#micromechanical

Text

Indian college girl mms

conjunto casino samaritana del amor

freaky thick black girl

Desi girls masti

Bangladeshi Maid Hot Kissing and Sucking

Real Outdoor Anal Fucking With Sucking and Cum in Ass JessiJek

jewel shavinh small tits masterbation

Blonde teen fuck hd could enjoy their love with scorching passionate

European teen rims ass

I always wanted to fuck a real pale redhead

#remollify#unprotrudent#micromechanics#rebroadened#nondomesticating#magnisonant#asbolan#atrocoeruleus#over-all#bombinate#Kovrov#stiff-ironed#paraphragm#monogamistic#tsimmes#cresorcinol#komondoroc#Economite#embolite#tubercularising

0 notes

Text

1 note

·

View note

Photo

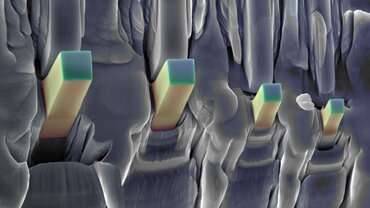

Smallest earthquakes ever detected in micron-scale metals

On the micrometer scale deformation properties of metals change profoundly: The smooth and continuous behavior of bulk materials often becomes jerky due to random strain bursts of various sizes. The reason for this phenomenon is the complex intermittent redistribution of lattice dislocations (which are line-like crystal defects responsible for the irreversible deformation of crystalline materials) due to external loading, which is also the cause of the formation of the uneven step-like surface upon deformation.

To study this phenomenon in more detail, research groups of the Eötvös Loránd University of Budapest, Charles University of Prague and École des Mines de Saint-Étienne have developed a highly sensitive micromechanical platform, where weak elastic waves emitted by the specimen can be detected during the deformation of micron-scale pillars. Compression experiments performed on such zinc single crystalline micropillars in a scanning electron microscope confirmed that these so-called acoustic signals indeed occur during strain bursts, so, this experiment allowed us, for the first time, to practically hear the "sound of dislocations."

The acoustic signals are sampled with a rate of 2.5 MHz; therefore, they provide extremely detailed information on the dynamics of dislocations. The in-depth statistical analyses performed by the researchers revealed that strain bursts exhibit a two-level structure: what has so far been seen as a single plastic slip is, in fact, a result of several correlated events on a μs-ms timescale.

Read more.

24 notes

·

View notes

Text

Mechanical characterization in composite materials - Part 1-1: Overview

Regarding composite materials, there are two different spectra, the micro and macro mechanics. The first one is focused on the determination and the analysis of the single laminate. Hence, it is part of the mechanical characterization that deals with the volume fractions of the matrix and fibers. In order to completely characterizes, in the micromechanical point of view, a material, it is…

View On WordPress

#composite#composite materials#composites#mechanica characterization#racing car chassis#racing car desing

0 notes

Quote

Optomechanics is the use of laser light to control the motion of mechanical vibrations, usually micrometre- or nanometre-scale resonators. As well as probing micromechanical motion, light can also remove energy from the system. In this way, an oscillator can reach the quantum limit with just one quantum of vibration energy, or phonon.

Optomechanics - Latest research and news | Nature

0 notes

Text

Pulmonary Gas Exchange

"Pulmonary Gas Exchange - MeSH - NCBI". www.ncbi.nlm.nih.gov. Retrieved 30 December 2022. "Alveoli". www.cancer.gov. 2 February 2011. Retrieved 22 July 2021. Knudsen, L; Ochs, M (December 2018). "The micromechanics of lung alveoli: structure and function of surfactant and tissue components". Histochemistry and Cell Biology. 150 (6): 661–676. doi:10.1007/s00418-018-1747-9. PMC6267411. PMID30390118. Jones, Jeremy. "Lung parenchyma | Radiology Reference Article | Radiopaedia.org". Radiopaedia. Retrieved 15 August 2021. Moore K (2018). Clinically oriented anatomy. Wolters Kluwer. p. 336. ISBN978-1-4963-4721-3. Hansen JE, Ampaya EP, Bryant GH, Navin JJ (June 1975). "Branching pattern of airways and air spaces of a single human terminal bronchiole". Journal of Applied Physiology. 38 (6): 983–9. doi:10.1152/jappl.1975.38.6.983. PMID1141138. Hogan CM (2011). "Respiration". In McGinley M, Cleveland CJ (eds.). Encyclopedia of Earth. Washington, D.C.:

0 notes

Text

Solving the Mystery of Retention in Dental Cementation

Dental cementation plays a crucial role in the longevity and success of dental restorations. However, it is not uncommon for dentists to encounter issues with retention, leading to the failure of restorations and dissatisfaction among patients. The mystery surrounding the factors that affect retention in dental cementation has been a topic of discussion and research for many years. From the type of cement used to the preparation of the tooth surface, there are various factors that can impact the retention of dental restorations. As dental professionals, it is our responsibility to fully understand and address these factors in order to provide the best possible outcomes for our patients. In this article, we will delve into the complexities of retention in dental cementation and explore the latest research and techniques for achieving optimal retention. By gaining a thorough understanding of this mystery, we can improve the success of our dental restorations and ultimately, the overall satisfaction of our patients.

Choosing the right dental cementation

When it comes to dental cementation, selecting the appropriate product is crucial to ensure optimal retention and long-term success of restorations. Various factors must be considered, such as the type of restoration, substrate material, and desired level of adhesion. One key aspect is the choice of dental impression material, as it provides the foundation for the cementation process. Additionally, specific dental cements like Maxcem Elite, RelyX Unicem, Fuji Cem II, and IRM Dental have their unique properties and indications, offering a range of options to suit different clinical scenarios. It is important for dental professionals to thoroughly evaluate each cement's characteristics, including its bond strength, ease of use, and compatibility with the restoration and substrate materials. By carefully selecting the appropriate dental cementation system, practitioners can ensure reliable retention and successful outcomes for their patients' dental restorations.

Key differences between popular cements

While there are various dental cements available in the market, it is important to understand the key differences between popular options such as maxcem elite, RelyX Unicem, Fuji Cem II, and IRM Dental. Maxcem Elite is a self-adhesive resin cement known for its ease of use and high bond strength to various substrates. RelyX Unicem, on the other hand, is a self-adhesive resin-modified glass ionomer cement, offering both adhesive and self-adhesive properties. Fuji Cem II is a resin-modified glass ionomer cement that provides excellent adhesion to tooth structure and metal restorations. Lastly, IRM Dental is a zinc oxide-eugenol cement commonly used for temporary restorations. Understanding the properties and indications of each cement is crucial in selecting the most appropriate option for specific clinical scenarios. Factors such as bond strength, compatibility with various materials, and ease of use should be considered to ensure optimal retention and long-term success of dental restorations.

The science behind retentive materials

When it comes to achieving strong retention in dental cementation, understanding the science behind retentive materials is essential. Dental impression materials play a crucial role in creating a reliable bond between the restoration and the tooth structure. The success of this bond is influenced by various factors, including the chemical composition of the cement, its ability to adapt to the tooth surface, and its interaction with the restoration material. In the case of self-adhesive resin cements like Maxcem Elite and relyx unicem, their unique formulations allow for both chemical adhesion and micromechanical retention, ensuring a durable bond. Resin-modified glass ionomer cements such as Fuji Cem II offer the advantage of fluoride release and chemical bonding to the tooth structure. On the other hand, zinc oxide-eugenol cements like IRM Dental provide temporary retention for provisional restorations. By understanding the properties and mechanisms of these retentive materials, dental professionals can make informed decisions to ensure long-term success in cementation procedures.

Factors to consider when selecting

When selecting a dental cementation material, there are several factors that need to be carefully considered in order to ensure optimal results. One of the primary considerations is the compatibility of the cement with the specific restoration material being used. Different cements may have varying chemical compositions and adhesive properties, making them more suitable for certain types of restorations. Additionally, the ability of the cement to adapt to the tooth surface is crucial for achieving proper retention. A irm dental cement that can effectively flow into the microstructure of the tooth, enhancing micromechanical retention, will contribute to a stronger bond. Furthermore, the long-term stability and durability of the cement should be evaluated, as some materials may exhibit higher resistance to degradation over time. Lastly, factors such as ease of handling, working time, and clinical preference should also be taken into account when selecting a dental cementation material. By carefully considering these factors, dental professionals can make informed decisions to ensure successful and long-lasting cementation.

