#fiber laser

Link

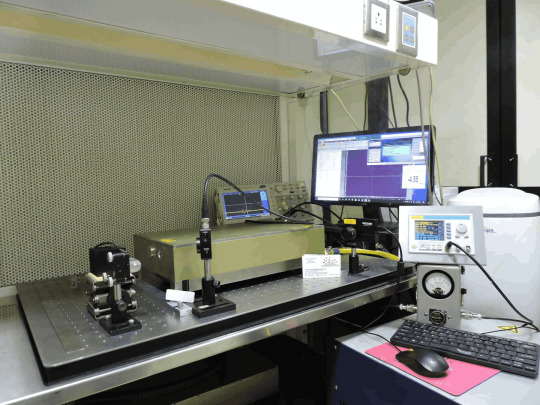

C. And C. Laser Engineering Pvt Ltd. is known for offering all kinds of industrial laser solutions and a range of Scientific and Industrial Laser Products and Services. This includes Industrial Products right from small components, and various spares of laser systems to the installation of complete laser workstations along with maintenance and servicing.

We provide laser workstations with or without material handling systems that are used for laser marking, laser engraving, deep engraving, laser welding, laser cutting, nanosecond micro-machining, and ultra-micro-machining.

We also offer laser-based solutions using Nano–Pico – Femtosecond, IR, Green, UV and DUV lasers.

We have more than 30 years of experience in the laser industry and with this vast experience and range of laser technology available, we are able to provide high-quality laser services and laser systems in the industry.

We provided lasers and services as well for our principal namely –

Control Laser Corporation,

Iradion

MegaWatt Lasers

QPC Lasers

Amplitude Lasers (Continuum),

PhotoScribe

Uptek

The Scientific range of products from C. And C. Laser Engineering have various applications and some of them are LIDAR, Macromolecules research, Laser microprobes analysis, Fiber Bragg grating diagnostics, Laser-Induced Breakdown Spectroscopy (LIBS), laser flash photolysis, Synchronized pumping of other lasers, Interferometry, Biological imaging, Materials process research.

Our laser marking job work and laser engraving job work is acknowledged and appreciated for their precision, details, and uniformity on any metals and non-metals.

Our prime goal is to offer the best and excellent services and quality products to our customers and always put in our best efforts to achieve that objective.

#lasers#laser technology#laser applications#laser marking#laser welding#laser cutting#laser engraving#micromachining#lidar#iradion lasers#co2 lasers#fiber laser#uv laser#laser systems#laser machines

4 notes

·

View notes

Text

Raycus Fiber Laser Source for Laser Marking, Engraving, and Cutting

Rycus Fiber Laser Source is an industrial-grade marking and micro-processing laser that provides high peak power, high single pulse energy, and variable spot diameter. The Q-switch pulsed fiber laser series is capable of marking metal, wood, plastic, and glass with a minimum spot size of 3mm. To learn more about the capabilities and applications of this laser, contact us.

#fiber laser#laser source#laser marking#laser#laser engraving#laser cutting#Rycus fiber laser source#fiber laser source

2 notes

·

View notes

Text

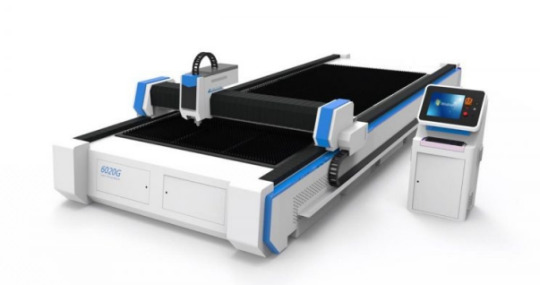

Fiber Laser Cutting Reduces Production Time

Fiber Laser Cutting Reduces Production Time:

As industries strive to meet increasing demands while maintaining high-quality standards, innovations in technology play a pivotal role in streamlining production processes. One such innovation that has transformed the landscape of manufacturing is fiber laser cutting. By harnessing the power of concentrated laser beams, fiber laser cutting has emerged as a game-changer, significantly reducing production time and enhancing overall productivity. Let's explore how fiber laser cutting achieves these efficiencies and its impact on various industries.

