#vadodara

Text

Lakshmi Vilas Palace, Vadodara, Gujarat, India

#art#design#architecture#history#luxury lifestyle#style#luxury house#luxury homes#palace#lakshmi vilas palace#vadodara#india#gujarat#patio#fountain#luxury home

985 notes

·

View notes

Text

Lukshmi Vilas Palace, Vadodara, India.

#beyondheritage#lukshmi villas palace#vadodara#gujarat#india#south asia#architecture#indian architecture

149 notes

·

View notes

Text

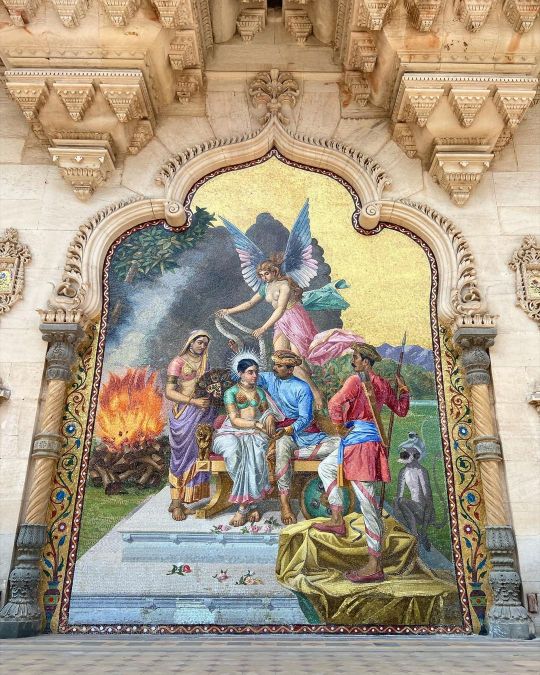

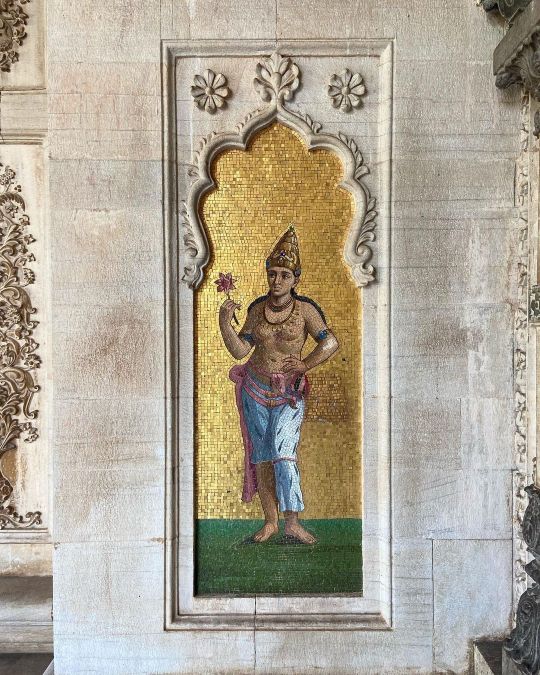

venetian mosaic murals at laxmi vilas palace, vadodara, india; ph. sharang pawar

#so gorg omg#laxmi vilas palace#vadodara#india#indian architecture#venetian murals#italian architecture#sharangpawar#upl#🌟#art

109 notes

·

View notes

Text

How Artificial Intelligence is Transforming the Future of IT Services

In an age dominated by technological advancements, the integration of Artificial Intelligence (AI) has emerged as a revolutionary force, reshaping the landscape of IT services globally. As businesses strive to stay ahead in the digital race, it becomes imperative to understand the transformative power of AI in the realm of Information Technology. In this blog post, we explore how Artificial Intelligence is not just a trend but a fundamental shift that is redefining the future of IT services.

Embracing AI for Enhanced Efficiency

1. Intelligent Automation:

AI-driven automation has become the cornerstone of IT services, streamlining processes, and significantly reducing operational costs. Nivida Software, as a leading IT company in India, recognizes the pivotal role of AI in optimizing workflows and increasing overall efficiency.

2. Predictive Analysis:

Nivida Software leverages AI algorithms to analyze vast datasets, enabling proactive identification of potential issues and predicting trends. By staying ahead of challenges, our IT services ensure a seamless experience for clients across Gujarat and Vadodara.

