#typical annealed

Text

Amplifying Revolution: The Polymerase Chain Reaction (PCR)

Imagine a scenario where you have a crucial document, but there's only one fragile copy. You need numerous duplicates to analyze and share. This is exactly the challenge faced by scientists dealing with DNA. Thankfully, a revolutionary technique called Polymerase Chain Reaction (PCR) comes to the rescue. PCR, often referred to as molecular photocopying, is a fundamental tool in molecular biology. It allows scientists to exponentially amplify a specific DNA segment, creating millions of copies from a minuscule sample. This has revolutionized various fields, from diagnosing diseases to unraveling genetic mysteries.

The credit for inventing PCR is widely attributed to Kary Mullis, a biochemist working at Cetus Corporation in the early 1980s. Inspired by his nighttime drives through California, Mullis envisioned a method for exponentially copying DNA segments through repeated cycles of heating, annealing (primer attachment), and extension (polymerase-mediated DNA synthesis). This elegant concept became the foundation of PCR. Mullis's concept was brilliant, but a crucial hurdle remained. The process required a DNA polymerase enzyme that could withstand repeated heating and cooling cycles. The solution came from an unexpected source: hot springs. In 1976, researchers discovered Taq polymerase, a heat-stable enzyme isolated from the thermophilic bacterium Thermus aquaticus. This discovery was a game-changer, as Taq polymerase could function optimally during the high-temperature steps of PCR. In recognition of its transformative impact on science, Kary Mullis was awarded the Nobel Prize in Chemistry in 1993, alongside Michael Smith, who pioneered site-directed mutagenesis.

While the core concept of PCR was established, the technique required further refinement. Pioneering researchers like Henry Erlich at Cetus played a vital role in optimizing reaction conditions, automating the process, and developing the now-ubiquitous thermal cyclers that precisely control the temperature changes needed for PCR. The 1980s and 1990s witnessed a surge in PCR applications. In 1985, PCR was used for the first time to analyze sickle cell anemia, demonstrating its potential for clinical diagnostics. Forensic science embraced PCR in 1987, with the successful amplification of DNA from a single human hair. By 1989, highly sensitive DNA fingerprinting techniques based on PCR became a game-changer in criminal investigations.

At the heart of PCR lies a clever exploitation of the natural process of DNA replication. The key players in this drama are:

Template DNA: The DNA sequence that contains the target region to be amplified

Primers: Short sequences of nucleotides that flank the target DNA region and serve as starting points for DNA synthesis.

DNA Polymerase: Enzyme responsible for synthesizing new DNA strands by extending the primers using nucleotides.

Nucleotides: The building blocks of DNA, including adenine (A), thymine (T), cytosine (C), and guanine (G).

Buffer Solution: Provides optimal conditions for the enzymatic reactions to occur.

Thermal Cycler: Instrumentation used to automate the PCR process by cycling through different temperatures.

At its core, PCR mimics the natural process of DNA replication within an organism. However, PCR condenses this complex process into a series of controlled steps carried out within a test tube. Here's a breakdown of the PCR cycle:

Denaturation: The first step involves heating the reaction mixture to a high temperature (usually around 95°C), causing the double-stranded DNA to separate into two single strands. This process is known as denaturation.

Annealing: The temperature is then lowered to allow the primers to bind (anneal) to their complementary sequences on the single-stranded DNA. This typically occurs around 50-65°C, depending on the primer sequences.

Extension: With the primers bound, the temperature is raised again, and DNA polymerase synthesizes new DNA strands by extending from the primers using the nucleotides present in the reaction mixture. This step occurs at a temperature optimal for the DNA polymerase enzyme, typically around 72°C.

Cycle Repetition: These three steps—denaturation, annealing, and extension—are repeated multiple times (usually 20-40 cycles), resulting in an exponential increase in the number of DNA copies. Each cycle doubles the amount of DNA, leading to millions of copies of the target sequence after just a few cycles.

The beauty of PCR lies in its repetitive nature. With each cycle, the number of copies of the target DNA segment doubles. After 30 cycles, for example, you can have billions of copies of the specific DNA region, enough for further analysis.

This versatile technique has spawned numerous variations, each tailored for a specific purpose. Let's delve into some of the most common types of PCR:

Real-Time PCR (qPCR): Real-Time PCR, or quantitative PCR (qPCR), revolutionized nucleic acid quantification by enabling the real-time monitoring of DNA amplification. This technique utilizes fluorescent reporter molecules to measure the accumulation of PCR products during each cycle. qPCR is invaluable in gene expression analysis, microbial quantification, and diagnostic assays due to its high sensitivity and quantitative capabilities.

Reverse Transcription PCR (RT-PCR): Reverse Transcription PCR combines PCR with reverse transcription to amplify RNA sequences. This technique converts RNA into complementary DNA (cDNA) using reverse transcriptase enzyme before proceeding with PCR amplification. RT-PCR is pivotal in gene expression studies, viral load quantification, and the detection of RNA viruses such as HIV and SARS-CoV-2.

Nested PCR: Nested PCR involves two rounds of amplification, with the second round using a set of nested primers that bind within the product of the first round. This nested approach increases specificity and reduces nonspecific amplification, making it ideal for detecting low-abundance targets and minimizing contamination. Nested PCR is commonly used in forensic analysis, pathogen detection, and rare allele identification.

Multiplex PCR: Multiplex PCR allows simultaneous amplification of multiple target sequences within a single reaction. This technique employs multiple primer sets, each specific to a distinct target region, enabling the detection of multiple targets in a single assay. Multiplex PCR is valuable in microbial typing, genetic screening, and detection of pathogens with complex genetic profiles.

Digital PCR (dPCR): Digital PCR partitions the PCR reaction into thousands of individual micro-reactions, each containing a single DNA template molecule or none at all. By counting the number of positive and negative partitions, dPCR accurately quantifies target DNA molecules without the need for standard curves or reference samples. This technique is useful for absolute quantification of rare targets, allelic discrimination, and copy number variation analysis.

Allele-Specific PCR: Allele-Specific PCR selectively amplifies alleles containing specific nucleotide variations, enabling the detection of single nucleotide polymorphisms (SNPs) or mutations. This technique utilizes primers designed to match the target sequence with single-base mismatches at their 3' end, allowing discrimination between different alleles. Allele-Specific PCR finds applications in genetic testing, pharmacogenomics, and population studies.

PCR's ability to amplify DNA has made it an indispensable tool in various fields. Here are a few examples of its diverse applications:

Disease Diagnosis and Surveillance: PCR plays a pivotal role in the rapid and accurate diagnosis of infectious diseases. By amplifying specific nucleic acid sequences, PCR enables the detection of pathogens with high sensitivity and specificity. PCR-based tests have become indispensable in diagnosing viral infections such as HIV, hepatitis, influenza, and COVID-19. Additionally, PCR facilitates the surveillance of disease outbreaks and the monitoring of antimicrobial resistance.

Genetic Testing and Personalized Medicine: PCR empowers genetic testing by enabling the detection of genetic mutations, polymorphisms, and variations associated with inherited diseases, cancer, and pharmacogenomics. Through techniques like allele-specific PCR and real-time PCR, researchers can identify disease-causing mutations, assess drug efficacy, and tailor treatments to individual patients. PCR-based genetic tests have transformed healthcare by enabling early disease detection, risk assessment, and personalized therapeutic interventions.

Forensic Analysis and DNA Profiling: PCR has revolutionized forensic science by enabling the analysis of minute DNA samples collected from crime scenes. Techniques like short tandem repeat (STR) analysis and multiplex PCR allow forensic experts to generate DNA profiles with high resolution and accuracy. PCR-based DNA profiling is used in criminal investigations, paternity testing, disaster victim identification, and wildlife forensics, contributing to the administration of justice and conservation efforts worldwide.