Speed and Precision: One of the primary reasons fiber laser cutting reduces production time is its unparalleled speed and accuracy. Traditional cutting methods can be slow and prone to wear. Fiber lasers deliver concentrated beams of light that can cut through materials with incredible speed and accuracy. The high cutting speeds of fiber lasers allow manufacturers to complete jobs in a fraction of the time, thereby reducing overall production time significantly.

Minimal Setup and Tooling: Another factor contributes to the time-saving capabilities of fiber laser cutting. Traditional cutting methods often involve extensive setup times, including the installation of specialized tools, fixtures, and templates. In contrast, fiber laser cutting is a non-contact process. It eliminates the need for physical tooling and reduces setup times. This flexibility enables manufacturers to respond quickly to changing production requirements and optimize workflow efficiency.

Versatility in Material Handling: Best CNC laser sheet cutting machine in India offers unparalleled creativity in material handling. It allows manufacturers to process a wide range of materials with ease. Whether it's metals like steel, aluminum, copper, or non-metallic materials, fiber lasers can cut through them with accuracy and consistency. This creativity eliminates the need for multiple cutting processes and pieces of equipment.

Integration with Automation: The integration of fiber laser cutting technology with automation systems enhances overall productivity by optimizing workflow efficiency and reducing labor costs. Automated material handling, loading, and unloading systems enable continuous operation and minimize downtime between jobs. Additionally, advanced software solutions and intelligent control systems automate process monitoring and optimization. It ensures optimal cutting parameters for each job and minimizes errors and rework.

Impact Across Industries: The time-saving benefits of fiber laser cutting have a profound impact across various industries, from automotive and aerospace to electronics and consumer goods. In automotive manufacturing, for example, fiber laser cutting speeds up the manufacture of structural components, body panels, and engine parts, allowing for faster turnaround times and improved production capacity. Similarly, in aerospace engineering, fiber lasers speed up the fabrication of complex components like turbine blades and structural elements.

In the electronics industry, CNC fiber laser cutting machine manufacturer facilitates the rapid prototyping and production of circuit boards, enclosures, and other electronic components, enabling faster time-to-market for new products. Moreover, in the consumer goods sector, fiber laser cutting enables manufacturers to quickly iterate designs and produce custom products with short lead times.

Future Outlook: As fiber laser cutting technology continues to evolve, we can expect further advancements that will drive even greater efficiencies and productivity gains. Prolonged research and development efforts focused on increasing laser power, improving beam quality, and enhancing automation capabilities will speed up production procedures and expand the scope of fiber laser cutting's uses across sectors. Additionally, innovations in software solutions and data analytics will enable manufacturers to optimize cutting parameters, predict and prevent errors, and maximize overall equipment effectiveness.

Application of the Fiber Laser Cutting Machine:

1. Automotive Industry

2. Aerospace Industry

3. Electronics Industry

4. Medical Equipment Manufacturing

5. Architectural and Interior Design

6. Textiles and Apparel

7. Jewelry Making

8. Tool and Die Making

9. Shipbuilding and Offshore Industries

10. Signage and Advertising

We can expect even more accuracy, speed, and adaptability from this incredible equipment as technology develops.

0 notes

Text

KAPALI KASA FİBER LAZER | ROBART LAZER

youtube

Delikli sac lazer kesimi ile delikli sac malzemelerin özel kesimlerini yapmak, tasarım ve inşaat sektörlerinde kullanılan malzemelerin gereksinimlerini karşılamak açısından önemlidir. Robart Fiber Metal Kesim lazerleri ile delikli sac lazer kesim konusunda uzmanlaşmış ekip ve ekipmanlarıyla müşteri memnuniyetini en üst düzeye çıkarmaktadır.

Robart Fiber lazerler ile Perfore malzemelerin lazer kesimi, özellikle dekoratif ve fonksiyonel amaçlar için yaygın olarak kullanılmaktadır. Firmamız, perfore lazer kesimde kaliteyi ve hassasiyeti bir araya getirerek müşterilerine çeşitli tasarım fiber lazer seçenekleri üretir.

