#Styrenic Polymers Market trends

Text

#Styrenic Polymers Market Overview#Size#Share#Trends#Scope#and Growth Predictions for 2022-2028 | 200 Pages Report#intellectualmarketinsights

0 notes

Text

Styrenic Polymer Packaging Market by Product, Types, Procedure, Application, End-user Global Forecast to 2029

Industry Analysis

Data Bridge Market Research analyses that the styrenic polymer packaging Market was valued at USD 5.53 billion in 2021 and is expected to reach USD 9.08 billion by 2029, registering a CAGR of 6.4 % during the forecast period of 2022 to 2029.

Data Bridge market report covers an array of aspects of the market analysis which today’s businesses call for. This market document also defines a chapter on the global market and allied companies with their profiles, which provides important data pertaining to their insights in terms of finances, product portfolios, investment plans, and marketing and business strategies. This market research report is generated with a nice blend of industry insight, talent solutions, practical solutions and use of technology to advance user experience. An outstanding Data Bridge market report puts light on many aspects related to Materials and Packaging industry and market.

Market Insights and Scope

Styrenic polymers are economical plastics that contain many plastic products with styrene as their primary building block. Due to their amorphous structure, these polymers can be quickly processed well above their softening point and over a varied temperature range. Styrenic polymers do not have a different melting point than other partly crystalline polymers. Styrenic polymers allow faster processing of these polymers and high dimensional stability and outstanding mechanical properties.

Additionally, the credible Styrenic Polymer Packaging Market report helps the manufacturer in finding out the effectiveness of the existing channels of distribution, advertising programs, or media, selling methods and the best way of distributing the goods to the eventual consumers. Taking up such market research report is all the time beneficial for any company whether it is a small scale or large scale, for marketing of products or services. It makes effortless for Materials and Packaging industry to visualize what is already available in the market, what market anticipates, the competitive environment, and what should be done to surpass the competitor.

Industry Segmentation

The styrenic polymer packaging market is segmented based on products and end-user. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Products

Polystyrene (PS)

Acrylonitrile Butadiene Styrene (ABS)

Expanded Polystyrene (EPS)

Unsaturated Polyester Resin (UPR)

Styrene-Butadiene Rubber (SBR)

Other Polymers

Application

Building and construction

Automotive industry

Packaging

Medical

Electrical and electronics

Consumer goods

Get a Free Sample of The Report: https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-styrenic-polymer-packaging-market

Market Country Level Analysis

The countries covered in the styrenic polymer packaging market report is

U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia and New Zealand, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, United Arab Emirate, Saudi Arabia, Egypt, Israel, South Africa, Rest of Middle East and Africa.

Get full access to the report: https://www.databridgemarketresearch.com/reports/global-styrenic-polymer-packaging-market

Industry Share Analysis

Some of the major players operating in the styrenic polymer packaging market are:

BASF SE (Germany)

Lanxess A (Germany)

SABIC (south Arabic)

Dow (U.S)

Chimei (Taiwan)

LG Chem (South Korea)

Chevron Philips Chemical Company (U.S)

RocketReach.co (U.S)

Versalis SpA (Italy)

NOVA Chemicals Corporate (Canada)

Synthos (Poland)

INEOS Styrolution Group GmbH (Germany)

PS Japan Corporation (U.S)

Kraton Corporation (U.S)

An influential Styrenic Polymer Packaging Market research report displays an absolute outline of the market that considers various aspects such as product definition, customary vendor landscape, and market segmentation. Currently, businesses are relying on the diverse segments covered in the market research report to a great extent which gives them better insights to drive the business on the right track. The competitive analysis brings into light a clear insight about the market share analysis and actions of the key industry players. With this info, businesses can successfully make decisions about business strategies to accomplish maximum return on investment (ROI).

Get TOC Details: https://www.databridgemarketresearch.com/toc/?dbmr=global-styrenic-polymer-packaging-market

Browse Related Reports@

Global 1, 4-Cyclohexanedimethanol Dibenzoate Market

Global Plant Hydrocolloids Market

U.S. Tahini Market

Asia-Pacific Hydroxyl-Terminated Polybutadiene (HTPB) market

West Africa Shisha Tobacco Market

Global Orthostatic Hypotension Drugs Market

Europe Customer Journey Analytics Market

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

#Styrenic Polymer Packaging Market-by Product-Types-Procedure-Application-End User-Global-Forecast to-2029#Styrenic Polymer Packaging Market-Global Opportunity-Analysis and-Industry-regional#Styrenic Polymer Packaging Market-Growth-Competition-Scenario-Outlook#Styrenic Polymer Packaging Market-Insights-Country-Share-Competitors-Research-Study#Styrenic Polymer Packaging Market-Demands-Size-Share-Top Trends-Report-to-2029#Styrenic Polymer Packaging Market Value-Segmentation-CAGR rate-Future Trends#Styrenic Polymer Packaging Market-drivers-advantages-restraints-challenges#Styrenic Polymer Packaging Market-Leading Brands-Business-Materials and Packaging#Styrenic Polymer Packaging Market-Growing Popularity-Traffic-DBMR

0 notes

Text

Global Styrenic Block Copolymer Market to be Driven by Growing Demand for Green Construction Materials in the Forecast Period of 2022-2027

The new report by Expert Market Research titled, ‘Global Styrenic Block Copolymer Market Report and Forecast 2022-2027’, gives an in-depth analysis of the global styrenic block copolymer market, assessing the styrenic block copolymer market, based on its segments like products, applications, and major regions. The report tracks the latest trends in the industry and studies their impact on the overall market. It also assesses the market dynamics, covering the key demand and price indicators, along with analysing the market based on the SWOT and Porter’s Five Forces models.

Request a free sample copy in PDF or view the report summary@ https://www.expertmarketresearch.com/reports/styrenic-block-copolymer-market/requestsample

The key highlights of the report include:

Market Overview (2017-2027)

Historical Market Size (2020): About USD 8.1 billion

Forecast CAGR (2022-2027): 4.60%

Forecast Market Size (2026): Nearly USD 10.6 billion

The growth in the global market for styrenic block copolymer is being driven by the rising demand for styrene-butadiene-styrene (SBS). This can be associated with the rising demand for SBS from the polymer modification, footwear, construction, adhesives and sealant segments. The demand for SBS in the construction sector is being led by its applications in paving and roofing. This trend is further supported by rising construction and reconstruction activities around the world on account of rising urbanisation and industrialisation. Geographically, the Asia Pacific region is likely to account for a significant share of the market during the forecast period.

Industry Definition and Segmentation

Styrenic block copolymers refer to high-performance thermoplastic elastomers. These are specifically designed to increase product application and performance in end-use sectors. Styrenic block copolymers are thermally stable, crystal clear, and resistant, with little cytotoxic or mutagenic potential.

