#home construction cost estimation

Text

Cost estimation

Cost estimation plays a crucial role in various aspects of business and project management. Some of the key benefits of cost estimation include:

Budget Planning: Cost estimation helps in planning and allocating budgets for projects or business operations. By accurately estimating costs, organizations can ensure that they have sufficient funds to complete the project without exceeding the budget.

Resource Allocation: It enables effective allocation of resources such as manpower, materials, equipment, and time. With a clear understanding of the costs involved, organizations can allocate resources efficiently to maximize productivity and minimize waste.

Risk Management: Cost estimation allows for better identification and mitigation of risks associated with a project. By anticipating potential cost overruns or budget constraints, organizations can implement risk management strategies to address these issues proactively.

Decision Making: Accurate cost estimation provides decision-makers with valuable insights for making informed decisions. It helps in evaluating the feasibility of projects, comparing alternative options, and selecting the most cost-effective solutions.

Contract Negotiation: In business transactions, cost estimation serves as a basis for negotiating contracts with suppliers, vendors, and clients. It helps in setting fair prices, establishing payment terms, and ensuring that both parties agree on the financial aspects of the agreement.

Performance Measurement: Cost estimation provides a benchmark for evaluating the performance of projects or business activities. By comparing estimated costs with actual costs, organizations can assess their financial performance, identify areas for improvement, and implement corrective actions if necessary.

Customer Satisfaction: Accurate cost estimation contributes to customer satisfaction by ensuring that projects are completed within budget and delivered on time. It helps in building trust and credibility with clients, which can lead to repeat business and positive referrals.

Legal and Regulatory Compliance: Cost estimation is often required for regulatory compliance and legal purposes. It helps organizations ensure that they meet financial reporting requirements, adhere to industry standards, and comply with relevant laws and regulations.

Overall, cost estimation is essential for effective financial management, project planning, and decision-making in both business and project management contexts. It helps organizations optimize resources, minimize risks, and achieve their objectives in a cost-efficient manner.

Suggestions for cost estimation company

Jamie Thompson

EXCABILER ESTIMATING LTD

Company Number: 15153674

Address: 30 Riverhead Close, London.

www(.)exacabilerestimating(.)co(.)uk

also for USA

Jamie Thompson

Cost Masters Inc

2316 Short Street Austin Texas, TX 78741, WWW(.)costmasters (.)us

#COST ESTIMATION#COST#ESTIMATION#CONTRACTOR#construction#renovation#modern architecture#steel structure#architectural design#Contractore#takkup#accurate#100% accurate#home builders#home extension

2 notes

·

View notes

Text

Sydney Estimator is a team of experts in construction estimation and project management who serve Sydney and NSW. We provide cost effective Construction Estimating Services for the Building and Construction Industry.

#building construction estimate#building construction cost estimator#home construction cost estimator#building estimation#residential building estimate

0 notes

Text

https://aashiyana.tatasteel.com/in/en/buy-our-products.html?utm_source=Backlink&utm_medium=Offpage+Submission&utm_campaign=Offpage+Backlink+Submission&utm_id=seo_referral_backlink#buy-building-materials-online

Buy home plans & building supplies online. We provide the best-priced home design & construction materials all over India. Visit https://aashiyana.tatasteel.com/in/en/buy-our-products.html for more details

#house design#railing design#steel railing design#balcony railing design#new home design#new house design#house gate design#house construction#house railing designs#house construction cost#steel doors and windows#house construction materials#house construction cost estimator#construction material suppliers near me#material required for house construction#buy construction steel online

0 notes

Text

0 notes

Text

Why is Document Management Software Important in Construction Industry?

Managing digital documents is a complex task, especially in the building industry. The problem is that most records are unstructured. It's hard to find the necessary information and challenging to complete a workflow. Document management software saves you time and ensures your files are secure.

Along with DMS, your construction company should choose the right Commercial estimating software. These online systems reduce mistakes and improve the accuracy of your bids and documentation.

You can coordinate with suppliers and subcontractors more practically through efficient and user-friendly DM and estimating software. This will allow you to make better estimates and create secure records for each project.

Automation of File Keeping and Retrieval

Automating the process of document creation, storage, distribution, and review can increase productivity in your business. Document automation tools help employees to fill out and submit documents faster. It can also reduce errors and redundancies.

