#wool processing

Text

Today I started the experiment!

Filled up a black bucket with 2l of distilled water and 50g of raw fleece! Now we wait for the warmth and microbes to do the rest!

And

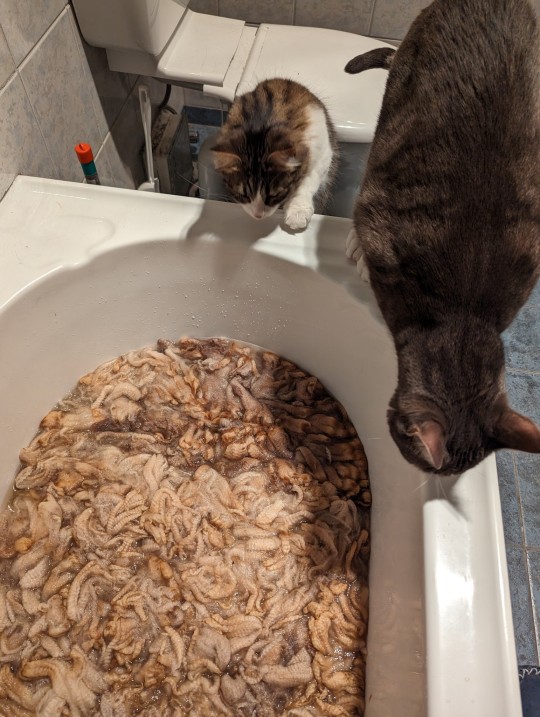

100g washed with power scour from unicorn fiber

I used 3.8ml of power scour on 2 liters of water 47°C for 100g raw fleece, and needed to rinse 4 times with 2 liters of water roughly 38 to 40°C each time.

Geels, looks and smells already very clean. Vegeta let matter will be carded and combed out later

(left raw fleece and left from the washed fleece)

87 notes

·

View notes

Text

Been a couple days but I've been a busy bee!

The Shetland Cheviot fleece I ordered came in a couple days ago and I've been working on scouring it! It cleans up really well!! It's slow going but I'm having fun. Wool combs are on pause while I wash it, because I don't want it sitting unwashed for longer than it Has to, but we'll get there!

I got this fleece on eBay from the island farm shop up in Orkney. I don't know enough about fleeces to say much on it, to be honest, but it's been nice enough to work with and cleans up really well. I'm enjoying it even if it's hard work!

#perrin says#Penryth; baby's first fleece#hand spinning#wool processing#hand crafts#idk what tags people use for this but oh well! i hope you enjoy :3

7 notes

·

View notes

Text

My new flicker is very bitey. I am getting better at the floof though.

7 notes

·

View notes

Text

A good day..

I had the joy and privilege to attend a Traditional Wool Crafting Workshop with Quw'utsun' Elder May Sam.

May is a Salish Knitter by birthright; as a child she supported the family's efforts to produce "Cowichan Knit" sweaters. May is over 70 and a survivor of the Duncan Indian Day School. She Still processes wool, spins and knits her family's traditional designs into hats and headbands, sweaters and pouches. She also teaches and offers workshops throughout island communities. She is an Esteemed Elder in Residence at UVic, and a lovely warm person. I first met her at the First People's House when I attended Uni.

Today we made pompoms! I'll have a few new ones to go with the one May taught me to make over 10 years ago. (It's worn down!)

for me personally though.. the BEST part of this experience:

this Indigenous great-grandmother looked at me (spinning on a drop-spindle) and she spoke to me, and about me, and described what I was doing to the group.. and NEVER ONCE mis-gendered me.

She clocked that I'm non-binary and never once used a gendered pronoun! Astonishing! this has never happened to me before. I feel so seen and respected. Gender Euphoria!

#Quw'utsun#Tsartlip#elder May Sam#indigenous culture#cultural exchange#fibre arts#salish knitting#wool processing#just queer things#gender nonconforming#gender euphoria#international fibre nerds#landback#with gratitude#all our relations#makers#felting

61 notes

·

View notes

Text

The dyed ryå lambs fleece ! Left is alum mordanted, right is a homemade copper mordant, both using yellow onion skin as the dye. Am also so happy with the yarn, although I have zero idea what to do with 100 yards of laceweight singles.

Im not sure how a stripey sock yarn with these two colors would look so it might end up being two pairs, one primarily yellow with orange heel and toe and vice versa. We shall see

#handspun yarn#natural dyeing#the combs should get in in the next day or two#which is just as well bc this fleece isnt actually dry yet. needs a bit longer#have work soon which is unfortunate bc i feel a million times more sick today#struggling not to cough with every word and when i do cough. it is very painful#would love to not go to work but i have tomorrow off...#so im gonna go today and if by tomorrow i dont feel any better then ill call in sick#hate being sick#ah well#ryå lambswool fleece#wool processing#wool fleece

65 notes

·

View notes

Text

Just got a pair of wool combs to help me process this bit of Gotland fleece, and holy fuck I love them. Wasn't happy working with how the hand carders on this one, and just picking by hand was still giving me a lot of uneven slubby-ness, but the combs are great for fluffing and straightening the fibers so they draft out without much fuss. With any luck I'll spin through the last of this one tonight. Then tomorrow I can wash either the Gestrike or the Värmland wool.