Environmental Monitoring and Microbial Ecology: PCR facilitates the study of microbial communities in diverse environments, including soil, water, air, and the human microbiome. Environmental DNA (eDNA) analysis using PCR-based methods enables the detection and characterization of microbial species, including bacteria, fungi, and archaea. PCR-based assays are employed in environmental monitoring, food safety testing, and microbial source tracking, aiding in the preservation of ecosystems and public health.

Agricultural Biotechnology and Food Safety: PCR plays a vital role in agricultural biotechnology by enabling the detection of genetically modified organisms (GMOs), plant pathogens, and foodborne pathogens. PCR-based assays are used to verify the authenticity and safety of food products, detect allergens, and monitor the presence of contaminants such as pesticides and toxins. PCR-based technologies contribute to ensuring food security, quality control, and regulatory compliance in the food industry.

Evolutionary Biology and Phylogenetics: PCR-based methods are indispensable tools for studying evolutionary relationships and biodiversity. Techniques like DNA barcoding and metagenomics employ PCR to amplify and analyze DNA sequences from diverse organisms, elucidating their evolutionary history and ecological interactions. PCR facilitates the identification of new species, the study of population genetics, and the conservation of endangered species, enriching our understanding of the natural world.

PCR's versatility and precision make it indispensable in unlocking the secrets of genetics and unraveling complex biological mysteries. Its ability to amplify minute DNA samples with remarkable speed and accuracy has opened doors to countless possibilities in research and diagnostics. s we delve deeper into the intricacies of the genetic world, PCR will undoubtedly remain a powerful tool for unlocking the secrets of life itself.

#science sculpt#life science#science#molecular biology#biology#biotechnology#artists on tumblr#double helix#genetics#dna#polymerase chain reaction#medical science#the more you know#scientific research#scifiart#scientific advancements#scientific illustration#scientific instruments#scientific discovery

2 notes

·

View notes

Photo

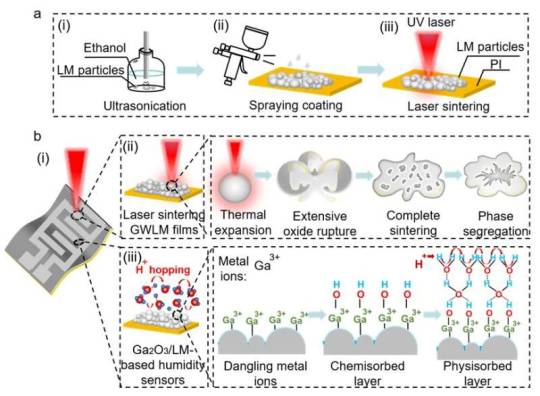

Laser direct writing of Ga2O3/liquid metal-based flexible humidity sensors

Recent studies in emerging flexible humidity sensors have achieved great developments in advanced manufacturing methods, as well as innovative applications including human health care detection, plant health management and noncontact human-machine interfaces. Capacitive-type humidity sensors have gained much attention due to reliable humidity sensing performance, low power consumption and facile structural designs. Generally, the performance of a capacitive humidity sensor is strongly correlated with the dielectric permittivity of functional materials between sensing electrodes.

Up to now, various active materials have been investigated as flexible capacitive humidity sensors, such as carbon materials, metal oxides, metal sulfides, and polymers. Similarly, they are typically endowed with large exposed surface areas and rich active sites to interact with water molecules. Ga2O3, as a potential metal oxide with high exposed hydrophilic groups, has been employed as an active material for capacitive humidity sensors.

Traditional fabrication techniques to obtain Ga2O3-based humidity sensors mainly involve chemical vapor deposition, thermal treatment, and hydrothermal methods. Nevertheless, these methods usually require high annealing temperature, complicated fabrication procedures as well as various material systems, hindering their practical applications.

Read more.

10 notes

·

View notes

Text

Closing a Chapter

(Warning for mentions of abandonment and mentions of execution)

With all the strength she could gather, Ningning pulled made her way up the steps to the blue door of the home she shared with her friends. She tried to be as quiet as she could be as to not wake anyone. Just as she reached for the handle, a parchment envelope with a dragon on it caught her eyes. It matched the letter that turned her world upside down so she knew it was for Giselle from Jiyong.

She grabbed the envelope and ducked around the outside of the house to make her way to her workshop. If her friends thought she was gone they wouldn’t even think twice about looking for her there. With the fires out for days a chill shook her body as she sat in the corner near the annealing oven. Her shaking hands ripped the envelope open to read the letter

Aeri, I hope this letter reaches you in time

I went back to the cafe the day after I sent the last letter and was able to speak to the woman longer. I’m more and more sure it’s her but I don’t understand how this woman could even be a part of Yizhuo. She was a young mom and while a group from their village tried to escape the fighting they were ambushed. She said the next thing she knew was she was alone and relieved. Relieved! I couldn’t believe my ears. She’s a monster and I’m not going to let Yi suffer for this. She’s been through enough. Commander Choi has a letter with information about a rogue magician in the castle town. It’ll be handled with soon. If this letter is too late just lie. I will be the villain to make sure she never knows. As always my dear, take care until the next letter.

⚔️ Jiyong

Over and over she read the letter but less and less made sense to her. A million questions ran through her head but in her heart she knew any chance of having answers way gone. Once Choi heard about the rogue magician it would only be a matter of hours before he demanded their head. This letter was written days ago at best.

A few tears splashed on the parchment and Ningning didn’t even know where they came from. She couldn’t imagine they were from her eyes. Not for the woman she didn’t know or would ever know.

Ningning stood on shaky legs. She lit the parchment and tossed the letter into her glass furnace. She watched the paper burn before adding kindling to heat the equipment again. Her frustrated hand swiped a few more tears away before she turned to finish her trip to her own room and bath.

“Ningie?” Winter asked, surprised to see her young friend walking through the door. Her chest aches to see the typically smiling face smudged with dirt and streaked with tears. “I’ll get Kari-“

“No. I just need a bath and nap,” Ningning whispered, brushing past her friend. “Just leave me alone." Without a discussion she locked the bathroom door and sunk into a hot bath up to her chin and closed her eyes.

38 notes

·

View notes

Text

All-Steel Stress, Blast and Coating

All-Steel Stress, Blast & Coating is a subsidiary steel heating treating company under the All-Steel Brand. All-Steel Stress, Blast and Coating provides heat treatment of steel, thermal stress relieving, industrial sandblasting/steel shotblasting and steel coating of:

Fabricated weldments

Machined parts

Machine components

Dry Outs

Their Massachusetts Facility offers a 40 Ton lifting capacity, 20 Ton forklift capacity and a dedicated, professional staff with over 50 years of combined experience in thermal stress relieving, sandblasting and priming/painting.

Thermal Stress Relieving, also referred to as Stress Relieving, Heat Treating, Post Weld Heat Treating (PWHT) and can also be referred to as annealing.

In our new, state of the art industrial size stress relieving oven we can stress relieve:

Fabricated Weldments for post-weld heat treatment

Machined Parts

Metal Components

In addition, we provide dry-out services for paint and refractory process curing. Our furnace will operate between 250 degrees F and 1600 degrees F. We perform quality inspections during the stress relieving process and we can provide our customers with Certificates of Compliance and detailed Heat Charts when required.

Our Stress Oven can accommodate customer jobs that are 12’H x 11’ W x 31’L and our rail-car capacity is 54,000lbs.

