#Automotive Vacuum Pump Market

Text

Automotive Electric Vacuum Pump Market Growth, Overview with Detailed Analysis 2022-2028

Automotive Electric Vacuum Pump Market Growth, Overview with Detailed Analysis 2022-2028

The Automotive Electric Vacuum Pump Market research report 2022-2030 provides an in-depth analysis of the changing trends, opportunities, and challenges influencing the growth over the next decade. The study includes a detailed summary of each market along with data related to demand, supply and distribution. The report examines Automotive Electric Vacuum Pump market growth strategies adopted by…

View On WordPress

#Automotive Electric Vacuum Pump#Automotive Electric Vacuum Pump forecast#Automotive Electric Vacuum Pump Industry#Automotive Electric Vacuum Pump Market#Automotive Electric Vacuum Pump price#Automotive Electric Vacuum Pump report#Automotive Electric Vacuum Pump research#Automotive Electric Vacuum Pump share#Automotive Electric Vacuum Pump trends#Covid-19 Impact Analysis

0 notes

Text

Zero Friction Coatings Market: Charting the Course for Enhanced Performance and Sustainable Solutions

The global zero friction coatings market size is estimated to reach USD 1,346.00 million by 2030 according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.6% from 2022 to 2030. Growth can be attributed to the fact that these coatings reduce friction and wear resulting in low fuel consumption and less heat generation. According to the European Automobile Manufacturers' Association, 79.1 million motor vehicles were produced across the globe in 2021 which was up by 1.3% as compared to 2020. Zero friction coatings can extend the time between component maintenance and replacement, especially for machine parts that are expensive to manufacture.

Zero Friction Coatings Market Report Highlights

In 2021, molybdenum disulfide emerged as the dominant type segment by contributing around 50% of the revenue share. This is attributed to its properties such as low coefficient of friction at high loads, electrical insulation, and wide temperature range

The automobile & transportation was the dominating end-use segment accounting for a revenue share of more than 35% in 2021 due to the rapid growth of the automotive industry across the globe

The energy end-use segment is anticipated to grow at a CAGR of 5.7% in terms of revenue by 2030, owing to the excessive wear on the drill stem assembly and the well casing during the drilling operations in the oil and gas sector

In Asia Pacific, the market is projected to witness the highest CAGR of 5.8% over the predicted years owing to the presence of car manufacturing industries in the countries such as Japan, South Korea, and China

For More Details or Sample Copy please visit link @: Zero Friction Coatings Market Report

Several applications in the automobile industry use wear-resistant plastic seals that require zero tolerance for failure and lifetime service confidence. Increasing demand for the product from the automotive industry across the globe for various applications including fuel pumps, automatic transmissions, oil pumps, braking systems, and others is expected to drive its demand over the forecast period.

Low friction coatings can be used in extreme environments comprising high pressure, temperatures, and vacuums. These coatings can provide improved service life and performance thereby eliminating the need for wet lubricants in environments that require chemicals, heat, or clean room conditions. The product containing molybdenum disulfide (MoS2) are suitable for reinforced plastics while those free from MoS2 are suitable for non-reinforced plastics.

Zero friction coatings are paint-like products containing submicron-sized particles of solid lubricants dispersed through resin blends and solvents. The product can be applied using conventional painting techniques such as dipping, spraying, or brushing. The thickness of the film has a considerable influence on the anti-corrosion properties, coefficient of friction, and service life of the product. Its thickness should be greater than the surface roughness of the mating surfaces.

ZeroFrictionCoatingsMarket #FrictionlessTechnology #CoatingInnovations #IndustrialEfficiency #ZeroFrictionSolutions #AdvancedMaterials #SurfaceCoatings #ManufacturingAdvancements #GlobalIndustryTrends #InnovativeCoatings #PerformanceOptimization #MechanicalSystems #SustainableTechnology #IndustrialApplications #FutureTech #InnovationInMaterials #EfficiencySolutions #ZeroFrictionMarket #TechnologyInnovation #EngineeringMaterials

#Zero Friction Coatings Market#Frictionless Technology#Coating Innovations#Industrial Efficiency#Zero Friction Solutions#Advanced Materials#Surface Coatings#Manufacturing Advancements#Global Industry Trends#Innovative Coatings#Performance Optimization#Mechanical Systems#Sustainable Technology#Industrial Applications#Future Tech#Innovation In Materials#Efficiency Solutions#Zero Friction Market#Technology Innovation#Engineering Materials

2 notes

·

View notes

Text

Choosing the Right Vacuum Pump: Tips and Considerations

Vacuum pumps play a vital role in various industries, from manufacturing and research to healthcare and automotive. They're essential for creating vacuum environments necessary for processes like material handling, degassing, and vacuum sealing.

However, selecting the right vacuum pump for your specific application can be a daunting task, given the multitude of options available in the market. To help you make an informed decision, let's explore some tips and considerations when choosing a vacuum pump.

Understand Your Application

The first step in selecting the right vacuum pump is understanding your application requirements thoroughly. Consider factors such as the desired vacuum level, flow rate, gas composition, and operating conditions. Different applications may require specific pump technologies to achieve optimal performance.

Types of Vacuum Pumps

Vacuum pumps Australia come in various types, each suited for different applications. Common types include rotary vane pumps, diaphragm pumps, scroll pumps, and turbomolecular pumps. Research the characteristics and capabilities of each type to determine which one aligns best with your application needs.

Vacuum Level Requirements

Vacuum levels vary depending on the application. Some processes require high vacuum levels, while others only need low or medium vacuum. Ensure the vacuum pump you choose can achieve and maintain the desired vacuum level consistently.

