#pharmaceutical technology

Text

lab prep with my friend ✨

#studyblr#productivity#studying#inspiration#studying together#lap prep#lab work#pharmaceutical technology#university#studyspo#aesthetic#pharmblr#pharma school#lions post

685 notes

·

View notes

Text

Diffusion is the process by which individual molecules of a substance move from an area of high concentration to an area of low concentration due to random molecular motion, driven by a concentration gradient.

Diffusion holds significant importance in pharmaceutical operations. Additionally, it serves as a crucial component in a wide range of applications. These include aiding drug release from various delivery systems, facilitating drug absorption and elimination processes within the body. Furthermore, diffusion plays an essential role in procedures like dialysis, osmosis, and ultrafiltration, which are indispensable in medical treatments and research.

Full article:

2 notes

·

View notes

Text

Today I did my project and went to deliver some papers to my college.

I never realized I missed walking there on the mornings

#messy academia#student#studyblr#studyspo#pharmacy#study aesthetic#the latinamerican college experience#pharmaceutical technology

10 notes

·

View notes

Text

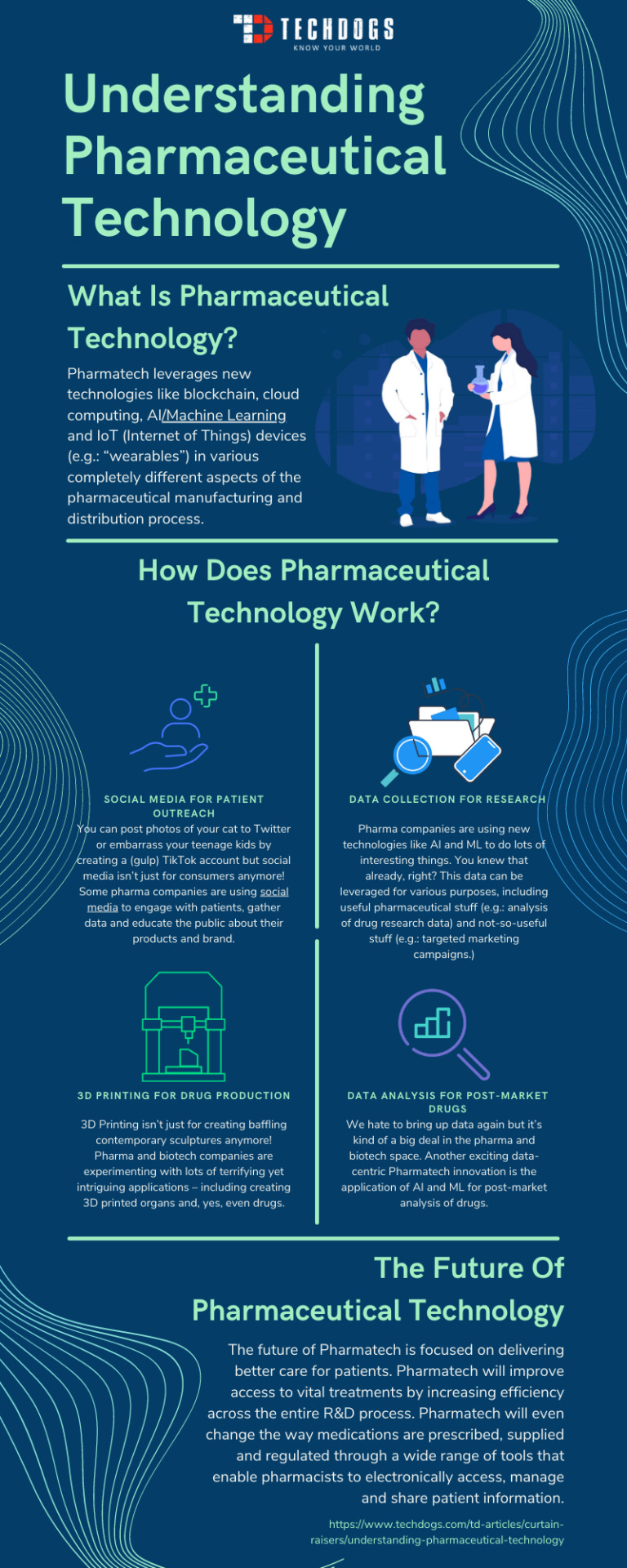

Understanding Pharmaceutical Technology

Pharmaceutical Technology (Pharmatech for short) is changing the pharmaceutical industry. Jump down the rabbit hole with us to learn what Pharmatech is and how new technology is streamlining and modernizing the way pharma companies are making new treatments and remedies. Let’s go!

