#china machined carbon fiber

Text

Carbon Fabric

8 characteristics of Carbon fiber material

I. Small density, light weight:

It is about 1/5 of copper and 3/5 of aluminum alloy, greatly reducing the product.

II. Good chemical resistance:

Substituting metal avoids corrosion and extends life.

III. Fatigue resistance, long service life:

No permanent deformation, greatly improving the safety and stability of product components.

IV. High strength, high modulus:

About 1.3 times of copper, 3.7 times of aluminum alloy, improve product strength, rigidity and other mechanical properties.

V. Low coefficient of thermal expansion:

It will not affect the use of products due to thermal expansion and cold contraction image products.

VI. Good electrical conductivity:

Excellent electrical conductivity in composite materials.

VII. Energy absorption and shock absorption:

It has excellent damping function to vibration, thus reducing vibration and noise.

VIII. Self-lubricating, wear resistance:

Make full use of self-lubricity to improve product smoothness and reduce component wear.

ABOUT US

We were founded in September 2015 and located in Zhijiang Industrial Park, Haining, Zhejiang, is a large scientific and technical enterprise focusing on scientific research, product development, production, sales and service in the area of fiberglass-based. Carbon Fabric Suppliers and Carbon Fabric Company.

The glass fiber products and glass fiber composite material we produce are widely used and can be used in electric appliances, electronics, transportation, chemical engineering, architectural engineering, heat insulation, sound absorption, fire prevention and environmental protection, and other high-tech fields. We use 4.6-meter automatic warping machines, 3.4-meter air-jet looms and 4.6-meter wide high-grade rapier looms, suitable for PTFE, PVA, PVC, PU, and silicone coating. Our main products are fiberglass cloth, fiberglass mesh, waterproof building material, special building material, bakeware, BBQ accessories, and sealing strip. Our products are sold to more than 30 provinces at home and several countries and regions in North America, South America, Europe, Mid East, Southeast Asia, Oceania, Africa, and so on.

We will be committed to becoming a professional fiberglass products company with China's competitive advantage and complete industry chain and forming a superior fiberglass composite material manufacturing enterprise.

0 notes

Text

The Rise of Selective Laser Sintering (SLS) 3D Printers in China

The Rise of Selective Laser Sintering (SLS) 3D Printers in China

The world of 3D printing has seen a significant transformation over the past few decades. One technology that has gained considerable attention is Selective Laser Sintering (SLS). This technology, invented by Carl Deckard in 19881, uses a laser to trace and solidify layers of powder polymers to create a finished part1. Initially, SLS 3D printers were industrial machines costing tens of thousands of dollars1. However, with recent patents expiring and a renewed interest in 3D printing, several more affordable SLS 3D printers have been developed.Get more news about china sls 3d printer,you can vist our website!

China, known for its technological advancements and manufacturing prowess, has emerged as a significant player in the SLS 3D printer market. Chinese manufacturers have been producing high-quality SLS 3D printers that are gaining recognition worldwide.

One such manufacturer is Xiamen Sinuowei Automated Science and Technology Co., Ltd. They offer a range of industrial printers with double nozzle numbers and metal printer materials. These printers are large-sized and are priced between US$30,000 to US$150,000. They cater to various sectors including dental, research and development, and non-standard machine manufacturing.

Another notable player in the Chinese market is the Polish manufacturer Sinterit. Their product, the Sinterit Lisa, is an affordable desktop SLS printer priced at around €9,995. It offers a printing volume of 150 x 200 x 150 mm, making it suitable for most single-part projects. Despite being a desktop printer, it weighs 41kg, making it less portable1. The Sinterit Lisa is compatible with PA12 Nylon and Flexa black materials and offers a layer thickness of between 0.075-0.175mm.

SLS printers have a more restricted material range than technologies like Fused Deposition Modeling (FDM), mostly restricted to Nylon Polyamide powders1. Some are restricted to just black PA12, whereas some can also print powders including PA11 and PA61. Increasingly, powder mixes are compatible with industrial and desktop SLS 3D printers. These include glass mixes, carbon fiber mixes, and even food-grade powders for niche applications1.

The rise of SLS 3D printers in China is not just limited to manufacturing. Companies like Protofab offer industrial 3D printer rental services3, catering to businesses that need high-quality printing but cannot afford to purchase their own machines. These rental services offer fast printing speed, high printing accuracy, high surface finish, and high printing success rate.