Flow Rate

Flow rate, measured in cubic meters per hour (m³/h) or liters per minute (L/min), is another critical consideration. It determines how quickly the vacuum pump can evacuate air or gas from the system. Select a pump with a flow rate suitable for your application's demands to ensure efficient operation.

Chemical Compatibility

Consider the compatibility of the vacuum pump with the gases or vapors present in your application. Certain pump materials may react with specific chemicals, leading to contamination or corrosion. Choose a pump constructed from materials resistant to the substances it will encounter.

Noise and Vibration Levels

Depending on where the vacuum pump will be installed, noise and vibration levels may be significant factors to consider. Some applications require quiet operation, while others can tolerate higher levels of noise. Look for pumps with noise and vibration reduction features if necessary.

Maintenance Requirements

Regular maintenance is essential for prolonging the life of your vacuum pump and ensuring optimal performance. Consider factors such as ease of maintenance, availability of spare parts, and serviceability when choosing a pump. Selecting a pump with minimal maintenance requirements can save time and money in the long run.

Energy Efficiency

Energy consumption is a significant operating cost for vacuum pumps Australia. Look for pumps with high energy efficiency ratings to minimise energy usage and reduce operating costs. Features such as variable speed drives and automatic shut-off mechanisms can help optimise energy consumption.

Footprint and Installation Requirements

Consider the physical footprint of the vacuum pump and whether it will fit into your existing space. Also, assess installation requirements such as power supply, ventilation, and any special mounting considerations. Choosing a pump that integrates seamlessly into your facility can simplify installation and operation.

1Budget Constraints

Finally, consider your budget constraints when selecting a vacuum pump. While it's essential to invest in a high-quality pump that meets your application requirements, be mindful of cost considerations. Evaluate the total cost of ownership, including initial purchase price, operating costs, and maintenance expenses, to make an informed decision.

Conclusion

Choosing the right vacuum pumps Australia requires careful consideration of various factors, including application requirements, vacuum level, flow rate, chemical compatibility, noise and vibration levels, maintenance requirements, energy efficiency, installation considerations, and budget constraints.

By thoroughly assessing these factors and selecting a pump that aligns with your specific needs, you can ensure optimal performance and efficiency in your vacuum processes. Remember to consult with knowledgeable experts or suppliers to help guide you through the selection process and ensure you make the best choice for your application.

0 notes

Text

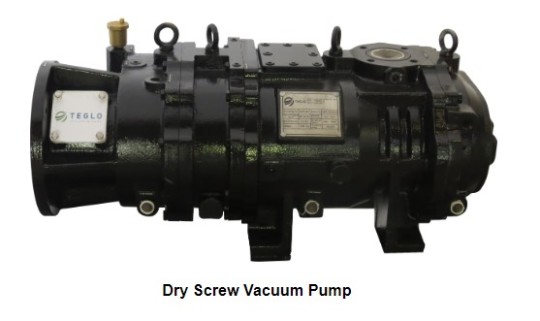

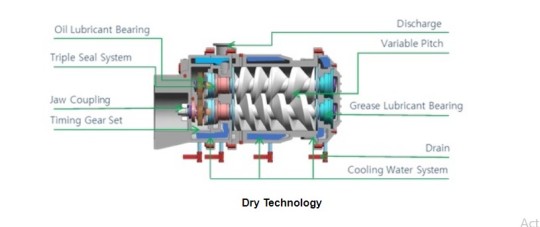

Unveiling Excellence: Tekman - Pioneering Dry Vacuum Pump Manufacturer in India

In the realm of industrial machinery, where efficiency meets innovation, Tekman stands tall as a trailblazer in the domain of dry vacuum pumps Manufacturer. Situated in the heart of India, Tekman has carved a niche for itself through its unwavering commitment to quality, precision engineering, and customer satisfaction. As we delve deeper into the world of Tekman, we unravel the story of a company that epitomizes excellence in every aspect of its operations.

Engineering Marvels: the Essence of Tekman’s Dry Vacuum Pumps

Modern dry vacuum pump technology is the cornerstone of Tekman's success. Tekman's dry pumps, in contrast to traditional oil-sealed pumps, are known for their lubricant-free design, which minimizes environmental effect and lowers maintenance costs. Recognized for their efficiency, dependability, and longevity, Tekman's pumps are designed to provide unmatched performance in a variety of industrial applications.

Precision Engineering: Redefining Performance Standards

Tekman stands out in a crowded market thanks to its dedication to precision engineering. Its dry Screw vacuum pumps go through extensive quality control and testing processes on every part to guarantee that the highest requirements for dependability and quality are met. Every phase of Tekman's production process, from design conception to manufacturing and assembly, is closely watched to ensure faultless functionality and unrivaled longevity.

Customer-Centric Approach: Fulfilling Unique Requirements with Custom Solutions

Customer satisfaction is the priority at Tekman. The company's capacity to customize solutions to match the particular needs of clients across a range of industries is indicative of its customer-centric approach. Tekman's team of professional’s works directly with customers in a variety of industries, including research laboratories, semiconductor manufacturing, automotive, and pharmaceuticals, to understand their objectives and provide personalized solutions that go above and beyond.

Innovating for Sustainability: Eco-Friendly Solutions for a Greener Future

In a time when environmental innovation is crucial, Tekman continues to lead the way. Supporting the advancement of dry Screw vacuum pumps that do away with the need for lubricants derived from oil helps Tekman's clients decrease their environmental effects while also lowering their carbon footprint. Tekman is leading the way in the manufacturing sector toward a more sustainable future with its unwavering dedication to green technologies.

Empowering Industries across the Spectrum: Tekman’s Versatile Applications

Tekman's dry vacuum pumps are used in a wide range of sectors, enabling companies to increase production and streamline processes. Tekman's pumps are essential for facilitating smooth operations and boosting productivity in a variety of industrial sectors, from semiconductor manufacture and solar cell production to vacuum distillation and freeze-drying in the pharmaceutical industry.