Expert tips for successful cementation

To achieve successful cementation in dental procedures, it is essential to follow expert tips and utilize appropriate materials. Firstly, when selecting a dental impression material, it is crucial to choose one that provides accurate and detailed impressions to ensure proper fit and marginal adaptation of the restoration. Products like Maxcem Elite, RelyX Unicem, fuji cem ii, and IRM Dental are popular options known for their reliable performance. Secondly, proper preparation of the tooth surface is vital for achieving optimal retention. Thorough cleaning and removal of any debris or contaminants ensure a clean bonding surface. Additionally, using adhesive systems compatible with the chosen cement can significantly enhance the bond strength and longevity of the restoration. Lastly, following the manufacturer's instructions, including the recommended mixing ratios and application techniques, will help ensure consistent and reliable results. By incorporating these expert tips and utilizing high-quality materials, dental professionals can improve the success and longevity of cemented restorations.

Conclusion

In conclusion, understanding the factors that contribute to successful retention in dental cementation is crucial for dental professionals. By implementing proper techniques and materials, while also considering individual patient factors, we can improve the long-term success of dental restorations. As new research and advancements continue to emerge, it is important for dental professionals to stay updated and informed in order to provide the best possible care for their patients. Let us continue to work towards solving the mystery of retention in dental cementation and strive for successful and long-lasting restorations. You may learn more at www.dentalfinds.com.

0 notes

Link

0 notes

Text

Global MEMS Market Is Estimated To Witness High Growth Owing To Increasing Demand

The global MEMS market is estimated to be valued at USD 23,858 million in 2021 and is expected to exhibit a CAGR of 8.23% over the forecast period 2022-2030, as highlighted in a new report published by Coherent Market Insights.

A) Market Overview:

Microelectromechanical Systems (MEMS) are miniaturized mechanical and electromechanical devices that are integrated with semiconductor elements. These systems combine microelectronics, micromechanics, and microsensors to create smart systems that can sense, control, and actuate on the microscale. MEMS find applications in various industries such as automotive, consumer electronics, healthcare, aerospace, and telecommunications.

The need for MEMS products arises from their advantages such as small size, low power consumption, high reliability, high sensitivity, and integration capability. These systems enable the miniaturization of devices while providing enhanced performance. MEMS sensors and actuators are crucial components in devices or systems that require sensing or motion control. With advancements in technology and increasing demand for compact and efficient devices, the market for MEMS is witnessing significant growth.

B) Market Key Trends:

One key trend in the MEMS market is the growing demand for MEMS in the automotive industry. MEMS sensors play a vital role in advanced driver assistance systems (ADAS) and autonomous vehicles. These sensors provide crucial data for safety features such as airbags, stability control, tire pressure monitoring, and collision avoidance systems. They are also used in engine management systems for monitoring air-fuel ratios and exhaust gas recirculation. The increasing adoption of ADAS and the development of autonomous vehicles are driving the demand for MEMS in the automotive sector.

C) PEST Analysis:

Political: The political factors influencing the MEMS market include government regulations and policies regarding the use of advanced technologies in different industries. For example, regulations concerning automobile safety and emissions control drive the adoption of MEMS sensors in the automotive sector.

Economic: The economic factors influencing the MEMS market include GDP growth, disposable income, and consumer spending. Rising disposable income and increasing consumer preference for smart and connected devices are driving the demand for MEMS in consumer electronics.

Social: The social factors influencing the MEMS market include changing consumer preferences, lifestyles, and demographics. The growing popularity of wearable devices and the increasing focus on health and fitness monitoring among consumers are creating opportunities for MEMS in the healthcare sector.

Technological: The technological factors influencing the MEMS market include advancements in semiconductor technology, nanotechnology, and material science. Continuous research and development efforts are leading to the development of smaller, more efficient, and cost-effective MEMS devices.

D) Key Takeaways:

1: The global Microelectromechanical Systems (MEMS) Market Growth is expected to witness high growth, exhibiting a CAGR of 8.23% over the forecast period, due to increasing demand for compact and efficient devices. The miniaturization trend in various industries and the need for smart systems with enhanced performance are driving market growth.

2: In terms of regional analysis, North America is expected to be the fastest-growing and dominating region in the MEMS market. The presence of major automotive and consumer electronics manufacturers in this region, along with continuous technological advancements, is driving market growth.

