eng. Engineering

Structural design

Compliance

Mechanical design

Energy efficiency

Single-boom spreaders

Bulk material transfer

Bulk material transport

Client-centric approach

Environmental impact

Material handling

Treatment facilities

Conveyor systems

Infrastructure design

Pneumatic transport

Refining

Material grading

Transfer points

Dust suppression

Material contamination

Bulk material degradation

Silo design

Loading docks

Workflow optimization

Advanced ventilation systems

Risk assessment

Sustainable engineering

Material integrity

Client testimonials

Automation in material handling

Bulk Material Handling & Processing

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Little P.Eng. Engineering#Structural design#Compliance#Mechanical design#Energy efficiency#Single-boom spreaders#Bulk material transfer#Bulk material transport#Client-centric approach#Environmental impact#Material handling#Treatment facilities#Conveyor systems#Infrastructure design#Pneumatic transport#Refining#Material grading#Transfer points#Dust suppression#Material contamination#Bulk material degradation#Silo design#Loading docks#Workflow optimization#Advanced ventilation systems#Risk assessment#Sustainable engineering#Material integrity#Client testimonials

0 notes

Text

How Drones Are Changing the Face of Adventure Photography

The advent of drone technology has revolutionized many industries, but perhaps one of the most visually striking transformations has occurred in the realm of adventure photography. Drones are changing photography in fundamental ways, offering unprecedented perspectives that were once impossible or financially out of reach for most photographers. This article delves into how drones have become…

View On WordPress

#adventure narratives with drones#adventure photography transformation#aerial photography evolution#capturing natural beauty#cinematic drone videos#drone accessibility#drone photography ethics#drone regulations compliance#drone technology impact#drones in adventure photography#dynamic aerial imagery#environmental impact of drones#ethical drone use#exploring with drones#future of drone photography#innovative photography techniques#minimizing environmental footprint#nature&039;s majesty captured#perspectives from above#privacy considerations in drone photography#storytelling enhancement#sustainable photography practices#technological advancements in drones#unreachable locations photography

0 notes

Text

Sustainability Initiatives Driving Change in North America Commodity Chemicals Landscape

Sustainability initiatives are increasingly becoming central to the transformation of the North America Commodity Chemicals landscape. As concerns over environmental impact and resource depletion escalate, stakeholders across the industry are embracing innovative strategies to foster sustainability throughout the value chain. From raw material sourcing to product manufacturing to waste management, sustainability is reshaping the way North America Commodity Chemicals are produced, distributed, and utilized.

In recent years, the North America Commodity Chemicals sector has witnessed a notable shift towards greener and more sustainable practices. Companies are investing in renewable energy sources, optimizing production processes to minimize waste and emissions, and implementing circular economy principles to maximize resource efficiency. These initiatives not only reduce the environmental footprint of North America Commodity Chemicals production but also enhance operational resilience and long-term viability in an increasingly sustainability-conscious market.

One of the driving forces behind sustainability initiatives in the North America Commodity Chemicals industry is the growing demand from consumers and businesses for environmentally friendly products. As awareness of climate change and environmental degradation grows, there is a rising preference for products that are produced sustainably, with minimal impact on the planet.

Regulatory pressures and mandates are pushing companies in the North America Commodity Chemicals sector to adopt more sustainable practices. Governments at the federal, state, and local levels are enacting regulations aimed at reducing greenhouse gas emissions, promoting renewable energy usage, and minimizing pollution. Compliance with these regulations not only ensures legal adherence but also fosters a culture of sustainability and responsible stewardship within the industry.

Get More Insights On This Topic: North America Commodity Chemicals

Explore More Related Topic: North America Commodity Chemicals

#North America#Commodity Chemicals#Sustainability#Environmental Impact#Renewable Energy#Circular Economy#Regulatory Compliance#Industry Collaboration

0 notes

Text

Reinvent Compliance Training–

Using Microlearning With

A Risk-Specific Approach

#compliance training#compliance training online#compliance training for employees#compliance courses#hr compliance training#corporate compliance training#compliance officer training#dot compliance training#hr compliance courses#environmental compliance training#staff compliance training#safety and compliance training#safety compliance training#annual compliance training#ethics and compliance training#training for compliance#regulatory and compliance training#compliance safety training#yearly compliance training#compliance training courses#compliance online training#compliance training vendors#compliance training providers#hr compliance training for employees#compliance and risk management courses#compliance training courses for employees#workplace compliance training#business compliance training#lab compliance training#laboratory compliance training

0 notes