Driving Excellence through Continuous Innovation: Tekman’s R&D Initiatives

The key to Tekman's success story is innovation. The company's cutting-edge R&D centers act as innovation hotspots, bringing brilliant scientists and engineers together to push the limits of technology. Tekman maintains a competitive edge by allocating resources towards research and development endeavors, continuously modifying its range of products to cater to the demands of its clientele and new market trends.

The Promise of Quality and Reliability: Tekman’s Commitment to Excellence

At Tekman, reliability and quality are unassailable values. The manufacturing facilities of the company, which have obtained ISO certification, follow strict quality management procedures to guarantee that all products bearing the Tekman name satisfy the highest standards of excellence. Tekman reiterates its dedication to providing products that inspire confidence and trust while maintaining an unwavering focus on quality control and ongoing improvement.

Embracing Digital Transformation: Tekman’s foray into Industry 4.0

Tekman is leading the way in digital transformation as the world welcomes the arrival of Industry 4.0. Through the integration of smart technology and data analytics into its manufacturing processes, Tekman is able to maximize resource consumption, increase productivity, and open up new business opportunities. Tekman uses state-of-the-art digital tools, such as remote monitoring and predictive maintenance solutions, to stay ahead of the curve and spur innovation.

Conclusion: A Legacy of Excellence, a Vision for the Future In the annals of India’s manufacturing history, Tekman’s reputation shines brilliantly as a tribute to innovation, excellence, and unrelenting devotion to customer satisfaction. With its cutting-edge dry vacuum pump technology, adept precision engineering, and unwavering commitment to sustainability, Tekman is setting new benchmarks for the industry and motivating a fresh round of creative’s. Tekman is unwavering in its commitment to empowering industries, advancing progress, and creating a better future for future generations as it forges ahead into the future.

0 notes

Text

Vacuum Pumps Market to Reach $7.57 Billion by 2030

Meticulous Research®, a prominent global market research firm, has released a report titled, ‘Vacuum Pumps Market by Type (Gas Transfer Pumps, Gas Bindings/Entrapment Pumps), Lubrication (Dry Vacuum Pumps, Wet Vacuum Pumps), Pressure, End-use Industry and Geography - Global Forecasts to 2030.’

The vacuum pumps market is expected to grow from an estimated $5.51 billion in 2023 to $7.57 billion by 2030, with a compound annual growth rate (CAGR) of 4.6% during the forecast period from 2023 to 2030. This growth is fuelled by the increasing use of vacuum pumps in the mining industry, their rising importance in the chemicals industry, and the expansion of the automotive sector. However, the market growth is hindered by the high-power consumption of vacuum pumps.

The increasing use of vacuum pumps in seawater desalination and their growing significance in the photovoltaics value chain are anticipated to provide growth opportunities for market players. Nevertheless, improper installation of vacuum pumps poses a significant challenge to market growth.

The global vacuum pumps market is categorized by type, lubrication, pressure, end-use industry, and geography. The report also assesses industry competitors and examines markets at the country and regional levels.

Based on type, The global vacuum pumps market is divided into gas transfer pumps, gas binding/entrapment pumps, and other vacuum pumps. In 2023, the gas transfer pumps segment is projected to hold the largest share of the market. This dominance is due to the segment's applications requiring a high level of vacuum, their low maintenance costs, and the ease of operation in processes like chemical processing and vacuum deposition, among others.

Based on lubrication, The global vacuum pumps market is categorized into dry and wet vacuum pumps. In 2023, the wet vacuum pumps segment is anticipated to hold the larger market share. This is due to their high pumping speeds, increasing demand in industries such as chemical processing and pharmaceuticals, and their cost-effective and economical nature.

Based on pressure, The global vacuum pumps market is divided into rough vacuum (1 bar to 1 mbar), medium vacuum (1 mbar to 10–3 mbar), high vacuum (10–3 mbar to 10–7 mbar), ultra-high vacuum (10–7 mbar to 10–12 mbar), and extreme high vacuum (more than 10–12 mbar). In 2023, the high vacuum (10–3 mbar to 10–7 mbar) segment is expected to hold the largest market share. This is attributed to these pumps achieving higher pressure levels than any other rotary vane pump, leading to their significant market share.

Based on end-use industry, The global vacuum pumps market is segmented by end-use industries, including electronics & semiconductors, aerospace & defense, chemicals, automotive, healthcare, food & beverage, industrial manufacturing, oil & gas, mining, construction, energy & utilities, and others. In 2023, the oil & gas segment is expected to hold the largest market share. This is due to the increasing need to boost low-pressure gas from wellheads to high-pressure pipelines, the rising demand for oil, gas, and petrochemicals, and the significant adoption of vacuum pumps in oil-producing countries like Saudi Arabia, the UAE, and Russia.

Based on geography, The vacuum pumps market is divided into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2023, Asia-Pacific is projected to hold the largest share of the global market. This growth is driven by technological advancements in vacuum pumps and rising demand in emerging economies, fueled by increasing manufacturing activities in industries such as pharmaceuticals, automotive, and chemicals.

Key Players:

The major players in the global vacuum pumps market include Atlas Copco AB (Sweden), Agilent Technologies Inc. (U.S.), Busch Dienste GmbH (Germany), EBARA CORPORATION (Japan), Flowserve Corporation (U.S.), Gebr. Becker GmbH (Germany), Gast Manufacturing, Inc. (U.S.), Graham Corporation (U.S.), Ingersoll Rand Inc. (U.S.), KNF DAC GmbH (Germany), Kashiyama Industries, Ltd. (Japan), Pfeiffer Vacuum Technology AG (Germany), Shimadzu Corporation (Japan), Wenling Tingwei Vacuum Equipment Co., Ltd (China), VACUUBRAND GMBH + CO. KG (Germany), GlobalVac & Air (U.S.), and ULVAC, Inc. (Japan).