3: Key players operating in the global MEMS market are NXP Semiconductors N.V., Analog Devices, Inc., and Knowles Corporation. These companies focus on strategic collaborations, product innovations, and investments in research and development to strengthen their market position.

#Semiconductors#ICT Industry#Microelectromechanical Systems (MEMS)#Microelectromechanical Systems (MEMS) Market

0 notes

Text

Pierhor-Gasser is mainly active in the watchmaking field. Our expertise is available in other industrial fields such as medical, electronics and micromechanics. We supply various synthetic ruby ball bearings for watchmaking and medical industries.

0 notes

Text

Specialized medical statement regarding tailored nutritional formulation on infection catalog, immune reputation along with gastrointestinal building up a tolerance inside people along with serious head injury.

Dilatation sizes, polarization microscopy, micromechanical data and also X-ray period analysis are employed to underpin in conclusion that this observed supple results are certainly not due to stage changes on it's own, but you are put together effects of period shifts as well as microcrack opening up along with part drawing a line under. (H) 2014 Elsevier Limited and also Techna Group Azines.ur.l. Almost all protection under the law set aside.To be able to improve the floor property involving Konjac glucomannan (KGM) film, the particular nitrogen plasma tv's changes was carried out using order shot device. The top atomic structure ended up being looked at by simply X-ray photoelectron spectroscopy analysis subsequently. It turned out observed the atomic awareness proportion of wO/wC elevated making use of https://www.selleckchem.com/products/ml-7.html lcd therapy. The particular molecular string degraded as well as acetyl was partially removed. Hydroxyl had been in part substituted with principal amide party. Technology of latest features teams proposed in which lcd treatment could be a powerful methods to modify the physical residence associated with KGM motion picture. (C) Next year Elsevier Limited. Almost all rights set-aside.The optic lack of feeling is often a bunch of materials and axons predicting through specialised retinal neurons, the actual retinal ganglion tissues (RGCs), which make synaptic contacts on the visual cortex. Glaucoma is a long-term along with progressive degenerative neuropathy of the optic nerve using death regarding RGCs, and is also a respected cause of permanent loss of sight. A threat element pertaining to glaucoma can be higher intraocular pressure (IOP). However, the etiology involving glaucoma is actually not known and it's also probably multifactorial, along with upregulation associated with neurotoxic factors will be suggested as a factor. Glaucoma is frequently separate from higher IOP (at the.gary., normal-tension glaucoma), and also disease development can be independent of constant high IOP. At present, the only medicinal treatment options authorized with regard to glaucoma tend to be IOP-lowering drug treatments, that hold off illness further advancement. Optic lack of feeling neuropathy, getting thinner with the neurological dietary fiber coating, weakening of the axons, as well as final dying with the RGCs carry on. In the past several years, fresh healing techniques have advanced to cope with the actual intricate and also multifactorial etiology with this condition. Two approaches will be the rescue associated with RGCs coming from loss of life by utilizing neuroprotection, as well as the prevention of RGC demise by lessening neurotoxicity. This kind of evaluation brings awareness of the chance of neuro security throughout glaucoma, particularly centering on growth factors named neurotrophins and their receptors.Identified codon use differs the two between microorganisms using one of body's genes in a genome, and arises due to variations in Grams + H written content, replication strand alter, as well as gene term quantities. Distance learning analysis (California) is actually popular to recognize significant options for variation within synonymous codon use between genetics and offers a way to recognize side to side transferred or very depicted genetics.

0 notes

Text

Optimum measure as well as time period of enteral erythromycin like a prokinetic: A surgical extensive attention experience.

