#ferrosilicon

Text

Enhancing Steel Quality: The Role of Nadularisers

Understanding Nodularisers in Steel Production In the realm of steel manufacturing, nodularisers play a pivotal role in enhancing the quality and properties of steel. But what exactly are nodularisers?

Nodularisers are additives used in the steelmaking process to facilitate the formation of nodular graphite structures within the steel matrix. These structures are crucial for improving the mechanical properties of the steel, such as strength, ductility, and toughness. By promoting the formation of nodular graphite, nodularisers help mitigate the formation of undesirable graphite forms like flakes or vermicular graphite, which can weaken the steel.

Importance of Choosing the Right Nodulariser Selecting the appropriate nodulariser is paramount for achieving the desired steel quality. Factors such as the base metal composition, casting conditions, and desired mechanical properties must be considered when choosing a nodulariser. Different nodularisers contain varying compositions of elements such as magnesium, cerium, calcium, and rare earth metals, each offering unique benefits and characteristics.

Conclusion:

Nodularisers play a vital role in improving the quality of steel by promoting the formation of nodular graphite structures. Choosing the right nodulariser is essential for optimizing steel properties and ensuring superior performance in various applications. For companies like Bansal Brothers, committed to delivering high-quality steel products, understanding and utilizing nodularisers effectively can be a key differentiator in the competitive steel market.

0 notes

Text

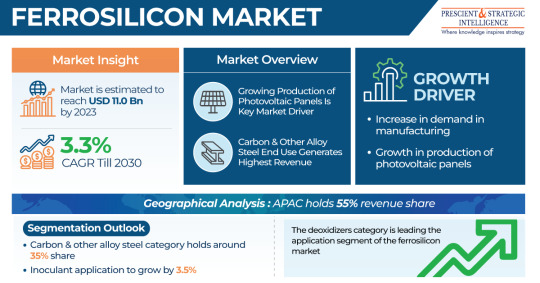

Worldwide Ferrosilicon Market Will Reach USD 13.7 Billion By 2030

The projected revenue of the worldwide ferrosilicon market is around USD 11.0 billion for 2023, with an anticipated increase to USD 13.7 billion by 2030. This growth is forecasted to occur at a compound annual growth rate (CAGR) of 3.3% between 2024 and 2030. This growth of the market can be credited to the extensive variety of applications of this material in the automotive, construction, and…

View On WordPress

#alloy#challenges#environmental considerations#ferrosilicon#global demand#Growth opportunities#industrial applications#market#market trends#metallurgy#pricing dynamics#regulatory landscapes#steel production#Technological advancements

0 notes

Text

Good afternoon, everyone

This is Danae from Anyang Changxing Cast Steel Metallurgy Co., Ltd,We export LCFeCr,MCFeCr,MCFeMn,LCFeMn,CaSi, SiCr, BaSi, FeSi, Cr Metal, Mn Metal, Mg Metal, Ca Metal.

You are welcome to visit the factory anytime

First time to blog, please take care

1 note

·

View note

Text

Ferro Alloys Producer in India: Sarda Metals Leading the Way

In today's fast-paced industrial landscape, Ferro Alloys Producer in India, Sarda Metals, stands out not only for its exceptional alloys but also for its unwavering commitment to employee well-being and fostering a remarkable work culture. Let's delve into how Sarda Metals is setting the gold standard in these aspects.

Employee Well-being at the Core

At Sarda Metals, the well-being of its workforce takes center stage. The company recognizes that its employees are its most valuable assets, and their health and happiness directly impact productivity and innovation. To this end, Sarda Metals has implemented a range of initiatives to ensure the physical, mental, and emotional well-being of its employees.

Health and Safety First

Safety is non-negotiable at Sarda Metals. The company maintains stringent safety protocols to create a hazard-free work environment. Regular safety training, state-of-the-art safety equipment, and constant monitoring ensure that every employee returns home safely after each shift.

Employee Benefits Galore

Sarda Metals understands that employee well-being extends beyond the workplace. Hence, they offer a comprehensive benefits package that includes healthcare, retirement plans, and educational assistance. These benefits not only provide peace of mind but also foster loyalty among the workforce.

Work-Life Balance

The company places a strong emphasis on work-life balance, recognizing that a harmonious personal life positively impacts job performance. Flexible work schedules and family-friendly policies allow employees to excel at work while nurturing their personal lives.

