#Vibration Sensors Market Outlook

Text

Underwater Monitoring System for Oil and Gas Market Analysis 2023 Dynamics, Players, Type, Applications, Trends, Regional Segmented, Outlook & Forecast till 2033

The underwater monitoring system for oil and gas market was valued from USD 879.0 Million in 2023 to USD 1665.56 Million in 2033. It is estimated to advance at a CAGR of 6.6% from 2024 to 2033.

Overview and Summary

The underwater monitoring system market for oil and gas is an essential segment focused on ensuring the safety, efficiency, and environmental compliance of offshore and underwater oil and gas operations. These systems provide real-time data and surveillance of underwater environments, infrastructure, and activities, helping to detect leaks, monitor equipment integrity, and comply with environmental regulations. Underwater monitoring systems are critical for preventing accidents, optimizing production, and minimizing the environmental impact of oil and gas extraction.

Market Trends

Increased Offshore Exploration: The growth in offshore oil and gas exploration and production activities, driven by the discovery of new reserves and advancements in drilling technologies, is fueling demand for underwater monitoring systems.

Environmental Regulations: Stringent environmental regulations and standards aimed at preventing oil spills and protecting marine ecosystems are driving the adoption of advanced monitoring systems.

Technological Advancements: Innovations in sensor technologies, data analytics, and underwater communication systems are enhancing the capabilities of underwater monitoring systems, making them more reliable and efficient.

Digitalization and IoT Integration: The integration of Internet of Things (IoT) devices and digital technologies is enabling real-time data collection, remote monitoring, and predictive maintenance, improving operational efficiency and safety.

Focus on Safety and Risk Management: The oil and gas industry’s emphasis on safety and risk management is leading to increased investments in monitoring systems to detect potential issues before they escalate into major problems.

Market Analysis

Key Drivers

Operational Efficiency: Underwater monitoring systems help optimize the production process by providing accurate data on underwater conditions and equipment performance, leading to better decision-making and reduced downtime.

Cost Savings: By enabling early detection of leaks, structural issues, and equipment failures, these systems can significantly reduce maintenance costs and prevent costly environmental fines and cleanup operations.

Technological Innovation: Advances in autonomous underwater vehicles (AUVs), remotely operated vehicles (ROVs), and advanced sensors are enhancing the effectiveness and deployment of underwater monitoring systems.

Technical Overview

Underwater monitoring systems for oil and gas typically comprise various sensors, data transmission systems, and monitoring platforms:

Sensors: These include acoustic sensors (for detecting sounds and vibrations), optical sensors (for visual inspections and detecting changes in water clarity), and chemical sensors (for monitoring hydrocarbon levels and other chemical parameters).

Data Transmission: Underwater data transmission is achieved through wired (subsea cables) or wireless (acoustic and optical communication) methods. These systems ensure real-time data transfer from underwater sensors to surface control centers.

Monitoring Platforms: These can be fixed (installed on subsea structures) or mobile (mounted on AUVs or ROVs). These platforms collect and transmit data, which is then analyzed to monitor the health and performance of underwater infrastructure.

Data Analysis and Visualization: Advanced software tools and algorithms analyze the collected data, providing actionable insights and visualizations to operators for decision-making and operational optimization.

Receive the FREE Sample Report of Underwater Monitoring System for Oil and Gas Market Research Insights @ https://stringentdatalytics.com/sample-request/underwater-monitoring-system-for-oil-and-gas-market/15159/

Market Segmentations:

Global Underwater Monitoring System for Oil and Gas Market: By Company

Schlumberger-OneSubea

Kongsberg Maritime

Teledyne Marine

SONARDYNE

Fugro

Ocean Sonics

DSPComm

KCF Technologies

Mitcham Industries

Global Underwater Monitoring System for Oil and Gas Market: By Type

Frequency Division Multiple Access(FDMA)

Time Division Multiple Access(TDMA)

Code Division Multiple Access(CDMA)

Space Division Multiple Access(SFMA)

Global Underwater Monitoring System for Oil and Gas Market: By Application

Deepwater Monitoring

Subsea Pipeline Monitoring

Regional Analysis of Global Underwater Monitoring System for Oil and Gas Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Underwater Monitoring System for Oil and Gas market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Underwater Monitoring System for Oil and Gas Market Research Report @ https://stringentdatalytics.com/purchase/underwater-monitoring-system-for-oil-and-gas-market/15159/?license=single

Key Report Highlights:

Key Market Participants: The report delves into the major stakeholders in the market, encompassing market players, suppliers of raw materials and equipment, end-users, traders, distributors, and more.

Comprehensive Company Profiles: Detailed company profiles are provided, offering insights into various aspects including production capacity, pricing, revenue, costs, gross margin, sales volume, sales revenue, consumption patterns, growth rates, import-export dynamics, supply chains, future strategic plans, and technological advancements. This comprehensive analysis draws from a dataset spanning 12 years and includes forecasts.

Market Growth Drivers: The report extensively examines the factors contributing to market growth, with a specific focus on elucidating the diverse categories of end-users within the market.

Data Segmentation: The data and information are presented in a structured manner, allowing for easy access by market player, geographical region, product type, application, and more. Furthermore, the report can be tailored to accommodate specific research requirements.

SWOT Analysis: A SWOT analysis of the market is included, offering an insightful evaluation of its Strengths, Weaknesses, Opportunities, and Threats.

Expert Insights: Concluding the report, it features insights and opinions from industry experts, providing valuable perspectives on the market landscape.

Report includes Competitor's Landscape:

➊ Major trends and growth projections by region and country

➋ Key winning strategies followed by the competitors

➌ Who are the key competitors in this industry?

➍ What shall be the potential of this industry over the forecast tenure?

➎ What are the factors propelling the demand for the Underwater Monitoring System for Oil and Gas ?

➏ What are the opportunities that shall aid in significant proliferation of the market growth?

➐ What are the regional and country wise regulations that shall either hamper or boost the demand for Underwater Monitoring System for Oil and Gas ?

➑ How has the covid-19 impacted the growth of the market?

➒ Has the supply chain disruption caused changes in the entire value chain?

Customization of the Report:

This report can be customized to meet the client’s requirements. Please connect with our sales team ([email protected]), who will ensure that you get a report that suits your needs. You can also get in touch with our executives on +1 346 666 6655 to share your research requirements.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Linkedin | Facebook | Twitter | YouTube

0 notes

Text

Vibration Control Systems Market Future Trends and Scope Analysis Forecast 2024-2033

Market Definition

A vibration control system is a system designed to reduce or eliminate the transmission of vibration from a source to a structure. The most common type of vibration control system is a isolation system, which isolates the source of vibration from the structure. Isolation systems can be passive or active. Passive isolation systems use materials that have a high natural frequency and a low damping coefficient to absorb vibration. Active isolation systems use sensors to detect vibration and then use active devices, such as electromagnets, to cancel out the vibration.