Robart Fiber Metal Lazer Kesim Makinaları , uzun yıllara dayanan deneyimi, profesyonel ekibi ve son teknoloji lazer kesim ekipmanları ile müşteri ihtiyaçlarına özel çözümler sunmaktadır. İhtiyaçlarınıza uygun lazer kesim makinaları için bizimle iletişime geçmekten çekinmeyin. Daha fazla bilgi için robartlazer.com tıklayabilirsiniz.

#fiber laser#fiber laser cutting#robart lazer#fiber lazer kesim makinası fiyatları#lazer kesim makinası#Youtube

0 notes

Text

Discover Top Greenhouse Suppliers & Manufacturers in UAE on TradersFind

Explore the best greenhouse suppliers and manufacturers in UAE on TradersFind. Find comprehensive product details, connect with trusted companies. Contact Now!

0 notes

Text

Máy tẩy rỉ set laser cầm tay giá thấp là giải pháp tiên tiến cho việc làm sạch bề mặt kim loại. Với khả năng vệ sinh tẩy rỉ sét cùng các lớp phủ như sơn, dầu, xi mạ, bụi, máy này mang lại hiệu quả vượt trội trên nhiều loại vật liệu khác nhau như sắt, thép, inox, nhôm.

Tham khảo chi tiết hơn về máy tẩy rỉ cầm tay giá thấp tại Vlaser: https://www.vlaser.vn/tin-tuc/may-tay-ri-set-laser-cam-tay-gia-thap

#vlaser#fiber laser#lasertechnology#laser machine#lasercleaningmachine#tẩy rỉ#máy làm sạch#máy tẩy rỉ set giá thấp#máy tẩy rỉ laser

0 notes

Text

How to Fiber Laser Cutting Machine Cut Stainless Steel ?

Fiber Laser Cutting Machine Introduction

A common option for cutting stainless steel is a fiber laser cutting machine. In comparison to other cutting techniques, they have a variety of benefits, including high precision, clean cuts, a lack of burrs and dross, and quick cutting speed.

We'll talk about using a fiber laser cutting machine to cut stainless steel in this blog post. We'll talk about the following subjects:

What is a fiber laser cutting machine?

How do fiber laser cutting machines work?

Why do fiber laser cutting machine cut stainless steel so well?

Advantages of cutting stainless steel with a fiber laser machine

How to set up a fiber laser cutting machine for stainless steel cutting

Common Problems When Using Fiber Laser Cutting Machine

How to fix issues with a fiber laser cutting machine while cutting stainless steel

Conclusion

What is a fiber laser cutting machine?

A machine that cuts metal with a laser beam is called a fiber laser cutting machine. A fiber laser, a kind of laser that sends laser light across a fiber optic cable, produces the laser beam. Fiber lasers are incredibly effective and can provide extremely powerful laser beams.

How do fiber laser cutting machines work?

Metal is vaporised when it is exposed to the laser beam. The metal is then expelled by a stream of gas, such as oxygen or nitrogen, once it has vaporised. The laser beam can quickly cut through metal because of its rapid movement.

Why do fiber laser cutting machine cut stainless steel so well?

Although stainless steel is an extremely durable material, it also reflects light very well. Due to this, cutting with conventional techniques like plasma cutting or waterjet cutting is challenging. Because the laser beam is absorbed by the metal, fiber laser cutting machines are excellent at cutting stainless steel. •

Advantages of cutting stainless steel with a fiber laser machine

High precision: Fiber laser cutting machine can create very exact cuts. This is crucial for applications where the cut's accuracy is crucial, like the production of aeronautical or medical products.

Smooth cuts: Fiber laser cutting machine deliver clean, burr- and dross-free cuts. This improves the appearance of the cuts and lessens the need for post-processing.

Fast cutting speed: Steel may be quickly and efficiently cut with fiber laser cutting machines. When cutting huge amounts of material, this can save both time and money.

How to set up a fiber laser cutting machine for stainless steel cutting

You require the following in order to set up a fiber laser cutting machine to cut stainless steel:

If you are cutting stainless steel, choose the right laser power for the thickness.