In conclusion, the growth of SLS 3D printers in China is a testament to the country’s technological advancements and its ability to adapt to global trends. With manufacturers producing high-quality machines at competitive prices and companies offering rental services for businesses of all sizes, China is poised to become a global leader in the SLS 3D printer market.

0 notes

Text

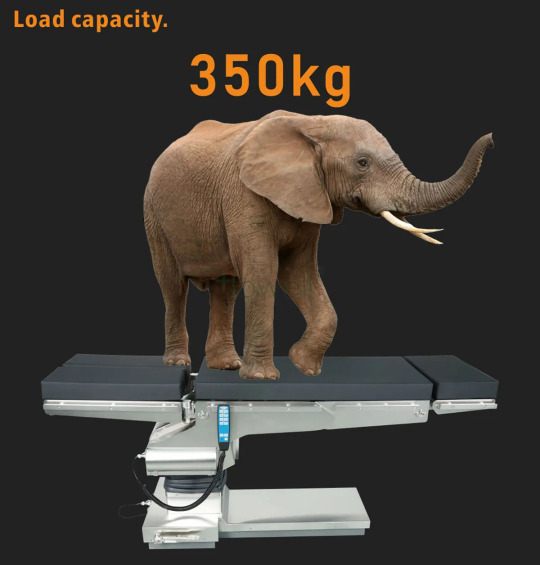

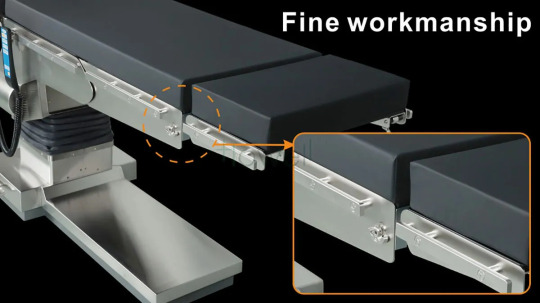

4 Section G-Arm Operating Table C-Arm Carbon Fiber Orthopedic Surgery Table HE-608-M (4 section)

Using the most advanced microcomputer control and electro-hydraulic transmission system, the product has a unique structure, beautiful appearance, simple operation, safety and reliability, and its quality has reached the international level. The design of the unilateral column, the material panel that can be scanned through perspective, the excellent X-ray perspective space and the accurate picture, suitable for urology, thoracic surgery, renal surgery, and all operating departments that need to use C-arms and X-ray machines.

WhatsApp +8615146602893

Advantages and Characteristics

1、It applies a micro-computer control and adopts advanced electro-hydraulic drive technology instead of traditional electric pushing rod drive technology , realizing more accurate body positions as well as more uniform and smooth running speed

2、Main parts of the hydraulic system adopt imported parts , so that it is more reliable in wholeperformance and durable in use

3、New material of memory foam mattress thickness is 70mm , using 30mm memory foam and40mm high density sponge optimal combination , can release the long time operation caused by patient body and the bed surface caused by the contact pressure

4、Classical and elegant model made of high quality # 304 stainless steel . Advanced model ismade by aluminum alloy and # 304 stainless steel . Good looking , easy cleaning , anti-crash and anti-corrosion

The product can be equipped with the following functions according to customer needs:

Carbon fiber bed board, backup controller, one-key reset function, automatic bending, backup power storage function, electro-hydraulic brake function

With the advancement of science and technology, the strengthening of machining capabilities, and the improvement of design and manufacturing levels, the operating bed industry has developed rapidly. After years of steady development, Howell Medical has improved product quality, expanded production capacity, and introduced various advanced equipment. The company's products not only have a broad market in China but also are exported to many countries and regions around the world, winning the satisfaction and trust of global customers with their quality and price.