Delivering Precision with AI-Powered Solutions

3. Customized IT Solutions:

As an innovative IT company in Gujarat, Nivida Software understands the diverse needs of businesses. AI allows us to create tailored solutions that align with the unique requirements of our clients, ensuring maximum impact and value.

4. Enhanced Security Measures:

The integration of AI in IT services goes beyond efficiency; it's about fortifying digital landscapes. Nivida Software employs AI-driven security measures to safeguard sensitive data and protect against evolving cyber threats, setting new standards for IT security in Vadodara. Pioneering AI at Nivida Software

5. Cutting-Edge Development:

Nivida Software is at the forefront of AI development, constantly pushing boundaries to create innovative solutions. As an IT company in India, our commitment to staying ahead in the technological curve positions us as a reliable partner for businesses seeking cutting-edge IT services.

6. Nurturing Talent:

The future of IT services lies in the hands of skilled professionals. Nivida Software invests in talent development, ensuring that our team remains well-versed in the latest AI advancements, delivering top-notch services across India, Gujarat, and Vadodara.

Conclusion

Artificial Intelligence is not merely a technological evolution; it's a paradigm shift that is reshaping the future of IT services. Nivida Software, as a forward-thinking IT company, embraces AI to deliver unparalleled solutions to clients in India, Gujarat, and Vadodara. The journey towards a digitally transformed future begins with Nivida Software – where innovation meets excellence in IT services.

7 notes

·

View notes

Text

ERP in Manufacturing: What You Need to Know for Business Growth

In today's dynamic business landscape, manufacturing companies face numerous challenges, from volatile market demands to complex supply chain management. To thrive in this competitive environment, organizations are increasingly turning to Enterprise Resource Planning (ERP) systems. In this blog post, we will explore the significance of ERP systems for manufacturing companies, their role in software development companies, and the key factors that contribute to business growth.

Understanding ERP Systems for Manufacturing Companies

The Core of ERP: Integration and Automation

ERP systems are comprehensive software solutions designed to integrate and streamline various business processes within an organization. For manufacturing companies, ERP serves as a centralized platform that connects different departments such as production, inventory, procurement, finance, and human resources. The integration of these processes results in improved communication, data accuracy, and operational efficiency.

Key Features of ERP in Manufacturing

1. Production Planning and Scheduling:

ERP systems enable manufacturing companies to optimize production processes by providing real-time insights into resource availability, production capacity, and demand forecasting. This ensures that production schedules are aligned with market demands, reducing the risk of overproduction or stockouts.

2. Inventory Management:

Efficient inventory management is crucial for manufacturing companies. ERP software helps organizations maintain optimal inventory levels, minimize carrying costs, and prevent stockouts. It also facilitates better demand planning and order fulfillment.

3. Quality Control:

ERP systems play a vital role in maintaining product quality by tracking and managing every stage of the manufacturing process. This includes monitoring raw materials, production processes, and finished goods to ensure they meet industry standards and customer expectations.

4. Supply Chain Visibility:

With ERP, manufacturing companies gain better visibility into their supply chain. This visibility helps in identifying potential bottlenecks, reducing lead times, and enhancing collaboration with suppliers. A transparent supply chain is essential for meeting customer demands and maintaining a competitive edge.

5. Financial Management:

ERP systems provide robust financial modules that help manufacturing companies manage budgets, track costs, and generate accurate financial reports. This financial transparency enables informed decision-making and ensures compliance with regulatory requirements.

ERP for Software Development Companies: A Unique Perspective

While traditionally associated with manufacturing, ERP systems have found their way into software development companies as well. The principles of integration, automation, and streamlined processes are just as applicable in the software industry.

Project Management and Collaboration

In software development, ERP systems assist in project management by centralizing tasks, timelines, and resource allocation. This ensures that development teams work cohesively, deadlines are met, and resources are utilized efficiently. Collaboration is enhanced through shared data and communication channels, leading to improved project outcomes.

Resource Allocation and Time Tracking

ERP software allows software development companies to optimize resource allocation and track time spent on different projects. This data-driven approach enhances project planning, improves resource efficiency, and provides insights for future capacity planning.

Scalability and Flexibility

Software companies often face rapidly changing project scopes and client requirements. ERP systems provide the scalability and flexibility needed to adapt to these changes seamlessly. Whether it's adding new features, accommodating changes in project timelines, or expanding the scope, ERP systems empower software development companies to stay agile.