The benefits of automation include more accurate and consistent documentation, reduced risk of business-damaging fines, and improved client satisfaction.

Enhanced Collaborations

Document Management systems help team members work together. By storing all your documents in a centralized location, you can easily find them and share them with colleagues. Electronic records are perfect for inter-office distribution and working with clients.

Reliable software will have substantial version control, allowing users to check and reject changes with just one click. You should also be able to restrict access to authorized roles. A document management system should also enable your organization to comply with regulatory compliance requirements.

Saves Companies from Costly Litigation

A well-implemented solution can streamline your workflows and minimize the time spent on administrative tasks. Creating a central repository for all important documents will save you the time and hassle of relocating paper files. You can also access files from anywhere and work with colleagues across offices.

Implementing a digital record management system will also eliminate the need for multiple copies of the same document.

Bizprac helps users maximize their profit. An industry-leading Australian support team with extensive industry knowledge will also support you. Visit their website to learn more. https://www.bizprac.com/

#Document management software#Commercial estimating software.#construction software#construction project management software#construction management software australia#construction job management software#construction accounting software#building industry software#construction estimating software#best construction estimating software#building estimation and costing software#home building estimating software

0 notes

Text

Gruhom offer House construction in Bangalore Starting at Just Rs 1550/ sq ft onwards; We helps you get exact estimates of construction cost. Contact us: +91 9845208299

#house construction cost estimation#building construction cost estimation#estimate house construction#construction cost calculator bangalore#house construction companies in bangalore#building contractors bangalore#construction contractors in bangalore#best house construction companies in bangalore#build a home bangalore

1 note

·

View note

Text

The Importance of Document Management in Construction Projects

Document management is vital to the success of construction projects. It helps stakeholders find the information they need and avoids disputes. If a project document is missing, it could mean the difference between successful project completion and legal action. In addition, document management keeps all project documentation safe.

Secure Digital Document Storage System

One of the biggest challenges in running a construction business is storing and sharing project documents. That's why you'll need secure document management software. These cloud-based solutions can help you maintain a central library of project documents and protect your company's data from theft or loss. They also allow you to share documents with anyone who needs to see them, including other members of your extended team.

Having an easy-to-use, secure document control system can be the difference between success and failure. A good document management system (DMS) is a necessity when it comes to construction projects which require accurate calculations and pricing. By enabling remote sharing and storage, a DMS can save your project time and money. It can also make decision-making faster for project managers at multiple sites.

Open Communication with the Whole Team

Construction projects are complicated and often don't go as planned. That means that proper communication is essential to keep all parties informed of changes to documents, purchase orders, and requests for information.

Effective communication in construction can make the difference between a smooth project and a complicated one. By keeping open lines of communication, you can improve the management of construction documents and improve the collaboration between all members of the team.

Document Retention Policies

Document retention policies are important in the construction industry. Whether the project is digital or traditional, a builder company should have clear rules for preserving project documents. Most documents should be kept for at least 15 years after the project is complete. It is also important to have separate backups in case of system failure or document destruction.

Document retention policies should be specific to each company. They should consider the type of documents, the significance of the documents, the ongoing business functions, and the relationships the company has with third parties. These can include other businesses, employees, customers, partners, and government agencies.

Builder companies in Australia can use an integrated construction management software, Bizprac, for their various project administration needs. It also functions as a job control, costing, accounting, document management, and building material estimating software, all in one package.

Contact Biprac today to learn more about the product. https://www.bizprac.com/

#construction software#construction project management software#construction management software australia#construction job management software#construction accounting software#construction estimating software#building industry software#best construction estimating software#building estimation and costing software#home building estimating software#commercial construction project management software#building estimating software#asset building system#building estimating software australia#construction financial software#construction estimating software australia#commercial construction estimating software#commercial estimating software

0 notes

Text

[ID: Seven yoghurt balls on a plate drizzled with olive oil. The one in the center is plain; the others are covered in mint, toasted sesame seeds, ground sumac, za'tar, crushed red chili pepper, and nigella seeds. End ID]

لبنة نباتية / Labna nabatia (Vegan labna)

Labna (with diacritics: "لَبْنَة"; in Levantine pronunciation sometimes "لَبَنَة" "labanay") is a Levantine cow's, sheep's, or goat's milk yoghurt that has been strained to remove the whey and leave the curd, giving it a taste and texture in between those of a thick, tart sour cream and a soft cheese. The removal of whey, in addition to increasing the yoghurt's tanginess and pungency, makes it easier to preserve: it will keep in burlap or cheesecloth for some time without refrigeration, and may be preserved for even longer by rolling it into balls and submerging the balls in olive oil. Labna stored in this way is called "لبنة كُرَات" ("labna kurāt") or "لبنة طابات" ("labna ṭābāt"), "labna balls." Labna may be spread on a plate, topped with olive oil and herbs, and eaten as a dip for breakfast or an appetizer; or spread on kmaj bread alongside herbs, olives, and dates to make sandwiches.