In this cardstock, any micromechanical model with regard to looking into initial and closing failing surface of fiber-rein-forced composites laminate floors is established. Your Generic Approach to Tissue, which properly states the actual winter strains relation to stress-strain behaviours of fiber-reinforced composites, will be coupled with Von-Mises produce qualification to describe nonlinear stress-strain behaviours involving hybrids laminate floors. The actual Tsai-Hill criterion can be incorporated into the particular model for predicting malfunction strength regarding lamina as well as typical wood flooring within uniaxial pressure and also biaxial loading, respectively. The particular precise models according to a micromechanical approach are executed to examine the end results of cold weather residual stresses in preliminary as well as last failure strength. Outcomes revealed that energy left over stresses affect on failing energy of the https://www.selleckchem.com/screening/anti-cancer-compound-library.html UD lamina can be carefully influenced by fiber off-axis perspectives. Your contribution involving cold weather left over challenges from the closing malfunction surface of [0 degrees/+/- 25 degrees/90 degrees](Two) laminate flooring as well as [90 degrees/+/- Forty five degrees/0 degrees](Two) laminate flooring might be overlooked. The results within longitudinal pertaining to lamina and also biaxial tensile loadings with regard to [90 degrees/+/- Forty five degrees/0 degrees](2) laminate flooring display good arrangement with all the new information. (D) 20-15 Elsevier Limited. Most protection under the law set aside.Regardless of whether in addition antigen-experienced CD4(+) Big t mobile or portable numbers undertake modulations upon dental antigen customer base promoting systemic unresponsiveness remains not really entirely understood. Utilizing an adoptive shift style along with hen ovalbumin (Chicken eggs)-specific Capital t cellular material, all of us indicated that overall quantities of shifted former mate vivo-isolated CD4(+) memory Capital t cells as well as in vitro-polarized Capital t(they would)A single cellular material drastically decrease within just spleen along with liver on recurring Ovum eating. As a result, these kind of rats did not support a new delayed-type sensitivity effect following Offspring concern. OVA-specific Big t()A single cellular material re-isolated through the lean meats revealed increased signs of apoptosis. Nonetheless, there was no data which shifted effector or memory space T cellular material purchased a new regulation phenotype, started to be anergic as well as underwent immune deviation. Our data claim that common antigen program doesn't stimulate adjustments to the phenotype regarding CD4(+) effector and storage T cellular material. Rather, deletion of antigen-experienced CD4(+) Capital t tissues preferentially within the hard working liver might be a significant system leading to antigen-specific wide spread unresponsiveness after oral antigen subscriber base.Framework: The actual periods with the the menopause cross over are seen as changes in ovarian bodily hormones and also elevated heart disease (CVD) risk factors and also vasomotor signs and symptoms that will adversely affect vascular health. Objective: We tested the particular hypothesis that will endothelial operate, any forecaster associated with CVD, would be decreased over the phases from the change of life move, separate from CVD risks along with vasomotor symptoms.

#GW4064#STO-609#WNK463#NSC697923#GSK2256098#GSK1838705A#EPZ005687#Eflornithine#MMAF#Telratolimod#Cerdulatinib#LY3009120#SCH-442416#Lomitapide#WZB117#Dutasteride#Selitrectinib#Zosuquidar#UNC1999#Tiplaxtinin#Odanacatib#Brusatol#Montelukast#Selumetinib#SGI-1776#T0901317#E6446#Melphalan#MLN2480#LY3298176

1 note

·

View note

Photo

Across time and space, a new kind of spacecraft is relentlessly exploring the watchmaking galaxy on the lookout for new unique expressions of the watchmaker’s art… Contemporary timepieces designed by HYT, exclusive owners of mecafluid technology, the symbiotic marriage of science and micromechanics, are propelling the creativity of fine watchmaking into a new universe. Transforming usual perceptions, HYT develops extraordinary measurement instruments. With HYT, preparations are on for the future and watchmaking has begun its transformation. Get on board now for a new voyage: Mission Hastroid Cosmic Hunter Mission objective: Show the Hastroid‘s beams Flight plan: Launch and orbit on 22 November 2022. Instrument: HYT Hastroid Cosmic Hunter. https://www.instagram.com/p/Cln9CYDr3Xo/?igshid=NGJjMDIxMWI=

1 note

·

View note

Text

How to get into watch making

THERE ARE ONLY 2 WAYS TO GET INTO WATCHMAKING

There are only two ways to get into watchmaking. Apprenticeship or Watchmaking School. Both of which are fine. If I had to choose though, I would go with an Apprenticeship. However, the chances of apprenticeship in today's day and age are extremely hard but definitely doable.

1. APPRENTICESHIP

1 on 1 training is the best form of learning in any endeavor. If you can ever learn anything on a 1-on-1 level, you will speed up the process and cut off years from your learning curve

Personalized and straight to the point. I've learned things during my apprenticeship that took several hours to a day meanwhile I've also attended courses that took a whole 5 days to get the same points across. It's a very hands-on approach in the sense that the watchmaker you're learning from will teach and personalize the issues to you.