Explore the full report with the table of contents@ https://www.expertmarketresearch.com/reports/styrenic-block-copolymer-market

Based on product, the market can be segmented into:

Styrene-Butadiene-Styrene (SBS)

Styrene-Isoprene-Styrene (SIS)

Hydrogenated SBC (HSBC)

On the basis of application, the market divisions are:

Asphalt Modification

Wires and Cables

Polymer Modification

Adhesives and Sealants

Footwear

Others

The regional markets for styrenic block copolymer include:

North America

Europe

Asia Pacific

Latin America

Middle East and Africa

Latest News on Global Styrenic Block Copolymer Market@ https://www.expertmarketresearch.com/pressrelease/global-styrenic-block-copolymer-market

Market Trends

The growth in the global market for styrenic block copolymer is being positively influenced by applications in the medical equipment manufacturing sector. The increasing demand for medical equipment like tubing, bags, and IV drip chambers is driving the market forward. This can be attributed to the favourable properties of styrenic block copolymer which include high transparency, flexibility, good mechanical strength, kink resistance, and excellent UV and chemical resistance. Increasing medical spending and advancements in medical equipment technology are expected to further contribute to the growth of the market. Apart from this, the construction sector is projected to be a leading application segment owing to increasing investments in green building projects. This is likely to raise the demand for lightweight, environmentally friendly material like styrenic block copolymers, hence fuelling the growth of the market.

Key Market Players

The major players in the market are China Petrochemical Corporation, Asahi Kasei Corporation, JSR Corporation, Ineos Styrolution Group GmbH, Eastman Chemical Company, and Kumho Petrochemical, among others. The report covers the market shares, capacities, plant turnarounds, expansions, investments and mergers and acquisitions, among other latest developments of these market players.

About Us:

Expert Market Research is a leading business intelligence firm, providing custom and syndicated market reports along with consultancy services for our clients. We serve a wide client base ranging from Fortune 1000 companies to small and medium enterprises. Our reports cover over 100 industries across established and emerging markets researched by our skilled analysts who track the latest economic, demographic, trade and market data globally.

At Expert Market Research, we tailor our approach according to our clients’ needs and preferences, providing them with valuable, actionable and up-to-date insights into the market, thus, helping them realize their optimum growth potential. We offer market intelligence across a range of industry verticals which include Pharmaceuticals, Food and Beverage, Technology, Retail, Chemical and Materials, Energy and Mining, Packaging and Agriculture.

Media Contact

Company Name: Claight Corporation

Contact Person: Steven Luke, Corporate Sales Specialist – U.S.A.

Email: [email protected]

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

City: Sheridan

State: Wyoming

Country: United States

Website: https://www.expertmarketresearch.com

Read More:

Health Insurance Market: https://www.digitaljournal.com/pr/global-health-insurance-market-is-expected-to-grow-steadily-at-cagr-of-6-in-the-forecast-period-of-2021-2026-2

Noninvasive Neuromodulation Market: https://www.digitaljournal.com/pr/global-noninvasive-neuromodulation-market-to-be-driven-by-technological-and-medical-advancements-in-the-forecast-period-of-2021-2026

Alumina Trihydrate Market: https://www.digitaljournal.com/pr/global-alumina-trihydrate-market-to-be-driven-by-the-versatility-and-application-flexibility-of-alumina-trihydrate-in-the-forecast-period-of-2021-2026

Food Dehydrators Market: https://www.digitaljournal.com/pr/global-food-dehydrators-market-to-be-driven-at-a-cagr-of-5-in-the-forecast-period-of-2021-2026

Glucuronolactone Market: https://www.digitaljournal.com/pr/global-glucuronolactone-market-to-be-driven-by-the-heightened-demand-for-the-product-in-the-pharmaceutical-sector-in-the-forecast-period-of-2022-2027

Also, Check Procurement Intelligence which provides you with Infallible research solutions.

*We at Expert Market Research always thrive to give you the latest information. The numbers in the article are only indicative and may be different from the actual report.

#Styrenic Block Copolymer Market#Styrenic Block Copolymer Market Size#Styrenic Block Copolymer Market Analysis#Styrenic Block Copolymer Market Report

2 notes

·

View notes

Text

0 notes

Text

0 notes

Text

Styrene Market Report: Trends, Analysis, and Projections

Styrene, a key monomer in the production of various polymers and plastics, holds a significant position in the global petrochemical industry. This blog explores the dynamics of the global styrene market, analyzing key drivers, applications across industries, emerging trends, and future growth prospects.

Understanding the Styrene Market:

Styrene (C8H8) is an aromatic hydrocarbon obtained from the dehydrogenation of ethylbenzene, primarily used in the production of polystyrene, acrylonitrile-butadiene-styrene (ABS), styrene-butadiene rubber (SBR), and various thermoplastic elastomers.

Market Dynamics:

Polystyrene Production: Styrene is a crucial raw material for manufacturing polystyrene (PS), a versatile thermoplastic used in packaging, disposable containers, insulation, and consumer goods due to its lightweight and insulating properties.

ABS and SBR Production: Styrene contributes to the production of ABS, a high-impact engineering thermoplastic used in automotive parts, appliances, and electronics, as well as SBR, a synthetic rubber widely used in tires, footwear, and industrial applications.

Expanded Polystyrene (EPS): Styrene is essential for producing EPS foam, used in insulation boards, packaging materials, and construction applications due to its lightweight, thermal insulation, and cushioning properties.

Resins and Coatings: Styrene-based resins and coatings find applications in fiberglass-reinforced composites, boat hulls, automotive parts, and protective coatings for metal and concrete surfaces.

Applications Across Industries:

Packaging: Polystyrene foam, containers, packaging materials.

Automotive and Transportation: ABS plastics, SBR rubber for tires.

Construction: EPS insulation, foam boards, building materials.

Consumer Goods: Appliances, electronics, household products.

Market Trends:

Circular Economy Initiatives: Growing emphasis on recycling, sustainability, and circular economy models drive innovations in styrene recycling technologies and the development of bio-based styrene from renewable feedstocks.

Demand from Emerging Economies: Increasing urbanization, infrastructure development, and rising consumer demand in emerging economies fuel the demand for styrene-based products across multiple industries.

Technological Advancements: Innovations in polymerization processes, catalyst technologies, and material science lead to the development of high-performance styrene-based polymers with enhanced properties and applications.

Future Prospects:

The global styrene market is poised for continued growth, driven by the expanding plastics, packaging, automotive, and construction sectors. Sustainable practices, technological innovations, and strategic collaborations will shape the market's evolution towards greener and more efficient production processes.

Conclusion:

Styrene remains a vital component in the production of polymers, plastics, and rubber materials essential for diverse industries. Understanding market trends, regulatory shifts towards sustainability, and technological advancements is crucial for stakeholders in the styrene market. With a focus on innovation, recycling, and market diversification, the styrene market presents promising opportunities for growth and advancements in global industrial applications and sustainable solutions.