WhatsApp +8615146602893

0 notes

Text

China carbon fiber aluminum honeycomb sandwich panel suppliers

China carbon fiber aluminum honeycomb sandwich panel suppliers About Us Headquartered in Foshan, China, Guangdong Xinhemate Building Materials Co., Ltd (鈥榅inhe鈥? implements its engineering excellence through a wide range of customized interior and exterior products and services: Ceilings and claddings, facade and canopies. Xinhe meets the challenges posed by creative architectural design in the state-of-the-art production facilities in China鈥檚 dedicated industrial zone with a team of more than 25 years experienced, qualified , trained and motivated workforce. Equipped with advanced computer numeric control (CNC) machines that imported from German and Swizz, these facilities and people ensure complex design specifications are implemented as per schedule. Xinhe is always doing her best to meet the increasing needs and requirements of the global building and construction industry. In pursuit of excellence, Xinhe has developed and implemented a quality management system in compliance with the ISO 9001:2008 standards. We are looking forward to establish the long term business relationship with all of our agents and distributors, architects, consultants, contractors, construction company, wholesales and business partners who have interested in our products and services.China carbon fiber aluminum honeycomb sandwich panel suppliers website:http://www.aluminumdecorations.com/

0 notes

Text

Polyether Ether Ketone (PEEK) Market Growth, Global Revenue Forecast, Company Share, and Competitive Landscape 2030

Polyether ether ketone (PEEK) is a high-performance thermoplastic material that is known for its excellent mechanical, thermal, and chemical properties. It belongs to a family of semi-crystalline polymers that exhibit high heat resistance, low flammability, excellent chemical resistance, and good electrical properties. PEEK is often used in the aerospace, automotive, medical, and industrial sectors due to its unique combination of properties.

PEEK can be processed by various methods, including injection molding, extrusion, and machining. It is often used to replace metal parts due to its high strength-to-weight ratio, and it is also used in applications where high temperature resistance is required. Additionally, PEEK is biocompatible, making it suitable for medical implants and devices.

PEEK is an expensive material compared to other thermoplastics, which limits its use in certain applications. However, its unique properties make it an ideal choice for demanding applications where other materials may not be suitable.

Global polyether ether ketone market was valued at US$ 634.9 Million in 2021, in terms of revenue, and is expected to exhibit a CAGR of 7.18% during the forecast period (2022 to 2030).

One of the major drivers for the growth of the PEEK market is its increasing use as a replacement for traditional materials such as metal and ceramics in various applications due to its superior properties such as high strength-to-weight ratio, high-temperature resistance, and excellent chemical resistance. Additionally, the increasing demand for lightweight and fuel-efficient vehicles in the automotive industry is expected to further boost the demand for PEEK.

Geographically, Asia-Pacific is expected to be the fastest-growing market for PEEK due to the increasing demand from emerging economies such as China and India, where the industrial and automotive sectors are rapidly growing. North America and Europe are also significant markets for PEEK, driven by the presence of established end-use industries and increasing demand for high-performance materials.

Major players operating in the global polyether ether ketone (PEEK) market include Zyex Ltd., Solvay S.A., Victrex plc, Panjin Zhongrun High Performance Polymers Co. Ltd., Caledonian Industries Ltd., Quadrant EPP Surlon India Ltd., Evonik Industries AG, and Jrlon Inc.

The polyether ether ketone (PEEK) market is expected to grow at a steady pace in the coming years, driven by increasing demand from various end-use industries and the development of new grades and applications of PEEK. Some of the factors that are expected to drive the growth of the PEEK market are:

Growing demand from the aerospace industry: PEEK is used extensively in the aerospace industry due to its high strength-to-weight ratio and excellent temperature resistance, making it an ideal material for components in aircraft engines and other critical applications.

Increasing use in the medical industry: PEEK is biocompatible and has excellent mechanical properties, making it an ideal material for medical implants and devices. The growing demand for minimally invasive surgical procedures is expected to drive the demand for PEEK in the medical industry.

High-performance applications in the automotive industry: PEEK is increasingly being used in high-performance automotive applications, such as lightweight components in electric and hybrid vehicles, to improve fuel efficiency and reduce emissions.

Development of new grades and applications: The development of new grades of PEEK and the introduction of new applications in various end-use industries are expected to drive the growth of the PEEK market. For example, the development of carbon fiber reinforced PEEK is expected to provide improved mechanical properties and open up new applications in the aerospace and automotive industries.

The demand for polyether ether ketone (PEEK) is expected to continue to grow in the coming years, driven by its unique combination of mechanical, thermal, and chemical properties that make it ideal for use in a wide range of end-use industries. Some of the factors that are expected to drive the demand for PEEK are:

Aerospace industry: The aerospace industry is a significant user of PEEK due to its high strength-to-weight ratio and excellent temperature resistance. PEEK is used extensively in aircraft engine components and other critical applications.