There's a heavy emphasis on apprenticeships to just do. It's akin to being street smart vs book smart. Apprenticeships will often focus on you being able to get the job done versus in a school setting where you need to thoroughly understand all the levels via written and theoretical aspects.

Apprenticeship was really how watchmaking was originally taught back in the olden days. Watchmaking was taught to close friends, family, and relatives. There wasn't a certifying body to declare that you were a "watchmaker". Your results spoke for themselves. It was only when the industry needed more watchmakers that certifying bodies had to be created to facilitate qualified watchmakers.

Often deals with common repair aspects you'll come across in watchmaking vs the micromechanics and lathe work you may seldom come across. You'll do more battery and strap changes, and common overhauls rather than creating a barrel bushing with a lathe.

Quick ROI. You'll find that the stuff you learn is extremely applicable in every day repairs. Try This will mean more profits on the front end because you're able to repair common things.

Extremely hard to find a watchmaker today to agree to an apprenticeship.

No income. You will not get paid to apprentice. You will actually have to find another job to pay the bills if you decide to apprentice full-time. Part-time apprenticing is your best bet.

One of the issues I have with the apprenticeship is that you're tied to the watchmaker teaching you the skills. There's no quality assurance that the technique and skill they're teaching you are up to industry standards. As you get deeper into the field, you'll find that the industry is plagued with old-school watchmakers who refuse to get updated training.

2. WATCHMAKING SCHOOL

Group setting with fellow aspiring watchmakers will usually help you in the grand scheme of things.

Lots of theoretical and hands-on work. I like to think that Watchmaking school is more of a complete learning experience. You'll understand the underlying reasons why certain things work and that's extremely important the deeper you get into watchmaking. Extremely structured and organized.

Watchmaking school will teach you updated industry standards so you won't have to worry about the latest techniques for a good deal of time.

Controlled and contained environment. You're taught in a controlled situation. The tests, practices, and environment are all manufactured to teach you one set of objectives. You'll find that in a real world setting, you'll be dealing with 3-4 sets of problems at the same time. It will never be as pretty and easy as it is in watchmaking school. I go through a great deal trying to explain this on my Instagram and have since received messages from watchmaking schools trying to incorporate more real-world scenarios.

Watchmaking school can definitely help you network and get future jobs, prospects, and open doors. Often times watchmaking school instructors are in contact with industry professionals. It could be shop supervisors, brand technical trainers, jewelers, and other watchmakers. Their contacts are invaluable to you as a student.

You're tied to the group's learning pace in a classroom setting. So if the instructor is teaching the group and you pick up on something right away, you may find yourself doing it until the whole class understands it. Or the complete opposite. If the whole group picks something up and you're the only one who doesn't understand it, you may find that in a group setting you're reluctant to let the instructor know about your inefficiencies.

Hard to get into watchmaking school. There are only 3 in the USA and a handful across the world.

Expect to travel. Depending on where you live, you may find that you will have to travel to the school of choice. This may mean out of the town, city, state, or even country. If you have kids, spouse, family, etc. it could be costly to uproot your whole life.

Expensive. Watchmaking school isn't cheap. Factor in the tuition, watchmaking tools, cost of living, rent, food, transportation, etc. you'll find that watchmaking school isn't cheap. You also have to keep in mind that you might need a part-time job to pay for all the bills.

Watchmaking school can vary in terms of time. The average time is about 2-4 years.

Watchmaking school will teach you about 60% of the fundamental stuff you'll need as a watchmaker. You'll need another 5-10 years of on-the-job training for 35% of the stuff watchmaking school doesn't teach you. Just to put things in perspective, some of the best watchmakers I know in the world haven't even completed the last 5% of the puzzle and neither have I. Herein lies one of the beauties of watchmaking. You will never complete the puzzle.

0 notes

Text

How to get into watch making

THERE ARE ONLY 2 WAYS TO GET INTO WATCHMAKING

There are only two ways to get into watchmaking. Apprenticeship or Watchmaking School. Both of which are fine. If I had to choose though, I would go with an Apprenticeship. However, the chances of apprenticeship in today's day and age are extremely hard but definitely doable.