Key Considerations for Implementing ERP in Manufacturing

1. Customization and Flexibility:

Manufacturing companies should look for ERP solutions that offer customization options to align with specific industry needs. Flexibility is crucial, considering the diverse manufacturing processes and business models.

2. User Training and Change Management:

Successful ERP implementation requires thorough training of users and effective change management strategies. Employees need to understand the benefits of ERP and be comfortable with the new system to ensure smooth adoption.

3. Data Security and Compliance:

Given the sensitive nature of manufacturing data, security is a top priority. ERP systems must comply with industry regulations and provide robust security features to safeguard intellectual property, customer information, and business-critical data.

4. Integration with Existing Systems:

Seamless integration with existing software and systems is essential for a smooth transition to ERP. Compatibility with other tools and technologies ensures that there is no disruption in day-to-day operations during the implementation phase.

5. Scalability for Future Growth:

An ERP system should be scalable to accommodate the growing needs of a manufacturing company. It should support expansion into new markets, additional product lines, and increased production volumes without compromising performance.

Conclusion: Driving Business Growth with ERP

In conclusion, ERP systems have become indispensable tools for manufacturing companies seeking sustainable growth in a competitive market. By integrating and automating core business processes, ERP not only enhances operational efficiency but also provides valuable insights for strategic decision-making.

For software development companies, the adaptability of ERP systems offers a unique advantage in managing the dynamic and ever-evolving nature of the industry. The principles that make ERP effective in manufacturing—integration, automation, and streamlined processes—are equally applicable and beneficial in the software development landscape.

As businesses continue to evolve, embracing ERP is not just a technological choice; it's a strategic one. Those who invest in robust ERP solutions position themselves for improved competitiveness, increased profitability, and sustainable growth in the long run.

#ERP systems for manufacturing companies#ERP for manufacturing companies#ERP for software development company#ERP software for manufacturing companies#India#Gujarat#Vadodara#ERP India#Business Solutions#manufacurer#ERP software

7 notes

·

View notes

Text

PM Surya Ghar - Muft Bijli Yojna

Government major step towards sustainability towards solar

Residential solar subsidy upto Rs. 78,000, Installing solar evan more affordable

If you are interested, then contact us to know more.

Call: +91 6352010650

Visit: www.somenergysystems.com

#suryaghar#pmsuryaghar#muftbijli#solarsubsidy#solarrooftop#solar#gosolar#gogreen#solarenergy#vadodara#gujarat#india#ourvadodara

2 notes

·

View notes

Text

"𝐋𝐚𝐮𝐧𝐜𝐡 𝐘𝐨𝐮𝐫 𝐂𝐚𝐫𝐞𝐞𝐫 𝐰𝐢𝐭𝐡 𝐆𝐫𝐚𝐝𝐒𝐢𝐫𝐞𝐧 : 𝐄𝐱𝐜𝐢𝐭𝐢𝐧𝐠 𝐎𝐩𝐞𝐧𝐢𝐧𝐠𝐬 𝐟𝐨𝐫 𝐅𝐫𝐞𝐬𝐡 𝐌𝐢𝐧𝐝𝐬!" || 𝐑𝐞𝐠𝐢𝐬𝐭𝐞𝐫 𝐍𝐨𝐰

#freshers#itjobs#fresherjobs#gradsiren#jobopenings#jobsearching#software#career#careeropportunities#jobopportunities#jobs2024#freshershiring#fresherscareer#jobhiring#internships#Vadodara#bangalore#delhi

2 notes

·

View notes

Text

#PartyPlace#PartyPlaceinVadodara#CelebrationHubVadodara#VadodaraEventVenue#PartyDestinationVadodara#BestPartyPlaceVadodara#TopNotchPartyVenue#PartyInStyleVadodara#PrimePartyLocationVadodara#PartyPerfectionVadodara#Party#PartyLocation#Enjoy#BirthdayParty#FunWorld#FunworldinVadodara#Vadodara

2 notes

·

View notes

Text

Unlocking Success: The Importance of SEO Services in Vadodara

Introduction: In today's digital landscape, having a strong online presence is crucial for businesses in Vadodara, India, to thrive. To achieve this, search engine optimization (SEO) has emerged as a game-changer. As a leading provider of SEO services in Vadodara, Swetnil Digital Marketing is here to shed light on why investing in SEO is a smart move for businesses of all sizes.