We meet the following standards: ASME Section I: (900 – 1300F) Stress relieve /post -weld heat treat in accordance with ASME Sect. I, PW-39 for carbon steel weldments. ASME Section VIII: (900 – 1300F) Stress relieve/post-weld heat treat in accordance with ASME Sect. VIII, USC-56 for carbon steel weldments. AWS D1.1 (900-1200F): Stress relieve/post-weld heat treat in accordance with AWS D1.1, 5.8 for carbon steel weldments. Westinghouse 83030QA: (1175F +/- 25F) Westinghouse-approved stress relieve procedure for carbon steel welded structures. General Electric P8A-AG1, P10G-AL-0003 & 0004: (1125 – 1275F, 1125-1200F and 125-1300F) General Electric-approved stress relieve procedures for carbon steel. Standard Stress Relieve: (1100-1200F) Applied to ferrous materials to reduce residual stresses for improved dimensional stability or reduced risk of premature failure in service. Low Temperature Stress Relieve: (325-775F) Typically applied to stainless steel and aluminum welded fabrications to reduce residual stresses with little or no effect of the corrosion resistance and/or mechanical properties.

Industrial Sandblasting Services, also referred to as shot blasting can be done in our state-of-the-art facility in Central Massaschusetts. Our new, industrial-size facility provides our customers with sandblasting for:

Fabricated Weldments

Machined Parts

Metal Frames and Components

In our modern, clean blast room, our experienced blasters can accommodate the most specific blast media required for the job. We can blast customer jobs that are 16’H x 13’W x 30’L; and we have 40,000lbs rail-car capacity for our blasting facility.

Steel Coating Services: Industrial Priming, Painting and Coating for Steel and other Metals. Our new coating facility will be capable of providing priming/painting/coating services up to 16’H x 20’W x 50’L and weigh up to 80,000lbs. Our painters have extensive experience coating:

Fabricated Weldments

Industrial Machine Bases

Industrial Frames

Construction Equipment

Holding Tanks & Silos

Address:

84 Creeper Hill Road,North Grafton MA 01536

Phone:

(508) 839-4471

Our Social Pages:

facebook

twitter

linkedin

youtube

pinterest

3 notes

·

View notes

Text

Alloy Steel Buttweld Fittings Available Types

There are a variety of shapes and sizes available in alloy steel buttweld fittings. Fittings like these are used in a variety of industries, including automotive and industrial. Alloy steel fittings are made from alloy steels and other metals. The alloy steel buttweld fittings can be welded, machined, and heat treated to produce a wide range of products. When purchasing a set of steel fittings, as well as larger quantities, most fitting manufacturers offer package deals. Bulk purchases may also be discounted. Find out if shipping and handling charges are included in the pricing offered by your local supplier.

The article Alloy Steel Buttweld Fittings Available Types introduces Alloy Steel Buttweld Fittings Available Types. The book explains the composition and characteristics of alloy steel. The book includes detailed information on the basic machine processes and operating conditions of Alloy Steel Buttweld Fittings Available Types, heat treatment, machining procedures, and test methods for Alloy Steel Buttweld Fittings Available Types. To get a feel for what this product is like, you can also view our sample products. Do your research before buying.

Click on the links below to learn more about Alloy Steel Buttweld Fittings Available Types. A typical size is approximately 4 inches in diameter (roughly 0.926 inches thick) and 1/2 inch in thickness (roughly 0.127 inches thick). Standardized to BS EN 642 and AIB 6073, typical values are approximately 4 inches in diameter and 1/2 inch in thickness. Based on the total weight of the alloy, the material contains approximately 0.5% carbon by weight.

The versatile alloy of alloy steel buttweld fittings is used for a wide range of applications. Weldability, pressure bearing strength, and thermal stability are excellent. For superior durability under heavy loads, it possesses chromium, molybdenum, and ferrous. While fitting in the processing system, it resists corrosion caused by hazardous gases and chemicals. Weldable alloy steel buttweld fittings have a low carbon content and are resistant to carbide precipitation.

Various types of alloy steel buttweld fittings are made with chemical compositions of great strength and hardness. These chemicals include carbon, nickel, aluminum, manganese, titanium, and iron. There are even numerous specifications for these alloy fittings, such as size, standards, grade, types, thickness, forms, ends, surfaces, finishes, lengths, widths, applications, tolerances, conditions, and pressure.

Various properties of these alloy fittings include hardness, corrosion resistance, and sustainability at annealed temperatures. The properties of alloy fittings include thermal conductivity, electrical resistance, modulus of expansion, density, melting point, elongation, and electrical conductivity. There are numerous types of these fittings, including seamless, welded, fabricated, and ERW.

Among the many industries and general works that use alloy steel Buttweld Fittings are the pharmaceutical industry, gas processing, chemical equipment, pharmaceutical equipment, offshore oil drilling, industry, heat exchangers, condensers, seawater equipment, petrochemicals, power generation, food processing, paper mills, pulp mills, rail components, road transportation components, pumps, shafts, and military applications. The alloy steel Buttweld Fittings are made with several properties that enable them to be used in annealed temperatures and chloride environments without any deformation. The fittings are resistant to crevice corrosion, stress corrosion, cracking corrosion, pitting corrosion, and impact corrosion.

Pipe fittings (as opposed to Tube fittings) are butt-welded onto the pipe. They are produced according to different ‘schedules’. Based on the nominal bore pipe size, the schedule determines the wall thickness. It is common to find schedules 10 and 40, but schedules 80 and 160 are also available.

For more information visit

1 note

·

View note

Text

Laser Marking Machine Manufacturer and Suppliers in India

Laser marking machine is a process that uses a concentrated beam of light to create permanent marks on the surfaces of target components. The process is typically carried out with a laser machine using an oscillator, a scanning mirror, and a focusing lens. The laser marking machine technology creates lasting marks on component surfaces by generating focused beams of light containing high energy levels. The built-up energy is released in the coherent light beam directed at the material surface using mirrors. As a result of the light beam interacting with the component’s surface, there is a transfer of heat energy from the beam to the surface. Therefore, the appearance and properties of the material will change. Depending on the energy level, the laser can engrave, etch, anneal, or discolor surfaces with great precision. The concentrated beam targets only specific areas on the material, ensuring precise, high-contrast, and high-quality marks.

For more details clicks here - https://www.indiantradebird.com/product/laser-marking-machine

0 notes

Text

Unveiling the DNA Detective: A Look at Thermal Cyclers and Their Role in Molecular Biology

The building blocks of life, DNA, hold the secrets to our biology, health, and even our history. Molecular biology has emerged as a powerful field, unlocking these secrets through various techniques. One of the most fundamental tools in this realm is the thermal cycler, often simply called a PCR machine (polymerase chain reaction). This blog will explore the fascinating world of thermal cyclers, delving into their role in amplifying DNA and how they are revolutionizing various fields of science and medicine.

Beyond the Microscope: The Power of Thermal Cycling

Unlike microscopes that allow us to see biological structures, thermal cyclers work on a molecular level. They utilize a precise temperature control mechanism to facilitate DNA replication millions of times, a process known as PCR. Here's a simplified breakdown:

Sample Preparation: Isolated DNA containing the target sequence is placed in a reaction tube along with primers (short DNA fragments), DNA polymerase (an enzyme that builds new DNA strands), and necessary chemical components.

Thermal Cycling: The thermal cycler precisely regulates temperature changes through multiple cycles. These cycles typically involve denaturation (high temperature to separate DNA strands), annealing (lower temperature for primers to attach to specific target sequences), and extension (optimal temperature for DNA polymerase to synthesize new complementary DNA strands).

Amplification: With each cycle, the target DNA sequence is replicated, resulting in an exponential increase in copies. Millions of copies can be generated from a tiny starting amount of DNA.

Applications of Thermal Cyclers: Transforming Research and Medicine

Thermal cyclers are versatile workhorses used across various scientific disciplines:

DNA Cloning: Amplified DNA can be inserted into plasmids (circular DNA molecules) used for further analysis or genetic engineering applications.