The word "labna" comes from the Arabic root ل ب ن (l b n), which derives from a Proto-West-Semitic term meaning "white," and produces words relating to milk, yoghurt, nursing, and chewing. The related term "لَبَن" ("laban"; also transliterated "leban") refers to milk in Standard Arabic, but in Levantine Arabic is more likely to refer to yoghurt; a speaker may specify "لَبَن رَائِب" (laban rā'ib), "curdled milk," to avoid confusion.

Labna is a much-beloved food in Palestine, with some people asserting that no Palestinian home is without a jar. Making labna tabat is, for many, a necessary preparation for the winter season. However, by the mid-2010s, the continuation of Israel's blockade of the Gaza strip, as well as Israeli military violence, had severely weakened Gaza's dairy industry to the point where almost no labna was being produced. Most of the 11 dairy processors active in Gaza in 2017 (down from 15 in 2016) only produced white cheese—though Mustafa Eid's company Khalij had recently expanded production to other forms of dairy that could be made locally with limited equipment, such as labna, yoghurt, and buttermilk.

Dairy farmers and processors pushed for this kind of innovation and self-sufficiency against deep economic disadvantage. With large swathes of Gaza's arable land rendered unusable by Israeli border policing and land mines, about 90% of farmers were forced by scarce pasture land and low fodder production to feed their herds with increasingly expensive fodder imported from Israel—dairy farmers surveyed in 2017 spent an estimated 87% of their income on fodder, which had doubled in price since 2007. Cattle were thus fed with low quantities of, or low-quality, fodder, resulting in lower milk production and lower-quality milk.

Most dairy processors were also unable to access or afford the equipment necessary to maintain, upgrade, or diversify their factories. Since 2007, Israel has tightly restricted entry into Gaza of items which they consider to have a "dual use": i.e., a potential civilian and military function. This includes medical equipment, construction materials, and agricultural equipment and machinery, and impacts everything from laboratory equipment to ensure safe food supplies to packaging and labelling equipment. Of the dairy products that Gazan farmers and processors do manage to produce, Israel's control over their export can cause huge financial losses—as when Israel prohibited the export of Palestinian dairy and meat to East Jerusalem without warning in March of 2020, costing estimated annual losses of 300 million USD.

In addition to this kind of economic manipulation, direct military violence threatens Gaza's dairy industry. Mamoun Dalloul says that his factory was accused of holding rockets and subsequently bombed in 2008, 2010, 2012, and again in 2014, resulting in repeated moves and the loss of the capability to produce yellow cheese. The Israeli military partially or totally destroyed 10 dairy processing factories, and killed almost 2,000 cows, during its 2014 invasion of Gaza, resulting in an estimated 43 million USD of damage to the dairy sector alone. Damage to cow-breeding farms in 2014 reduced the number of dairy cows to 2,600, just over half their previous number. Damage to, or destruction of, wells, water reservoirs, water tanks, and the Gaza Power Plant's fuel tank exacerbated pre-existing problems with producing cattle feed and with the transportation, processing, and refrigeration of dairy products, leading to spoiled milk that had to be disposed of. Repeated offensives made dairy processors reluctant to re-invest in equipment that could be destroyed at any time.

Israeli industry profits by making Gazan self-sufficiency untenable. Israeli goods entering Palestine are not subject to import taxes, and Israeli dairy companies are not dealing with the contaminated water, limited electricity, high costs of feed, out-of-date and expensive-to-repair equipment, and scarce land (some companies, such as Tnuva, purchase milk from farms on illegal settlements in the West Bank) with which Gazan producers must contend. The result is that the local market in Gaza is flooded with imports that are cheaper, more diverse, and of higher quality than anything that local producers can offer. Many consumers believe that Israeli products are safer to eat.