0 notes

Text

The chemical industry relies on catalysts for over 90 percent of its processes and nearly all these catalysts consist of nanoparticles dispersed on top of a substrate. Researchers have long suspected that the size of individual nanoparticles and the distance between them play important roles in the speed of, and the products produced in the catalytic reaction, but because nanoparticles are prone to moving around and agglomerating during catalysis, it’s been difficult to study exactly how.

6 notes

·

View notes

Text

We’re talking about a woman who can’t stop being a brat and gave me MDMA then put on Grimes and went to college for engineering rockets btw

#context: I accidentally sprayed myself in the face. she said she’d give me permission to spray her with a hose in this weather#I said I would do it without asking permission anyway#and that is how we flirt#anyway if you think ur the same as my genius gf with more knowledge in science+math+philosophy than most people could accumulate…hm#+pharmaceuticals+technology/coding+….like the autism and homeschool personality in my gf is quite impressive#+history jfc i can’t beat her with info other than shit that’s so interesting that she didn’t know but makes sense#until we get to animals and general media and shit that always surprises me#such a narc that I’m dating someone that I know is way smarter than me woahhhhhhjajkaizjja#also older. I’ve never dated anyone younger than me. the closest was someone who I think is 4 years older#if I was basing my relationship on my ego it wouldn’t have started❤️

3 notes

·

View notes

Text

Exploring Advanced Pharmaceutical Equipment: Plethysmometer and Fluid Bed Processor

In the manufacturing of pharmaceuticals, efficiency and precision are critical. As technology advances, so too do the tools and equipment utilized in the production process. Two such innovations that have revolutionized pharmaceutical manufacturing are the plethysmometer and the fluid bed processor. Let's delve into what these instruments entail and their significance in the pharmaceutical industry.

Plethysmometer:

A plethysmometer is an advanced device that measures changes in organ volume, usually in the lungs and blood arteries, and is used in pharmacology and respiratory research. This apparatus is essential for assessing respiratory function, especially in animal model preclinical investigations. Researchers can evaluate characteristics like lung compliance, airway resistance, and pulmonary edema by accurately measuring changes in volume. This knowledge can help develop new treatments for respiratory conditions like asthma, chronic obstructive pulmonary disease (COPD), and pulmonary fibrosis.

Fluid Bed Processor:

The fluid bed processor is a versatile equipment widely employed in the pharmaceutical industry for various purposes, including drying, granulation, coating, and particle size reduction. It operates on the principle of fluidization, where solid particles are suspended and fluidized by hot air or gas, facilitating efficient heat and mass transfer. This results in uniform drying or coating of particles, making it an ideal choice for processing sensitive pharmaceutical ingredients.

Fluid Bed Processor for Granulation:

Granulation is a crucial step in pharmaceutical tablet manufacturing, where fine powder particles are agglomerated into granules to improve flow properties, compressibility, and content uniformity. The fluid bed processor for granulation offers several advantages over traditional granulation methods, such as wet granulation. It enables precise control over particle size distribution, enhances the uniformity of the final product, reduces processing time, and allows for solvent-free processing, making it environmentally friendly.

In conclusion, the plethysmometer and fluid bed processor represent cutting-edge technologies that have revolutionized respiratory research and pharmaceutical manufacturing, respectively. Their precision, efficiency, and versatility make them indispensable tools in advancing drug development and improving healthcare outcomes.

0 notes

Link

#market research future#cleanroom technology market#clean room infrastructure#pharmaceutical clean room#standard/drywall cleanrooms

0 notes

Text

DAILY DOSE: Global Coral Bleaching Crisis Now Fourth Event; Brexit Exacerbates UK's Growing Drug Shortages.

NOAA REPORTS FOURTH GLOBAL CORAL BLEACHING CRISIS BEGINS.