1. APPRENTICESHIP

1 on 1 training is the best form of learning in any endeavor. If you can ever learn anything on a 1-on-1 level, you will speed up the process and cut off years from your learning curve

Personalized and straight to the point. I've learned things during my apprenticeship that took several hours to a day meanwhile I've also attended courses that took a whole 5 days to get the same points across. I Found This Interesting 's a very hands-on approach in the sense that the watchmaker you're learning from will teach and personalize the issues to you.

There's a heavy emphasis on apprenticeships to just do. It's akin to being street smart vs book smart. Apprenticeships will often focus on you being able to get the job done versus in a school setting where you need to thoroughly understand all the levels via written and theoretical aspects.

Apprenticeship was really how watchmaking was originally taught back in the olden days. Watchmaking was taught to close friends, family, and relatives. There wasn't a certifying body to declare that you were a "watchmaker". Your results spoke for themselves. It was only when the industry needed more watchmakers that certifying bodies had to be created to facilitate qualified watchmakers.

Often deals with common repair aspects you'll come across in watchmaking vs the micromechanics and lathe work you may seldom come across. You'll do more battery and strap changes, and common overhauls rather than creating a barrel bushing with a lathe.

Quick ROI. You'll find that the stuff you learn is extremely applicable in every day repairs. This will mean more profits on the front end because you're able to repair common things.

Extremely hard to find a watchmaker today to agree to an apprenticeship.

No income. You will not get paid to apprentice. You will actually have to find another job to pay the bills if you decide to apprentice full-time. Part-time apprenticing is your best bet.

One of the issues I have with the apprenticeship is that you're tied to the watchmaker teaching you the skills. There's no quality assurance that the technique and skill they're teaching you are up to industry standards. As you get deeper into the field, you'll find that the industry is plagued with old-school watchmakers who refuse to get updated training.

2. WATCHMAKING SCHOOL

Group setting with fellow aspiring watchmakers will usually help you in the grand scheme of things.

Lots of theoretical and hands-on work. I like to think that Watchmaking school is more of a complete learning experience. You'll understand the underlying reasons why certain things work and that's extremely important the deeper you get into watchmaking. Extremely structured and organized.

Watchmaking school will teach you updated industry standards so you won't have to worry about the latest techniques for a good deal of time.

Controlled and contained environment. You're taught in a controlled situation. The tests, practices, and environment are all manufactured to teach you one set of objectives. You'll find that in a real world setting, you'll be dealing with 3-4 sets of problems at the same time. It will never be as pretty and easy as it is in watchmaking school. I go through a great deal trying to explain this on my Instagram and have since received messages from watchmaking schools trying to incorporate more real-world scenarios.

Watchmaking school can definitely help you network and get future jobs, prospects, and open doors. Often times watchmaking school instructors are in contact with industry professionals. It could be shop supervisors, brand technical trainers, jewelers, and other watchmakers. Their contacts are invaluable to you as a student.

You're tied to the group's learning pace in a classroom setting. So if the instructor is teaching the group and you pick up on something right away, you may find yourself doing it until the whole class understands it. Or the complete opposite. If the whole group picks something up and you're the only one who doesn't understand it, you may find that in a group setting you're reluctant to let the instructor know about your inefficiencies.

Hard to get into watchmaking school. There are only 3 in the USA and a handful across the world.

Expect to travel. Depending on where you live, you may find that you will have to travel to the school of choice. This may mean out of the town, city, state, or even country. If you have kids, spouse, family, etc. it could be costly to uproot your whole life.

Expensive. Watchmaking school isn't cheap. Factor in the tuition, watchmaking tools, cost of living, rent, food, transportation, etc. you'll find that watchmaking school isn't cheap. You also have to keep in mind that you might need a part-time job to pay for all the bills.

Watchmaking school can vary in terms of time. The average time is about 2-4 years.

Watchmaking school will teach you about 60% of the fundamental stuff you'll need as a watchmaker. You'll need another 5-10 years of on-the-job training for 35% of the stuff watchmaking school doesn't teach you. Just to put things in perspective, some of the best watchmakers I know in the world haven't even completed the last 5% of the puzzle and neither have I. Herein lies one of the beauties of watchmaking. You will never complete the puzzle.

0 notes

Text

How to get into watch making

THERE ARE ONLY 2 WAYS TO GET INTO WATCHMAKING

There are only two ways to get into watchmaking. Apprenticeship or Watchmaking School. Both of which are fine. If I had to choose though, I would go with an Apprenticeship. However, the chances of apprenticeship in today's day and age are extremely hard but definitely doable.