Genetic Testing: Thermal cyclers are vital for detecting genetic mutations, diagnosing inherited diseases, and identifying pathogens like viruses and bacteria.

Forensic Science: DNA profiling from crime scene evidence utilizes thermal cyclers to amplify trace amounts of DNA for identification purposes.

Oncology Research: Cancer research heavily relies on thermal cyclers to study genetic mutations involved in tumor formation and progression.

The Ever-Evolving World of Thermal Cyclers

Thermal cycler technology is constantly advancing:

Real-Time PCR: These machines monitor DNA amplification as it occurs, providing real-time data for faster analysis.

High-Throughput Screening: Automated systems allow parallel processing of multiple samples, increasing efficiency for large-scale studies.

Miniaturization: The development of compact thermal cyclers facilitates DNA testing at the point of care in clinical settings.

Thermal cyclers are indispensable tools in molecular biology research and diagnostics. By amplifying DNA, these machines enable scientists and medical professionals to diagnose diseases, understand biological processes, and develop new therapeutic approaches. As technology continues to evolve, thermal cyclers will undoubtedly play an even more significant role in shaping the future of medicine and scientific discovery.

When selecting thermal cyclers, research institutions and laboratories should partner with reputable suppliers like HospitalStore to ensure they receive high-quality, reliable equipment backed by excellent customer service and technical support.

0 notes

Text

Understanding Jindal SS 316 Sheet Price List

Stainless steel has become an indispensable material in various industries due to its exceptional properties like corrosion resistance, durability, and aesthetic appeal. Among the different grades of stainless steel, SS 316 stands out for its superior corrosion resistance, making it ideal for applications in harsh environments such as marine and chemical processing. Jindal Stainless Limited, a leading stainless steel manufacturer, offers a wide range of SS 316 sheets, and understanding their price list is crucial for businesses and consumers alike. In this blog, we'll delve into the factors influencing the price of Jindal SS 316 sheets and provide insights into interpreting the price list.

Factors Influencing SS 316 Sheet Prices

Raw Material Costs: The primary raw material for stainless steel production is scrap metal, nickel, and chromium. Fluctuations in the prices of these raw materials significantly impact the overall cost of manufacturing SS 316 sheets. For instance, an increase in nickel prices due to geopolitical tensions or supply chain disruptions can lead to higher sheet prices.

Manufacturing Process: The manufacturing process adopted by Jindal Stainless Limited also influences the price of SS 316 sheets. Advanced production techniques, such as hot rolling, cold rolling, and annealing, may incur higher production costs, reflecting in the final price of the sheets.

Market Demand and Supply: Like any other commodity, stainless steel prices are subject to market dynamics, including demand-supply imbalances. During periods of high demand or limited supply, prices tend to rise. Conversely, oversupply or weak demand may lead to price corrections.

Quality and Specifications: Jindal offers SS 316 sheets in various grades, thicknesses, and finishes to cater to diverse customer requirements. Sheets with higher quality finishes or precise specifications may command a premium price due to additional processing and quality control measures involved.

Interpreting Jindal SS 316 Sheet Price List

Jindal Stainless Limited provides a comprehensive price list for its SS 316 sheets, detailing various specifications and corresponding prices. Here's how to interpret the price list effectively

Grade and Thickness: The price list typically categorizes SS 316 sheets based on their grade (316), thickness (measured in gauge or millimeters), and surface finish (e.g., 2B, BA, No.4).

Quantity and Packaging: Prices may vary depending on the quantity of sheets ordered and packaging preferences (e.g., standard bundles, coils, or custom packaging). Bulk orders often qualify for volume discounts, which are reflected in the price list.

Currency and Pricing Units: Ensure that you understand the currency (e.g., USD, INR) and pricing units (e.g., price per kg, price per sheet) mentioned in the price list to accurately assess the cost implications.

Additional Charges: Consider any additional charges such as taxes, transportation costs, or surcharges, which may not be explicitly mentioned in the price list but can affect the overall procurement cost.

Conclusion

Jindal Stainless 316 sheets are renowned for their quality, durability, and corrosion resistance, making them a preferred choice for various industrial and architectural applications. By understanding the factors influencing SS 316 sheet prices and interpreting Jindal's price list effectively, businesses and consumers can make informed decisions regarding procurement while ensuring value for money. Stay updated with market trends and collaborate with reliable suppliers like Jindal Stainless Limited to optimize your stainless steel procurement process.

0 notes

Text

What is the ASTM grade of Monel 400?

In the realm of metallic materials, Monel 400 holds a distinct position as a nickel-copper alloy with exceptional corrosion resistance and high strength. Therefore, understanding the ASTM grade of Monel 400 is very important for its application in various industries, especially those involving harsh environmental conditions.

What is the ASTM grade of Monel 400?

Monel 400, also known by its UNS number N04400, is a nickel-copper alloy primarily composed of approximately 63% to 70% nickel and 28% to 34% copper, with minor additions of iron, sulfur, carbon, silicon, and manganese. This composition gives it remarkable resistance to corrosion in a wide range of environments, including seawater, hydrogen fluoride, fluorine, sulfuric acid, and alkaline media.

The ASTM grade of Monel 400 is specified in several ASTM standards, including ASTM B127, ASTM B163, ASTM B164, and ASTM B165. These standards define the chemical composition, mechanical properties, and other characteristics of the alloy, ensuring its consistent performance across different applications.

The chemical composition specified in these ASTM standards ensures that Monel 400 maintains its corrosion resistance and mechanical properties. The high nickel content, in particular, confers immunity to chloride-induced stress corrosion cracking, a common failure mode in many other alloys. Additionally, the alloy’s ductility and toughness allow it to be easily formed and processed into various shapes and sizes.

Mechanically, Monel 400 exhibits high strength and toughness over a broad temperature range. Its yield strength and tensile strength, as defined by the ASTM standards, are sufficient to withstand significant loads and stresses in demanding applications. Furthermore, its ductility enables it to absorb deformation without fracturing, enhancing its reliability and durability.

Physically, Monel 400 has a density of approximately 8.80 grams per cubic centimeter and a melting range of 1300-1350 degrees Celsius. Its thermal conductivity and specific heat capacity are also within the range specified by the ASTM standards, ensuring consistent thermal performance.

The processing characteristics of Monel 400 are also addressed in the ASTM standards. It can be easily processed using traditional machining operations, making it suitable for a wide range of manufacturing processes. Its soft nature allows for hot forming into almost any shape, while cold working is typically performed on annealed material to optimize its mechanical properties.

Conclusion

In conclusion, the ASTM grade of Monel 400 is defined by a set of standards that ensure its consistent chemical composition, mechanical properties, and processing characteristics. These standards are the foundation for its widespread use in various industries, where its corrosion resistance and high strength are paramount.

Thank you for reading our article and we hope it can help you to have a better understanding of the ASTM grade of Monel 400. If you are looking for Monel Alloy suppliers and manufacturers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Monel Alloy products from Shanghai China, Huaxiao Alloy offers customers high-quality Monel alloy products such as Monel 400 and Monel K500 at a very competitive price.

0 notes

Text

Applications of Copper Sheets

Copper sheets are more than just shiny metal; they are versatile materials with a wide range of applications across various industries. From architecture to electronics, these sheets play a crucial role in delivering exceptional performance and durability. As a leading copper sheets manufacturer, supplier, stockist, and exporter, Bullion Pipes & Tubes LLP takes pride in offering a wide range of copper sheet solutions tailored to meet the diverse needs of our esteemed customers.

In this blog post, we'll delve into the diverse applications of copper sheets and how they contribute to innovation and functionality in different fields.