Nurturing Work Culture

A thriving work culture is not merely a byproduct of success; it's a catalyst for it. Sarda Metals recognizes this fact and has consciously cultivated a work culture that inspires creativity, collaboration, and continuous growth.

Open Communication

Transparent and open communication channels are the lifeblood of Sarda Metals. Employees are encouraged to voice their opinions and concerns, fostering a sense of belonging and ownership in the company's vision.

Learning and Development

Sarda Metals invests in its employees' growth through continuous training and development programs. This not only enhances individual skill sets but also keeps the company at the forefront of industry trends and innovations.

Recognition and Rewards

Exceptional work doesn't go unnoticed at Sarda Metals. The company regularly acknowledges and rewards outstanding contributions, motivating employees to consistently strive for excellence.

Teamwork and Collaboration

Sarda Metals fosters a collaborative work environment where teamwork is celebrated. This approach not only boosts productivity but also nurtures a sense of unity among employees.

Conclusion

In the competitive landscape of Ferro Alloys Producer in India, Sarda Metals shines not only for its top-quality alloys but also for its unwavering commitment to employee well-being and cultivating a thriving work culture. With a focus on safety, benefits, work-life balance, open communication, learning, recognition, and teamwork, Sarda Metals sets a commendable example for the industry.

In summary, Sarda Metals understands that its success is intrinsically tied to the well-being and satisfaction of its workforce. By prioritizing its employees, the company not only ensures a harmonious workplace but also secures its position as a frontrunner in the ferro alloy industry.

#FerroAlloys#AlloyProduction#ManganeseAlloys#SiliconManganese#FerroSilicon#SteelIndustry#Metallurgy#IndustrialProduction#FerroAlloyProducers#ManganeseMining#AlloyManufacturing#MetalProcessing#Steelmaking#HighQualityAlloys#MetalsIndustry#ManganeseOre#SilicoManganese#FerroAlloyMarket#FerroAlloyProduction#AlloyExports

0 notes

Text

Leading Ferro Silicon manufacturer

Orient New Material manufacture high quality Ferro silicon. Ferro silicon is made through a complicated process that includes melting, reducing, purifying, and solidifying a variety of basic ingredients.

Visit: https://www.orientnewmaterial.com/ferro-silicon-p-19.html

0 notes

Text

Ferro Silicon Magnesium - Calcium Inoculant

Inoculants are included fluid cast iron to give the best and reliable qualities in the last projecting. They are utilized to control framework structure and try not to project deserts. Inoculants can be found under a few grain size disseminations to fulfil the area of the inoculant expansion inside the foundry interaction. Those locations of inoculant addition are known as in furnace, in ladle, in stream or in mould.

Inoculants are ferrosilicon based combinations. All components which are barium, Calcium Inoculant, aluminium, and uncommon earth can be included the specific sum into the base fluid iron to incite and confirm the last projecting lattice structure.

Website Link : https://www.ferrosiliconmagnesium.com/products.php

#ferrosiliconmagnesium#magnesium#Calciuminoculant#ferrosilicon#ferrosiliconmagnesiuminindia#ferrosiliconmagnesiummanufacturersinindia#ferrosiliconmagnesiummanufacturers

0 notes

Text

Ferroalloy refers to an alloy of iron containing a significant proportion of one or more other elements like silicon, manganese, chromium, aluminum, or titanium. It is used in the production of steel and alloys.

For suitable quality ferroalloys, visit us at https://www.srggroup.info/ or contact +91 93910 24338, +91 94933 97710

#ferro#ferroalloys#srggroup#metallurgy#steel#raw#alloy#metal#silicon#ferroalloy#boron#chrome#material#materials#iron#ferrochromium#ferrosilicon#osmond#ferrovanadium#ferronickel#ferromanganese#ferroniobium#alloys#metals#ferrotantalum#ferroboron#ferromagnesium#ferrochrome#carbon#ferrosiliconmagnesium

0 notes

Text

#Email:[email protected]#Skype/Whatsapp/telegra : +86-166-9277-8735#Ferrochrome#siliconCarbon#ferromanganese#siliconmanganese#SICaalloy#ferrosilicon#SiBa#FeSi#SiMn#FeCr#FeMn#manganese#ferroalloys#steelmaking#steelindustry#foundry#Furnace#foundries#iron#ironcast#metal