Market Outlook

The key trends in vibration control systems technology are miniaturization, system integration, and the use of smart materials.

Miniaturization: The trend towards miniaturization is driven by the need for ever smaller and more portable devices. This has led to the development of miniaturized vibration control systems that can be used in a variety of applications, such as mobile phones and wearable devices.

System integration: The trend towards system integration is driven by the need for ever more complex systems. This has led to the development of integrated vibration control systems that can be used in a variety of applications, such as aircraft and automotive systems.

Smart materials: The trend towards the use of smart materials is driven by the need for ever more efficient and effective vibration control systems. This has led to the development of smart materials that can be used in a variety of applications, such as buildings and bridges.

There are several key drivers of the vibration control systems market.

Firstly, the increasing awareness of the need for vibration control in various industries is fuelling the demand for these systems.

Secondly, the stringent regulations regarding vibration control in various industries is another key driver of this market.

Thirdly, the increasing adoption of smart technologies in vibration control systems is another key driver of this market.

Fourthly, the increasing construction activities around the world is another key driver of this market.

To Know More: https://www.globalinsightservices.com/reports/vibration-control-systems-market//?utm_id=1014

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request Sample: https://www.globalinsightservices.com/request-sample/GIS22790/?utm_id=1014

Market Segmentation

The Vibration Control Systems Market is segmented by system type, application, and region. By system type, the market is divided into motion control and vibration control. Based on application, it is bifurcated into automotive, aerospace & defense, manufacturing, electrical & electronics, healthcare, and others. Region-wise, the market is divided into North America, Europe, Asia-Pacific, and the Rest of the World.

Request Customization@ https://www.globalinsightservices.com/request-customization/GIS22790/?utm_id=1014

Major Players

The Vibration Control Systems Market includes players such as ContiTech AG, Lord Corporation, Resistoflex, HUTCHINSON, Fabreeka, Sentek Dynamics Inc., VICODA GmbH, Isolation Technology Inc., Trelleborg AB, and Kinetics Noise Control, Inc.

Request Discounted Pricing@ https://www.globalinsightservices.com/request-special-pricing/GIS22790//?utm_id=1014

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis

Buy your copy here: https://www.globalinsightservices.com/checkout/single_user/GIS22790/?utm_id=1014

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC

16192, Coastal Highway, Lewes DE 19958

E-mail: [email protected]

Phone: +1-833-761-1700

Website: https://www.globalinsightservices.com/

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

0 notes

Text

How Digitalization is Revolutionizing the Steel Industry and What Benefits It Brings

The global steel market reached a value of US$ 874.6 Billion in 2021. Looking forward, IMARC Group expects the market to reach a value of US$ 1,052.25 Billion by 2027, exhibiting a growth rate (CAGR) of 3.02% during 2022-2027. Significant growth in the automotive industry across the globe is creating a positive outlook for the market. But with growth comes a lot of challenges in the steel manufacturing process. Companies in the industry face major challenges with rapid digitalization and unlocking potential in data, shifts in consumer demands, and the attraction of top talents.

Unlocking the potential in digitalization and data

The development of smart factories for automated production to streamline production and support functions will be a giant step for players competing in the field for efficient practices. Investment in digital technologies will be a vital step in promoting effective virtual work to enhance actions across operations ranging from maintenance to customer support functions. The utilization of data in the metals industry will be a disruptor in the valuation of the products and services provided by the industry. Digitally-integrated products and services will become the new norm. Skills in IT and digital technologies will become a vital requirement across industries in order to manage highly valuable IT infrastructures and digital functions.

Shifts in Consumer Demands

By the year 2040, consumer demands for product and service standards will be altered drastically by trends affecting everyday lives. The global population will grow by 25% by the year 2040, causing concerns in demand expectations for industries heavily involved in infrastructural developments such as construction and transportation. More than 68% of people will be living in urban areas by the year 2050, therefore the metals industry must meet demands from rapid urbanization. Metals will be vital players in the development of sustainable and smart infrastructures globally as investments in infrastructure are projected to increase along with the growing population and growing middle class.

Talent Drought

With developing technologies and evolving working cultures, talent acquisition for top talents is a constant challenge in the eyes of employers. This is a current issue in the metals industry that will carry on into the future – especially with talent with modern technologies for functions such as plant management and maintenance. Industries like metals must make strong efforts in building reputable brands for employment that meet the desires of the potential talent for future generational challenges.

With all these challenges in place, steel and metal industries must look into the future in order to maintain the assets, have proper data management in place, and with a talent shortage, more automation should be there for increasing operational efficiency. Some of the ways by which steel industries can improve their manufacturing plants are listed below

Predictive Maintenance using artificial intelligence

Due to the mass automation of the smart metals plant, physical access to the plant is mainly required in order to maintain equipment and machinery. Utilizing artificial intelligence, maintenance can be scheduled according to the production schedules onsite, reducing lag time and delays. Immediate repairs that may cause halts to production can be communicated and coordinated between onsite engineers and digital control managers. Onsite or offsite, maintenance can be assisted digitally from start to finish. For example, with the use of Vibration sensors and Edge devices, employees can receive real-time assistance and guidance about the machine’s health and the actions needed to be taken. These tools provide step-by-step instructions and guidelines required in order to carry out maintenance operations – they will guide employees through what maintenance work needs to be done and in what order in order to ensure efficiency and prevent mistakes. As the maintenance is managed digitally, data will be collected on maintenance processes and improved automatically.

Digitalization and Data Integration

With rapid digitalization in the metals industry, the organization must be able to manage a vast amount of data collected throughout the entire production process and the ecosystem surrounding the plant. Integrating collaborative data management into the metals production cycle is imperative in managing production cycles, shipments, resource management, and maintenance of equipment and machinery in order to develop a streamlined production process. For eg with the help of Vibration sensors, the steel manufacturers read the data in real-time and analyze the anomaly using various AI/ML methods. Based on the data and insights from the expert’s team, the team can take necessary actions based on the data provided to alert the users and take proactive actions to reduce unplanned downtimes.

Digitally Driven employees

A majority of plant operations will be controlled virtually and remotely in the coming years. With the development of AI/ML technologies, Edge computing, and predictive maintenance, processes can be controlled and supervised in real-time. Due to the exponential improvements in automation and the vast amounts of data collected, human interaction with these processes is mainly limited to maintenance, process development, and attention to special, unpredicted situations. A majority of the work in day-to-day processes will be the development of digital technologies and IT infrastructures controlling the automated processes in the plant. With talent shortages in the future, companies like CIMCON Digital can act as the partner who can help the employees by providing the data in real-time, and automating the processes, so that the employees need to act only when it is required instead of manual intervention.