Copper Sheets

Copper sheets are thin, flat pieces of copper metal typically used in various industrial, construction, and artistic applications. They are manufactured by rolling copper ingots through a series of rollers to achieve the desired thickness. These sheets possess excellent conductivity, corrosion resistance, and malleability, making them ideal for electrical wiring, roofing, decorative elements, and crafting purposes. Copper sheets come in various sizes and thicknesses to suit different needs and are valued for their durability and aesthetic appeal.

Benefits of Copper Sheets

Excellent Conductivity: Copper sheets offer high electrical and thermal conductivity, making them ideal for various applications in electrical wiring, electronics, and heat transfer systems.

Corrosion Resistance: Copper possesses natural corrosion resistance, which prolongs the lifespan of copper sheets and reduces maintenance requirements.

Antimicrobial Properties: Copper exhibits antimicrobial properties, helping to inhibit the growth of bacteria, viruses, and fungi on surfaces, and promoting cleaner environments in applications such as hospitals and food processing facilities.

Ductility: Copper sheets are highly ductile, allowing them to be formed into various shapes and sizes without compromising their structural integrity, offering versatility in manufacturing processes.

Recyclability: Copper is a highly recyclable material, with nearly all copper used in various applications being recyclable, contributing to sustainability efforts and reducing environmental impact.

Aesthetic Appeal: Copper's distinctive reddish-brown color and luster add aesthetic appeal to architectural designs, decorative elements, and artistic endeavors.

Malleability: Copper sheets can be easily shaped and molded without cracking or breaking, enabling intricate designs and detailed craftsmanship in various industries, including jewelry making and metalworking.

High Strength: Despite its malleability, copper possesses significant strength, offering durability and reliability in structural applications such as roofing, cladding, and architectural accents.

Compatibility: Copper is compatible with a wide range of materials, including other metals and alloys, facilitating its integration into diverse systems and applications without compatibility issues.

Thermal Stability: Copper maintains its mechanical and electrical properties over a wide temperature range, making it suitable for applications subjected to extreme temperatures, such as automotive components and industrial machinery.

Specifications of Copper Sheet

ASTM Specification

ASTM B152 UNS C12200, ASME SB152, MSRR, AMS, BS

Specification

MSRR, AMS, BS, ASTM B152 / ASME SB152

ASTM Standard Designations for C10200 OFHC Copper plate and sheet

ASTM B152

C10100 meets ASTM F68 specifications.

Length & Sizes

1000 mm x 2000 mm, 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2m, 2.44m, 3m, 36″ X 120″ or 48″ X 144″, Cut to size available

Thickness

0.1mm to 100 mm Thk

Sheet Width

36” widths – .032”, .0625”, .125”

Hardness

Soft, Hard, Half Hard, Quarter Hard, Spring Hard, etc.

Temper

Annealed, 1/4-Hard, 1/2-Hard, 3/4-Hard, Full Hard, Hard as Rolled, Spring

Condition

Polished on both sides

Finish

Bare/Standard, Hot Tin Dipped, Tin Plated, Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)

Stock in the form of

C101 Copper Sheet, Foils, Rolls, Plain Sheet, Shim Sheet, Rolling Sheet, Flat Sheet, Flat Shim, Blank (Circle),

Uses and Applications of Copper Sheets

Roofing: Copper sheets are often used as roofing material due to their durability, corrosion resistance, and attractive appearance. They provide excellent protection against weathering and can last for decades.

Electrical Conductors: Copper is an excellent conductor of electricity, making it ideal for use in electrical wiring, circuits, and busbars. Copper sheets are used in the construction of electrical panels, transformers, motors, and generators.

Heat Exchangers: Copper's high thermal conductivity makes it suitable for use in heat exchangers. Copper sheets are used in HVAC systems, radiators, boilers, and air conditioning units to transfer heat efficiently.

Decorative Applications: Copper's unique reddish-orange hue and malleability make it popular for decorative purposes. Copper sheets are used in architectural elements such as ornamental facades, countertops, backsplashes, and sculptures.

Plumbing: Copper pipes and tubing are widely used in plumbing systems for transporting water and gases. Copper sheets are also used in the fabrication of fittings, valves, and fixtures due to their corrosion resistance and antimicrobial properties.

Craftsmanship and Artwork: Copper sheets are popular among artists and craftsmen for creating jewelry, sculptures, and other decorative items. Its malleability allows for intricate designs and textures.

Electronics: Copper sheets are used in the manufacture of printed circuit boards (PCBs) and semiconductor devices due to their excellent electrical conductivity and reliability.

Antimicrobial Surfaces: Copper exhibits natural antimicrobial properties, making it suitable for applications where hygiene is critical. Copper sheets are used in hospitals, public transportation, and food processing facilities to reduce the spread of bacteria and viruses on surfaces.

Solar Panels: Copper is used in the production of photovoltaic cells for solar panels. Copper sheets serve as conductive layers within the cells, helping to capture and transfer solar energy efficiently.

Automotive Industry: Copper is used in various automotive components, including radiators, heat exchangers, wiring harnesses, and brake lines. Copper sheets are also used in automotive gaskets and seals due to their malleability and sealing properties.

Final Words!

From electrical conductivity to corrosion resistance, copper sheets offer a myriad of benefits across diverse industries, ranging from electrical and construction to automotive and aerospace sectors. At Bullion Pipes & Tubes LLP, we are committed to providing top-notch copper sheet solutions tailored to meet your specific project requirements. Explore our extensive range of copper sheets, copper shim sheets, and copper perforated sheets to discover the perfect solution for your application needs. Partner with us for unparalleled quality, reliability, and customer satisfaction.

0 notes

Text

Can Broken Alloy Wheels Be Repaired?

Can Damaged Alloy Wheels Be Restored? A Comprehensive Guide to Repairing Bent and Buckled Wheels

Alloy wheels, with their blend of style and functionality, often face the harsh reality of road damage. When these wheels encounter bends, buckles, or cracks, the question arises: can broken alloy wheels be restored? Delving into the nuances of wheel damage, repair techniques, durability, and costs, let’s unravel the possibilities of rejuvenating your prized alloy wheels to their former glory.

Key Takeaways

The repair of alloy wheels hinges on the nature and severity of the damage.

Scratches and scuffs can often be fixed through polishing or refinishing.

Cracks and dents may require professional repair techniques like welding or filling.

Bent or misaligned wheels can be straightened using specialized equipment.

Choosing a reputable and experienced alloy wheel repair service is crucial for quality repairs.

Assessing the Damage: Bent, Buckled, and Broken Wheels

Bent or buckled wheels, caused by potholes, impacts, or collisions, can compromise not only the aesthetics but also the structural integrity of alloy wheels. In severe cases, cracks or fractures may develop, posing safety risks and affecting performance.

Bends and Buckles: Commonly caused by potholes or impacts, these issues affect the wheel’s shape, leading to visible deformities. These are subtle deformations that may not always be immediately noticeable but can still affect performance. More severe than bends, buckles are visible distortions that significantly impact the wheel’s functionality and safety.

Cracks and Structural Damage: Severe impacts or prolonged wear can result in cracks, weakening the structural integrity of the wheel.

Importance of Repair

Repair Methods

Professional Repair

Wheel repair typically involves a professional assessment to determine the extent of the damage. Some common repair methods include:

Straightening Dented or Bent Alloy Wheels: When it comes to repairing minor dents and bends on alloy wheels, specialized tools and techniques can make all the difference. One method used is heat treatment, specifically annealing. Annealing involves applying controlled heat to the affected area of the wheel to soften the aluminum and make it more malleable. In addition to heat treatment, another effective technique employed in straightening alloy wheels is the use of hydraulic presses or roller machines. These powerful tools allow for controlled force application, making it possible to gently push out dents or bends without causing further damage. With careful adjustments and precise measurements, skilled technicians can gradually restore the wheel’s integrity and bring it back into its original alignment. This process requires expertise and precision to ensure that no additional stress is placed on the wheel.