0 notes

Text

Top 10 Plastics Market Size and Share Analysis

Top 10 Plastics Market report provides the broader perspective of the market place with its comprehensive market insights and analysis which eases surviving and succeeding in the market. This market report brings into focus plentiful of factors such as the general market conditions, trends, inclinations, key players, opportunities, and geographical analysis which all aids to take the business towards the growth and success. Moreover, Top 10 Plastics Market report explains better market perspective in terms of product trends, marketing strategy, future products, new geographical markets, future events, sales strategies, customer actions or behaviours. Hence, the Top 10 Plastics Market report brings into the focus, the more important aspects of the market or Chemicals & Materials industry.

Top 10 Plastics Market, by Type (Polyethylene, Polypropylene, Polystyrene, Polyethylene Terephthalate, Polyvinyl Chloride, Polycarbonate, Acrylonitrile Butadiene Styrene, Polyoxymethylene, Polyamide, Polyurethane), End-Use Industry (Building & Construction, Electronics & Consumer, Automotive, Textile, Packaging), and region (North America, Europe, Asia-Pacific, Middle East and Africa and South America).

Download Free Sample Report: https://www.delvens.com/get-free-sample/top-10-plastics-market

Top players covered in the Top 10 Plastics Market report:

Arkema

BASF SE

Braskem

Celanese Corporation

Chevron Phillips Chemical Co., LLC

Covestro AG

Dow Inc

Ducor Petrochemicals

DuPont de Nemours, Inc

Eastman Chemical Company

Evonik Industries

Exxon Mobil Corporation

Formosa Plastic Corporation

INEOS

Lotte Chemical Corporation

Mitsui & Co. Plastic Ltd.

Reliance Industries Limited

Repsol

SABIC

Sumitomo Chemical Co., Ltd.

Toray Industries, Inc.

Top 10 Plastics Market Recent Developments:

In August 2023, A joint venture agreement was formed by the biopolymer manufacturer Braskem and SCG Chemicals to create bio-ethylene from bio-ethanol dehydration and to market Braskem's "I'm green" bio-based Polyethylene.

In June 2023, BASF set up a new polyethylene plant in Zhanjiang Verbund site in China. The brand-new facility, with a yearly capacity of 500,000 metric tons of PE, will meet China's rapidly expanding demand. In 2025, the facility is expected to begin operations.

The Top 10 Plastics Market size was estimated at USD 503.11 billion in 2023 and is projected to reach USD 777.21 billion in 2030 at a CAGR of 6.41% during the forecast period 2023-2030.

Although they generally incorporate additional materials, plastics are high molecular mass organic polymers. The majority of the time, they are synthetic and made from petrochemicals. However, the current emphasis on the environment has led to an increase in the number of plastics made from renewable resources, such as cellulosic from cotton linters and polylactic acid made from corn. Due to their comparatively low cost, simplicity of production, adaptability, and water resistance, plastics are now used in a wide variety of items. Plastic is used in everything, from basic items like paperclips to large ones like airplanes. Based on their availability and application, the top 10 most abundantly used plastics are polyethylene, polypropylene, polystyrene, polyethylene terephthalate, polyvinyl chloride, polycarbonate, acrylonitrile butadiene styrene, polyoxymethylene, polyamide and polyurethane.

Plastic consumption is being driven by the food and beverage sectors' expanding requirement for packaging materials. product manufacturers seek packaging that guards against contamination and deterioration of product quality. Demand is being fuelled by plastic's ability to act as a shield between food products and the outside world. Moreover, their increased demand in textile, electrical and electronic, automotive, and consumer goods sectors is driving the growth of the market further.

Make an Inquiry Before Buying at: https://www.delvens.com/Inquire-before-buying/top-10-plastics-market

Top 10 Plastics Market Key Findings:

Based on type, the market is segmented into polyethylene, polypropylene, polystyrene, polyethylene terephthalate, polyvinyl chloride, polycarbonate, acrylonitrile butadiene styrene, polyoxymethylene, polyamide, polyurethane. Polyethylene dominated the market in this segment owing to its extensive usage packaging, construction, electrical & electronics and construction. Moreover, the substitution of metal-based products with plastic based products is expected to drive the growth of polyethylene market further during the forecast period.

Based on end use industry, the market is segmented into building & construction, electronics & consumer, automotive, textile, packaging. Packaging dominated the market in this segment owing to the increased packaging demand from the rapidly growing food and beverages industry.

The market is also divided into various regions such as North America, Europe, Asia-Pacific, South America, and Middle East and Africa. Asia Pacific is estimated to account for the largest market share during the forecast period owing to the rapidly growing construction sector, increased R&D activity, presence of major key players and easily available raw materials.

Top 10 Plastics Market Regional Analysis:

Asia Pacific to Dominate the Market

Asia Pacific is estimated to account for the largest market share during the forecast period owing to the rapidly growing construction sector and increased R&D activity within the region.

Moreover, the presence of major key players and availability of raw materials are expected to drive the growth of the market further during the forecast period.

Top 10 Plastics Market report involves use of latest tools and techniques for researching, analyzing and gathering of data and information. The market analysis here includes competitive study, product information analysis, applications, and region-wise analysis, competitor landscape, consumption and revenue study, cost structure analysis, price evaluation and revenue analysis up to 2030. This Top 10 Plastics Market report performs systematic gathering, recording and analysis of data about the issues related to the marketing of goods and services and serves the businesses with an excellent market research report. The global Top 10 Plastics Market report provides smart solutions to the complex business challenges and commences an effortless decision-making process.

Direct Purchase of the Top 10 Plastics Market Research Report at: https://www.delvens.com/checkout/top-10-plastics-market

Explore Related Reports:

Fire Protection Materials Market

Battery Recycling Market

Metal Foam Market

3D Printing Metals Market

About Us:

Delvens is a strategic advisory and consulting company headquartered in New Delhi, India. The company holds expertise in providing syndicated research reports, customized research reports and consulting services. Delvens qualitative and quantitative data is highly utilized by each level from niche to major markets, serving more than 1K prominent companies by assuring to provide the information on country, regional and global business environment. We have a database for more than 45 industries in more than 115+ major countries globally.

Delvens database assists the clients by providing in-depth information in crucial business decisions. Delvens offers significant facts and figures across various industries namely Healthcare, IT & Telecom, Chemicals & Materials, Semiconductor & Electronics, Energy, Pharmaceutical, Consumer Goods & Services, Food & Beverages. Our company provides an exhaustive and comprehensive understanding of the business environment.

Contact Us:

UNIT NO. 2126, TOWER B,

21ST FLOOR ALPHATHUM

SECTOR 90 NOIDA 201305, IN

+44-20-8638-5055

#consulting company#strategic advisory firm#best market reports#market analysis reports#trending reports#syndicated reports#Top 10 Plastics Market#Top 10 Plastics#Top 10 Plastics Industry#Chemicals & Materials#Chemicals

0 notes

Text

Analyzing the Global Methyl Methacrylate Market: Trends, Growth Drivers, and Industry Insights

Methyl Methacrylate: Properties, Synthesis and Industrial Uses of Methacrylate

Chemical Properties

Methyl methacrylate, commonly known as MMA, is an organic compound with the formula C5H8O2. It is a colorless, volatile liquid with an acrid odor. MMA is moderately soluble in water but highly soluble in most organic solvents such as alcohol, ether, acetone and dichloromethane.