Benefits of the steel industry with Digitalization

There are several machines used in Steel and Metal industries like De scaler pumps, Cooling towers, Downstream and upstream rolling mills, Piercing mills, and many others. All these machines can have unwanted issues and if not managed properly can cause huge delays in the introduction and unplanned downtimes, leading to huge losses. With the advent of technology and hardware like Vibration sensors, Edge Computing merged with AI/ML technologies, steel manufacturers can not only reduce losses but improve the health of the assets, thereby improving operational efficiency.

Some of the major benefits of implementing the latest technology are

Real-time monitoring of critical equipment’s health

Prioritizing and planning maintenance before catastrophic failure

Reduce the risk to safety operators with remote monitoring

Reduce planned downtime and eliminate unplanned downtime

Reduce process and quality-related issues

Increase equipment efficiency and reduce carbon emissions

Conclusion

Steel and metal industries are going through major transformations and it is essential for steel and metal manufacturers to look for technologies that can aid them in reducing manual work, making good use of data, and improving the health of their assets. With the latest technological developments, steel and metal manufacturers can not only predict failures in advance but also look at data and take proactive actions in order to reduce unplanned downtime and improve the operational efficiency of the plants.

0 notes

Text

Piezoelectric Sensors Market: Global Demand Analysis & Opportunity Outlook 2036

Research Nester’s recent market research analysis on “Piezoelectric Sensors Market: Global Demand Analysis & Opportunity Outlook 2036” delivers a detailed competitor’s analysis and a detailed overview of the global Piezoelectric sensors market in terms of market segmentation by sensor type, vibration mode, type, end user, and by region

Request Report Sample@

High Resistance to Rigid Conditions to Promote Global Market Share of Piezoelectric Sensors Market

The global piezoelectric sensors market is estimated to grow majorly on account of increased use of aircrafts, as piezoelectric sensors are used for a wide range of functions in the aeronautics sector. Piezoelectric sensors grew in demand on the account of growth coming from aeronautics sector owing to its huge range of functions in aircrafts, including their measurement capacity & accuracy. There is a constant demand of piezo accelerometers, flow meters, gyroscopes and level sensors in the aeronautics sector. Restructuring of various products, such as APC International’s APC 840/841 and 880 are proprietary hard ceramics piezoelectric material which is made from a formula of high purity lead zirconate titanate, it is used for the production of high-power actuators, high frequency transducer and ultrasonic cleaners.

Growth Drivers:

Increasing demand of piezoelectric sensors in the automobile industry as it used for manufacturing sensors for deployment of airbags.

High Utilization in healthcare sector due to its high precision and sensitivity.

Challenges:

The high cost of specialized materials like lead zirconate titanate which is a ceramic perovskite material used for making piezoelectric sensors. The high cost of the material can be attributed to the low availability of raw material due to the demand and supply disruption and factors including measures approved by policymakers. In addition to that the high cost of designing instruments and installing devices with piezoelectric sensors may be very expensive for limited. Making it very difficult for manufacturers to compete on price and especially in manufacturing cost efficient applications. Hence, these are the factors credited to restraint the market growth of piezoelectric sensors market in the forecast period.

By end user, the piezoelectric sensors global market is segmented into healthcare, IT & telecom, defense & aerospace, industrial manufacturing, automotive, oil & gas. The healthcare segment is to garner a highest revenue by the end of 2036 by growing at a significant CAGR over the forecast period. The segment growth is attributed to the inflated use of piezoelectric sensors in various healthcare application, such as ultrasonic scalers for the removal of plaque using dental scales scanners and for medical imaging, ultrasonic surgery instruments. Furthermore, piezoelectric sensors have a robotic surgery equipment. According to major market surveys between 2012 and 2022 the rate of robotics surgery globally grew by 1.8% to 21.5%.

By region, the European market is to generate the ample revenue by the end of 2036. This growth is anticipated by the growing demand in piezoelectric devices in various industries which include automotive, aerospace, medical and industrial in region. The regional automotive industry driven by countries like Germany and U.K. are attributing to major share in the market with the addition of piezoelectric sensors in electric vehicles. The electric car battery can be charged by the electricity generated by the piezoelectric transduction device. According to European Environment Agency electric vehicles accounted for 12.2% of total new car registration in 2002.

Access our detailed report at:

Research Nester is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates and executives to take wise decisions for their future marketing strategy, expansion and investment etc. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds. Our out of box thinking helps our clients to take wise decision in order to avoid future uncertainties.

Contact for more Info:

AJ Daniel

Email: [email protected]

U.S. Phone: +1 646 586 9123

U.K. Phone: +44 203 608 5919

0 notes

Text

The global demand for condition monitoring services is projected to surpass the valuation of US$ 9.7 Billion by 2033 end. As suggested by a new Future Market Insights (FMI) report, substantial growth in the condition monitoring service market is mainly backed by the growth of the power generation industry, which holds a prominent share of the overall market value, closely followed by the chemical and petrochemical industries. Increasing urbanization and rapid industrialization are creating massive opportunities for key market players in the automotive & transportation industry, thereby bolstering the adoption of condition-monitoring services in the global market. On the flip side, the current global coronavirus pandemic is expected to cost the global economy about US$ 1 Tn in 2022, as per the UN Conference on Trade and Development. Request For Sample Report: Elevate Your Industry Intelligence with Actionable Insights: https://www.futuremarketinsights.com/reports/sample/rep-gb-11280 The automotive, logistics, and petrochemical industries, in particular, are well within the radar of the potential impact of the virus. Several business executives have halted their manufacturing operations, given the large-scale lockdowns in the majority of countries. As the COVID-19 pandemic spreads, condition monitoring services will see a notable decline in their adoption. Key Takeaways of Condition Monitoring Service Market Study According to our research, the portable machine diagnostic segment is shaping the revenue pool of the condition monitoring service market as the portable equipment is used to analyze data from the sensors, saving time of operation. In the current scenario, integration of condition monitoring software with computerized maintenance management services & process control software is an emerging trend in the global condition monitoring service market. North America is a prominent market for condition monitoring services and is expected to continue its hegemony, owing to its strong industrial growth and high adoption of the services in the region. In the global condition monitoring service market, over 55% of the revenue comes through vibration analysis and oil analysis segments. Rising focus on maintenance in order to minimize asset downtime is fueling the deployment of both techniques. Competition Landscape Analysis The global condition monitoring service market is slightly competitive, with the presence of a moderate number of local and global manufacturers. Key manufacturers such as SKF, Fuji Electric, Siemens AG, ABB, Honeywell International Inc., Meggit PLC, General Electric, and Parker Hannifin Corp. account for nearly half of the share of the overall market. Manufacturers are focusing on strengthening their product portfolio by launching advanced condition-monitoring services and collaborating with end users. South Asia Represents Potential Growth Avenues The demand for condition monitoring services is expected to gain traction in South Asia in the coming years, owing to increasing investments in power generation, and petrochemical industries. Governments in countries such as India, and Indonesia are encouraging private sector players to minimize the deficit in power in order to fulfill maximum power requirements. This, in turn, is underpinning the condition monitoring service market in the region More About the Report The research report analyzes the total sales of condition monitoring services on the basis of volume (units) and value (US$ Mn). The condition monitoring service market is projected on the basis of factors such global energy consumption, oil & gas industry outlook, wind energy installed capacity, hydropower installed capacity, and natural gas production and consumption in various regions. Also, the report includes a competition analysis section that includes tier structure analysis, market structure analysis, competition development, and other crucial information of condition monitoring service providers.