Download Sample Report Here: https://www.meticulousresearch.com/download-sample-report/cp_id=5500

Key Questions Answered in the Report:

What are the market segments experiencing significant growth in terms of type, lubrication, pressure, end-use industry, and geography?

What is the past market size of vacuum pumps worldwide?

What are the projected market forecasts and estimates for the timeframe between 2023 and 2030?

What are the primary factors propelling, inhibiting, offering potential, and posing obstacles in the global vacuum pumps market?

Who are the key players in the market, and what are their respective shares of the market?

What does the competitive scenario look like in the global vacuum pumps market?

What are the latest advancements or changes observed in the global vacuum pumps market?

What are the various approaches taken by the leading players in the market?

What are the significant geographical patterns, and which countries are experiencing notable growth?

Who are the emerging local players in the global vacuum pumps market, and what strategies do they employ to compete with established competitors?

Contact Us:

Meticulous Research®

Email- [email protected]

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Vacuum Pumps Market#Gas Transfer Pumps#Positive Displacement Pumps#Oscillation Displacement Pumps#Piston Pump#Diaphragm Pump#Scroll Pumps#Semiconductor and Electronics

0 notes

Text

Electric Motor Market - Forecast(2024 - 2030)

Electric Motor Market Overview

Electric Motor Market Size is forecast to reach $169 billion by 2030, at a CAGR of 5.6% during 2024-2030. The increase in global electricity consumption and the use of electrical equipment and machines in different industries and the renewables sector are major factors driving the growth in the electric motor market during the forecast period. An increase in awareness of green vehicles among customers has been a key factor leading the market. Besides this, a rising number of government incentives to encourage sales of green vehicles for safeguarding the environment from carbon emissions is analysed to drive the market. The growing interest in sustainable transportation has driven the demand for electric vehicles. Electric motors play a crucial role in powering EVs, and advancements in motor technology contribute to increased efficiency and range. The industrial sector is witnessing the integration of electric motors with the Internet of Things (IoT) and Industry 4.0 technologies. This integration allows for real-time monitoring, predictive maintenance, and improved efficiency in industrial processes.

Smart motor technologies, incorporating features like connectivity, sensors, and advanced control systems, are becoming more prevalent. These innovations contribute to better performance, remote monitoring, and enhanced automation in various applications. Developments in motor control systems, including advanced algorithms and power electronics, contribute to improved motor performance, reduced energy losses, and enhanced control precision. There is an increasing emphasis on developing more energy-efficient electric motors to meet sustainability goals and reduce energy consumption. Regulations and standards promoting energy efficiency also influence the design and manufacturing of electric motors. Additionally, Electric motors have been observing several advancements in technology over the past few years, owing to which its demand is set to gain higher traction during the forecast period 2024-2030.

Report Coverage

The report: “Electric Motor Market Report– Forecast (2024-2030)”, by IndustryARC covers an in-depth analysis of the following segments of the Electric Motor market

By Product Type: AC Motor (Induction Motor, Synchronous Motor, Servo Motor, Stepper Motor), DC Motor (Brushed DC Motor, Brushless DC Motor, Servo Motor, Series Motor, Stepper motor, Compound Motor).

By Product Category: Permanent Magnet, Non-Permanent Magnet.

By Phase: Single Phase, Three Phase.

By Power Rating: Below 0.5W, 0.5W-1W, 1W to 100W, 100W to 1KW, 1KW to 10KW, 10KW and Above.

By Efficiency: IE1, IE2, IE3, IE4.

By Application: Commercial (Automated Doors, Elevators & Escalators, Blowers, Electric Sweepers, Hand Dryers, Data Center & UPS, Pumps, Power Tools, Water Coolers, Camera PTZ Control, Drones, Others), Consumer Products (Pumps, Hair Dryers, Lawn Mowers, Boilers, Dishwashers, Vacuum Cleaners, washing machine, Blenders & Mixers, Fans & Chimneys, Desktop & Laptops, Smartphones, Refrigerators, Others), Automotive (Body Control motors, EPS Motors, Brake Booster BLDC Motor, Seat Adjustment, Belt Tensioner, Car Window Motor, Door Lock Motors, Wiper Motor, Others), Medical & Healthcare (Diagnostic Equipment (CT Scanners, MRI, Biopsy Systems, Diagnostics Analyzers, Ultrasound Transducers, X-Ray, Others), Medical Centrifuges, Medical Pumps, Blowers and Compressors, Surgical Instruments (Saws, Drills, Surgical Robots, Others), Dental CAD/CAM Milling Machines, Exoskeleton & Prosthetics, Microscopes, Wheelchairs & Scooters, Stair Lifts, Hospital Beds & Exam Tables, Others).

By Geography: North America (U.S, Canada, Mexico), South America(Brazil, Argentina and others), Europe(Germany, UK, France, Italy, Spain, Russia, Netherlands, Poland, Czechia, Belgium, Sweden and Others), APAC(China, Japan India, SK, Aus and Others), and RoW (Middle East and Africa)

Request Sample

Key Takeaways

• The rising demand for efficient energy usage over concerns of environmental impact of energy generation from conventional sources such as coal and natural gas, is expected to help grow the electric motor market in APAC.

• The DC Motor segment is growing at a significant CAGR of 7.6% in the forecast period 2024-2030. A DC motor consists of a stator and a rotor.

• Medical & Healthcare sector is expected to witness a highest CAGR of 8.5% the forecast period 2024-2030, due to its extensive reliance on electrically powered devices and equipment. Diagnostic imaging equipment, such as MRI and CT scanners, demands high-performance electric motors for precise movements and accurate imaging.