The thickness of the material will determine how much laser power is needed to cut stainless steel. In general, thicker materials require greater laser power to be sliced.It's important to keep in mind that these are only guiding principles.Depending on the particular type of stainless steel, the size of the laser cutting machine, and other factors, the actual laser power needed will differ. It is usually preferable to speak with the laser cutting machine's manufacturer to find the ideal laser power setting for your particular application.

Common Problems When Using Fiber Laser Cutting Machine

The most common problems when using a fiber laser cutting machine are:

• Poor cuts: These can be the result of employing the incorrect cutting speed or feed rate, excessive or insufficient laser power, or all three.

• Burrs: If the cutting speed is too slow or the cutting nozzle is not properly positioned, burrs may form on the cut's edges.

• Drossl: If the cutting gas is the wrong kind or the pressure is too low, drossl may form on the cut's edges.

• Slow cutting speed: If the laser power is too low or the cutting speed is too high, the cutting speed may be slow.

How to fix issues with a fiber laser cutting equipment while cutting stainless steel

1.Check the laser power setting. The amount of energy given to the material being sliced is known as the laser power. A low laser power will result in a rough or incomplete cut. The material may overheat and change if the laser strength is too high.

2.Check the cutting speed and feed rate. The speed at which the laser beam traverses the material is known as the cutting speed. The material moves under the laser beam at a certain pace, which is known as the feed rate. The cut may be imperfect or hard if it is made too quickly. Too slow of a cutting speed could cause the material to overheat and distort.

3.Check the cutting nozzle alignment. The component of the laser cutting device that directs the laser beam onto the material being cut is called the cutting nozzle. The laser beam may not be properly focused and the cut may be imperfect or rough if the cutting nozzle is not correctly positioned.

4.Check the cutting gas type and pressure. Molten material in the cutting area is removed with the use of the cutting gas. The quality of the cut can be impacted by the type and pressure of the cutting gas.

If you have looked into all possibilities and are still having trouble using a fiber laser cutting machine to cut stainless steel, you may need to seek help from the laser cutting machines manufacturer or a certified laser cutting expert.

Additional advice for troubleshooting issues with cutting stainless steel with a fiber laser cutter is provided below:

Maintain a clean laser cutting system. The laser beam may scatter and the cut may be uneven or incomplete if the laser cutting machine is filthy.

Regularly swap out the cutting nozzle. The laser beam can spread as a result of a worn cutting nozzle, resulting in an incomplete or sloppy cut.

Make use of the right kind of cutting gas. The kind of cutting gas used can impact the cut's quality.

Use the proper cutting gas pressure. The quality of the cut may be impacted by the cutting gas's pressure.

Monitor the cutting process. To make sure the cut looks good it's crucial to keep an eye on the cutting procedure. If the cut does not look good, change the laser's power, cutting speed, feed rate, cutting nozzle alignment, cutting gas type, or cutting gas pressure.

Conclusion

A versatile and effective instrument, fiber laser cutting machines can be used to cut a range of materials, including stainless steel. You may learn how to set up and operate a fiber laser cutting machine to accurately and precisely cut stainless steel by using the advice in this blog post.

0 notes

Text

https://remcorfiberlasermachine.com/products/laser-cutting-machine.html

1 note

·

View note

Text

High-Performance Motherboard for Laser Engraver

The high-performance Motherboard For Laser Engraver is the ultimate solution for anyone looking to upgrade their Laser Master 2 Pro S1. With a one-year warranty and stable output, this motherboard provides the reliability and performance you need to tackle even the toughest engraving projects. Whether you’re a professional or a hobbyist, this high-performance motherboard is sure to exceed your expectations. So why wait? Check out this amazing motherboard now and take your laser engraving to the next level!