0 notes

Text

Insightful Analysis: Estimated Market Size and Key Drivers of the 2024 Global Industrial Control & Factory Automation Market

The Industrial Control & Factory Automation by The Business Research Company provides market overview across 60+ geographies in the seven regions - Asia-Pacific, Western Europe, Eastern Europe, North America, South America, the Middle East, and Africa, encompassing 27 major global industries. The report presents a comprehensive analysis over a ten-year historic period (2010-2021) and extends its insights into a ten-year forecast period (2023-2033).

Learn More On The Industrial Control & Factory Automation Market:

https://www.thebusinessresearchcompany.com/report/industrial-control-and-factory-automation-global-market-report

According to The Business Research Company’s Industrial Control & Factory Automation, The industrial control & factory automation market size has grown strongly in recent years. It will grow from $150.24 billion in 2023 to $163.9 billion in 2024 at a compound annual growth rate (CAGR) of 9.1%. The growth in the historic period can be attributed to efficiency and cost reduction goals, adoption of dcs systems, integration of mes systems, human-machine interface (hmi), computer numerical control (cnc).

The industrial control & factory automation market size is expected to see strong growth in the next few years. It will grow to $224.79 billion in 2028 at a compound annual growth rate (CAGR) of 8.2%. The growth in the forecast period can be attributed to smart manufacturing practices, emphasis on energy efficiency, artificial intelligence and machine learning integration, rapid adoption of iot devices, industry 4.0 evolution.. Major trends in the forecast period include remote and smart manufacturing, energy efficiency and sustainability, predictive maintenance strategies, edge computing in automation, cybersecurity measures.

The emergence of connected enterprises is expected to propel the growth of the industrial control and factory automation market going forward. Connected enterprises are businesses that have digitalized all of their business processes using IoT technology to improve operations.

Get A Free Sample Of The Report (Includes Graphs And Tables):

https://www.thebusinessresearchcompany.com/sample.aspx?id=8978&type=smp

The industrial control & factory automation market covered in this report is segmented –

1) By Component: Industrial Robots, Machine Vision System, Process Analyser, Field Instruments, Human–Machine Interface (HMI), Industrial PC, Industrial Sensors, Industrial 3D Printing, Vibration Monitoring, Other Components

2) By Solution: Distributed Control System (DCS), Supervisory Control and Data Acquisition (SCADA), Programmable Logic Controller (PLC), Manufacturing Execution System (MES), Product Life Cycle Management (PLM), Plant Asset Management (PAM), Functional Safety

3) By Industry: Process Industry, Discrete Industry

Product innovation is a key trend gaining popularity in the industrial control and factory automation market. Major companies operating in the industrial control and factory automation market are introducing new innovative products to sustain their position in the market.

The industrial control & factory automation market report table of contents includes:

Executive Summary

Market Characteristics

Market Trends And Strategies

Impact Of COVID-19

Market Size And Growth

Segmentation

Regional And Country Analysis

.

.

.

Competitive Landscape And Company Profiles

Key Mergers And Acquisitions

Future Outlook and Potential Analysis

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

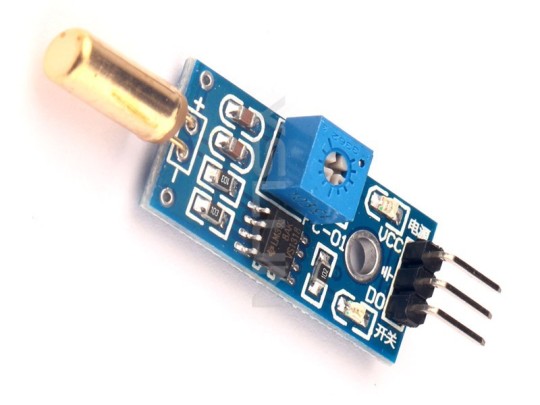

Vibration Sensor Market Size, Share, Trends, Outlook, Forecast 2024-2032

According to IMARC Group latest report titled “Vibration Sensor Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032”, offers a comprehensive analysis of the industry, which comprises insights on vibration sensor market forecast. The report also includes competitor and regional analysis, and contemporary advancements in the global market.

The global vibration sensor market size reached US$ 4.5 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 7.4 Billion by 2032, exhibiting a growth rate (CAGR) of 5.4% during 2024-2032.

Request a Free Sample Report: https://www.imarcgroup.com/vibration-sensor-market/requestsample

A vibration sensor, also known as an accelerometer or vibration transducer, is a device designed to detect and measure vibrations in machinery or structures. It converts mechanical vibrations into electrical signals, providing valuable data for monitoring equipment health and identifying potential issues. Vibration sensors are widely used in various industries, including manufacturing, aerospace, automotive, and infrastructure. They help prevent equipment failure, reduce maintenance costs, and enhance overall operational efficiency by detecting abnormal vibrations that may indicate misalignments, imbalance, or wear. The collected data aids in predictive maintenance strategies, ensuring timely intervention and preventing unexpected breakdowns in machinery or structural components.

Market Trends:

The global market is majorly driven by the increasing emphasis on predictive maintenance. In line with this, industries worldwide are increasingly adopting predictive maintenance strategies, leveraging vibration sensors to monitor equipment health. These sensors play a pivotal role in detecting abnormalities in machinery early on, reducing downtime, and optimizing maintenance schedules. Furthermore, the rise of Industry 4.0 and the broader trend of industrial automation contribute significantly to the market's growth. Vibration sensors are integral components of smart manufacturing systems, enabling real-time monitoring and control of machinery. This facilitates data-driven decision-making, improves overall equipment effectiveness, and supports the transition toward more efficient and connected industrial processes. Besides, the expanding use of vibration sensors in diverse applications, including automotive, aerospace, healthcare, and infrastructure, drives market diversification. In the automotive sector, for example, vibration sensors contribute to vehicle safety and performance monitoring. In healthcare, they play a role in medical diagnostics and monitoring equipment. Additionally, rapid technological advancements, particularly in sensor design and data analytics, enhance the capabilities of vibration sensors. Integrated wireless communication and Internet of Things (IoT) connectivity enable seamless data transmission and remote monitoring, fostering the adoption of these sensors across various industries.

View Full Report with TOC & List of Figure: https://www.imarcgroup.com/vibration-sensor-market

Competitive Landscape

The competitive landscape of the industry has also been examined along with the profiles of the key players operating in the market.

Analog Devices Inc.