Welding Broken Alloy Wheels: Repairing broken alloy wheels requires a different approach compared to fixing dents and bends. In cases where broken are present, welding techniques become essential for restoring structural integrity. Extensive damage such as cracks, and welding techniques are utilized to mend and reinforce the affected areas, ensuring structural stability. Welding proves effective due to its ability to provide stronger bonds between metals.

Machining: Precision machining can smooth out imperfections on the wheel’s surface.

The Durability Dilemma: Will My Repaired Wheel Hold Up?

Fear not, the days of shoddy repairs are gone! Advancements in technology and materials ensure that repaired alloy wheels can be incredibly strong and durable. In fact, with proper care, a repaired wheel can last just as long as a new one.

The durability of a repaired alloy wheel depends on various factors:

Severity of Damage: Mild bends are often successfully repaired and can maintain durability. Severe damage might compromise the wheel’s structural integrity even after repair.

Quality of Repair: A professionally done repair using appropriate techniques and materials can enhance durability.

Driving Conditions: Rough roads and aggressive driving styles might impact the longevity of the repaired wheel.

Limitations and Considerations in Repairing Alloy Wheels

Factors that affect repairability (e.g., location and extent of damage)

Repairing broken alloy wheels is not always feasible or advisable under certain circumstances. Several factors influence the repairability of damaged wheels, such as the location and extent of the damage itself. If a crack extends too far or reaches critical structural components like mounting points or spoke junctions, repairing it may compromise safety.

Similarly, severely bent rims that exceed manufacturers’ tolerance limits might not be safely salvageable through repair methods alone. It is crucial to assess these factors before determining whether repairing a specific wheel is a viable option.

Safety concerns associated with repaired alloy wheels

While professional repairs can restore functionality, it is essential to consider potential safety concerns associated with repaired alloy wheels. Repaired cracks could weaken the overall structure, compromising stability and increasing the risk of catastrophic failure under stress conditions.

Furthermore, heat-treated rims might experience changes in metallurgical properties that can impact long-term durability if not executed precisely according to industry standards. It is vital to adhere strictly to recommended repair procedures outlined by reputable experts in order to minimize any potential safety risks.

Importance of seeking professional expertise for complex repairs

Given the intricacies involved in repairing broken alloy wheels, it becomes evident why seeking professional expertise is paramount for complex repairs. Professionals possess the necessary knowledge, experience, and access to specialized tools and equipment to ensure proper execution of repair techniques.

They can accurately assess the extent of damage, provide expert guidance on repair or replacement options, and implement industry-approved methods with precision. By entrusting complex repairs to skilled professionals, one can have peace of mind knowing that their alloy wheels are being restored with expertise and attention to detail.

Conclusion

Repairing broken alloy wheels encompasses a range of techniques designed to address both minor surface damages and more significant structural issues. From sanding and polishing for cosmetic repairs to welding techniques for cracks and heat treatment methods for bent rims, professional experts employ these processes meticulously. However, it is crucial to recognize the limitations in repairability based on factors like location and extent of damage while also considering safety concerns associated with repaired wheels.

By seeking professional expertise for complex repairs, individuals can trust that their alloy wheels will be restored properly. Ultimately, this ensures not only the aesthetic appeal but also the safety and longevity of these vital components in the automotive world.

Frequently Asked Questions (FAQs)

Can all types of damage be repaired on alloy wheels?

The repair feasibility depends on the extent and type of damage. Minor scratches and scuffs are usually repairable, while more significant structural damage might require professional intervention.

How long does alloy wheel repair typically take?

The duration varies based on the extent of damage. Minor repairs like polishing can be done swiftly, while more complex repairs might take a bit longer.

Is it safe to drive on a bent alloy wheel?

It’s not advisable. A bent wheel can affect your vehicle’s performance and safety. Getting it repaired or replaced promptly is recommended.

What should I look for in an alloy wheel repair service?

Look for experience, reputation, and certifications. A trustworthy service will offer warranties and have skilled technicians proficient in various repair techniques.

Remember, restoring your bent or buckled alloy wheels is an investment in your peace of mind, safety, and driving experience. Don’t hesitate to seek professional help and reclaim the harmony of your car’s performance on London’s vibrant streets.

Article Source : https://jralloywheelrepair.co.uk/can-broken-alloy-wheels-be-repaired/

0 notes

Text

Galvanized iron wire is typically made from low-carbon steel, which is then cleaned, annealed, and pickled to prepare the surface for the electroplating process. During electroplating, the wire is immersed in a bath of molten zinc and an electrical current is passed through the wire, causing the zin c to deposit onto the surface. The resulting zinc coating ranges from about 25 to 75 micrometers thick, depending on the application and specification.

https://www.facebook.com/wiremeshmetalproduct

1 note

·

View note

Text

Laser Stamping Machine: Revolutionizing Metal Fabrication with Mega Long Laser Marking

Introduction

The Sparkle Laser Mega Long Laser Marking Machine has emerged as a revolutionary tool in the realm of metal fabrication. Specifically designed for individuals involved in crafting metal items, this laser marking engraving machine by Sparkle Laser guarantees unparalleled quality.

Ready-to-Use Efficiency

Sparkle Laser’s Laser Stamping Machine��seamlessly integrates into production lines, offering unparalleled efficiency. The laser heads operate independently, generating all necessary identification data for your products. These “Ready-to-use” machines eliminate the need for additional connection equipment, effortlessly integrating with most PLCs brands due to their compatibility with various communication protocols.

Swift Laser Stepping Control

This Laser Marking Engraving Machine enables rapid laser stepping control of text and codes, providing instant results for your designs. The incorporation of the laser source and power supply into a single component enhances the machine’s compactness. Its versatility shines, catering to the marking needs of large or taller products.

Aesthetic and Compact Design

The appearance of this laser etching machine is not only sleek and minimal but also easy to transport. With a high speed of electrical-optical conversion, it excels on metallic surfaces. The compact size of the Mega Long Laser Marking Machine comes with auto-marking functionality, capacity, and round preview features.

User-Friendly Features

Users can easily monitor the status, integrate product reports, and benefit from secure closures for enhanced safety. The Laser Engraving Machine facilitates the creation of round parts or shapes and can print barcodes, 2D data matrix codes, parcel codes, and date codes.

Material Versatility

The Mega Long Laser Marking Machine proves its versatility by being usable on various materials, including Aluminum, Stainless Steel, Titanium, Plastic, Alloy Steel, Bronze, Copper, and Platinum. Experience efficient metal product marking with this laser etching machine.

Specifications of Laser Marking Machine

A. Laser Type

Pulsed Fiber Laser

B. Average Output Power

20 W (Optional 30/50/80/100 W)

C. Wavelength

1064 nm

D. Output Power Stability (Typical)

5%

E. Power Adjusting Range

1 ~ 100 %

F. Resolution Frequency

20–500 KHz (Optional)

G. Beam Quality (M²)

<1.6

H. Output Beam Diameter (1/e2)

6–9 mm

I. Max. Linear Speed

Max 12000 mm/s

J. Marking Depth

0.01~0.3 mm (Material Dependent)

K. Work Area

110mm x 110 mm

L. Min. Character Height

0.2 mm

M. Power Supply Single Phase

220V / 50Hz

N. Power Consumption

~ 500 W

O. Ambient Temperature Range

0° to 25° C

P. Cooling System

Air Cooling System

Features

Portable machine design with compact size

Production Report Integration

Status monitoring and safe shutdown

Circumferential Markings (Mark Round Parts)

Maintenance-Free with low power consumption (~ 500 W)

Bar-coding, 2D Data Matrix Codes, Lot Codes, Date Codes

Real-time red beam preview ensures accurate positioning

Compatible with Surface Marking, Engraving, and Texturing

Support customized software and automation integration

Scribing operations, Surface Annealing, and Etching

Marking Alphanumerics, Serial Numbers, and Part Numbers

Marking of Logos, Schematics, Complex Graphics (PLT, SVG, DXF, DWG), and Pictures (BMP, JPEG, PNG)

Auto Marking functionality, Boundary & Round Preview

Conclusion

In conclusion, the Mega Long Laser Marking Machine by Sparkle Laser stands as a testament to innovation in metal fabrication. Its features, efficiency, and user-friendly design make it an indispensable tool for those seeking precision and quality in their metal products.