1 note

·

View note

Text

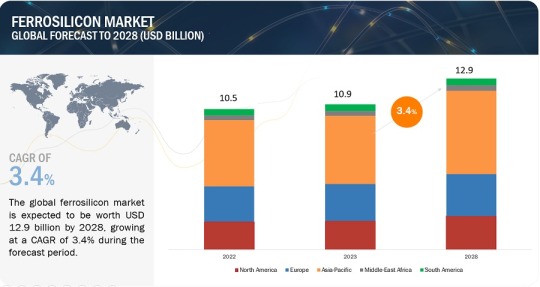

Driving Efficiency: Ferro Silicon Market Soars with Deoxidizer and Inoculants Applications

The report “Ferro Silicon Market by Type (Atomized Ferrosilicon, Milled ferrosilicon), Application (Deoxidizer, Inoculants), End-use Industry (Stainless Steel, Cast Iron, Magnesium), and Region (Asia Pacific, Europe, North America, MEA, SA) – Global Forecast to 2028″, is projected to reach USD 12.9 billion by 2028, at a CAGR of 3.4% from USD 10.9 billion in 2023.

The ferrosilicon market is…

View On WordPress

#Atomized Ferrosilicon#Deoxidizer#Ferro Silicon#Ferro Silicon Alloy Market#Ferro Silicon Analysis#Ferro Silicon Consumption#Ferro Silicon Demand#Ferro Silicon Export Market#Ferro Silicon Growth#Ferro Silicon Industry#Ferro Silicon Manufacturer#Ferro Silicon Market#Ferro Silicon Market Dynamics#Ferro Silicon Market Forecast#Ferro Silicon Market Graph#Ferro Silicon Market Outlook#Ferro Silicon Market Research#Ferro Silicon Market Segmentations#Ferro Silicon Market Segments#Ferro Silicon Powder Market#Ferro Silicon Pricing#Ferro Silicon Production#Ferro Silicon Regional Growth#Ferro Silicon Supply#Ferro Silicon Trends#Global Ferro Silicon Market#Inoculants#Milled Ferrosilicon

0 notes

Text

Ferrosilicon Market | Manufacturers, Regions, Type and Application, Forecast by 2029

#Ferrosilicon Market#Ferrosilicon Market size#Ferrosilicon Market growth#Ferrosilicon Market application#Ferrosilicon Market Ferrosilicon Market#Ferrosilicon Market analysis

0 notes

Text

Ferro Silicon Magnesium (FeSiMg): Leading Manufacturers in India

In the dynamic landscape of metal alloy production, Ferro Silicon Magnesium (FeSiMg) has emerged as a crucial component with diverse applications. India, a key player in the global metallurgical industry, boasts prominent manufacturers specializing in FeSiMg alloys. This article delves into the significance of these alloys, exploring the offerings of leading manufacturers and their contributions to the industry.

Ferrosilicon Magnesium (FeSiMg): It is an important alloy in metallurgy.FeSiMg is a spheroidizing agent widely used in the production of spherical ductile iron castings. Magnesium silicate is known for its ability to improve the sphericity and mechanical strength of steel and is used in many industries such as automotive, construction and engineering.Ferrosilicon Magnesium (FeSiMg): It is an important alloy in metallurgy.

FeSiMg is a spheroidizing agent widely used in the production of spherical ductile iron castings. Magnesium silicate is known for its ability to improve the sphericity and mechanical strength of steel and is used in many industries such as automotive, construction and engineering.

Leading Ferro Silicon Magnesium manufacturers in India

Quality Standards with FeSiMG 8-10:

FeSiMG is India's leading company, specialized in FeSiMG alloy as well as FeSiMG 8-10 variant. This metal contains 8-10% magnesium and is known for its quality and consistency. It plays an important role in making the magnetic material with the best material.

Precision in Alloy Composition with FeSiMg 6-8:

Another notable product from these manufacturers is the FeSiMg 6-8 alloy. With a magnesium content ranging from 6-8%, this alloy offers precision in composition, catering to specific requirements in metallurgical processes. Its application contributes to the production of cast iron with improved nodularity and thermal stability.

Industry Impact and Applications

The influence of these manufacturers extends beyond national borders, with their FeSiMg alloys making a significant impact on the global metallurgical landscape. Industries reliant on high-quality ductile iron, such as automotive manufacturing, benefit from the consistent and reliable performance of these alloys.

Commitment to Quality and Innovation

The manufacturers highlighted here prioritize quality control and innovation in their production processes. Rigorous testing procedures ensure that their FeSiMg alloys meet international standards, guaranteeing optimal performance in various metallurgical applications.