Bosch Sensortec GmbH (Robert Bosch GmbH)

Dytran Instruments Inc.

Emerson Electric Corp.

FUTEK Advanced Sensor Technology Inc.

Hansford Sensors Ltd.

Honeywell International Inc.

National Instruments Corporation

NXP Semiconductors N.V.

Rockwell Automation

Safran Colibrys SA

SKF

TE Connectivity Ltd.

Texas Instruments Incorporated.

Key Market Segmentation:

Our report has categorized the market based on region, product, technology, material, and end-use industry.

Breakup by Product:

Accelerometers

Velocity Sensors

Non-Contact Displacement Transducers

Others

Breakup by Technology:

Piezoresistive

Strain Gauge

Variable Capacitance

Optical

Others

Breakup by Material:

Doped Silicon

Piezoelectric Ceramics

Quartz

Breakup by End-Use Industry:

Automotive

Healthcare

Aerospace and Defence

Consumer Electronics

Industrial Machinery

Others

Breakup by Region:

North America (United States, Canada)

Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

Asia Pacific (China, Japan, India, Australia, Indonesia, South Korea, Others)

Latin America (Brazil, Mexico, Others)

Middle East and Africa

Key Highlights of the Report:

Market Performance (2018-2023)

Market Outlook (2024-2032)

Porter’s Five Forces Analysis

Market Drivers and Success Factors

SWOT Analysis

Value Chain

Comprehensive Mapping of the Competitive Landscape

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

0 notes

Text

Efficient Energy Solutions: Innovations in Energy Harvesting Systems

In the pursuit of sustainable and efficient energy solutions, the Energy Harvesting System Market emerges as a frontrunner, revolutionizing the way we harness and utilize power from ambient sources. As we step into 2023, this market continues to witness remarkable advancements, offering innovative technologies that pave the way towards a greener and more self-sufficient future.

The Concept of Energy Harvesting

Energy harvesting, also known as energy scavenging, involves capturing and converting energy from surrounding sources such as light, heat, vibration, or motion into usable electrical power. This principle serves as the foundation for diverse applications across various industries, enabling the generation of electricity where traditional power sources may be limited or inaccessible.

Diverse Sources of Energy

The Energy Harvesting System Market embraces a spectrum of ambient energy sources, each with its unique potential for power generation. Solar photovoltaic cells capture sunlight to produce electricity, while thermoelectric generators harness temperature differentials to generate power. Furthermore, kinetic energy from vibrations or motion can be converted into electrical energy through piezoelectric or electromagnetic systems.

Applications Across Industries

One of the key driving forces behind the Energy Harvesting System Market's growth is its diverse applications across industries. In the realm of IoT (Internet of Things), energy harvesting enables self-powered sensors, wireless devices, and remote monitoring systems, eliminating the need for batteries and facilitating continuous and autonomous operation.

In building automation and smart infrastructure, energy harvesting technologies power wireless sensors for environmental monitoring, lighting control systems, and smart meters, contributing to energy efficiency and reducing maintenance costs.

Moreover, in the automotive sector, these systems find applications in tire pressure monitoring systems (TPMS) and vehicle health monitoring, enhancing safety and efficiency while reducing the environmental impact.

Advancements Driving Efficiency

Technological advancements continue to drive the efficiency and effectiveness of Energy Harvesting Systems. Ongoing research focuses on improving the conversion efficiency of energy harvesters, enhancing energy storage solutions, and optimizing system integration to maximize power output from ambient sources.

Additionally, miniaturization and advancements in material science lead to the development of more compact and lightweight energy harvesting devices, making them more versatile and applicable across a wider range of scenarios.

Sustainability and Environmental Benefits

The Energy Harvesting System Market of 2023 aligns with global sustainability goals, offering eco-friendly solutions that reduce reliance on traditional power sources and minimize carbon footprints. By utilizing renewable and ambient energy sources, these systems contribute to a more sustainable and greener future while reducing waste associated with disposable batteries.

For More Info@ https://www.gmiresearch.com/report/energy-harvesting-system-market/

Future Outlook and Innovation Trajectory

Looking ahead, the Energy Harvesting System Market shows promise for further expansion and innovation. Research initiatives focus on exploring novel materials, advanced integration techniques, and hybrid energy harvesting systems that combine multiple sources for increased efficiency and reliability.

Moreover, advancements in AI (Artificial Intelligence) and machine learning are poised to optimize energy harvesting systems by predicting and adapting to varying ambient conditions, maximizing energy capture and utilization.

Conclusion

The Energy Harvesting System Market in 2023 embodies a paradigm shift towards sustainable and self-sufficient energy solutions. As it continues to evolve and innovate, this market remains a cornerstone in the journey towards a future powered by renewable and ambient energy sources. With its diverse applications, technological advancements, and commitment to sustainability, energy harvesting promises a more efficient, autonomous, and environmentally conscious world.

0 notes

Text

Sensor Bearing Market Growing High CAGR During 2023-29

According to Precision Business Insights, the global Sensor Bearing Market is poised to grow at a significant CAGR of 5.5% during forecast period 2023-2029

The global sensor bearing market size was valued at USD 6.62 billion in 2022 and is poised to grow at a significant CAGR of 5.5% during the forecast period 2023-29. It also includes market size and projection estimations for each of the five major regions from 2023 to 2029. The research report includes historical data, trending features, and market growth estimates for the future. Furthermore, the study includes a global and regional estimation and further split by nations and categories within each region. The research also includes factors and barriers to the sensor bearing market growth, as well as their impact on the market's future growth. The report gives a comprehensive overview of both primary and secondary data.

View the detailed report description here - https://www.precisionbusinessinsights.com/market-reports/global-sensor-bearing-market

The global sensor bearing market segmentation:

1) By Functionality : Displacement, Speed, Temperature, Vibration and Others.

2) By Application : Anti-lock Brake Systems (ABS), Electric Motors, Material Handling Equipment and Others.

3) By End User : Aerospace & Defense, Automotive, Metal & Mining, Oil & Gas, Transportation and Others.

The primary factors of the sensor bearing market drivers are the increasing demand for bearings with longer service life, higher efficiency, and lower maintenance requirements. The sensor bearing market report helps to provide the best results for business enhancement and business growth. It further helps to obtain the reactions of consumers to a novel product or service. It becomes possible for business players to take action for changing perceptions. It uncovers and identifies potential issues of the customers. It becomes easy to obtain the reactions of the customers to a novel product or service. It also enlightens further advancement, so it suits its intended market.

The sensor bearing marketresearchreport gives a comprehensive outlook across the region with special emphasis on key regions such as North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Asia Pacific was the largest region in the sensor bearing market report, accounting for the highest share in 2022. It was followed by Asia Pacific, and then the other regions.