FAQs

Q1: Can the Mega Long Laser Marking Machine handle different materials?

Yes, it is designed to work on various materials such as Aluminum, Stainless Steel, Titanium, Plastic, Alloy Steel, Bronze, Copper, and Platinum.

Q2: Is the machine easy to integrate into existing production lines?

Absolutely, the “Ready-to-use” design ensures seamless integration with most PLCs brands.

Q3: What are the key features that set this laser marking machine apart?

Some standout features include its compact size, auto-marking functionality, and compatibility with different marking tasks.

Q4: Can it mark complex graphics and pictures?

Yes, the machine is capable of marking complex graphics, schematics, and pictures with precision.

Q5: Is maintenance required for the Mega Long Laser Marking Machine?

The machine is maintenance-free with low power consumption, providing hassle-free operation.

0 notes

Text

The Unbreakable Thread: Exploring the World of Steel Pipes

In the realm of construction, infrastructure, and industry, steel pipes are the unsung heroes that connect the modern world. These robust conduits serve as the arteries through which materials flow, and they underpin our civilization in ways we often take for granted. In this latest blog, we will embark on a journey into the fascinating world of steel pipes, uncovering their types, manufacturing processes, diverse applications, and the pivotal role they play in shaping our modern world.

Types of Steel Pipes

Steel pipes come in various forms, each tailored to specific purposes and applications. Here are some common types:

1. Seamless Steel Pipes:

Manufactured without seams, these pipes are highly durable and suitable for high-pressure applications.

Used in industries like oil and gas, petrochemicals, and power generation.

2. Welded Steel Pipes:

Created by welding together steel plates or coils.

Available in various shapes and sizes and used for a wide range of applications, including construction and infrastructure.

3. Galvanized Steel Pipes:

Coated with a layer of zinc to enhance corrosion resistance.

Commonly used for water supply, plumbing, and outdoor applications.

4. ERW (Electric Resistance Welded) Pipes:

Produced by welding the edges of a steel strip to form a tube.

Widely used in industries such as construction, automotive, and infrastructure.

The Steel Pipe Manufacturing Process

The manufacturing of steel pipes involves several key steps, ensuring their quality and reliability:

1. Raw Material Selection:

High-quality steel, typically low-carbon or alloy steel, is selected for its durability and strength.

2. Pipe Formation:

The selected steel is shaped into a pipe through processes like seamless extrusion, hot rolling, or welding.

3. Heat Treatment:

To enhance the pipe's properties, heat treatment may be applied, including annealing or quenching and tempering.

4. Surface Treatment:

Depending on the application, pipes may undergo treatments such as galvanization or coating to prevent corrosion.

5. Testing and Inspection:

Rigorous quality control measures ensure that the pipes meet industry standards, including checks for dimensions, strength, and integrity.

Applications of Steel Pipes

Steel pipes serve as the backbone of numerous industries, contributing to the development of modern society:

1. Construction:

Steel pipes are used in construction projects for structural support, scaffolding, and plumbing systems.

2. Oil and Gas:

They play a vital role in the exploration, extraction, and transportation of oil and natural gas.

3. Infrastructure:

Steel pipes are used in the construction of bridges, pipelines, water treatment plants, and roadways.

4. Automotive:

In the automotive industry, steel pipes are used for manufacturing exhaust systems and chassis components.

5. Water Supply and Plumbing:

Due to their durability, steel pipes are commonly used in water supply systems and plumbing.

Sustainability in Steel Pipe Manufacturing

In an era where sustainability is a top priority, the steel pipe manufacturing industry is making significant strides toward environmentally friendly practices. Some of these sustainability initiatives include:

Recycling: Recycling scrap steel to produce new pipes reduces the demand for virgin materials and minimizes waste.

Energy Efficiency: Implementing energy-efficient technologies and production processes reduces the carbon footprint of steel pipe manufacturing.

Reducing Emissions: Efforts to reduce greenhouse gas emissions and air pollutants during manufacturing contribute to cleaner production.

Corrosion-Resistant Coatings: Developing advanced coatings that extend the lifespan of steel pipes and reduce the need for replacements, thus conserving resources.

Innovations in Steel Pipe Manufacturing

Innovation is driving continuous improvement in steel pipe manufacturing. Some notable innovations include:

High-Strength Steel Alloys: The development of advanced steel alloys allows for the production of lighter, stronger pipes, reducing material usage and transportation costs.

Advanced Welding Techniques: Enhanced welding processes result in stronger, more durable welds, ensuring the integrity of steel pipes.

Smart Manufacturing: Integration with digital technologies, such as the Internet of Things (IoT) and automation, enhances production efficiency and quality control.

Corrosion-Resistant Coatings: The development of new coatings that provide superior corrosion resistance, extending the lifespan of steel pipes in harsh environments.

Customization and Versatility

Steel pipe manufacturers understand the importance of customization to meet the diverse needs of various industries. They offer an extensive range of sizes, thicknesses, and coatings, allowing architects, engineers, and contractors to select the ideal steel pipes for their specific projects. This versatility ensures that steel pipes remain a practical and adaptable solution for a wide range of applications.

The Future of Steel Pipe Manufacturing

As we look ahead, the future of steel pipe manufacturing is promising. These pipes will continue to be the backbone of infrastructure, industry, and construction projects worldwide. With ongoing advancements in technology, sustainability, and customization, steel pipes are poised to remain a reliable and indispensable component of modern society.

In conclusion, steel pipes are not just conduits for materials; they are conduits of progress, underpinning our modern world. Rooted in time-tested techniques and continuously evolving through innovation and sustainability efforts, steel pipes will continue to play a pivotal role in building the foundations of our societies for generations to come. As manufacturers continue to refine their processes and embrace sustainability, the future of steel pipe manufacturing looks brighter than ever, promising reliability, durability, and performance for the future.

Conclusion

Steel pipes are more than mere conduits; they are the unbreakable thread that weaves our modern world together. These pipes, born from raw steel and shaped through precision manufacturing, are the hidden heroes that enable the flow of materials, energy, and progress in our societies.

As we look ahead, steel pipes will continue to be at the forefront of construction, industry, and infrastructure development. Their strength, durability, and versatility will ensure that they remain indispensable, supporting our ever-evolving world for generations to come. In an era of innovation and sustainability, steel pipes will continue to be the unbreakable thread that binds our modern civilization.

More Read: Steel pipe | ERW Pipes

1 note

·

View note

Text

Everything You Need to Know About RF Shield Box

If you’re considering investing in an RF shield box, it is vital to know everything there is to know about it first.

For the uninitiated, RF is short for Radio Frequency Shield Box. It helps to block or restrict electromagnetic (EM) or radio frequency (RF) interference.

As you may already know, radio frequency has become omnipresent in this digital age. So it is critically important to protect computers and other types of electronic devices from radio frequency waves.