1. APPRENTICESHIP

1 on 1 training is the best form of learning in any endeavor. If you can ever learn anything on a 1-on-1 level, you will speed up the process and cut off years from your learning curve

Personalized and straight to the point. I've learned things during my apprenticeship that took several hours to a day meanwhile I've also attended courses that took a whole 5 days to get the same points across. It's a very hands-on approach in the sense that the watchmaker you're learning from will teach and personalize the issues to you.

There's a heavy emphasis on apprenticeships to just do. It's akin to being street smart vs book smart. Apprenticeships will often focus on you being able to get the job done versus in a school setting where you need to thoroughly understand all the levels via written and theoretical aspects.

Apprenticeship was really how watchmaking was originally taught back in the olden days. Watchmaking was taught to close friends, family, and relatives. There wasn't a certifying body to declare that you were a "watchmaker". home kartz watch making kit spoke for themselves. It was only when the industry needed more watchmakers that certifying bodies had to be created to facilitate qualified watchmakers.

Often deals with common repair aspects you'll come across in watchmaking vs the micromechanics and lathe work you may seldom come across. You'll do more battery and strap changes, and common overhauls rather than creating a barrel bushing with a lathe.

Quick ROI. You'll find that the stuff you learn is extremely applicable in every day repairs. This will mean more profits on the front end because you're able to repair common things.

Extremely hard to find a watchmaker today to agree to an apprenticeship.

No income. You will not get paid to apprentice. You will actually have to find another job to pay the bills if you decide to apprentice full-time. Part-time apprenticing is your best bet.

One of the issues I have with the apprenticeship is that you're tied to the watchmaker teaching you the skills. There's no quality assurance that the technique and skill they're teaching you are up to industry standards. As you get deeper into the field, you'll find that the industry is plagued with old-school watchmakers who refuse to get updated training.

2. WATCHMAKING SCHOOL

Group setting with fellow aspiring watchmakers will usually help you in the grand scheme of things.

Lots of theoretical and hands-on work. I like to think that Watchmaking school is more of a complete learning experience. You'll understand the underlying reasons why certain things work and that's extremely important the deeper you get into watchmaking. Extremely structured and organized.

Watchmaking school will teach you updated industry standards so you won't have to worry about the latest techniques for a good deal of time.

Controlled and contained environment. You're taught in a controlled situation. The tests, practices, and environment are all manufactured to teach you one set of objectives. You'll find that in a real world setting, you'll be dealing with 3-4 sets of problems at the same time. It will never be as pretty and easy as it is in watchmaking school. I go through a great deal trying to explain this on my Instagram and have since received messages from watchmaking schools trying to incorporate more real-world scenarios.

Watchmaking school can definitely help you network and get future jobs, prospects, and open doors. Often times watchmaking school instructors are in contact with industry professionals. It could be shop supervisors, brand technical trainers, jewelers, and other watchmakers. Their contacts are invaluable to you as a student.

You're tied to the group's learning pace in a classroom setting. So if the instructor is teaching the group and you pick up on something right away, you may find yourself doing it until the whole class understands it. Or the complete opposite. If the whole group picks something up and you're the only one who doesn't understand it, you may find that in a group setting you're reluctant to let the instructor know about your inefficiencies.

Hard to get into watchmaking school. There are only 3 in the USA and a handful across the world.

Expect to travel. Depending on where you live, you may find that you will have to travel to the school of choice. This may mean out of the town, city, state, or even country. If you have kids, spouse, family, etc. it could be costly to uproot your whole life.

Expensive. Watchmaking school isn't cheap. Factor in the tuition, watchmaking tools, cost of living, rent, food, transportation, etc. you'll find that watchmaking school isn't cheap. You also have to keep in mind that you might need a part-time job to pay for all the bills.

Watchmaking school can vary in terms of time. The average time is about 2-4 years.

Watchmaking school will teach you about 60% of the fundamental stuff you'll need as a watchmaker. You'll need another 5-10 years of on-the-job training for 35% of the stuff watchmaking school doesn't teach you. Just to put things in perspective, some of the best watchmakers I know in the world haven't even completed the last 5% of the puzzle and neither have I. Herein lies one of the beauties of watchmaking. You will never complete the puzzle.

0 notes