Request sample report at - https://www.precisionbusinessinsights.com/request-sample/?product_id=27699

The important profiles and strategies adopted by sensor bearing market key players are Timken (US), NSK Corporation (Japan), Schaeffler Technologies AG & Co. KG (Germany), NTN Corporation (Japan), Nachi Europe GmbH (Germany), Mageba SA (Switzerland), JTEKT Corporation (Japan), Fersa Bearing SA (Spain), BRTEC (China), ABB Group (Switzerland), SKF (Sweden), covered here to help them in strengthening their place in the market.

About Precision Business Insights:

We are a market research company that strives to provide the highest quality market research insights. Our diverse market research experts are enthusiastic about market research and therefore produce high-quality research reports. We have over 500 clients with whom we have a good business partnership and capacity to provide in-depth research analysis for more than 30 countries. In addition to deliver more than 150 custom solutions, we already have accounts with the top five medical device manufacturers.

Precision Business Insights offers a variety of cost-effective and customized research services to meet research requirements. We are a leading research service provider because of our extensive database built by our experts and the services we provide.

Contact:

Mr. Satya

Precision Business Insights | Toll Free: +1 866 598 1553

Email: [email protected]

Kemp House, 152 – 160 City Road, London EC1V 2NX

Web: https://precisionbusinessinsights.com/ | D U N S® Number: 852781747

#sensor bearing market size#sensor bearing market share#sensor bearing market growth#sensor bearing market trends#sensor bearing market dynamics

0 notes

Text

0 notes

Text

Exploring the Evolution and Future Outlook of the Smart Pallet Sensors Market: Comprehensive Analysis of Technological Advancements, Industry Trends, Market Dynamics, Competitive Landscape, and Key Growth Opportunities To 2030

Smart Pallet Sensors Market: Overview

Smart pallet sensors are devices that are used to track and monitor pallets of goods in the supply chain. They are equipped with sensors that can measure a variety of data points, such as temperature, humidity, vibration, and location. This data can be used to track the movement of pallets, identify potential problems, and improve the efficiency of the supply chain.

The smart pallet sensors market is growing rapidly, due to the increasing demand for visibility and traceability in the supply chain. The market is also being driven by the increasing adoption of IoT technologies in the manufacturing and logistics industries.

Market Drivers

The following are some of the key drivers of the smart pallet sensors market:

Increasing demand for visibility and traceability in the supply chain: Businesses are increasingly demanding visibility into the movement of their goods throughout the supply chain. Smart pallet sensors can provide this visibility by tracking the location, temperature, and humidity of pallets. This information can be used to identify potential problems, such as temperature excursions or pallet damage, and to improve the efficiency of the supply chain.

Adoption of IoT technologies in the manufacturing and logistics industries: The manufacturing and logistics industries are increasingly adopting IoT technologies. This is being driven by the need to improve efficiency, reduce costs, and improve customer service. Smart pallet sensors are a key component of IoT-enabled supply chains.

Government regulations: Governments are increasingly introducing regulations that require businesses to track the movement of goods in the supply chain. This is being driven by concerns about food safety, counterfeit goods, and environmental protection. Smart pallet sensors can help businesses to comply with these regulations.

Market Challenges

The following are some of the key challenges of the smart pallet sensors market:

High cost: Smart pallet sensors are more expensive than traditional pallet sensors. This could limit their adoption by some businesses.

Data security: Smart pallet sensors collect and transmit sensitive data. This data needs to be protected from unauthorized access or disclosure.

Interoperability: There is no single standard for smart pallet sensors. This could make it difficult to integrate different sensors into a single supply chain management system.

Market Opportunities

The following are some of the key opportunities of the smart pallet sensors market:

Growth of the e-commerce market: The e-commerce market is growing rapidly, and this is driving demand for smart pallet sensors. Smart pallet sensors can help businesses to track the movement of goods from the warehouse to the customer's door.

Development of new sensor technologies: New sensor technologies, such as RFID and blockchain, are being developed that could make smart pallet sensors more affordable and interoperable.

Growth of the global supply chain: The global supply chain is growing, and this is creating new opportunities for smart pallet sensors. Smart pallet sensors can help businesses to improve the efficiency and visibility of their supply chains.

Market Forecast

The global smart pallet sensors market is expected to grow at a CAGR of 4.2% from 2022 to 2030. The market is being driven by the increasing demand for visibility and traceability in the supply chain, the adoption of IoT technologies in the manufacturing and logistics industries, and government regulations.

Key Players

Some of the key players in the smart pallet sensors market include:

ADLINK Technology Inc.

Ambrosus

Chainvu

Ahrma Group

Ennomotive

Metiora

LogTrade Technology AB

NFC Group

TronicsZone

RM2

Lightning Technologies LLC

Conclusion

The smart pallet sensors market is growing rapidly, due to the increasing demand for visibility and traceability in the supply chain. The market is also being driven by the adoption of IoT technologies in the manufacturing and logistics industries and government regulations. The key players in the market are developing new sensor technologies and integrating them with existing supply chain management systems. This is expected to further drive the growth of the market in the coming years.

1 note

·

View note

Text

Industrial Primary Lithium Batteries Market Outlook on Key Growth Trends, Factors and Forecast 2032

Industrial Primary Lithium Batteries Market Overview:

The industrial primary lithium batteries market refers to the market for non-rechargeable lithium batteries used in various industrial applications. These batteries offer high energy density, long shelf life, and reliable performance, making them suitable for critical and demanding industrial operations. Global Primary Lithium Battery Market Insight [2023-2030] Estimated to Reach USD 3907.4 Million (Growing at a CAGR of 4.3%)

Here is an overview of the industrial primary lithium batteries market and its key factors:

Key Factors:

Industrial Applications: Industrial primary lithium batteries find extensive use in a wide range of industries such as oil and gas, mining, manufacturing, transportation, aerospace, defense, and utility sectors. These batteries power various equipment and devices, including remote monitoring systems, sensors, meters, wireless communication devices, and backup power solutions.

High Energy Density: Industrial primary lithium batteries are known for their high energy density, meaning they can store a significant amount of energy in a compact size. This characteristic is crucial in industrial applications where space is limited, and long-lasting power supply is essential.

Long Shelf Life: Lithium batteries have an extended shelf life, retaining their charge even when stored for extended periods. This is advantageous in industrial settings where batteries may need to be deployed on-demand or stored as backup power solutions.

Temperature Performance: Industrial primary lithium batteries offer excellent performance in extreme temperatures, including high and low temperature conditions. This makes them suitable for applications that require reliable operation in harsh environments.

Reliability and Safety: Industrial operations often rely on critical equipment and systems where reliable power supply is crucial. Primary lithium batteries are known for their stable voltage output and consistent performance throughout their lifespan. Additionally, they are designed with safety features to prevent issues such as leakage or thermal runaway, ensuring safe operation in industrial environments.

Durability and Resistance: Industrial primary lithium batteries exhibit durability and resistance to vibrations, shocks, and various environmental factors such as humidity, dust, and chemicals. These characteristics make them suitable for rugged industrial applications and challenging operating conditions.