The primary property of MMA is that it undergoes free radical polymerization, which leads to the formation of PMMA. During polymerization, the carbon double bonds in MMA monomers react to form long chains or polymers. This conversion of a low-molecular-weight liquid to a high-molecular-weight solid plastic through polymerization is the reason why MMA finds numerous industrial applications.

MMA polymerizes via a free radical mechanism initiated by heat, light or chemicals like peroxides. The polymerization is exothermic and needs to be controlled carefully. During industrial production of PMMA, monomers, polymers and residual reactants must be kept separate to avoid premature or uncontrolled polymerization.

Synthesis of MMA

Commercially, MMA is produced through the acetone cyanohydrin process, which involves the reaction of acetone and hydrogen cyanide to form acetone cyanohydrin. This intermediate is then reacted with methanol in the presence of an acid catalyst to yield MMA.

CH3COCH3 + HCN → CH3C(OH)CN + H2O

CH3C(OH)CN + CH3OH → CH2=C(CH3)COOCH3 + H2O

The overall reaction involves the replacement of the nitrile group in acetone cyanohydrin by a methoxy carbonyl group through acid-catalyzed esterification. Major process parameters are the selection of acid catalyst, temperature control and recovery of byproducts.

MMA can also be synthesized through the methacrylic acid process, which involves the carbonylation of acetylene to methacrylic acid, followed by esterification with methanol. However, the acetone cyanohydrin process is preferred industrially due to lower costs.

Industrial Uses of MMA

Some of the major industrial applications of MMA and PMMA are:

Plexiglas and Optical Materials - PMMA in the form of Plexiglas sheets finds widespread use as an alternative to glass in lighting fixtures, transport equipment, window panes and optical instruments. It offers advantages of lighter weight, thermal insulation and durability.

Automotive and Aircraft Industries - MMA is used to manufacture canopies, light covers, glazing panels and translucent roof panels for aircraft, vehicles, trains and boats. PMMA offers crash resistance, high optical clarity and weatherability.

Paints and Coatings - MMA or blends of MMA and styrene are used as monomers in paints and coatings for their resistance to solvents, weathering and aging. Applications include automotive finishes and industrial flooring.

Adhesives - MMA based adhesives bond plastics, metals, wood, ceramics and composites. They offer high adhesion strengths along with heat, chemical and water resistance.

Acrylic Fibers - Polymerization of MMA leads to acrylic fibers used in textiles and apparels. They mimic the feel and appearance of wool but are cheaper and easier to maintain.

Medical Devices - PMMA is approved by FDA for applications such as bone cement, breast implants and contact lenses due to its biocompatibility and durability.

In summary, methyl methacrylate serves as a vital building block monomer in the synthesis of PMMA, which then finds diverse industrial applications leveraging its outstanding material properties. Strict process control during MMA production and polymerization is needed for safety and maximal output.

0 notes

Text

Exploring Polystyrene: Manufacturing and Market Trends (2023-2034)

Polystyrene stands as a versatile plastic polymer deeply embedded in various aspects of our daily lives. Its utility extends from packaging and food containers to insulation materials, showcasing a wide range of benefits. Despite its adaptability, polystyrene raises environmental concerns due to its non-biodegradable nature. In this comprehensive examination of polystyrene, we will delve into its unique characteristics, manufacturing processes, diverse applications, and the environmental challenges it presents. We'll explore its lightweight composition, durability, and moldable properties that make it a preferred material for many industries. Furthermore, we'll examine its significant role in sectors such as packaging, food service, and construction. With the global polystyrene market valued at around 11.2 million tons in 2023, it is projected to grow at a Compound Annual Growth Rate (CAGR) of 3.39% until 2034.

Introduction

Polystyrene is a synthetic resin characterized by its robust, rigid, and translucent properties. It is derived from styrene, a liquid hydrocarbon, which acts as the monomer in the polymerization process. Polystyrene's unique attributes, such as its lightweight nature and insulation properties, drive its utilization across various industries. The benefits of polystyrene plastic injection molding encompass its minimal shrinkage, versatility in being utilized in blended and foam states, and its moldability. Polystyrene, like all thermoplastics and can be easily molded, exhibiting minimal shrinkage throughout the injection molding process.

Various forms of polystyrene exist, each tailored for specific applications:

1. Solid Plastic: This category includes General Purpose Polystyrene (GPPS) and High Impact Polystyrene (HIPS), designed for different levels of impact resistance. High-impact grades of polystyrene typically contain 6–12% elastomers, while medium-impact grades have about 2–5%. High impact polystyrene (HIPS) resins are valued for their ease of processing, good dimensional stability, impact strength, and rigidity. These qualities make HIPS suitable for a variety of applications where toughness and durability are required, such as packaging, appliances, and consumer goods.

2. Foam: Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS) are foam variants suitable for insulation, packaging, and construction purposes.

3. Films: Oriented Polystyrene (OPS) finds applications in packaging films, offering clarity and stiffness. Oriented Polystyrene (OPS) is processed through orientation techniques to enhance its strength and clarity. Commonly used in clear containers, trays, and lids for food packaging, OPS offers excellent transparency, making it ideal for showcasing food items like salads, desserts, and deli products. OPS stands as a versatile material in the food packaging industry, meeting the demands for both aesthetic appeal and functional performance.

Manufacturing Process

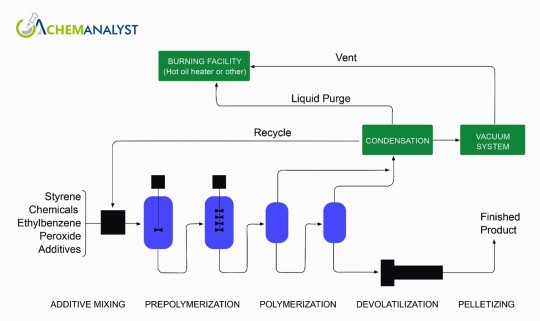

Polystyrene is produced through batch processes that ensure high conversion efficiency, minimizing emissions of unreacted styrene. In the batch bulk polymerization process, styrene monomer, and optionally comonomer, are dissolved in a feed dissolver. The continuous mass peroxide-initiated polymerization of styrene is a multi-stage process designed for efficiency and control. Beginning with the monomer and chemicals into a mixing section, the mass reaction occurs in the presence of a solvent. This mixture then progresses to the polymerization section, typically comprising two continuously stirred tank reactors (CSTRs), where heat generated during the reaction is dissipated by evaporating volatile components. Following the reaction, the polymer solution undergoes devolatilization in two consecutive stages under vacuum conditions, eliminating monomers and low-boiling compounds. The resulting polymer is then transferred to the pelletizing unit, supplied with heat via a thermal oil system.