Nevertheless, Gazans continue building and rebuilding. Despite significant decreases in ice cream factories' production after the imposition of Israel's blockade in 2007, Abu Mohammad noted in 2015 that locally produced ice cream was cheaper and more varied than Israeli imports. In 2017, the amount of dairy sold in 74 shops in Gaza that was sourced locally, rather than from Israel, had increased from 10% to 60%. Ayadi Tayyiba, the region's first factory with an all-woman staff, opened in 2022; it produced cheese, yoghurt, and labna with sheep's milk from affiliated farms. However, demand for sheep's milk products has decreased in Gaza due to its higher production costs, leading the factory to supplement its supply with purchased cow's milk.

The current Israeli genocidal offensive on Gaza has caused damage of the same kind as—though to a greater extent than—previous shellings and invasions. Lack of ability to sell milk that had already been produced to factories, as well as lack of access to electricity, caused an estimated 35,000 liters of milk to spoil daily in October of 2023.

Support Palestinian resistance by calling Elbit System’s (Israel’s primary weapons manufacturer) landlord, donating to Palestine Legal's activist defense fund, and donating to Palestine Action’s bail fund.

Equipment:

A blender

A kettle or pot, to boil water

A cheesecloth or tea towel

Ingredients:

1 cup (130g) cashews (soaked, if your blender is not high-speed)

3/4 cup filtered or distilled water, boiled

1-3 vegetarian probiotic capsules (containing at least 10 billion cultures total)

A few pinches sea salt

More water, to boil

Arabic-language recipes for vegan labna use bulghur, almonds, or cashews as their base. This recipe uses cashew to achieve a smooth, creamy, non-crumbly texture, and a mild taste like that of cow's milk labna. You might try replacing half the cashews with blanched almonds for a flavor more similar to that of sheep's or goat's cheese.

Make sure your probiotic capsules contain no prebiotics, as they can interfere with the culture. The probiotic may be multi-strain, but should contain some of: Lactobacillus casei, Lactobacillus rhamnosus, Bifidobacterium bifidus, Lactobacillus acidophilus. The number of capsules you need will depend on how many cultures each capsule is guaranteed to contain.

Instead of probiotic capsules, you can use a speciality starter culture pack intended for use in culturing vegan dairy, many of which are available online. Note that starter cultures may be packaged with small amounts of powdered milk for the bacteria to feed on, and may not be truly vegan.

If you want a mustier, goat-ier taste to your labna, try replacing the water with rejuvelac made with wheat berries.

You can also start a culture by using any other product with active cultures, such as a spoonful of vegan cultured yoghurt. If you have a lot of cultured yoghurt, you can just skip to straining that directly (step 5) to make your labna—though you won't be able to control how tangy the labna is that way.

Instructions:

This recipe works by blending together cashews and water into a smooth, creamy spread, then culturing it into yoghurt, and then straining it (the way yoghurt is strained to make labna). It's possible that you could skip the straining step by adding more cashews, or less water, to the yoghurt to obtain a thicker texture, but I have not tested the recipe this way.

1. If your blender is not high-speed, you will need to soak your cashews to soften them. Soak in filtered or distilled water for 2-4 hours at room temperature, or overnight in the fridge. Rinse them off with just-boiled water.

2. Boil several cups of water and use the just-boiled water to rinse your blender, tamper, measuring cups, the bowl you will ferment your yoghurt in, and a wooden spoon or rubber spatula to stir. Your bowl and stirring implement should be in a non-reactive material such as wood, clay, glass, or silicone.

3. Make the yoghurt. Blend cashews with 3/4 cup just-boiled water for a couple of minutes until very smooth. Transfer to your bowl and allow to cool to about skin temperature (it should feel slightly warm if dabbed on the inside of your wrist). If the mixture is too hot, it may kill the bacteria.

4. Culture the yoghurt. Open the probiotic capsules and stir the powder into the cashew paste. Cover the bowl with a cheesecloth or tea towel. Ferment for 24 hours: on the countertop in summer, or in an oven with the light on in winter.

Taste the yoghurt with a clean implement (avoid double-dipping!). Continue fermenting for another 12-24 hours, depending on how tangy you want your labna to be. A skin forming on top of the yoghurt is no problem and can be mixed back in. Discard any yoghurt that grows mold of any kind.