From left to right- loaded comb not yet combed through, comb with wool already combed and ready to spin, trusty drop spindle, two singles waiting for a third for plying, small hank of chain-plied yarn ready for a soak to set the twist.

20 notes

·

View notes

Text

i keep forgetting to post things, but look! last batch of wool that needed washed is drying now.

13 notes

·

View notes

Text

Fleece prep begins!!

#i love both the smell of raw wool and washed locks#so rewarding to see it turn white#fibercraft#fiber#wool#wool processing#wool washing#fleece#fleece proccesing

73 notes

·

View notes

Text

Grandma by the Spinning Wheel

by Anders Beer Wilse 1929

29 notes

·

View notes

Text

PAKIGE!!!

I had a new experiment idea!

What kind of affect has the cleaning method for raw wool on the finsihed yarn (softness, look, cleanness)

Before and after cleaning with dish detergent!

Spinning was a bit bumpy, because I didn't do any prepping

But 4,2 m on 0.21, not too bad (also very proud of the thinness)

I'll try:

scouring with potash

Suit fermentation (in tab water and destilled water)

Power scour from unicorn fiber

Plant based sapoids (chestnuts)

Store bought detergents (woolwash or dischsoap)

I bought 500g of raw Merino fleece so I can use 100g for each method (suit fermentation and store bought detergents 50g each)

I want to know how much water I need, how much energy, how much of a pain in the ass is the process, how lanolin free is the fiber after... (Any more questions I should get into? Let me know! How far friendly is it, listen I KNOW from my research that the suit method will be a PvP against my neighbors, but I need to smell for myself)

I'll dukument everything and maybe I'll write a article for my guilds magazine 👀

89 notes

·

View notes

Text

FLEECE

Flicking out the fleece to prep for carding and spinning. Because I need to flick outside due to dirty tips and freeing out all the look dirt and VM.

2 notes

·

View notes

Text

I've been spinning daily for months- king away at a brown Finn wool fleece I picked up last summer. I needed to switch it up.

SO! I decided to prep some matching colourways for this turquoise Corriedale I dyed a few years back.

there are 2 distinct batches of rolags here:

is white Corriedale top mixed with a mixed merino colourway

is white BFL top mixed with the same merino colour blend

It's really interesting to see how differently the Corriedale and BFL handle on the blending board. the BFL is silky and straight and smooth by comparison. The Corriedale is springy and fuzzy and the BFL has a sheen to it.

excited to spin it up!

#click through for embiggen#tour de fleece 2022#ad hoc#hand spinning#wool processing#wool prep#blending board#colourway#international fibre nerds

19 notes

·

View notes

Text

Ok so ! Some experimentation is afoot (pun intended). I've blended several potential fibers with southdown babydoll roving in an attempt to find a good thread to hold alongside the toe of the next sock.

Context for the newcomers--i wear through the toes/ball of the foot of my socks ridiculously quickly, and have been trying on and off to design a sock blend that is kolya-proof for the last several years (mostly to no avail. I do a lot of sock mending 😔). @swords-n-spindles suggested i hold a thread alongside. I want it to add some support to the rest of the yarn, but it also needs to be stretchy enough that it will still conform to the shape of my foot. So, im currently trying to find a good blend to spin into a thin singles (perhaps even a felted singles, in honor of the yarn design spin along since i still havent done february's).

I'm using southdown babydoll because thats what the socks im currently knitting are made of, but i also think it might have been a good choice anyway, since sdb is extremely elastic and fairly durable.

Everything was blended using combs and pulled off without dizzing, bc my elbow already hurts.

So, from top to bottom: plain southdown babydoll roving. Then sdb + firestar (aka nylon). There's a little sample of it so you can see. Then sdb + kid mohair combing waste. I chose waste specifically bc the staple length of the mohair is about double the staple length of the sdb, which does not lead to good top. So the waste was the much shorter bits, which integrate a lot better.

Then we've got sdb + bactrian camel hair. I have a bit of partially dehaired bactrian camel down floating around in my room, and i used my combs to skim the hair off, to reasonable success. The bit on top is just the partially dehaired camel down as i got it, the bottom is partially dehaired camel down that's been de-downed, if you will, so that it's mostly hair. Now, these are much shorter and finer hairs than what youd find if you got a totally intact piece of bactrian camel fleece, but i sadly don't have any. If this sample works out i may need to acquire a piece of intact fleece and see how that goes (i'll need to cut the hair to a suitable staple length, but still). Lastly, we have sdb + karakul fleece. The staple lengths were identical and it blended really nicely.