Polymerization Stage

CSTR reactors facilitate precise control over molecular weight, Alternative configurations, like CSTR combined with plug flow reactors (PFR), offer flexibility to meet diverse process needs.

Devolatilization Stage

The devolatilization section ensures efficient removal of monomers and organic substances, minimizing polymer degradation without additional agents through high rates of heat and mass transfer. This stage consists of a two-step process with low residence periods and high heat and mass transfer rates. Even at very low operating temperatures, the effective removal of monomers and organic compounds is ensured by this special combination.

Expanded polystyrene (EPS), synthesized through suspension polymerization and impregnation with a blowing agent like pentane, and exhibits rigidity, lightweight nature, and low thermal conductivity. Expanded Polystyrene (EPS) foam is derived from expandable polystyrene beads, a rigid cellular plastic containing an expansion agent, typically sourced from oil. The EPS manufacturing process intricately links back to the initial chemical transformation from oil to expandable polystyrene. Now, we delve into the subsequent stages leading to the formation of EPS foam parts. In the first stage of pre-expansion, the raw beads undergo heating in specialized pre-expanders using steam. This process reduces the material density significantly, transforming hard beads into cellular plastic beads with small, closed cells containing air. Following pre-expansion, the beads undergo intermediate maturing and stabilization. As the recently expanded particles cool, they form a vacuum inside, which is compensated for by air diffusion. This enhances mechanical elasticity and expansion capacity, achieved during the material's intermediate maturing in aerated silos or mesh bags, where simultaneous drying occurs. In the final stage of expansion and molding, the stabilized pre-expanded beads are transferred to molds, where they are exposed to steam again to bind together. This results in the formation of large blocks through block molding or products in their final finished shape through shape molding, catering to various applications like boards, panels, and cylinders.

Market Dynamics

The global Polystyrene market is propelled by its distinctive attributes, including its water-resistant nature, making it a preferred choice in the packaging industry. Additionally, its ability to blend seamlessly with other polymers further enhances its versatility and widens its range of applications. Polystyrene's utilization in the manufacturing of automotive components and electronic goods is poised to drive market growth in the coming years, owing to its properties such as insulation and high strength.

Applications of Polystyrene:

1. Construction

Polystyrene is extensively utilized in the construction industry for various purposes. It is a key component in the production of lightweight concrete blocks, which are prized for their ease of handling and installation on construction sites.

2. Appliances

Polystyrene, both in solid and foam forms, is a prevalent material choice for a wide array of appliances, including refrigerators, air conditioners, ovens, microwaves, vacuum cleaners, and blenders.

3. Automotive

Polystyrene serves as a fundamental material in the manufacturing of numerous automotive components.

4. Electronics

Polystyrene is essential for crafting housing and components in televisions, computers, and IT equipment. Its lightweight and moldable nature allow for intricate designs that balance functionality and aesthetics.

5. Food Packaging

Polystyrene foodservice packaging is renowned for its superior insulation properties, which effectively maintain food freshness for extended periods. Compared to alternative packaging materials, polystyrene offers better insulation for hot & cold foods.

Market Outlook:

The global Polystyrene market is anticipated to reach approximately 17.8 million tonnes by 2034. Its affordability, combined with its excellent insulation capabilities, makes polystyrene a preferred choice in various industries, meeting both practical and economic needs effectively. Asia Pacific region is the leading consumer of Polystyrene and with rapid urbanization & construction paired with increasing dispensable income anticipated to remain so in the coming years.

Polystyrene Key Market players

Significant companies in the Global Polystyrene market are Total Petrochemicals, INEOS Styrolution, PS Japan, Jiangsu Laidun Baofu Plastifying, Zhenjiang Chi Mei Chemical, Shanghai Secco Petrochemical, Formosa Plastics, Versalis, Trinseo, Supreme Petrochem Limited, LG Chem, DIC Corporation, and Jiangsu Lyan Qingfeng Newmaterial.

Challenges and Opportunities

While the polystyrene market offers numerous opportunities, it also faces several challenges that impact its growth.

· Environmental Concerns: One of the significant challenges facing the polystyrene market is its environmental impact. Polystyrene is non-biodegradable and can persist in the environment for hundreds of years, contributing to pollution and posing risks to wildlife.

· Shift Towards Alternatives: Growing awareness of environmental and health issues associated with polystyrene has led to a shift towards alternative materials in various industries. Biodegradable and compostable alternatives, as well as recyclable plastics, are gaining popularity as consumers and businesses seek more sustainable options, posing a competitive challenge for the polystyrene market.

Conclusion:

The polystyrene market is diverse and driven by its versatile properties and cost-effectiveness. It finds applications in packaging, construction, automotive, electronics, and more. Polystyrene's advantages include its lightweight nature, thermal insulation properties, and moldability. In packaging, it is known for its resistance to moisture and impact, making it suitable for food packaging and protective materials. High Impact Polystyrene has remarkable dimensional stability alongside easy thermoforming capabilities. Its high impact resistance renders it ideal for various applications such as refrigerator liners, toilet seats, and disposable items, offering both functionality and aesthetic appeal, especially when painted. Additionally, its suitability for food packaging, exemplified by yogurt cups, underscores its versatility. Polystyrene foams leverage their excellent thermal insulation properties for diverse applications in construction and packaging.

0 notes

Text

Emulsion Polymers Market to Attain the Value of US$54.9 Billion by 2023

The global emulsion polymers market is poised for significant expansion between 2023 and 2031, driven by the increasing demand for environmentally friendly and cost-effective polymer solutions across various industries. Emulsion polymers, also known as latex or water-based polymers, find extensive applications in coatings, adhesives, textiles, paper, and construction materials due to their versatility, stability, and ease of use.

In 2022, the global industry was valued at US$ 28.8 billion. It is anticipated to grow at a Compound Annual Growth Rate (CAGR) of 6.7% from 2023 to 2031, reaching US$ 51.7 billion by the end of 2031.

Emulsion polymers are colloidal dispersions of polymers in water, stabilized by surfactants. They offer several advantages over solvent-based polymers, including low VOC emissions, improved safety, and ease of handling. The market for emulsion polymers is witnessing steady growth, driven by the growing emphasis on sustainable manufacturing practices and regulatory compliance.

Discover Valuable Insights: Download the sample of our Emulsion Polymers Market - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=1705

Market Segmentation:

By Service Type: Manufacturing, Formulation, Application

By Sourcing Type: Acrylics, Styrene-Butadiene Latex, Vinyl Acetate Polymers, Others

By Application: Paints & Coatings, Adhesives & Sealants, Paper & Paperboard, Textiles & Nonwovens, Others

By Industry Vertical: Construction, Automotive, Packaging, Textile, Paper & Printing, Others

By Region: North America, Europe, Asia Pacific, Latin America, Middle East & Africa

Regional Analysis:

North America: Mature market with a strong presence of key players and a focus on sustainable coatings and adhesives.