• Electric Motor companies are strengthening their position through mergers & acquisitions and continuously investing in research and development (R&D) activities to come up with solutions to cater to the changing requirements of customers.

Electric Motor Market Segment Analysis - By Product Type

The DC Motor segment is expected to grow at a significant CAGR of 7.6% during the forecast period 2024-2030. Owing to the growing penetration of brushless DC motors across various industry verticals substituting brushed dc and even ac induction motors in certain applications such as home appliances. DC motors are used in electric vehicles in the automotive industry for various non-traction applications, contributing to the ongoing shift towards sustainable transportation. As the demand for electric vehicles grows, so does the demand for efficient and dependable DC motors. DC motors are also widely used in industrial automation, powering conveyor systems, robotics, and manufacturing equipment. Owing to the ease of control, they are suitable for accurate and regulated movements in automated processes.

Inquiry Before Buying

Electric Motor Market Segment Analysis - By Application

Medical & Healthcare sector is expected to witness a highest growth of CAGR 8.5% during the forecast period 2024-2030, owing to the increase in investments in healthcare and medical sector, along with growing penetration of advanced medical devices & equipment in the sector such as surgical robots, advanced imaging & diagnostic equipment, prosthetics and so on. Medical advances and technical improvements have resulted in the development of a wide range of medical instruments and gear that significantly rely on the precision and efficiency provided by electric motors. High-performance electric motors are required for precise motions and accurate imaging in diagnostic imaging equipment such as MRI and CT scanners. Electric motors provide stability and consistency to patient care and monitoring systems such as infusion pumps and monitoring equipment. Furthermore, the incorporation of electric motors in mobility aids such as electric wheelchairs and patient lifts improves accessibility for people who have mobility issues. Electric motors are used in laboratory equipment, robotic surgical systems, and a variety of medical tools, all of which contribute to the overall efficiency and improvement of healthcare techniques. The demand for electric motors is on the rise as the healthcare industry evolves and adopts more technologically sophisticated solutions, fueling additional innovation in this critical sector.

Electric Motor Market Segment Analysis - By Geography

Electric Motor market in Asia-Pacific region held significant market share of 38% in 2023. Increasing compliance for energy efficient motors and rising adoption of motor-driven electric vehicles are the key factors driving market growth. The rising demand for efficient energy usage over concerns of environmental impact of energy generation from conventional sources such as coal and natural gas, is expected to help grow the electric motor market. In addition, advancements in the agriculture sector and enormous investments in industrialization in countries such as China, India, South Korea, and Australia is driving the market growth. Further, the increasing production and sales of electric vehicles in countries including China and Japan is also analyzed to drive the market growth.

Schedule a Call

Electric Motor Market Drivers

Rise in demand for Electric Vehicles

The electric car market has witnessed rapid evolution with the ongoing developments in automotive sector and favorable government policies and support in terms of subsidies and grants, tax rebates. Major manufacturers such as General Motors, Toyota, and BMW plan to release a potential of 400 models and estimated global sales of 25 million by 2025. In 2022, Ford Motor has committed to increase its investments in electric vehicles to $50 billion by 2026, up from a previous spend of $30 billion by 2025. Similarly, in 2020, Volkswagen, Chinese ventures has committed to invest $17.5 billion in electric vehicles by 2025. As electric vehicles use various types of electric motors for traction & auxiliary applications, the rising demand for electric vehicles globally is set to assist the market growth for electric motors used in the same.

Growing R&D activities

Manufacturers are continuously focusing on R&D to develop new and effective electric motors to meet consumer demand. Increasing concerns, such as environmental pollution and regulations, are forcing manufacturers to develop electric motors that reduce vibration and increase efficiency. For instance, a synchronous electric motor is around 80% more efficient than an induction electric motor. Similarly, the development of a new type of steel for electric motors, which reduces the weight of the electric motor and makes it more efficient and powerful. This new type of electric motor will be small in size and cost effective, which will raise demand from residential and commercial applications. Moreover growing developments from various companies is also analysed to drive the market growth. Hence these factors are analysed to drive the market growth in the forecast period 2024-2030.

Electric Motor Market Challenges

Easy availability of low-quality electric motors

The market for electric motors is highly fragmented, with a significant number of domestic and international manufacturers. Product quality is a primary parameter for differentiation in this market. The organized sector in the market mainly targets industrial buyers and maintains excellent product quality, while the unorganized sector offers low-cost alternatives to tap local markets. Local manufacturers of electric motors in most countries target the unorganized sector and compete strongly with the global suppliers in the respective markets. Leading market players are currently exposed to intense competition from such unorganized players supplying inexpensive and low-quality electric motors. This acts as a key challenge for the growth of the market.

Buy Now

Market Landscape

Product launches, acquisitions, Partnerships and R&D activities are key strategies adopted by players in the Electric Motor market. Electric Motor top 10 companies include:

ABB Ltd

Johnson Electric Holdings Limited

Siemens AG

Rockwell Automation

Nidec Corporation

Bosch Electric

Regal Rexnord

Franklin Electric Company Inc.

Teco Electric & Machinery Co. Ltd.

Wolong Electric Group co. ltd.

Acquisitions/Product Launches

• In July 2023, Nidec Corporation announced that it has successfully developed a new electric power steering motor power pack*1 (“EPS-PP”).

• In July 2023, WEG announced new investments for its motor manufacturing plant located in Manaus, Brazil. The Company will invest R$ 48 million, in the next three years, to expand production capacity and adapt the plant to produce a new line of permanent magnet electric motors for split-type air conditioners

• In December 2023, Johnson Electric Launches 48-Volt Cooling Fan Module with High Power and Efficiency. Johnson Electric is pleased to announce the launch of the 48-Volt Cooling Fan Module with power up to 1.5kW to meet the most demanding cooling requirements. The need to reduce emissions and increase the electrification of the vehicle, requires higher cooling performance and efficiency.