5. Strain the yoghurt to make labna. Place a mesh strainer in a bowl, making sure there's enough room beneath the strainer for liquid to collect at the bottom of the bowl; line the strainer with cheesecloth or a tea towel, and scoop the cultured yoghurt in. Sprinkle salt over top of the yoghurt. Fold the towel or cheesecloth back over the yoghurt, and add a small weight, such as a ceramic plate or a can of beans, on top.

You can also tie the cheesecloth into a bag around a wooden spoon and place the wooden spoon across the rim of a pitcher or other tall container to collect the whey. The draining may occur less quickly without the weight, though.

Strain in the refrigerator for 24-48 hours, depending on the desired texture. I ended up draining about 2 Tbsp of whey.

6. If not making labna balls: Put in an airtight jar, and add just enough olive oil to cover the surface of the labna. Store in the fridge for up to two months.

7. To form balls (optional): Oil your hands to form the labna into small balls and place them on a baking sheet lined with parchment paper. They may still be quite soft.

Optionally sprinkle with, or roll in, dried mint, za'tar, sesame seeds, nigella seeds (القزحة), ground sumac, or crushed red chili pepper, as desired.

Optionally, for firmer balls, lightly cover with another layer of parchment paper and then a kitchen towel, and leave in the refrigerator to dry for about a day.

Place labna balls in a clean glass jar and add olive oil to cover. Retrieve labna from the jar with a clean implement. They will last in the fridge for about a year.

533 notes

·

View notes

Text

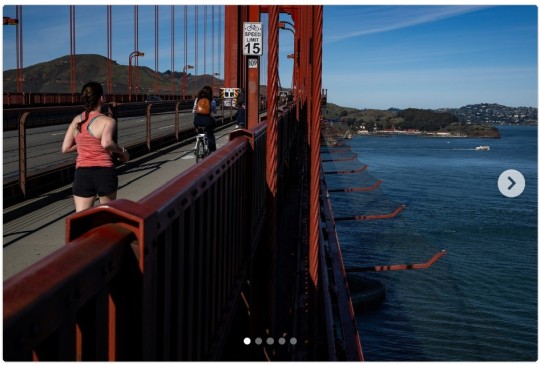

The Golden Gate Bridge is an Iconic landmark, but it's also a lethal one. About 2,000 people are estimated to have jumped to their death since 1937 – an average of about two people a month. Suicide prevention advocates have pushed for a deterrent for decades.

After years of meetings and delays, their dreams are a reality.

For Kay James this development hit close to home. Her son Michael James Bishop had taken his life at the bridge back in 2011. He had struggled with depression in the past and on the morning of March 28th he drove to the bridge and got out, leaving a note on his car seat.

Dennis Mulligan, the general manager for the organization that oversees the bridge, says the public did not want the net to detract from the bridge's beauty. Finally, he says, the Golden Gate Bridge board concluded that they would build something. The Federal highway grants covered the $224 million cost to construct the barrier.

The net is made of reddish orange beams connected by a stainless steel silver net that looks like chain link fencing. It's suspended 20 feet below the pedestrian walkway and spans 1.7 miles down both the west and east sides of the bridge.

29 notes

·

View notes

Photo

Update: Remember this post of an old basketball gym that was for sale in Wilkinson, Indiana for $299K?

Well, Kyle and Lauren were not looking for a new home when they saw the listing, and certainly had no interest in the rickety skeleton of a 72-year-old gym.

But because they lived nearby, they stopped in for a look. The pictures, they thought, had not done the space justice.

They were awed by its cavernous proportions, but they looked around and went home.

A week and a half later, the couple, (who has 3 kids), decided they wanted to own it. They called the real estate agent that morning and made an offer. It was accepted before they went to bed that night.

Lauren in front of the gym. “It was the strangest thing I’d ever heard of, and the coolest thing I’d ever heard of,” she said. The next day, after their offer of $300K was accepted, the real estate agent called and said the listing went viral and offers were pouring in from as far away as Singapore.

Among miscellaneous furniture, boxes await unpacking. Meanwhile, the viral moment faded as quickly as it appeared. The worldwide attention subsided.

Their daughter riding her bike in the gym. They realized one night that a colony of bats had taken up residence in the gym & spiders continue to emerge all over the house. Moving has been a slow process.