Europe: Stringent environmental regulations drive the adoption of water-based polymer solutions across various industries.

Asia Pacific: Rapid industrialization, urbanization, and infrastructure development fuel the demand for emulsion polymers in emerging economies such as China, India, and Southeast Asian countries.

Latin America and Middle East & Africa: Growing construction activities and increasing investments in infrastructure projects contribute to market growth in these regions.

Market Drivers and Challenges:

Drivers:

Growing demand for eco-friendly and low-VOC polymers

Increasing use of emulsion polymers in architectural coatings and adhesives

Technological advancements in polymerization techniques

Rising consumer awareness regarding sustainable products

Challenges:

Volatility in raw material prices

Intense competition from alternative technologies

Regulatory challenges and compliance requirements

Limitations in performance compared to solvent-based polymers in certain applications

Market Trends:

Focus on Bio-Based Emulsion Polymers: Rising interest in bio-based and renewable polymer feedstocks to reduce environmental footprint and dependency on fossil fuels.

Development of High-Performance Formulations: Introduction of emulsion polymers with enhanced properties such as improved adhesion, abrasion resistance, and weatherability to meet the evolving needs of end-users.

Customization and Tailored Solutions: Increasing demand for customized polymer formulations tailored to specific application requirements and performance criteria.

Future Outlook:

The emulsion polymer market presents lucrative opportunities for growth driven by increasing environmental awareness, stringent regulations, and the shift towards sustainable solutions. Market players are expected to focus on innovation, research, and development to introduce novel products and capture a larger market share.

Key Market Study Points:

Analysis of market dynamics including demand-supply trends and pricing fluctuations

Assessment of regulatory landscape and its impact on market growth

Evaluation of key market segments and growth drivers

Identification of emerging applications and untapped market opportunities

Competitive Landscape:

Key players in the emulsion polymers market include:

BASF SE

Dow Inc.

Arkema Group

Synthomer plc

Celanese Corporation

These companies leverage strategic partnerships, mergers & acquisitions, and investments in research and development to maintain their competitive edge and expand their market presence globally.

Capitalize on the booming Emulsion Polymers Market! Buy your research report now - https://www.transparencymarketresearch.com/checkout.php?rep_id=1705<ype=S

Recent Developments:

Introduction of sustainable and bio-based emulsion polymers

Strategic collaborations for technology transfer and market expansion

Investment in advanced manufacturing facilities and process optimization

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll-Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Hot Melt Adhesives

The global market size of hot melt adhesives is estimated to surpass USD 9.3 billion in 2019, with a projected compound annual growth rate (CAGR) of 5.4% during the forecast period, creating significant revenue opportunities for industry stakeholders.

Hot melt adhesive (HMA) has garnered widespread adoption across various industries due to its low emission of volatile organic compounds (VOC) and prolonged shelf life compared to solvent-based adhesives. This sector has exhibited robust growth, outperforming the overall chemical industry, driven by the escalating demand for high-performance solutions across heavy industries. The competitive landscape of the industry has intensified, prompting players to focus on product innovation and securing patents to fortify their market presence.

Several leading companies have undertaken strategic initiatives to enhance revenue and establish a prominent brand presence. For example, in 2015, Eastman Chemical Company introduced Aerafin Polymer A, a novel polyolefin for hot melt adhesives, while Jowat introduced PUR hot melt adhesive for window profile wrapping. Furthermore, there has been a notable surge in patent registrations post-2010, indicating a sustained trend of innovation within the industry.

Global Hot Melt Adhesives Market Size and Forecast: By Product

The market for polyolefin-based hot melt adhesives is projected to witness the fastest growth, with a CAGR of 6.1% during the forecast period. These adhesives offer superior adhesive properties and rapid setting speeds, finding extensive applications across diverse industries.

Global Hot Melt Adhesives Market Size and Forecast: By Application

Packaging emerges as the largest end-use market for hot melt adhesives, expected to account for 24% of the global share in 2019. The burgeoning USD 550 billion packaging industry presents substantial growth opportunities for hot melt adhesive manufacturers.

Global Hot Melt Adhesives Market Size and Forecast: Regional Analysis

Asia Pacific is anticipated to command a significant market share, accounting for 45% in 2019, with China leading the regional market. The region's robust market presence can be attributed to its cost-effective production capabilities, favorable government policies, and extensive demand generated by its thriving packaging and consumer electronics sectors.

Global Hot Melt Adhesives Market Size and Forecast: Competition Landscape

Industry players are prioritizing product innovation to maintain competitiveness and drive returns on investment.

Key Hot Melt Adhesives Players Include:

Adhesive Technologies, Inc.

Worthen Industries Inc.

American Chemical, Inc.

3M

Jowat SE

Evans Adhesive Corporation Ltd.

Avery Dennison Corporation

Tex Year Industries Inc.

Bostik Inc.

Capital Adhesives & Packaging Corp.

LORD Corporation

Costchem srl

Daubert Chemical Company, Inc.

Ashland Global Holdings Inc.

Dow Corning Corporation

Alfa International Corporation

H.B. Fuller Company

Henkel AG & Co. KGaA

Sika AG

Industry Segmentation:

By Product Type:

EVA

Polyolefins

Styrene Block Copolymers (SBC)

Polyurethane (PUR)

Hot Melt Pressure Sensitive Adhesives

Others

By Application:

Packaging

Electronics

Automotive

Hygiene Products

Construction

Furniture

Textile

Others

0 notes

Text

India Butyl Acrylate Market Outlook, Report 2023-2030

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the India Butyl Acrylate Market size by value at USD 432.99 million in 2023. During the forecast period between 2024 and 2030, BlueWeave expects the India Butyl Acrylate Market size to expand at a CAGR of 7.85% reaching a value of USD 534.03 million by 2030. The Butyl Acrylate market in India is propelled by the increasing application as a solvent in the paints and coatings, as well as adhesive and sealants sectors, predominantly within the expanding construction and automotive industries. India has witnessed a rising trend in residential and commercial development in recent years, driven by increasing investments and evolving lifestyles. Also, butyl acrylate plays a crucial role as an ingredient in pressure-sensitive adhesives, widely employed by the textile and construction sectors. Its presence in PVC modifiers and molding or extrusion additives further enhances its application in the plastics sector. With the upswing in construction activities and infrastructure development, there is an anticipated surge in demand for commodities like paints & coatings and plastics, consequently boosting the overall demand for butyl acrylate over the forecast period.

By volume, BlueWeave estimated the India Butyl Acrylate Market size at 261.66 thousand tons in 2023. During the forecast period between 2024 and 2030, BlueWeave expects the India Butyl Acrylate Market size by volume is projected to grow at a CAGR of 7.01% reaching the volume of 301.09 thousand tons by 2030. The increasing use of butyl acrylate in the production of thermoplastic ethylene acrylate copolymers (EAC), containing up to 35% butyl acrylate, stands out as pivotal factor contributing to market expansion. The combination of butyl acrylate with other monomers, such as vinyl acetate, methyl methacrylate, acrylic acid, styrene, and other acrylate ester monomers, opens up possibilities for diverse copolymer compositions.