#Electric Motor Market#Electric Motor Market size#Electric Motor industry#Electric Motor Market share#Electric Motor top 10 companies#Electric Motor Market report#Electric Motor industry outlook

0 notes

Text

Vacuum Sucker Market Size, Share, Industry Demand, Research 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Vacuum Sucker Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2031.” The study provides a detailed analysis of the industry, including the global Vacuum Sucker Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Vacuum Sucker?

The global vacuum sucker market revenue was USD 860.61 Million in 2021. The expected revenue CAGR over the forecast period is 6.4% and the market value is expected to reach USD 1127.26 Million in 2031.

What are Vacuum Sucker Market?

A vacuum sucker is a device crafted to generate suction by eliminating air or other gases from a confined space, inducing a partial vacuum. It usually involves a pump or mechanism that evacuates air from an enclosed area, generating negative pressure, consequently attracting fluids, particles, or objects towards the vacuum source. Vacuum suckers are utilized in a wide range of applications, ranging from household vacuum cleaners employing suction to eliminate dirt and debris to industrial settings where they play a crucial role in material handling, packaging, and diverse manufacturing processes requiring the extraction of air or gases.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1901

What are the growth prospects and trends in the Vacuum Sucker Market industry?

The vacuum sucker market growth is driven by various factors. The vacuum sucker market is witnessing robust growth, driven by a rising demand across various industries. These devices, designed to generate suction and create a partial vacuum, are finding increased applications in manufacturing, packaging, and material handling sectors. The market is experiencing continuous expansion with technological advancements, leading to product innovations and improved capabilities. Globally, the vacuum sucker market is characterized by competitiveness, as key players emphasize research and development to introduce efficient and adaptable suction solutions that meet the evolving requirements of diverse industries. Recognizing the advantages of vacuum suckers in enhancing processes and efficiency, industries are contributing to the ongoing expansion of the market. Hence, all these factors contribute to vacuum sucker market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Type:

Electric Vacuum Suckers

Pneumatic Vacuum Suckers

Hybrid Vacuum Suckers

By End-Use Industry:

Automotive

Electronics

Food & Beverage

Packaging

Pharmaceutical

Logistics & Warehousing

Others

By Application:

Material Handling

Assembly & Robotics

Pick & Place

Packaging & Palletizing

Inspection & Testing

Others

By Sales Channel:

Direct Sales

Distributors/Wholesalers

E-commerce

Global Market Segmentation by Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europ

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Piab AB

Schmalz Inc.

Festo AG & Co. KG

SMC Corporation

Aventics GmbH

VACUUBRAND GMBH + CO KG

Vaccon Company, Inc.

SMC Corporation of America

Pneumadyne, Inc.

Schmalz GmbH

Vuototecnica S.p.A.

DESTACO, a Dover Company

ANVER Corporation

AERO-LIFT Vakuumtechnik GmbH

VMECA Co., Ltd.

Discover more: https://www.reportsandinsights.com/report/Vacuum Sucker-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

#Vacuum Sucker Market Size#Vacuum Sucker Market Share#Vacuum Sucker Market Demand#Vacuum Sucker Market Analysis

0 notes

Text

Vacuum Pumps Market Projected to Reach USD 8.0 Billion, at a 4.90% CAGR by 2032 – Report by Market Research Future (MRFR)

0 notes

Text

#Global Vacuum Pump Brake System Market Size#Share#Trends#Growth#Industry Analysis#Key Players#Revenue#Future Development & Forecast

0 notes

Link

#market research future#vacuum pumps applications#vacuum pumps market types#vacuum pumps manufacturers#vacuum pumps market trends

0 notes

Text

0 notes

Video

vimeo

The road to Electric will be shaped by more than the vehicles themselves. from Our Auto Expert on Vimeo.

In an era where the captivating roar of combustion engines is gradually giving way to the serene hum of electric motors, we stand on the precipice of a monumental shift in the automotive domain. A revolution is underway, silently accelerating as the allure of electric vehicles (EVs) captures the imagination of consumers worldwide. A recent Auto Pacific study sheds light on this seismic shift, revealing a surge in consumer interest that could very well dictate the trajectory of the automotive industry.

The pulse of the market is quickening, with data indicating a leap in purchase intentions for EVs from 11% in 2022 to an impressive 17% in 2023. This uptick is not merely a statistic; it’s a testament to a growing enthusiasm among drivers to embark on electric voyages, with a staggering 58% of survey respondents expressing openness to considering an EV for their next vehicle purchase. This burgeoning interest heralds a new era of mobility, one that is cleaner, quieter, and more sustainable.

But the journey toward electric mobility is not powered by cars alone; it’s the infrastructure that will fuel this revolution. Future EV owners are not just looking for a new set of wheels; they’re envisioning a redefined charging experience. The AutoPacific EV Consumer Insights Study, which canvassed the opinions of over 7,200 potential EV buyers, unveils a wishlist for public charging stations that mirrors the conveniences of the traditional gas station, but with a modern twist. Clear signage, charging speed and pricing information, alongside amenities like windshield cleaners, air pumps, and vacuums, are among the top demands. This isn’t just about fueling cars; it’s about refueling the driver’s spirit with a touch of convenience and comfort.

The study offers more than just a peek into consumer preferences; it serves as a beacon for the automotive industry, guiding manufacturers and service providers through the evolving landscape of consumer desires. With insights gleaned from AutoPacific’s annual Future Attribute Demand Study, industry players are equipped with the intelligence needed to navigate the future market. This research isn’t just groundbreaking; it’s transformative, painting a vivid picture of a future where electric vehicles are not only desired but are also supported by an ecosystem that caters to the nuanced needs of the driver.