0 notes

Text

#laser cutting#laser#laser cutter#laser cutting machine#laser engraving#cutting#laser cut#laser engraver#fiber laser cutting#fiber laser#laser cutting fabric#laser cutting projects#how to design laser cutting files#cutting laser#pagar cutting laser#mesin cutting laser#20w laser cutting#laser cutting 101#tube laser cutting#fast laser cutting#laser cutting metal#metal laser cutting#laser metal cutting#laser cutting vinyl#mesin laser cutting

1 note

·

View note

Quote

Best Variobend long length slitter folder

Looking for variobend long length slitter folder at the best price? Contact Stamac. We even have a scanner that takes your hand-drawn sketch into a finished usable bending program just by scanning in the picture, plus our bending software is free for you to use, our customers save heaps of downtime normally caused by programming and drawing up the profiles.

#Fiber laser cutting automation#Coil storage system#Fiber laser#New heavy duty brake press#Machinery and equipment#Sheet metal folding machine price

0 notes

Text

not me coming up with a whole cyberpunk LimLife AU featuring revolutionary hackers TIES, corrupt government Clockers, rival criminal team Bad Boys, paid enforcer Body Neighbors and underground rave scene Coral Kids.

#i don't need another au#but ask me about it anyway lol#who reblogged that post with the story about the person running fiber optics and shining lasers across town#this is your fault actually. thank you.#dark fibre au

96 notes

·

View notes

Text

youtube

Would you like your logo or name engraved on your metal mug, or would you like to personalize your stainless steel cups, or would you like to add value to your products and services by engraving a metal mug? Then here it is, HeatSign's fiber laser marking machine with a special rotary chuck allows you to easily engrave your desired text and design onto a variety of cylindrical cups with comfort.

1 note

·

View note

Text

I’m discovering an important part of aging. If I have a problem that I’ve never found help for, I have to manually ask myself, “How long has it been since you tried?”

If it’s been 3+ years, there’s sometimes new tools or strategies or knowledge, and it is crucial for me to periodically check for new help for old problems. Otherwise I will just suffer needlessly. Even 1 chronic thing is fucking exhausting and it’s so cool to finally finally finally get it fixed, even if there isn’t help for all of my Health Stuff.

#this is kinda about dentist work and GI issues#when I was 18 I asked for the dentist to fix something and she said no. lol. she said it would probably fix itself and that the surgery for#it was frustrating for the surgeon and the patient and it was painful and tricky.#but I have dental insurance now and apparently after 8 years they now use lasers and it takes like 30 minutes and isn’t that bad!#also for my GI issues??? I’ve always struggled with the ‘eat more fiber’ advice because it never helps and often makes it worse#but recently! a doctor explained various types of fiber! and recommended I increase one and decrease the other! and I’m so bad at changing m#my diet so it’s a slow process to test out the advice. but so far it seems to be helping! either that or the slight improvement is coinciden#either is possible. but still! new knowledge! new strategies! new understandings of old strategies!#it’s really cool#soren learning to survive capitalism

65 notes

·

View notes

Text

youtube

Fiber Lazer Kesim Makinası Robart Fiber Lazer kesim makinası ile Metal, modern teknoloji ile boru profil, delikli sac ve perfore gibi çeşitli malzemelerin lazer kesim ihtiyaçlarını karşılamaktadır.

Boru profil lazer kesim hizmetleri de sunan firma, çeşitli endüstriyel uygulamalar için kullanılan boru profillerin hassas lazer kesimini gerçekleştirmektedir. Yüksek kalitede lazer teknolojisi sayesinde, istenilen ölçülerde kesimler yaparak müşterilerimize özel çözümler üretmekteyiz.

Robart Fiber Metal Kesim Lazeri ile sizlerde ihtiyacınız olan lazer kesim makinalarına kolayca ulaşabilirsiniz

0 notes

Text

🚀 Khám phá sự kỳ diệu của máy khắc laser và những ứng dụng đa dạng trong cuộc sống hàng ngày! 🛠️ Từ việc tạo bảng quảng cáo đẹp mắt, chế tạo trang sức sáng tạo đến thi công biển logo thương hiệu, máy khắc laser đang biến mọi ý tưởng thành hiện thực. Cùng Vlaser tìm hiểu cách công nghệ này thay đổi cuộc sống hàng ngày tại đây.

#MáyKhắcLaser #CôngNghệSángTạo

0 notes