Sample Request @ https://www.blueweaveconsulting.com/report/india-butyl-acrylate-market/report-sample

Opportunity – Expanding automotive industry

The expanding automotive industry in India is anticipated to drive the need for butyl acrylate. The compound plays a crucial role in polymer manufacturing, specifically contributing to the production of car dashboards and leather seats. Additionally, butyl acrylate serves as a key component in the production of sealants, utilized in various automotive applications such as within the trunk, hood, doors, front dash, and on both the interior and exterior metal joints of vehicles. The global surge in motor vehicle production stands as a significant factor contributing to the anticipated growth of the butyl acrylate market in the coming years.

Impact of Escalating Geopolitical Tensions on India Butyl Acrylate Market

Increasing geopolitical tensions can have a multifaceted impact on the India Butyl Acrylate Market. The surge in upstream values, particularly crude oil, is exerting pressure on downstream derivatives, thereby elevating inflationary concerns for consumers. Butyl acrylate prices in the domestic market have responded with buoyancy, driven by multiple elements contributing to these fluctuations. A substantial driver for this upward trajectory is the notable increase in crude oil values, impacting critical feedstocks like n-Butanol and Acrylic Acid. The exponential rise in crude oil prices is a consequence of global uncertainties, with low inventories in the USA driving up spot prices of Brent. Simultaneously, geopolitical tensions between Russia and Ukraine have further heightened global contract purchases. Additionally, increased consumption in China, post-easing of the dual energy policy and winter Olympics-related restrictions, has influenced the overall pricing dynamics for crude oil globally. Also, heightened demand fundamentals for Butyl Acrylate in the downstream derivative segment contribute to the overall upward price trend in the Indian market.

India Butyl Acrylate Market

Segmental Information

India Butyl Acrylate Market – By Application

On the basis of application, the India Butyl Acrylate Market is divided into Paints & Coatings, Adhesives & Sealants, Chemical Synthesis, Plastic Additives, and Textiles segments. The paints & coatings segment holds the highest share in the India Butyl Acrylate Market by application closely followed by the adhesive & sealants segment. It is primarily due to their growing applications in the construction and automotive industries. Additionally, the rising trend of substituting old coatings with water-based alternatives in combination with the increased usage of adhesives further contributes to the sustained leadership of these industries in the market.

India Butyl Acrylate Market – By Region

Geographically, the India Butyl Acrylate Market is divided into North India, South India, East India, and West India regions. West India holds the highest market share and is expected to maintain its dominance during the forecast period. Its dominance is attributed to key consumption in states like Gujarat and Maharashtra, driven by prominent companies, such as Asian Paints. Until FY2022, India relied on imports to meet the demand for butyl acrylate.

Competitive Landscape

The India Butyl Acrylate Market is fragmented, with numerous players serving the market. The key players dominating the India Butyl Acrylate Market include Bharat Petroleum Corporation Limited, BASF, Vizag Chemical, Dhalop Chemicals, Dow, Arkema, Otto Chemie Pvt Ltd, KR Chemicals, and LG Chem. The key marketing strategies adopted by the players are facility expansion, product diversification, alliances, collaborations, partnerships, and acquisitions to expand their customer reach and gain a competitive edge in the overall market.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

Navigating the ABS Plastic Market: Manufacturing Insights and Pricing Considerations

In the realm of modern manufacturing, ABS plastic stands as a cornerstone material renowned for its versatility, durability, and cost-effectiveness. As manufacturers explore the landscape of ABS plastic, understanding its production intricacies and pricing dynamics becomes paramount. This article delves into the world of ABS plastic manufacturing, focusing particularly on ABS plastic sheets, including insights into production, applications, and pricing considerations.

ABS (Acrylonitrile Butadiene Styrene) plastic is a thermoplastic polymer known for its exceptional mechanical properties, making it an ideal choice for a wide array of applications across industries such as automotive, construction, electronics, and consumer goods. Its unique blend of strength, impact resistance, and machinability renders it indispensable for manufacturers seeking reliable and versatile materials.

Manufacturing ABS plastic involves a meticulous process of polymerization, where acrylonitrile, butadiene, and styrene monomers are combined through polymerization to form the final product. The process typically involves injection molding, extrusion, or thermoforming techniques, each tailored to specific product requirements. ABS plastic manufacturers prioritize quality control measures to ensure consistency and adherence to industry standards throughout the production cycle.

ABS plastic sheets, in particular, are highly sought after for their ease of fabrication and diverse applications. These sheets come in various thicknesses, including the popular 3/8 inch variant, and standard sizes like 4x8 feet. The versatility of ABS plastic sheets makes them suitable for applications ranging from signage, automotive interior components, to prototyping and model-making.

When considering ABS plastic sheet price, several factors come into play, influencing the final cost. Raw material costs, manufacturing processes, and market demand all contribute to pricing fluctuations. The price of ABS plastic sheets, including the 3/8 inch 4x8 variant, can vary based on factors such as quantity ordered, customization requirements, and supplier pricing strategies.

Raw material costs significantly impact ABS plastic sheet pricing. Fluctuations in the prices of acrylonitrile, butadiene, and styrene monomers, influenced by factors like crude oil prices and supply chain disruptions, directly influence the cost of ABS plastic production. Manufacturers closely monitor these market dynamics to adjust pricing accordingly and maintain competitiveness.

Manufacturing processes also play a crucial role in determining ABS plastic sheet prices. Efficiency improvements, technological advancements, and economies of scale can help manufacturers optimize production costs, thereby offering competitive pricing to customers. Additionally, factors such as sheet thickness, surface finish, and color customization may influence pricing variations.

Market demand and supply dynamics further influence ABS plastic sheet pricing. Increased demand from key industries or seasonal fluctuations can impact pricing trends. Moreover, geographical factors, logistics costs, and regulatory requirements may also contribute to regional price variations.

For manufacturers seeking ABS plastic sheets, navigating pricing considerations requires careful evaluation of quality, customization options, and supplier reliability. Partnering with reputable manufacturers and suppliers ensures access to high-quality ABS plastic sheets at competitive prices, backed by reliable customer support and timely delivery.

Conclusion

ABS plastic remains a cornerstone material in modern manufacturing, offering unparalleled versatility and performance across diverse applications. ABS plastic sheet pricing, including popular variants like the 3/8 abs plastic sheet 4x8, is influenced by factors such as raw material costs, manufacturing processes, and market dynamics. By understanding these intricacies and partnering with reliable suppliers, manufacturers can harness the full potential of ABS plastic for their production needs, driving innovation and efficiency in their respective industries.

FAQ:

What are the limitations of ABS plastic?

ABS plastic has limitations including poor UV resistance, susceptibility to high temperatures causing softening, chemical sensitivity leading to degradation when exposed to certain solvents, limited strength and rigidity compared to other engineering plastics, tendency to warp or shrink during cooling, and environmental concerns due to non-biodegradability and reliance on petroleum-based resources in production.