So, what’s the takeaway from all this data and desire? The shift to electric vehicles is unfolding as a comprehensive reimagining of the automotive experience. This isn’t merely about swapping gas for electricity; it’s about redefining what it means to drive, to refuel, and to enjoy the journey. As we race toward electrification, the findings from AutoPacific challenge the industry to innovate, ensuring that the evolution of EV technology and infrastructure addresses both the practical and experiential aspects that make electric vehicles genuinely enticing.

As American drivers stand on the threshold of this electric revolution, it’s clear that the path forward will be charted by more than just the cars we drive. It will be defined by how seamlessly we integrate these new vehicles into our lives, making certain that the future of mobility is not only sustainable but also resonant with the aspirations of its drivers. The electrified future is on the horizon, and it promises a journey filled with innovation, sustainability, and a new vision for the automotive experience. Stay tuned; the best is yet to come.

0 notes

Text

"Scrolling into the Future: Innovations in Dry Scroll Vacuum Pumping"

As the prevalence of electronics and semiconductors continues to rise, the industry is increasingly turning to dry vacuum pumps for various applications, including coating and drying processes. These dry vacuum pumps find utility across a range of end-use sectors, such as electronics and semiconductors, pharmaceuticals, and chemicals. Their applications span vacuum drying, mixing, de-aeration, filtering, particle transfer, material handling, and even in scientific tools like laser scanning microscopes. In the past, industrial applications predominantly relied on oil-filled vacuum pumps, but the demand for safety and cleanliness has prompted the adoption of oil-free or dry vacuum pumps, particularly in industrial and laboratory settings.

𝐑𝐞𝐪𝐮𝐞𝐬𝐭 𝐒𝐚𝐦𝐩𝐥𝐞 𝐏𝐃𝐅 𝐁𝐫𝐨𝐜𝐡𝐮𝐫𝐞 : https://www.alliedmarketresearch.com/request-toc-and-sample/15220

COVID-19 Impact Analysis:

The outbreak of the COVID-19 pandemic had a detrimental impact on the dry scroll vacuum pumps market. Shutdowns in industries including oil and gas, food, automotive, power, chemical, construction, and water treatment led to reduced demand for dry scroll vacuum pumps. Lockdown measures implemented due to the pandemic disrupted the production of these pumps and caused disruptions in the global supply chain, resulting in a decrease in demand and a decline in revenue for the dry scroll vacuum pumps market.

Key Impacting Factors:

Over the past two decades, dry running and contact-free dry vacuum pumps have emerged as an attractive choice globally, offering energy efficiency and noise reduction. The advantages of dry vacuum pumps include the delivery of clean, high-quality vacuum, extended operational life, consistent performance, quick integration and installation, substantial access features for maintenance, and real-time data availability without time lag. The dry vacuum pumps sector has evolved into a high-value market with robust growth rates in recent times. It is expected to continue growing steadily in the foreseeable future. The growing adoption of dry vacuum pumps in the electronics and semiconductor industries, as well as the pharmaceutical sector, is expected to drive this growth further.

𝐄𝐧𝐪𝐮𝐢𝐫𝐲 𝐁𝐞𝐟𝐨𝐫𝐞 𝐁𝐮𝐲𝐢𝐧𝐠 : https://www.alliedmarketresearch.com/purchase-enquiry/15220

Market Trends:

Increased investments in the electronics, semiconductor, and pharmaceutical industries in the Asia-Pacific region are expected to boost the growth of the dry vacuum pump market.

The market's expansion is being fueled by increased investments from countries like Germany, Japan, South Korea, and the U.S. in regions such as India and Brazil.

In addition to leading players in the global dry vacuum pumps market, regional businesses are also contributing to market growth.

Collaboration with sales and service organizations has been a significant strategy for major market participants to enhance their market presence.

While the availability of low-cost products from Chinese companies concerns major manufacturers, mergers, acquisitions, and partnership initiatives by large players are compelling end-users to adopt modern dry vacuum pumps.

Key Benefits of the Report:

This report offers an analytical overview of the dry scroll vacuum pumps industry, providing insights into current trends and future investment opportunities.

It presents information related to key drivers, restraints, and opportunities, along with a detailed analysis of market share.

The report quantitatively analyzes the market's growth and uses Porter's five forces analysis to assess the market's competitive dynamics.

𝐆𝐞𝐭 𝐚 𝐂𝐮𝐬𝐭𝐨𝐦𝐢𝐳𝐞𝐝 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡 𝐑𝐞𝐩𝐨𝐫𝐭: https://www.alliedmarketresearch.com/request-for-customization/15220

Dry Scroll Vacuum Pumps Market Report Highlights:

By Product Type:

Dry Screw Vacuum Pump

Dry Scroll Vacuum Pump

Dry Diaphragm Vacuum Pump

Dry Claw and Hook Pump

Others (Dry Lobe Vacuum Pump and Dry Rotary Vane Vacuum Pump)

By End-User Industry:

Electronics & Semiconductor Industry

Pharmaceutical Industry

Chemical Industry

Others (Printing Industry, Packaging Industry, Food and Beverages Industry)

By Region:

Asia-Pacific (China, India, Japan, South Korea, Rest of Asia-Pacific)

North America (U.S., Canada, Mexico)

Europe (Germany, United Kingdom, France, Italy, Rest of Europe)

LAMEA (Brazil, UAE, Saudi Arabia, South Africa, Rest of LAMEA)

Key Market Players:

Anest Iwata

SKY Technology Development

Air Squared

Edwards

Agilent

ULVAC

Labconco

Leybold

Geowell

Busch

ScrollTEC

Please feel free to let me know if you need further information or revisions.