Kyle and his father examine carvings on an original wooden school desk left in the home. “We’re still walking around here thinking, ‘What did we just do?’” said Kyle, who estimated the cost of renovations, over a period of years, would eventually exceed the original cost of the home.

They have a photo showing the construction of the Wilkinson High School gym. They want to refurbish the court and open it up somehow to the Wilkinson community. The community is rooting for them and waiting to see what happens next.

https://www.nytimes.com/2022/09/24/sports/basketball/indiana-family-lives-in-gym.html

170 notes

·

View notes

Text

Sydney Estimator Services aims to ascertain the cost of materials and labour based on the proposed project design and specifications. Commercial and residential construction estimating services, tendering and cost management in Sydney. Contact us today!

Owner builder cost estimator

#new construction cost estimator#new home construction cost estimator#building estimation#residential building estimate#residential building cost estimator#owner builder cost estimator

0 notes

Text

Ditch the calculator and get an estimate of the construction materials required to build your dream home. Visit https://aashiyana.tatasteel.com/in/en.html and enter the specifications of your plot or house plan to get an instant estimate of rebars, roofing material and fencing wire required.

#building material calculator#house construction cost#house construction materials#house construction cost estimator#construction material suppliers near me#material required for house construction#home building contractors

0 notes

Text

(Reuters) - The administration of U.S. President Joe Biden will release a final rule as soon as this week that will make it more difficult for companies to treat workers as independent contractors rather than employees that typically cost a company more, an administration official said.

The U.S. Department of Labor rule, which was first proposed in 2022 and is likely to face legal challenges, will require that workers be considered employees entitled to more benefits and legal protections than contractors when they are "economically dependent" on a company.

A range of industries will likely be affected by the rule, which will take effect later this year, but its potential impact on app-based services that rely heavily on contract workers has garnered the most attention. Shares of Uber Technologies Inc, Lyft Inc and DoorDash all tumbled at least 10% when the draft rule was proposed in October 2022.

The rule is among the most impactful regulations ever issued by the Labor Department office that enforces U.S. wage laws, according to Marc Freedman, vice president at the U.S. Chamber of Commerce, the largest U.S. business lobby. But he said the draft version of the rule provides little guidance to companies on where to draw the line between employees and contractors.

"Economic dependence is an elusive concept that in some cases may end up being defined by the eyes of the beholder," Freedman said.

The Labor Department in the proposed rule said it would consider factors such as a worker's "opportunity for profit or loss, investment, permanency, the degree of control by the employer over the worker, (and) whether the work is an integral part of the employer’s business."

The rule replaces a Trump administration regulation that said workers who own their own businesses or have the ability to work for competing companies, such as a driver who works for Uber and Lyft, can be treated as contractors.

The department's sharp break from the Trump-era regulation will likely be the focus of lawsuits challenging the new rule, legal experts have said. Federal law requires agencies to adequately explain their decision to withdraw and replace existing rules.

The Biden administration has said the Trump-era rule violated U.S. wage laws and was out of step with decades of federal court decisions, and worker advocates have said a more strict standard was necessary to combat the rampant misclassification of workers in some industries.

The left-leaning Economic Policy Institute in a report last year estimated that a truck driver treated as a contractor earns up to $18,000 less per year than one who is deemed an employee, while construction workers' earnings drop by nearly $17,000 and home health aides lose out on up to $9,500 in pay and benefits.

Business groups sharply criticized the draft rule after it was proposed. Any change in policy is expected to increase labor costs for many sectors including trucking, retail and manufacturing.

Most federal and state labor laws, such as those requiring a minimum wage and overtime pay, only apply to a company's employees, who studies suggest can cost companies up to 30% more than independent contractors.

Nearly 40% of U.S. workers, or more than 64 million people, did some freelance work in the past 12 months, according to a December survey by freelancing marketplace Upwork.

10 notes

·

View notes

Text

More than three years after the Canadian government agreed to fund a in-community mercury poisoning care home for Grassy Narrows First Nation, construction hasn't started, estimated costs are skyrocketing, and the chief is questioning the prime minister's commitment.

"It makes me very uneasy," said Rudy Turtle of the situation facing his community, also known as Asubpeeschoseewagong Netum Anishinabek, about 90 kilometres north of Kenora, Ont.