What is abs plastic sheet price?

The price of ABS plastic sheets can vary depending on factors such as thickness, size, quantity ordered, customization options, and supplier pricing strategies. On average, ABS plastic sheets may range from to per square foot for standard thicknesses and sizes. However, prices may fluctuate based on market demand, raw material costs, and other factors.

1 note

·

View note

Text

Shaping Tomorrow's Chemistry: The Dynamics and Growth of the Latin America Styrene Market

The Latin America styrene market achieved a significant milestone in 2023, attaining a value of approximately USD 6,447.40 million. Poised for continued growth, the market is projected to experience a compound annual growth rate (CAGR) of 2.6% from 2024 to 2032, reaching an estimated value of USD 8,151.44 million in 2032. This article delves into the dynamic landscape of the Latin America styrene market, exploring key factors driving its expansion, industry applications, technological developments, and the role it plays in the regional chemical sector.

Market Dynamics and Growth Drivers:

The Latin America styrene market witnessed robust growth in 2023, driven by a confluence of factors contributing to increased demand for this versatile chemical. The projected CAGR of 2.6% signifies a sustained trajectory, influenced by:

Industrialization and Economic Development: As Latin American economies continue to industrialize, the demand for styrene, a key component in the production of various polymers and plastics, has surged. Rapid economic development has led to an upswing in manufacturing activities, boosting the consumption of styrene across diverse industries.

Expansion of End-User Industries: Styrene serves as a fundamental building block for a wide range of products, including packaging materials, insulation, and consumer goods. The growth in end-user industries such as packaging, automotive, and construction has propelled the demand for styrene-based materials, fostering market expansion.

Urbanization and Consumer Lifestyle Changes: Urbanization trends and shifts in consumer lifestyles contribute to the demand for innovative materials and products. Styrene-based polymers and resins play a vital role in meeting these demands, particularly in applications such as packaging, household items, and electronic devices.

Applications Across Industries:

Polystyrene Production: Polystyrene, a major derivative of styrene, finds extensive use in packaging, disposable containers, insulation, and consumer products. The versatility of polystyrene makes it a preferred material in various applications, contributing significantly to the overall styrene market.

Expanded Polystyrene (EPS): Styrene is a key component in the production of Expanded Polystyrene (EPS), widely utilized in construction for insulation, packaging for fragile goods, and even in the crafting of model aircraft. The versatility, lightweight, and insulating properties of EPS contribute to its widespread application.

ABS Resins: Acrylonitrile Butadiene Styrene (ABS) resins, another derivative of styrene, are essential in the automotive industry for manufacturing components like interior trims, panels, and exterior body parts. The durable and versatile nature of ABS resins underscores their significance in automotive applications.

Styrene-Butadiene Rubber (SBR): Styrene is a crucial component in the production of Styrene-Butadiene Rubber (SBR), widely used in the tire industry for its excellent abrasion resistance and durability. The demand for SBR in the automotive sector contributes to the overall growth of the styrene market.

Technological Advancements:

Green Styrene Initiatives: The styrene industry in Latin America is witnessing a growing emphasis on sustainable practices and environmental responsibility. Green styrene initiatives focus on adopting eco-friendly production processes, reducing emissions, and exploring bio-based alternatives, aligning with global sustainability goals.

Research and Development: Ongoing research and development efforts within the Latin America styrene market aim to enhance production efficiency, reduce environmental impact, and discover novel applications for styrene derivatives. Collaborations between industry players and research institutions contribute to technological advancements.

Market Challenges and Regulatory Landscape:

Environmental Concerns: The styrene market faces challenges related to environmental concerns, including emissions during production and end-of-life disposal of styrene-based products. Stringent regulations and increasing awareness of environmental impacts necessitate sustainable practices and innovation in the styrene industry.

Raw Material Price Volatility: The styrene market is influenced by the volatility of raw material prices, particularly feedstocks such as benzene and ethylene. Fluctuations in raw material costs can impact production costs and, subsequently, the pricing of styrene-based products.

Regulatory Compliance: Compliance with regulations governing chemical manufacturing, handling, and transportation poses challenges for styrene manufacturers. Adherence to safety standards and evolving regulatory frameworks requires continuous monitoring and adaptation within the industry.

Market Outlook and Future Trends:

The Latin America styrene market, with its value projected to reach USD 8,151.44 million by 2032, is poised for a transformative phase marked by innovation and sustainability. Key trends shaping the market's future include:

Bio-Based Styrene Development: The exploration of bio-based styrene, derived from renewable sources, is gaining traction. Research and development efforts are focused on creating sustainable alternatives to traditional styrene production methods.

Circular Economy Initiatives: Initiatives promoting a circular economy, including recycling and the development of recyclable styrene-based materials, are expected to gain prominence. Manufacturers are exploring ways to enhance the recyclability and reusability of styrene-derived products.

Technological Integration: Continued technological integration, including advancements in catalyst technologies and production processes, will play a pivotal role in enhancing the efficiency and sustainability of styrene production.

Collaborations for Sustainability: Collaborations between industry stakeholders, research institutions, and regulatory bodies will drive sustainability initiatives within the styrene market. The sharing of best practices and the development of standardized sustainability measures will be crucial.

Trade Dynamics and Global Influence:

The Latin America styrene market is not isolated but actively participates in global trade dynamics. The region engages in the import and export of styrene-based products, contributing to the interconnectedness of the global chemical industry. Trade partnerships, market collaborations, and adherence to international quality standards play a vital role in positioning Latin America within the broader context of the styrene market.

Investments in Capacity Expansion:

In response to the growing demand for styrene, Latin American countries are witnessing investments in capacity expansion within the chemical industry. Manufacturers are strategically expanding production facilities, adopting advanced technologies, and exploring opportunities for vertical integration to meet the evolving market requirements. Such investments contribute to regional economic growth and job creation.

Supply Chain Resilience and Raw Material Sourcing:

Ensuring a resilient supply chain is crucial for the styrene industry in Latin America. The region's manufacturers focus on securing a stable supply of raw materials, such as benzene and ethylene, essential for styrene production. Diversification of raw material sources and strategic partnerships with suppliers enhance supply chain resilience and mitigate potential disruptions.

Market Competitive Landscape:

The Latin America styrene market is characterized by the presence of key industry players and multinational chemical corporations. Competition among manufacturers is influenced by factors such as product innovation, production efficiency, and sustainability practices. Market leaders often engage in strategic collaborations, acquisitions, and partnerships to strengthen their market position and expand their product portfolios.

Consumer Trends and Material Preferences:

Consumer trends and preferences have a direct impact on the demand for styrene-based products. The Latin American market is responsive to shifts in consumer preferences toward sustainable and eco-friendly materials. Manufacturers align their product offerings with these trends, introducing recyclable, biodegradable, and environmentally conscious styrene-based materials to meet evolving consumer expectations.

0 notes