If you fail to restrict radio frequency interference, it can affect the performance as well as the functionality of electronic devices. And this is the part where RF shield boxes come into play.

Today, there are plenty of use cases for an RF shield box.

In this blog, we’ve explained which materials are used in RF shield boxes, their types, costs, and how to uplift their effectiveness, should you decide to buy one.

What is RF Shield Box Used For?

RF shield boxes can come in variety of forms, materials, and manufacturing methods. This is because RF shield boxes have a wide range of applications across various industries.

For starters, RF shield boxes can be used for many different purposes including automotive multimedia tests, wireless semiconductor tests, mobile telephone tests, WLAN/Bluetooth/WiMax tests, cellular network tests, and even base station transceiver tests.

Which Material is Used for Manufacturing RF Shield Box?

RF shield boxes are generally manufactured using three different types of metals:

⦁ Copper

⦁ Aluminium

⦁ Steel

The aluminum material is typically used in the form of foil to prevent low-frequency radio field waves.

The steel-based material, on the other hand, is used for different processes including cold rolling, hot rolling, annealing of material, etc., which can have an incredible effect on shielding capabilities.

The copper-based RF shield boxes not only have high conductivity but also provide greater resistance to oxidation & corrosion.

So if you’re looking for an ideal RF shield box for outdoor environments, copper would be the right material choice.

However, knowing the materials used for RF shield box manufacturing is not enough to make the right decision. You also need to know about the different types of RF shield boxes available in the market.

To Read Full Blog : RF Shield Box

0 notes

Text

C45/EN8/EN8D/EN9 Steel in Bangalore:

ALLOY CARBON STEEL are stockiest; supplier and manufactures of carbon steel, alloy steel, tool steel, mold steel. We have experience of more than 50 years in iron and steel industries.

Alloy Carbon Steel are committed to provide best and varieties of products at reasonable, best price to customers. To know more about our products just click and give us chance to serve you and fulfil your requirements.

The particular heat treatment and processing circumstances that materials like EN8, EN8D, and C45 go through might affect their hardness. I can, however, give you a broad picture of their usual hardness values as follows :

EN8: When it is in its normalized state, its Brinell Hardness (HB) is normally between 200 and 250. Hardness can increase dramatically after quenching and tempering, frequently reaching levels between 30 and 40 HRC (Rockwell Hardness C-scale).

EN8D: Essentially, EN8D is an EN8 variation with a little higher carbon content. Generally speaking, EN8D has a harder texture than EN8. In its state of normalcy: It may have a hardness of 200–250 HB, similar to EN8.

C45: In its normalised state, C45 typically has a hardness of 170 to 210 HB. Following quenching and tempering, the hardness can rise significantly and is typically in the range of 55 to 58 HRC.

EN9: EN 9 steel is a medium carbon steel grade used in general engineering purposes. Its hardness can vary based on the heat treatment it has undergone and other factors. The hardness of EN 9 steel can typically range from around 180 to 280 on the Vickers hardness scale (HV).

Following heat treatment, the hardness can reach hardness values of between 30 and 45 HRC, a significant increase in hardness.

Properties of C45:

Strength: Good hardness and tensile strength.

Machinability: Excellent machinabilitywhenhot rolled or in its normalized state.

Weldability: It is weldable, however care must be taken to prevent cold cracking.

Properties of EN8:

Strength: Excellent toughness and tensile strength.

Machinability: From decent to excellent.

Weldability: It is weldable, however care must be taken to prevent cold cracking.

Properties of EN8D:

Strength: Greater hardness and tensile strength than EN8.

Machinability: Excellent machinability is a must.

Weldability: In general, it can be welded, but care must be given to guarantee the required mechanical qualities and prevent cold cracking.

Properties of EN9:

Strength: The yield strength of EN 9 steel is usually between 350 MPa to 600 MPa when in the normalized condition. Again, the specific value can depend on various factors.

Machinability: EN 9 steel, when in the normalized or annealed condition, has good machinability. However, it’s essential to use appropriate speeds and feeds to achieve desired results.

Weldability: EN 9 can be welded using standard methods. Preheating and post-weld heat treatment might be necessary for specific applications to minimize the risk of cracking and to achieve desired mechanical properties in the weld region.

Here are some common uses of these materials:

C45: C45 steel is frequently used for parts and components, such as gears, shafts, axles, and bolts, that need to be moderately strong and robust.

EN8: EN8 steel is frequently used in general engineering applications, such as automobile and construction equipment parts, machinery, and machinery.

EN8D: Crane wheels, machine parts, gears, shafts, axles, bolts and studs are applications of en8d steel.

EN9: EN9 is often used in the manufacture of various engineering components such as shafts, gears, studs, bolts, and spindles due to its good strength and toughness.

TYPES OF OTHER GRADES AVAILABLE :

C45, EN8, EN9, EN19, EN24, EN31,EN36C, EN41B, EN47, EN353, IS2062, 42Crmo4, HCHCR, OHNS, D2, D3, H-11, H-13,M2, M35, M42, M48,1.2714, SKD-11, P20, P20+S, P20+Ni, P20+Ni+HH, SAE 4140, SAE4340, SAE 8620, 16MNCR5, 20MNCR5, C35, C40, C50, C60, CK45, 40C8, 45C8, 55C8, C55MN75, SAE 52100, S40C,S355J2G3.

AREA OF SUPPLYING:

Uttar Pradesh:

Kanpur,Lucknow,Ghaziabad,Agra,Meerut,Varanasi,Prayagraj,Bareilly,Aligarh,Moradabad,Saharanpur,Gorakhpur,Noida, greater Noida, udham nagar,Firozabad,Jhansi,Muzaffarnagar,Mathura,Ayodhya,Rampur,Shahjahanpur,FarrukhabadFategarh,Budaun,Maunath,Bhanjan,Hapur,Etawah,Mirzapur,Vindhyachal,Bulandshahr,Sambhal,Amroha,Hardoi,Fatehpur,Raebareli,Orai,Sitapur,Bahraich,Modinagar,Unnao,Jaunpur,Lakhimpur,Hathras,Banda,Pilibhit,Barabanki,Khurja,Gonda,Mainpuri,Lalitpur,Etah,Deoria,Badaun,Ghazipur,Sultanpur,Azamgarh,Bijnor,Sahaswan,Basti,Chandausi,Akbarpur,Ballia,Tanda,Shikohabad,Shamli,Awagarh,Kasganj.

Rajasthan:

Jaipur, Jodhpur, Kota ,Bikaner ,Bhiwadi ,Ajmer ,Udaipur ,Bhilwara ,Alwar ,Bharatpur,bharan ,Sri Ganganagar ,Sikar ,Pali ,Tonk ,Kishangarh ,Beawar ,Hanumangarh ,Dhaulpur ,Gangapur City, SawaiMadhopur ,Churu ,Jhunjhunu ,Baran ,Chittaurgarh ,Makrana ,Nagaur ,Banswara ,Dungarpur, pratapgarh

Haryana:

Faridabad (New Township) ,Gurgaon , Panipat, Yamunanagar, Rohtak, Hisar, Karnal, Sonipat, Panchkula (Urban Estate), Ambala Sadar, Bhiwani, Ambala, Sirsa, Bahadurgarh, Jind, Thanesar, Kaithal, Rewari, Palwal, Hansi, Narnaul, Fatehabad, Gohana, Tohana, Narwana.

Other Region: Tamil Nadu, Chennai, Pune, Maharashtra, Nagpur, Bangalore, West-Bengal, Kanyakumari, Odhissa

For more details:

Phone no-8076217931

Office Address:

Alloy Carbon Steel

693 Saini Vihar, Mundka, Delhi 110041

Email [email protected]

Website Link-http://alloycarbonsteel.com/

0 notes