Boosting Online Visibility: With countless websites vying for attention, it's essential to stand out in the virtual crowd. SEO services offered by Swetnil Digital Marketing ensure that your website ranks higher on search engine results pages (SERPs). This increased visibility translates to more organic traffic, making it easier for potential customers to find your business online.

Driving Targeted Traffic: SEO enables you to attract relevant and highly targeted traffic. By optimizing your website's content and keywords to match the intent of your potential customers, Swetnil's expert team ensures that your website appears before those actively seeking the products or services you offer in Vadodara.

Maximizing Return on Investment (ROI): Compared to traditional advertising methods, SEO is a cost-effective strategy with a high ROI. By targeting an audience that is already interested in your products or services, you can convert leads into customers more efficiently. Swetnil's SEO services guarantee you get the most value for your marketing budget.

Enhancing User Experience: SEO is not just about keywords and rankings; it's also about providing a seamless user experience. Swetnil Digital Marketing optimizes your website's structure and content, ensuring easy navigation, faster loading times, and mobile responsiveness. A positive user experience leads to higher customer satisfaction and increased chances of conversion.

Gaining a Competitive Edge: In a competitive market like Vadodara, staying ahead of your rivals is vital. Swetnil's SEO experts conduct in-depth competitor analysis to identify gaps and opportunities. By leveraging this data, they tailor strategies that put your business ahead in the digital race.

Conclusion: In a world where online visibility can make or break a business, investing in SEO services has become a necessity rather than an option. Swetnil Digital Marketing, as a trusted provider of SEO services in Vadodara, empowers your business with increased visibility, targeted traffic, and a competitive edge. Embrace the power of SEO today and unlock the door to lasting success for your Vadodara-based business.

2 notes

·

View notes

Text

Need temporary or permanent staffing solutions? Our recruitment consultancy can help you find the best candidates for your open positions, no matter your staffing needs.

#Job#Recruitment#Hiring#Jobplacement#Latestjobs#Overseasrecruitment#Recruiter#Keshavencon#Vadodara#India#newjobs#Vacancy#Engineers#Engineering#recruiting#career#employment#jobseekers#jobvacancy#jobopening#nowhiring#staffing

2 notes

·

View notes

Text

Top-Rated IT Company in Vadodara, Gujarat, India - Transforming Businesses with Cutting-Edge Solutions

Looking for an IT company in Vadodara, Gujarat, or anywhere in India? Look no further! Discover our innovative IT solutions tailored to meet your business needs. With a proven track record of excellence and a team of seasoned professionals, we specialize in providing top-notch IT services, including software development, web design, cybersecurity, and more. Partner with us to take your business to new heights in the digital realm.

7 notes

·

View notes

Text

How to Select the Right ERP Software for Your Indian Manufacturing Firm: Key Considerations

Introduction

In the dynamic landscape of the Indian manufacturing industry, the integration of an efficient Enterprise Resource Planning (ERP) system is paramount. Selecting the right ERP system for manufacturing industry can significantly impact a firm's operational efficiency, productivity, and overall competitiveness. This article delves into the crucial aspects of choosing the best ERP system tailored for the unique needs of Indian manufacturing firms.

Understanding the Unique Needs of the Indian Manufacturing Industry

1. Regulatory Compliance: Navigating the Complexities

One of the primary considerations for Indian manufacturers is ensuring compliance with local regulations. The selected ERP modules for manufacturing industry should seamlessly align with the Goods and Services Tax (GST) framework, a cornerstone of the Indian taxation system. It is imperative to choose a system that streamlines compliance with industry-specific regulations, safeguarding the manufacturing firm from legal complications.

2. Scalability: Growing with Your Business

As Indian manufacturing firms aspire for growth, scalability becomes a pivotal factor in ERP selection. Opt for a system that can effortlessly adapt to the evolving needs of your business. Scalability is particularly crucial for Indian manufacturers aiming for expansion in a market known for its dynamism and ever-changing demands.

3. Localization: Aligning with the Indian Operational Landscape

ERP software must be tailored to the nuances of the Indian market. Look for solutions offering localization features, including support for multiple languages, adherence to regional accounting standards, and culturally relevant interfaces. This ensures that the Best ERP for manufacturing industry seamlessly integrates into the operational fabric of your Indian manufacturing firm.

Key Features to Consider

1. Supply Chain Management: Navigating the Complex Web

Efficient supply chain management is integral for Indian manufacturers dealing with diverse suppliers and fluctuating market demands. The chosen ERP system should provide real-time visibility into the entire supply chain, encompassing procurement, production, and distribution. This ensures that your manufacturing firm can proactively respond to market changes and optimize resource allocation.