The National Oceanic and Atmospheric Administration’s (NOAA) Coral Reef Watch has announced the onset of the fourth global coral bleaching event, signaling a dire phase for the world’s corals and the communities dependent on them. Triggered by a consecutive ten-month streak of record-breaking global air temperatures in 2024, ocean…

View On WordPress

#Africa#artificial intelligence#Asia#Australia#climate change#coral reefs#deep fakes#environment#Europe#evolution#Featured#geology#meteorology#North America#pharmaceutical industry#South America#sustainability#technology

0 notes

Text

Powder compression, the primary technique for tablets manufacturing, involves applying pressure to force particles together in a confined space, creating a porous, solid specimen with defined geometry. This process occurs within a die using upper and lower punches to apply compressive force, resulting in a reduction in volume and the formation of bonds between particles. As a result, a compact, coherent tablet is produced.

The article:

#tablet manufacturing#manufacturer#industrial#pharmaceutical technology#pharmaceutical#pharmacy#physics#chemistry#biopharmaceuticals

1 note

·

View note

Text

Published in Nature Photonics, the UCLA study describes the new focal-plane array, which involves fitting 283,500 nanoantennas in a space smaller than the size of a typical sesame seed. The array is capable of providing spatial amplitude and phase distributions, as well as an imaged object’s temporal and spectral data directly, thereby bypassing the need for raster scanning. The team also utilized a machine learning-trained neural network to enhance the resolution of the captured images in real time.

3 notes

·

View notes

Text

Advancing Research and Production: Rapid Dryer, Spheronizer, and Watermaze

In the realms of research and manufacturing, innovation is key to achieving breakthroughs and enhancing efficiency. Three essential tools that have revolutionized their respective fields are the Rapid Dryer, Spheronizer, and Watermaze. Let's explore how these instruments have contributed to progress and success in their domains.

Rapid Dryer: Streamlining Drying Processes for Improved Efficiency

The Rapid Dryer represents a crucial component in industrial processes where quick and efficient drying is essential. This versatile equipment utilizes advanced drying techniques to rapidly remove moisture from various substances, including powders, granules, and liquids. Its high-speed drying capabilities make it invaluable in sectors such as pharmaceuticals, chemicals, and food processing.

With the Rapid Dryer, manufacturers can significantly reduce drying times, thereby enhancing productivity and minimizing energy consumption. The precise control over drying parameters ensures uniform drying and preserves the quality of the final product. Additionally, the compact design and user-friendly interface of Rapid Dryer make it a preferred choice for facilities aiming to optimize their drying processes.

Spheronizer: Shaping the Future of Granulation

The Spheronizer stands as a cornerstone in pharmaceutical manufacturing for its ability to transform irregularly shaped granules into spherical particles with uniform size and density. This innovative equipment employs a unique extrusion and spheronization process to produce uniform spheres, ideal for use in tablets, capsules, and pellets. Its versatility and precision make it indispensable for achieving consistent product quality and performance.

Pharmaceutical manufacturers rely on the Spheronizer to enhance the flow properties and compressibility of granules, thereby improving the manufacturability and dissolution characteristics of oral dosage forms. The ability to customize spheronization parameters allows for the optimization of granule properties, leading to increased process efficiency and cost-effectiveness.

Watermaze: Unlocking Insights into Cognitive Function

The Watermaze, also known as the Morris Water Maze, stands at the forefront of behavioral neuroscience research for its ability to assess spatial learning and memory in experimental animals. This versatile apparatus consists of a large pool of opaque water, wherein animals navigate to a hidden platform using spatial cues. The Watermaze provides researchers with valuable insights into cognitive processes and neurological disorders.

By utilizing the Watermaze, researchers can study various aspects of learning and memory, including spatial navigation, spatial memory, and cognitive flexibility. Its flexibility and reliability make it an indispensable tool for investigating the underlying mechanisms of cognitive function and developing potential interventions for neurological disorders such as Alzheimer's disease.

0 notes

Link

#market research future#cleanroom technology market#clean room infrastructure#pharmaceutical clean room#standard/drywall cleanrooms

0 notes

Text

https://www.onfeetnation.com/profiles/blogs/pharmaceuticals-and-food-anti-counterfeiting-technologies-market

Pharmaceuticals and Food Anti-Counterfeiting Technologies Market Size, Overview, Share and Forecast 2031

#Pharmaceuticals and Food Anti-Counterfeiting Technologies Market#Pharmaceuticals and Food Anti-Counterfeiting Technologies Market Scope#Pharmaceuticals and Food Anti-Counterfeiting Technologies Market Size

0 notes