"A few years ago, when Trudeau was out campaigning, he said on national television that money wouldn't be an issue building the treatment centre. Now, it's kind of like they're backing down on their word."

The federal government and Grassy Narrows signed a $19.5-million deal in April 2020 for the centre's community-led design and construction, which they followed with $68.9 million more in 2021 for operations and maintenance.

That brought the cash available to build and run the centre to nearly $90 million. But Turtle said this week the estimated cost of just construction is now $80 million — three times more than initially budgeted — which the government has, so far, not agreed to grant. [...]

Continue Reading.

Tagging: @politicsofcanada

#cdnpoli#Grassy Narrows#Asubpeeschoseewagong Netum Anishinabek#Indigenous politics#Ontario#healthcare

33 notes

·

View notes

Text

The Importance of Cost Estimation Software in Construction

Cost estimation in construction refers to determining the amount a project will cost. The process considers the materials and labour required, the project's timeline, and the overall market price of products and services.

It is effective in terms of the following:

· Company owners planning their business constructions

· Project managers handling the cost and material components of a commercial construction

· Construction design teams involved in detailing and designing large projects to match the cost and materials set by a company.

Cost estimation software helps you create a budget that includes all the costs associated with a construction project. It can also integrate with other tools, such as project management and accounting systems.

In terms of Materials and Budget

An estimator program can streamline the process of selecting materials for a project based on cost and quality.

Additionally, construction financial software can track labour costs and subcontractor expenses. This software helps construction businesses better manage time and workflow and account for variances. With accurate data, construction companies can make informed decisions about their budgets. This helps them avoid running in the red and secure cash flow.

In terms of Time and Project completion

Cost estimation software can help construction firms avoid common errors and ensure consistency. Using the same procedures and tools, they can more accurately determine the construction operation factors. Even the slightest mistake can put a project off the timeline.

Estimation programs include built-in formulas and provide quick, accurate cost estimates to make the estimation process easier. Estimating is no longer a time-consuming and error-prone process.

Without a good understanding of cost estimates, a construction company is at risk of incurring unexpected costs. This may affect the financial stability of the company in the long run. With accurate cost estimates, construction companies can secure cash flow and avoid financial dilemmas. This will lead to satisfied clients and solid reputations.

Bizprac is a construction estimating software in Australia that can manage other factors in your business, ensuring that you achieve your professional goal. To know more about how you can make your business easier and more profitable to run, contact Bizprac now. https://www.bizprac.com/

#commercial estimating software#commercial construction estimating software#construction estimating software australia#construction financial software#building estimating software australia#asset building system#building estimating software#commercial construction project management software#home building estimating software#building estimation and costing software#best construction estimating software#building industry software#construction estimating software#construction accounting software#construction management software australia#construction job management software#construction software

0 notes

Text

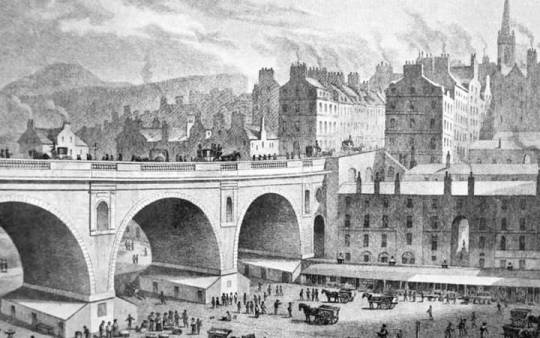

On October 1st 1763 the contract to build Edinburgh's North Bridge was signed.

Edinburgh in the 1700s was a very different city to the one we know today. The city boundary was restricted to the dramatic crag and tail feature which swept eastwards from the castle. Up to 35,000 people inhabited a space under a mile long making Scotland’s capital one of the most densely populated urban areas in the world at that time. The overcrowded population were crammed into crumbling tenements, many of them up to fourteen storeys high in order to make the most of the limited space. Make no mistake, Edinburgh at this point in it's history, was a skyscraper city, very few cities in the world had buildings the height of our capital!

Edinburgh’s nobility were often forced to accept the unthinkable and share dwellings with the lower classes. Change was not just desired, it was deemed an absolute necessity if the city was ever to move forward.