2. Production Planning and Control: Meeting the Complexities Head-On

The intricacies of manufacturing processes in India necessitate a comprehensive production planning and control module within the ERP system. Look for software that offers advanced features such as demand forecasting, capacity planning, and real-time monitoring of production processes. This empowers your manufacturing firm to enhance operational efficiency and meet customer demands with precision.

3. Quality Management: Upholding Excellence

Maintaining high-quality standards is non-negotiable for the success of any manufacturing firm. The ERP for manufacturing industry should include robust quality management modules that facilitate adherence to stringent quality control measures. This ensures that your products meet regulatory requirements and customer expectations, bolstering your reputation in the competitive Indian market.

Best ERP for the Indian Manufacturing Industry

1. Evaluating the Options

Selecting the best ERP for your Indian manufacturing firm involves a meticulous evaluation of available options. Consider industry-specific solutions renowned for their effectiveness in addressing the challenges prevalent in the Indian manufacturing landscape.

2. ERP Modules Specifically Tailored for Manufacturing

Explore ERP systems that offer modules explicitly designed for the manufacturing industry. These modules should cover essential aspects such as material requirements planning (MRP), shop floor control, and advanced planning and scheduling (APS). The seamless integration of these modules enhances operational visibility and control.

Customization and Integration: A Prerequisite for Success

1. Tailoring the ERP System to Your Needs

No two manufacturing firms are identical, and the chosen ERP system should accommodate this diversity. Look for software that allows customization to align with the unique processes and requirements of your Indian manufacturing firm. This ensures that the ERP system becomes an asset tailored to your specific needs rather than a one-size-fits-all solution.

2. Integration with Existing Systems

The ERP system should seamlessly integrate with existing software and systems within your manufacturing firm. This includes compatibility with Customer Relationship Management (CRM) software, Human Resource Management Systems (HRMS), and other relevant applications. A well-integrated ERP system for manufacturing industry streamlines data flow, minimizing redundancies and enhancing overall efficiency.

User-Friendly Interface and Training

Ensuring Adoption and Efficiency

An ERP system is only as effective as its adoption by the end-users. Prioritize user-friendly interfaces that facilitate easy navigation and understanding. Additionally, invest in comprehensive training programs to ensure that your team is proficient in utilizing the ERP system to its full potential. This approach maximizes the benefits derived from your ERP investment.

Cost Considerations: Balancing Investment and Returns

1. Calculating the Total Cost of Ownership (TCO)

While the initial cost of ERP implementation is a crucial consideration, it's equally essential to assess the Total Cost of Ownership (TCO) over the long term. Evaluate not only the upfront costs but also ongoing expenses related to maintenance, upgrades, and potential customization. This holistic approach ensures that the chosen ERP system aligns with your budgetary constraints without compromising on functionality.

2. Return on Investment (ROI): Ensuring Long-Term Value

Consider ERP implementation as a strategic investment rather than a mere expense. Calculate the anticipated Return on Investment (ROI) based on enhanced operational efficiency, reduced lead times, and improved customer satisfaction. A thorough ROI analysis ensures that the chosen ERP system delivers long-term value and contributes to the overall success of your Indian manufacturing firm.

Vendor Reputation and Support

1. Choosing a Reliable Partner

Selecting an ERP vendor with a proven track record in the manufacturing industry is crucial. Research and assess the reputation of potential vendors, considering factors such as the number of successful implementations, customer reviews, and the vendor's financial stability. A reliable vendor ensures ongoing support and updates, safeguarding your investment and providing peace of mind.

2. Support and Training Services

Evaluate the support and training services offered by the Best ERP for manufacturing industry. Responsive customer support and comprehensive training programs contribute to a smooth implementation process and ongoing success. Prioritize vendors that prioritize customer satisfaction and offer tailored support to address the unique needs of your Indian manufacturing firm.

Conclusion

In conclusion, choosing the right ERP software for manufacturing industry requires a strategic approach that considers the unique challenges and opportunities in the dynamic Indian market. By prioritizing regulatory compliance, scalability, localization, and key features such as supply chain management, production planning, and quality control, you can identify an ERP solution that aligns seamlessly with the needs of your manufacturing operations. Additionally, evaluating customization options, integration capabilities, user-friendliness, cost considerations, and the reputation of ERP software providers ensures a well-informed decision that propels your Indian manufacturing firm toward enhanced efficiency, productivity, and long-term success.