Conclusion: Nurturing Growth in Metallurgy

In the realm of Ferro Silicon Magnesium production, Indian manufacturers stand out for their commitment to quality and innovation. The FeSiMG 8-10 and FeSiMg 6-8 alloys produced by these manufacturers play a crucial role in enhancing the properties of ductile iron, contributing to the growth and advancement of metallurgical processes globally.

As the demand for exciting products continues, the role of companies specializing in ferrosilicon becomes important. Their commitment to precision, consistency and innovation make them significant contributors to the ever-evolving field of metallurgy.

Discover the products of Indian silicon-metal magnesium producers and witness the evolution of metal-silicon magnesium alloys in global use in metallurgy.

For more details visit us- www.ferrosiliconmagnesium.com

0 notes

Text

Ferrosilicon Market Segmented On The Basis Of Application, End-Use, Region And Forecast 2030: Grand View Research Inc.

San Francisco, 12 June 2023: The Report Ferrosilicon Market Size, Share & Trends Analysis Report By Application (Deoxidizer, Inoculants), By End-use (Stainless Steel, Cast Iron), By Region, And Segment Forecasts, 2023 – 2030

The global ferrosilicon market size is expected to reach USD 13.67 billion by 2030, registering a CAGR of 2.5% over the forecast period, according to a new report by Grand…

View On WordPress

#Ferrosilicon Industry#Ferrosilicon Market#Ferrosilicon Market 2030#Ferrosilicon Market Revenue#Ferrosilicon Market Share#Ferrosilicon Market Size

0 notes

Link

Ferro silicon is an alloy of iron and silicon with a silicon content ranging from 15% to 90%. It is produced by reduction of quartz or sand with coke in the presence of iron. The resulting alloy is used as a deoxidizer and alloying agent in the production of steel.

Visit: https://www.orientnewmaterial.com/what-ferro-silicate-a-62.html

0 notes

Text

Ferrosilicon Market 2022 | Deoxidizer Segment Accounted For The Largest Revenue Share

The global ferrosilicon market size is expected to reach USD 13.7 billion by 2030, according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 2.4% from 2022 to 2030. Rising demand for ferrosilicon in the steel and cast iron industries is anticipated to contribute to market growth over the forecast period. Ferrosilicon is used as a deoxidizer in the steel industry to prevent the loss of carbon during the production process. As a result, rising investment in the steel industry is anticipated to augment the market growth. For instance, in January 2022, POSCO commenced construction of a new galvanized steel plant in Tangshan, Hebei, China, which is jointly owned by HBIS Group.

Gain deeper insights on the market and receive your free copy with TOC now @: Ferrosilicon Market Report

The USD 600 million plants are anticipated to have an annual production capacity of 900 kilotons and will supply galvanized steel sheets to the automotive industry. Furthermore, due to their long life span and good compressive strength, cast iron pipes are widely used in plumbing applications. Companies involved in cast iron pipe production are expanding their capacity, thereby fueling ferrosilicon consumption. For instance, in December 2021, AMERICAN SpiralWeld Pipe Company, a producer of cast iron pipe, announced its decision to invest USD 40 million to expand its operation in Richland County, U.S. Furthermore, rising investments in China’s construction industry are expected to benefit market growth.

For instance, China initiated five major infrastructure projects in the third quarter of 2021, one of them was an investment of USD 4,793 million in the construction of a railway line from Liuzhou to Wuzhou covering a distance of 237.78 kilometers. Such projects are aiding the consumption of steel and related products, thereby, positively influencing market growth over the forecast period. The market is competitive with a presence of a large number of players scattered across different regions. To uphold and expand their presence, market vendors are involved in acquisition activities. For instance, in February 2022, Elkem ASA acquired the remaining 50% stake in the Salten energy recovery plant from Kvitebjørn Energi, thus, taking 100% ownership. This acquisition aims to enable the production of environmental-friendly ferrosilicon grade.

#Ferrosilicon Market Size & Share#Ferrosilicon Market Latest Trends#Ferrosilicon Market Growth Forecast#Ferrosilicon Industry Insights#COVID-19 Impacts On Ferrosilicon Market#Global Ferrosilicon Market

0 notes

Link

According to recent research study, the North America And EMEA Ferrosilicon market size & share is expected to grow at a CAGR of 4.6% between 2022 and 2030. The North America And EMEA Ferrosilicon industry revenue of USD 3.90 Billion in 2021 is expected to grow up to USD 6.11 Billion by 2030.

0 notes