#imsn

Text

i think i am. too tired to be in Nh aY shape or form, moved by the lazt of us hbo. like. hm, cool, good job. like how are yall so 🥹😭😭🥺 about it. about everything. im not even mad abojt it. like nothing happened to me. im just too tired.

#this sounds much more depressing than whT imsN#i msan*#I MEAN*#shit man#tlou#tlou2#the last of us 2#the last of us hbo

0 notes

Text

Hits the table*

IMSN NOTT OKAAYYYYSBFLSBDLDK

AKDVOSJSLDNSLWNLSISM

8 notes

·

View notes

Text

0 notes

Note

DINOOOOOOOOOOOOOOOO AHJDDNLLUSAYUKMGSSUOOYRVNLLLITDCNMLL the theme IS GORGEOUS i love it omg

THE GIF IS SO LOW QUALITY IMSNS SCREAMIN tumblr can shove a stick up it's ass that 10mb limit is the bane of my existence.

you are gorgeous i love you

1 note

·

View note

Text

o h my fuxking god imsn gianna die rob ight rip whos inheritijg my shits and my fuckifn f 2000 mcr shurts lets hope rhsi hosue is enough for you EVAN

1 note

·

View note

Text

Why Corrosion Monitoring In Data Centres Is Important?

Corrosion monitoring plays a very important and vital role for any electronic equipment throughout its lifetime. It is essential to understand the working environment of the data center or a critical control room so as to implement a monitoring and control solution that suits its requirements. New changes made in manufacturing due to regulation have made electronics more sensitive to corrosion than ever.

In this article, we will see why and how corrosion monitoring is implemented for data centers and control rooms, and its importance.

Why corrosion monitoring?

It is important for the equipment to operate in a safe environment for optimal functioning and a long service life. Electronics present in a dynamic environment mean that the severity of contaminants present can vary from time to time. A single opening and closing of a door can introduce contaminants that can ultimately lead to equipment failures. The major reason for corrosion monitoring is to monitor the contaminants inside and to classify the severity of the working condition. By doing this we can take necessary measures to prevent corrosion.

Corrosion monitoring will classify the region into G1, G2, G3, and GX based on severity ranging from mild to severe respectively. Once the class is identified, we can select an appropriate corrosion control technique. Corrosion monitoring can be further used to check the efficient performance of the corrosion control unit, that is, if a corrosion control unit is equipped and functioning then the corrosion monitor should be indicating a corrosion-free environment.

How is corrosion monitoring done?

Corrosion monitoring is done by measuring the reactivity of sensor metals in the working environment. It gives us a brief picture, how much reactivity the sensor metals showf proper corrosion management is absent.

The majority of metals used for sensors are copper, silver, and gold. And based on the reactivity of these metals we can find the class, severity, and conclusions as shown below;

Class

Severity

Copper reactivity(Å)

Silver reactivity(Å)

Comments

G1

Mild

<300

<200

Corrosion is not a factor in determining equipment reliability

G2

Moderate

<1000

<1000

Corrosion effects are measurable and corrosion may not be a factor, Enig and ImmAg PCB surface finish failures

G3

Harsh

<2000

<2000

High probability the corrosive attack will occur. OSP and ImSn PCB surface finish failures

GX

Severe

>2000

>2000

Only specially designed and packaged equipment to survive

The metals can be used as a passive coupon sensor where they are exposed to a minimum of 30 days and then taken to a lab for analysis, or as an active sensor that gives real-time information on corrosivity. The sensors might work on different techniques to measure reactivity. Please refer to the article- what are the best corrosion monitoring techniquesto know more about it.

At AQOZA technologies we offer both passive and active corrosion monitoring units to choose from based on your requirement. Being a specialist vendor in gas phase filtration and monitoring, AQOZA offers optimum performing corrosion control units to various industries. Get in touch with us to know more!!!

1 note

·

View note

Photo

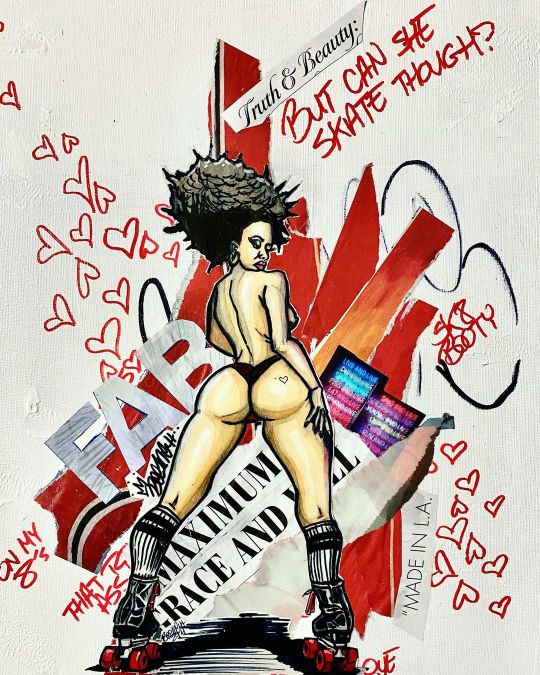

2020 goals include remembering when I'm being pulled in opposite directions and taking care of folks that #SelfCare matters. #imattertoo It's been a month since I skated. Being here now reminds me of the #littlethings and how much I love them. #sheskates #iamshe #sk8life #sk8love #wheelsonthewood #ificanwalkicanskate#imsn https://www.instagram.com/p/B6Paci2lmQR/?igshid=41mq2hzkcymv

#selfcare#imattertoo#littlethings#sheskates#iamshe#sk8life#sk8love#wheelsonthewood#ificanwalkicanskate#imsn

1 note

·

View note

Video

Light traffic play.... #imsn #shakeandbake #rollerskating #allamerican #hotskates (at HotSkates Rollerskating) https://www.instagram.com/p/B6NJfTxJ5Nv/?igshid=4ghvmgyaw2w1

1 note

·

View note

Photo

14 notes

·

View notes

Video

Credit to @skatelyfe_co : Scenes from Joi Loftons #sk8athon2018 🔥🔥 #SkateLyfe ____________ #Repost @sk8_vidzz 📽 ____________ #skate #rollerskate #atlanta #atl #rollbounce #imsn #skateparty #energy #sync #chitown (at St. Louis Lambert International Airport) https://www.instagram.com/p/BnjMJ8eHfT1/?utm_source=ig_tumblr_share&igshid=56421pz90cbu

#sk8athon2018#skatelyfe#repost#skate#rollerskate#atlanta#atl#rollbounce#imsn#skateparty#energy#sync#chitown

1 note

·

View note

Video

On the Money 😂😂😂 . #Repost @itsmyskatenight (@get_repost) ・・・ When you're deep in your practice session and a brownie skater interrupt your flow. Do you help? Answer in the comments below. #IMSN #itsmyskatenight #skatelife #rollerskating #skating #skatenight #skakefail #practice

2 notes

·

View notes