#ERP for manufacturing industry#ERP system for manufacturing industry#ERP software for manufacturing industry#Best ERP for manufacturing industry#ERP modules for manufacturing industry#India#Gujarat#Vadodara#STERP#shantitechnology

7 notes

·

View notes

Text

MSc Admission Open 2023

Website: devrajsciencecollege.com

Admissions are OPEN for MSc in Chemistry so seize this opportunity to pursue your passion! Apply now to secure your seat at Devraj Science College. Join with us at Devraj Science College to enhance your skills through our quality education.

Admission is open for:

✅ MSC Chemistry

Secure your seat

WhatsApp or Call now: 063548 44391

#Devrajgroupofcolleges#devrajinstituteofsocialwork#sciencecollege#msc#mastersdegree#mscchemistry#chemistry#2023admissions#mscadmissions#AdmissionsOpen2023#panchmahalcollege#bsc#devrajscienceofcollege#Pavagadh#vadodara#godhra

2 notes

·

View notes

Text

PTFE Lined Sight Flow Indicators: Understanding their Functionality and Applications

In many industrial processes, it is important to monitor the flow of liquids or gases through a pipeline or system. This is where sight flow indicators come in, providing a visual way to monitor the flow of fluids. Sight flow indicators can come in a range of materials and designs, but in this blog, we will focus on PTFE lined sight flow indicators manufacturers in India and their functionality and applications.

PTFE (Polytetrafluoroethylene) is a highly non-reactive and versatile material that is resistant to many corrosive chemicals and has a high temperature tolerance. When PTFE is lined on the inside of a sight flow indicator, it provides excellent corrosion resistance and makes it suitable for use in highly corrosive environments.

Functionality of PTFE Lined Sight Flow Indicators:

PTFE Lined Sight Flow Indicators are used to visually monitor the flow of liquids or gases through a pipeline. They consist of a transparent window, usually made of glass or acrylic, and a PTFE lined body that allows the fluid to flow through. The window is typically circular in shape and allows operators to see the flow of the fluid.

The PTFE lining helps protect the sight flow indicator from corrosive substances and ensures the fluid does not come into contact with any metal parts. This lining also helps to reduce friction between the fluid and the sight flow indicator, making it easier for the fluid to flow through.

Applications of PTFE Lined Sight Flow Indicators:

PTFE Lined Sight Flow Indicators have a wide range of applications across various industries due to their excellent resistance to corrosive substances. Some common applications Include:

Chemical Processing: PTFE Lined Sight Flow Indicators in Vadodara are used in the chemical industry to monitor the flow of corrosive chemicals such as acids, alkalis, and Solvents.

Pharmaceutical Industry: In the pharmaceutical industry, PTFE Lined Sight Flow Indicators are used to monitor the flow of high-purity liquids such as purified water, pharmaceutical solutions, and sterile liquids.

Food and Beverage Industry: PTFE Lined Sight Flow Indicators are used in the food and beverage industry to monitor the flow of liquids such as fruit juices, milk, and beer.

Petrochemical Industry: In the petrochemical industry, PTFE Lined Sight Flow Indicators are used to monitor the flow of corrosive liquids such as hydrochloric acid, sulfuric acid, and other hazardous substances.

Manufacturers of PTFE Lined Sight Flow Indicators:

There are many manufacturers of PTFE Lined Sight Flow Indicators manufacturers in India around the world. These manufacturers offer a range of designs and materials to suit various applications. Some of the top manufacturers of PTFE Lined Sight Flow Indicators include:

- L.J. Star Incorporated

- Kenco Engineering Company

- Techniquip Corporation

- Mettler-Toledo International Inc.

- Gems Sensors & Controls

Conclusion:

PTFE Lined Sight Flow Indicators are an essential component in many industrial processes, providing a visual way to monitor the flow of fluids through a pipeline or system. Their excellent resistance to corrosive substances and high temperature tolerance make them ideal for use in a range of applications across various industries. With the increasing demand for PTFE Lined Sight Flow Indicators, manufacturers are constantly improving their designs and materials to meet the needs of their customers.

#PTFE lined sight flow indicators manufacturers in India#PTFE Lined Sight Flow Indicators in Vadodara#manufacturers#india#vadodara

2 notes

·

View notes