I plan to spin each sample on my supported spindle, as fine as i can reasonably manage, and see what looks most promising.

My predictions:

FIRESTAR: i'm a little wary of this bc i couldnt blend it effectively. The firestar is very slippery and the sdb is not, so it's not well integrated. I think this sample will end up uneven, with sections of entirely firestar and sections of entirely sdb. I may need to make another sample where i cut the staple of the firestar in half and see if that helps at all, at least when doffing the comb.

MOHAIR: i think it will look and behave almost identically to the 100% sdb. The problem with mohair for these kinds of things is that it is extremely inelastic, so a mohair blend needs to be very sparing with the mohair if you want to retain any elasticity. I could probably have added a little more, though, so if it is identical i will make another sample with more mohair, and see how it is.

BACTRIAN CAMEL HAIR: really excited about this one. Camel hair is very very durable, and of course, quite inelastic. I added as much as i thought i could get away with. I think it will be a little wiry, but very strong.

KARAKUL: also excited about this one. Karakul is extremely durable as well, tyoically used for rugs and such. I added a fair amount to the sdb. I think it will be smoother than the camel hair, but hopefully just as strong. The one caveat is that the micron count is pretty high (30 is average, but i think this might be on the thicker end), which limits how fine i can spin a singles from it. So it may end up a little too thick for this application, but we'll see.

I'm going to spin these either tonight or tomorrow, and perhaps take a stab at felting them. I'll report back when they're spun and all :)

#kolya's ongoing saga of wearing through all its socks absurdly quickly#wool processing#sock knitting#wool combs#southdown babydoll#firestar#mohair#bactrian camel down#bactrian camel hair#karakul

37 notes

·

View notes

Text

Värmland fleece. Used wool combs to separate the tips from the undercoat. Now it's time to scour them. Curious to see how the two layers spin differently.

And a little bonus of doing little batches with a salad spinner in my kitchen sink is that it gives me some extra motivation to actually wash the damn dishes. I can't use the sink for wool washing until the dishes are cleared out.

15 notes

·

View notes

Text

4 notes

·

View notes

Text

drop everything (except your spindles)

Since my next 3D print project will be a spinning wheel, I decided to make the theme for today's fiber arts workshop (at FamiLab www.FamiLab.org every Sunday from 3-5) wool processing from sheep to fabric. I'm bringing in my drop spindles and some examples of raw wool, flax (linen) and cotton for anyone who wants to give spinning a go.

I also found some very informative videos at You Tube. Each describes how the wool comes off the sheep and gets processed, but each chooses to focus on different details and tools, including both hand tools and more industrialized, larger machines for processing in bulk. I would be interested in 3D printing or woodworking a Niddy Noddy, for example, and there are several other such tools and machines that could be fun to build and use.

One of the videos, ("where do I start - choose your tools - spinning yarn for beginners," by Jillian, Eve), mentions that some Maker Spaces are beginning to make Fiber Arts machines, such as spinning wheels and looms, available. I plan on making a 3D printed spinning wheel, and fabricating a table loom, (probably with more wood and metal working than 3D printing), but I would love to be able to make them and house them at the lab for other fiber arts people to use and learn on!

Here are the videos (you can watch on your own, I may pick one of the short ones to show today, if anyone is interested enough):

Wool production and processing - Merino wool processing - by the Woolmart company 3:10 https://youtu.be/YwRbyTCqOQY?si=XaHfsfDVC_Kn9GA2

spinning into yarn - by George Washington, Mt. Vernon, 2:13 https://youtu.be/ltXHYIc015M?si=SdNI7lGNaUROP1TQ

from wool to yarn - processing raw sheep wall into finished yarn by detlillespinneiet at 11:56 https://youtu.be/1y8Yq-aYW_w?si=B4XTVOFd9kDiGey9

sheep to cloth and craft tradition by Handcrafted Tradition 13:23 https://youtu.be/ngLoJxssEao?si=5vZA82YGdw-ny4SA

where do I start choose your tools spinning yarn for beginners, by Jillian, Eve, 19:57, https://youtu.be/MYR8M2Fbllc?si=TH8e6p9k4Z43NUwA

History of spinning playlist by Jillian, Eve (library of 24 videos) https://www.youtube.com/playlist...

Come learn, help teach others, or just work on your latest project in good company where we can help each other out.

#fiber arts#3D printing#fiber arts 3D printing mash up#spinning#wool processing#traditional crafts#drop spindles#spinning wheels#FamiLab#Fiber Arts Workshop

0 notes