Regenerate

0 notes

Text

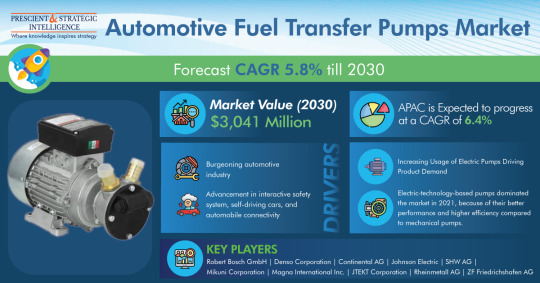

Automotive Fuel Transfer Pumps Market: Trends, Innovations, and Global Growth Insights

The size of the automotive fuel transfer pumps market was USD 1,831 million in 2021, and it will grow at a rate of 5.8% in the years to come, to reach USD 3,041 million by 2030, according to a report of P&S Intelligence.

Electric-technology-based pumps led the industry in the recent past, due to their improved performance and higher efficiency in comparison to mechanical pumps.

Furthermore, electric pumps offer numerous benefits, including improved pressure regulation, a lower wear and tear risk, and high strength. These devices are capable in operating at pressures between 30 and 40 pounds per square inch.

Vehicles featuring advanced injection systems make use of such pumps as these components are relatively safe and supply fuel to the engine proficiently, with a low loss of power. Electric vacuum fuel transfer pumps too help in the lessening of emissions of carbon dioxide from engines.

So, the acceptance of electricity-based injecting machines is relatively high, ensuing an increase in the price of an automobile. With the increasing awareness around the benefits, consumers are requiring automobiles fortified with electric pumps for transfer of gasoline.

The automobile fuel transfer pumps market was dominated by APAC and it will register the highest CAGR, of above 6.4%, in the years to come. The development of the automotive industry in China has grabbed the attention of numerous international automakers. Home to the major auto sector globally, the nation experiences a boom in the integration of components, transferring fuel from the tank to the engine.

Furthermore, the nation’s rapid embrace of hybrid vehicles has formed an increase in the sales of car, which bids a lot potential to auto component makers in the Peoples Republic.

#Automotive Fuel Transfer Pumps#Market Trends#Innovations#Global Growth Insights#Automotive Sector#Fuel Distribution#Market Players#Competitive Landscape#Pump Technology Advancements#Smart Fuel Transfer Systems

0 notes

Text

Global vacuum pumps market size was valued at $5.4 billion in 2021, and is projected to reach $9.3 billion by 2031, growing at a CAGR of 5.5% from 2022 to 2031.

0 notes

Text

Test The Altitude Effects Correctly with Altitude Chamber

Altitude, or you can say pressure testing, has become crucial for industrial, consumer, and military applications where components or products are required to work in low-pressure situations. These products need to be durable enough to handle rapid decompression easily. So, if you are manufacturing products for such industries, you must make sure that all the products meet the required standard. And for this, you can use an industry-grade pressure or altitude chamber. Read on to explore more about these chambers and how they can help you in your production line.

A Crucial Testing Chamber for Many Industries

Altitude or pressure chambers are designed to effectively simulate the temperature, vacuum as well as the altitude of various environmental conditions. The primary purpose of these chambers is to ensure that the parts and components can handle the pressure while shipping viaair. Different from a hypobaric test chamber, a modern pressure chamber can combine different factors, such as humidity, vibrations, icing, temperature,etc. By considering all these elements, you can create ideal real-world testing situations for effective analysis. These machines are widely used in automotive, aerospace, power, defence and other industries. And it is forecasted that altitude test chamber will grow at a CAGR of 5.5 percent in the coming years.

(Reference: https://dataintelo.com/report/global-altitude-test-chamber-market/).

Exploring Major Uses for These Chambers

Industrial altitude testing chambers are designed to create combined and extreme environments. As a result, it becomes easier for you to evaluate the resilience, strength as well as capabilities of products or components. However, there are certain vital considerations to remember if you want to invest in a modern altitude chamber. Let’s have a look at them:

Low And High Altitude

By using power vacuum pumps installed in the pressure chamber, you can easily create atmospheric conditions of up to 100,000 feet. On the other hand, to simulate situations like a sudden decrease in cabin pressure, you can use the rapid decompression features. Different situations can be simulated by adjusting instruments and programmed controls. It can be said that these powerful machines can greatly help with product improvement.

Temperature Testing

Equipped with advanced features,an altitude testing chamber can also offer a combined temperature and altitude simulation. However, while testing, ensure you adhere to the required test standards. These chambers meet the aeronautical environmental test norms and support different temperature profiles. Besides, some chambers come with an advanced cascade system that utilizes a refrigerant to lower the temperature. It supports a temperature range between -40-to-180-degree C.

Humidity Testing

Through humidity testing, you can test the longevity of different flight components under special circumstances. This test checks the durability of metals used, paints, coating, etc. By effectively diagnosing the humidity effects, you can extend your products’ lifespan. It can operate between a humidity range of 10-98 percent.

Vibration Testing

With an altitude chamber, it is possible to conduct vibration testing. That helps you know whether the components or parts can withstand vibrations’ effects. The machine will simulate various transportation conditions. With this test, you can determine the part’s point of failure. The data you will get from the machine can be analyzed for product improvement and other developments.

Final Words

With the best altitude chamber, you can easily examine the capabilities, resilience, and durability of components, instruments, and parts utilized in the aerospace industry. You can ensure that the products will perform at their maximum level under any condition. So, get in touch with a trusted supplier and buy this testing chamber now!

Blog Source:https://simultechaustralia.wordpress.com/2023/08/14/test-the-altitude-effects-correctly-with-altitude-chamber/

0 notes