Cost-effectiveness: Although the upfront cost of primary lithium batteries may be higher than other battery types, their long service life and reliable performance make them cost-effective solutions for industrial applications. The reduced need for frequent battery replacements and maintenance contributes to overall cost savings.

Technological Advancements: The industrial primary lithium batteries market benefits from ongoing technological advancements. These include improvements in battery chemistry, materials, and design, resulting in enhanced energy density, extended operational life, increased safety, and better performance in various industrial environments.

Increasing Industrial Automation: The growing trend of industrial automation and digitization drives the demand for reliable and long-lasting power solutions. Industrial primary lithium batteries provide the necessary energy supply for automated systems, wireless communication, and remote monitoring, supporting the advancement of industrial automation.

In summary, the industrial primary lithium batteries market is driven by the wide range of industrial applications, high energy density, long shelf life, temperature performance, reliability, safety, durability, cost-effectiveness, technological advancements, and the increasing adoption of industrial automation. As industrial operations continue to evolve and demand reliable power solutions, the market for industrial primary lithium batteries is expected to grow.

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/industrial-primary-lithium-batteries-market/6709/

Market Segmentations:

Global Industrial Primary Lithium Batteries Market: By Company

• EVE Energy

• SAFT

• Hitachi Maxell

• GP Batteries International

• Energizer

• Duracell

• Varta

• Changzhou Jintan Chaochuang Battery

• Vitzrocell

• FDK

• Panasonic

• Murata

• Wuhan Lixing (Torch) Power Sources

• Newsun

• Renata SA

• Chung Pak

• Ultralife

• Power Glory Battery Tech

• HCB Battery

• EEMB Battery

Global Industrial Primary Lithium Batteries Market: By Type

• Li/SOCL2

• Li/MnO2

• Li-SO2

• Others

Global Industrial Primary Lithium Batteries Market: By Application

• Automotive

• Security Equipment

• Communication Equipment

• Others

Global Industrial Primary Lithium Batteries Market: Regional Analysis

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Industrial Primary Lithium Batteries market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/industrial-primary-lithium-batteries-market/6709/

Reasons to Purchase Industrial Primary Lithium Batteries Market Report:

• To gain insights into market trends and dynamics: this reports provide valuable insights into industry trends and dynamics, including market size, growth rates, and key drivers and challenges.

• To identify key players and competitors: this research reports can help businesses identify key players and competitors in their industry, including their market share, strategies, and strengths and weaknesses.

• To understand consumer behavior: this research reports can provide valuable insights into consumer behavior, including their preferences, purchasing habits, and demographics.

• To evaluate market opportunities: this research reports can help businesses evaluate market opportunities, including potential new products or services, new markets, and emerging trends.

• To make informed business decisions: this research reports provide businesses with data-driven insights that can help them make informed business decisions, including strategic planning, product development, and marketing and advertising strategies.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Wireless Sensors#Smart Grid#Power Tools#Emergency Lighting#Security Systems#Environmental Monitoring#Transportation#Renewable Energy#Lithium Thionyl Chloride#Lithium Sulfur Dioxide#Lithium Manganese Dioxide#Lithium Iron Disulfide#Lithium Carbon Monofluoride.

0 notes

Text

Wireless Motor Monitoring System Market to Witness Excellent Revenue Growth Owing to Rapid Increase in Demand

Latest added Wireless Motor Monitoring System Market research study by AMA Research offers detailed outlook and elaborates market review till 2028. The market Study is segmented by key regions that are accelerating the marketization. At present, the market players are strategizing and overcoming challenges of current scenario;

Some of the key players in the study are:

The Emerson Electric Co. (United States)

General Electric (United States)

Honeywell International Inc. (United States)

National Instruments (United States)

SKF (Sweden)

Parker Hannifin Corporation (United States)

Rockwell Automation, Inc. (United States)

Siemens AG (Germany)

Yokogawa Electric Corporation (Japan)

SPM Instrument (Sweden)

Analog Devices, Inc. (United States)

etc.

In the current era automation has become a basic need for various industries such as automotive, oil & gas, food & beverages, and energy & power, among others. In addition to this, with the increasing use of electric machinery, there is surging need to extract data or information from the machines to improve their control system and maintenance management. In the current scenario, manufacturers are continuously focusing to develop innovative techniques and development in the quality of sensors, owing to increasing wireless motor monitoring system need in manufacturing industries across the world. Moreover, advancements in predictive maintenance technologies are encouraging the manufacturing companies to deploy wireless motor monitoring systems in mainstream operations propelling market growth.

Influencing Trend: Emergence of Cloud-Based Wireless Motor Monitoring System

Technological Advancement in the Wireless Equipment Monitoring System

Challenges: Lack of Awareness in the Emerging Economies

Opportunities: Rising Demand from the Automotive Industry

Increasing Demand from the Developing Economies Owing to Growth in Industrialization

Market Growth Drivers: Growing Need for Predictive Maintenance for Industrial Applications

Increasing Use of Wireless Sensors in the End-Use Industries

The Global Wireless Motor Monitoring System segments and Market Data Break Down by Type (Vibration Sensors, Power Sensors, Dual Analog Sensors, Others), Application (Oil and gas, Automotive, Water and wastewater, Food and beverage, Others), Deployment (On-Premises, Cloud-Based)

Presented By

AMA Research & Media LLP

0 notes

Text

Shape Memory Polymer Market Trends | Segmentation, Outlook, Industry Report to 2032

The global shape memory polymer market is projected to grow at a CAGR of 26.9% between 2022 and 2032, according to a recently published study by Future Market Insights. As of 2022, the market is slated to be valued at US$ 450.4 Million. By the end of the 2022-2032 forecast period, the market is expected to be valued at US$ 3.5 Billion.

Shape memory polymers are smart materials that can change their shape in response to external stimuli. The materials find extensive use in the automotive, biomedical, and aerospace industries.

The biomedical industry is a key end-user of SMPs as they are employed in producing a plethora of diagnostic and surgical devices such as catheters, sutures, stents, braces, splints, prosthetics, and grafts. These shape memory polymers (SMPs), as stimuli-responsive materials, have garnered worldwide fame.

Shape memory polymers are also intensively found in the construction industry and find use as self-healing materials in sensors or actuators or structural health monitors and vibration control systems. Their use in kinetic buildings will also hold significance to the industry. This is more so when the government is promoting an eco-friendly zone and green buildings to lower the carbon footprint and protect the environment.

Competitive Landscape

The global shape-memory polymer market is fairly consolidated as the majority of the market share is divided among a few players. Some of the key players in the market include BASF SE, COVESTRO AG, Evonik Industries AG, SMP Technologies Inc., and Spintech Holdings Inc., among others.