Plans to build a New Town to the north were discussed as early as the 1750s but without the means of connecting it with the rest of Edinburgh, it would be nothing more than a fanciful dream. Phase one required the draining of the ancient Nor’ Loch, a man-made stagnant body of water located in the area which we now term as Princes Street Gardens. Drainage began in 1759 and would continue up until the 1820s. Dry land at the east of the Nor’ Loch valley allowed for what was undoubtedly the most ambitious engineering project to have been built in the city at that point: An eleven-hundred foot long stone bridge. The North Bridge, as it would be named, enabled the New Town to become a reality. A brand new chapter in the city’s history was about to begin.

And so it was that the foundation stone of architect William Mylne’s North Bridge was laid on 1st October 1763 but it would be a further two years before any serious amount of progress was made. Nearing completion, the magnificent multi-arched bridge first opened to pedestrians in 1769 to much fanfare and excitement. However, the cheers would soon be emphatically silenced that summer due to a disaster of epic proportions.

On the evening of Thursday, 3rd August 1769 the side walls of the south abutment of the bridge suddenly gave way, causing a partial collapse of the structure and tragically claiming the lives of five people

Rescue efforts were recorded by newspaper the Caledonian Mercury which detailed the grim discoveries of bodies "buried in the rubbish, occasioned by the fall of the walls of the south abutment of the new bridge over the north loch".

Two of the bodies were identified as belonging to Mr Lawson, shoemaker, and Mr James Fergus, a local writer.

The Caledonian Mercury went on to mention that workers had been digging almost day and night since the collapse and that at least three to four others were feared to have shared the "same unhappy fate with the two already found".

A contemporary letter penned by a Darcy, Lady Maxwell recalls the evening of the collapse, which she had witnessed, writing

“The Lord, who is continually loading me with his benefits, has twice this day remarkable interfered on my behalf. In the evening he preserved me from broken bones to which I was exposed in a fall. A few hours after, when walking home from chapel, I witnessed a most melancholy scene occasioned by the falling in of the North Bridge. I… was within five minutes of passing over it… when almost in a moment, the greatest noise I ever heard (except on a similar occasion when I was remarkably preserved) filled the air."It seemed as if the pillars of nature were giving way. Instantly, the cry resounded “the bridge is fallen!”

A full inquiry followed and identified haste in construction and a poorly-calculated estimate regarding the depth of the foundations and sturdiness of the earth-filled abutments as the chief causes behind the disaster.

Rebuilding work demanded £18,000 (almost double the original £10,140 cost of the project) and the city would have to wait until 1772 before the grand reopening. The original North Bridge survived more than a century until the 1890s, when engineers devised an improved link that would allow for greater flow of traffic, this was at the time Waverley Train Station was being constructed.

Construction of the current steel bridge that we know today was completed in 1897 at a cost of £81,000., with the North British Railway Company contributing to a third of the cost.

A plaque recalling the founding and dismantling of the original North Bridge occupies a wall of the present bridge, which has now stood for roughly the same length of time as its predecessor.

The pictures show the evolution of the Nor Loch, I can’t find dates for them all, but you will see in the first one that the Loch is still not fully drained and very little signs of buildings on the North side, pic two shows buildings where the Balmoral Hotel now sits.

In the third pic there are signs of a Market where we now have Waverley Station, the street and buildings under the far side are now called Market Street. Pic four is dated around 1809, all the buildings you see on the left are now gone. On the top roght corner is what was The North British Train Station, the bottom of the picture you can see what is now known as “The Mound. Next pic is I guess from mid 19th century, still a long way from the construction of Waverley Station. Pic six shows the North Bridge being dismantling early 1896, and then "The Ceremony of Laying the Foundation Stone of the New North Bridge Edinburgh 25th May 1896, leading on to the commemorative plaque, which is from around the same time.

Finally is a pic of how the North Bridge looks in 2021, not much to see as it is in cladding while a multi-million restoration is taking place, the cost of refurbishing the bridge has soared from £22 million to £36m after the landmark structure was found to be in worse condition than expected. Last October the council issued a statement saying.

“Due to the nature of the construction of the bridge, full access behind the cast iron façade has not been available since it was constructed in 1897 and the last full refurbishment of this nature was in 1933. It has not been possible to properly inspect the hidden structural elements in almost 90 years.”

The briefing said testing had led to the discovery of “extensive issues” with the existing concrete bridge deck constructed in 1933.

I won't depress you with the latest details on when it will be finished, but at least it has opened to traffic now.

16 notes

·

View notes