Get a Sample Copy of the Report @

https://www.futuremarketinsights.com/reports/sample/rep-gb-15383

Key Segments Covered in the Shape Memory Polymer Industry Report

Shape Memory Polymer Market by Material:

Polyurethane (PU) Shape Memory Polymer

Polyvinyl Chloride (PVC) Shape Memory Polymer

Acrylic Shape Memory Polymer

Epoxy Shape Memory Polymer

Other Shape Memory Polymer Material

Shape Memory Polymer Market by Application:

Shape Memory Polymer for Research & Development

Shape Memory Polymer for Commercial Applications

Shape Memory Polymer Market by End Use:

Shape Memory Polymer for Biomedical Use

Shape Memory Polymer for Automotive

Shape Memory Polymer for Aerospace

Shape Memory Polymer for Textile

Shape Memory Polymer for Other End Uses

“With continued attraction for shape memory polymer product in end-user industries such as healthcare, biomedical, construction, automotive textile and aerospace, for changing contours dictated by random needs, and in a spate of lesser known applications, the product is poised to achieve growing market share in forthcoming years”, remarks the FMI Analyst.

Browse the latest Market Reports@

https://www.futuremarketinsights.com/category/chemicals-and-materials

0 notes

Text

Piezoelectric Sensors Market: Global Demand Analysis & Opportunity Outlook 2036

Research Nester’s recent market research analysis on “Piezoelectric Sensors Market: Global Demand Analysis & Opportunity Outlook 2036” delivers a detailed competitor’s analysis and a detailed overview of the global Piezoelectric sensors market in terms of market segmentation by sensor type, vibration mode, type, end user, and by region

Request Report Sample@

High Resistance to Rigid Conditions to Promote Global Market Share of Piezoelectric Sensors Market

The global piezoelectric sensors market is estimated to grow majorly on account of increased use of aircrafts, as piezoelectric sensors are used for a wide range of functions in the aeronautics sector. Piezoelectric sensors grew in demand on the account of growth coming from aeronautics sector owing to its huge range of functions in aircrafts, including their measurement capacity & accuracy. There is a constant demand of piezo accelerometers, flow meters, gyroscopes and level sensors in the aeronautics sector. Restructuring of various products, such as APC International’s APC 840/841 and 880 are proprietary hard ceramics piezoelectric material which is made from a formula of high purity lead zirconate titanate, it is used for the production of high-power actuators, high frequency transducer and ultrasonic cleaners.

Growth Drivers:

Increasing demand of piezoelectric sensors in the automobile industry as it used for manufacturing sensors for deployment of airbags.

High Utilization in healthcare sector due to its high precision and sensitivity.

Challenges:

The high cost of specialized materials like lead zirconate titanate which is a ceramic perovskite material used for making piezoelectric sensors. The high cost of the material can be attributed to the low availability of raw material due to the demand and supply disruption and factors including measures approved by policymakers. In addition to that the high cost of designing instruments and installing devices with piezoelectric sensors may be very expensive for limited. Making it very difficult for manufacturers to compete on price and especially in manufacturing cost efficient applications. Hence, these are the factors credited to restraint the market growth of piezoelectric sensors market in the forecast period.

By end user, the piezoelectric sensors global market is segmented into healthcare, IT & telecom, defense & aerospace, industrial manufacturing, automotive, oil & gas. The healthcare segment is to garner a highest revenue by the end of 2036 by growing at a significant CAGR over the forecast period. The segment growth is attributed to the inflated use of piezoelectric sensors in various healthcare application, such as ultrasonic scalers for the removal of plaque using dental scales scanners and for medical imaging, ultrasonic surgery instruments. Furthermore, piezoelectric sensors have a robotic surgery equipment. According to major market surveys between 2012 and 2022 the rate of robotics surgery globally grew by 1.8% to 21.5%.

By region, the European market is to generate the ample revenue by the end of 2036. This growth is anticipated by the growing demand in piezoelectric devices in various industries which include automotive, aerospace, medical and industrial in region. The regional automotive industry driven by countries like Germany and U.K. are attributing to major share in the market with the addition of piezoelectric sensors in electric vehicles. The electric car battery can be charged by the electricity generated by the piezoelectric transduction device. According to European Environment Agency electric vehicles accounted for 12.2% of total new car registration in 2002.

Access our detailed report at:

0 notes

Text

Condition Monitoring System Market Outlook, Trends & Demand Analysis during Forecast to 2031

The global demand for condition monitoring system market is expected to exceed US$ 6.79 billion by the end of 2031. Demand in Canada is expected to rise at a nearly 7% CAGR during the forecast period. The presence of a well-developed oil and gas industrial landscape, as well as a thriving food and beverage industry, drives the condition monitoring system market in Canada.

According to a new Future Market Insights (FMI) report, significant growth in the condition monitoring service market is being driven primarily by the expansion of the facility generation industry. Which has a significant share of the overall market value, followed by the chemical and petrochemical industries.

The automotive, logistics, and petrochemicals industries, in particular, are well aware of the virus's potential impact. Given the widespread lockdowns in the majority of countries, several business executives have halted their manufacturing operations.

Get a Sample Copy of this Report @

https://www.futuremarketinsights.com/reports/sample/rep-gb-11280

Increasing urbanization and rapid industrialization are creating massive opportunities for key market players in the automotive & transportation industry, thereby bolstering the adoption of condition monitoring services in the global market. On the flip side, the current global coronavirus pandemic is expected to cost the global economy about US$ 1 Tn in 2022, as per the UN Conference on Trade and Development.

Key Takeaways of Condition Monitoring Service Market Study

According to our research, the portable machine diagnostic segment is shaping the revenue pool of the condition monitoring service market as the portable equipment is used to analyze data from the sensors, saving time of operation.

In the current scenario, integration of condition monitoring software with computerized maintenance management services & process control software is an emerging trend in the global condition monitoring service market.

North America is a prominent market for condition monitoring services and is expected to continue its hegemony, owing to its strong industrial growth and high adoption of the services in the region.

In the global condition monitoring service market, over 55% of the revenue comes through vibration analysis and oil analysis segments. A rising focus on maintenance to minimize asset downtime is fueling the deployment of both techniques.

In order to minimize the asset downtime, it is necessary to monitor the assets continuously or in regular intervals, especially in facilities such as power generation and petrochemical plants. Given the criticality of highly accurate results in such facilities, manufacturers are striving to further develop condition monitoring software that can be integrated into the services to record the data.

Get More Information on this Report @

https://www.futuremarketinsights.com/reports/condition-monitoring-system-market

Condition Monitoring System Market by Category

By Technique:

Corrosion Monitoring

Infrared Thermography

Motor Condition Monitoring

Oil Analysis

Ultrasound Testing

Vibration Analysis

By Application:

Aerospace and Defense

Automotive and Transportation

Chemical and Petrochemical

Food & Beverage

Marine

Mining and Metal

Oil and Gas

Power Generation

By Region:

North America

Latin America

Europe

East Asia

South Asia & Pacific

Middle East and Africa (MEA)

0 notes