Medical industry: PEEK is biocompatible and has excellent mechanical properties, making it an ideal material for medical implants and devices. The demand for PEEK in the medical industry is expected to continue to grow as the trend towards minimally invasive surgical procedures and the use of medical implants and devices increases.

Automotive industry: The automotive industry is another major user of PEEK due to its high-performance properties. PEEK is increasingly being used in lightweight components in electric and hybrid vehicles to improve fuel efficiency and reduce emissions.

Industrial applications: PEEK is used in a wide range of industrial applications, including oil and gas, chemical processing, and electrical insulation. Its excellent chemical resistance and high-temperature resistance make it an ideal material for use in harsh environments.

Polyether ether ketone (PEEK) offers a number of benefits that make it an ideal material for various applications across different industries. Some of the key benefits of PEEK are:

High strength and stiffness: PEEK has excellent mechanical properties, including high strength and stiffness, making it ideal for high-performance applications in industries such as aerospace and automotive.

Excellent temperature resistance: PEEK has a high melting point and can withstand high temperatures, making it ideal for use in applications where exposure to high temperatures is a concern.

Chemical resistance: PEEK is resistant to a wide range of chemicals, including acids, bases, and organic solvents, making it suitable for use in harsh chemical environments.

Biocompatibility: PEEK is biocompatible and can be used in medical implants and devices, such as spinal implants and dental implants.

Lightweight: PEEK is a lightweight material, making it ideal for use in applications where weight is a concern, such as aerospace and automotive.

Durability: PEEK has excellent wear and abrasion resistance, making it ideal for use in applications where durability is a concern.

Overall, the unique combination of mechanical, thermal, and chemical properties of PEEK make it a versatile material that can be used in a wide range of applications across various industries, providing numerous benefits to end-users.

0 notes

Text

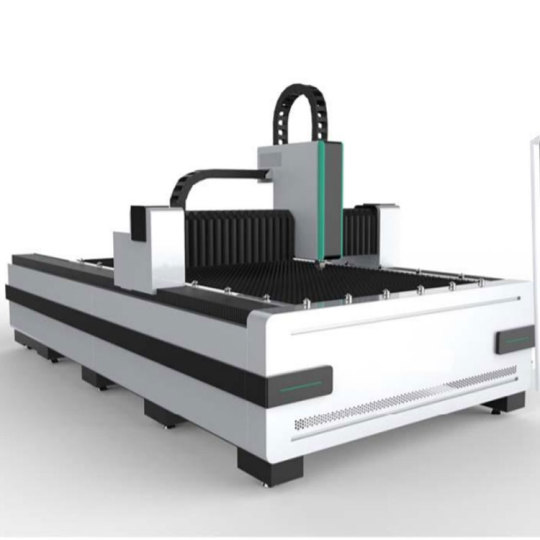

China Co2 Laser Machine manufacturers

China Co2 Laser Machine manufacturers High steady Cnc Metal Pipe Tube Fiber Laser Cutting Machine Price fiber laser cutting machine 1000w price Product Description Fiber laser cutting machine with tube cutting JNChangtai fiber laser cutting machine model TPF -1530 - S use the world top brand parts,Raytools fiber laser head ,the laser head can automatically focus, and imported Japan FUJI servo motors and drives, high precision, high speed, large torque, performance is stable and durable, ensure the high speed operation of the whole machine.Chinese top brand fiber laser source RAYCUS, high power,high precision. Top brand control system : Cypcut control system, with automatic layout optimization. 1. Application of gantry structure and integrated cast cross-girder to achieve higher rigidity, stability, shock resistance. 2. High-performance oring possible during the laser cutting process. Technical parameters Equipment modelTPF-1530-SLaser typefiber-optic laserLaser working mediumoptical fiberLaser wavelength1060-1080 nmRECOMMEND POWER1000W, 1500W, 2000W, 3000W, 400W,5000W, 6000W, 12000W Beam quality<0.373mradX-axis distance1500mmY-axis distance3000mmZ axis distance120mmEffective cutting range3000*1500mmPositioning accuracy鈮ぢ?.02mm/mRepeat positioning accuracy鈮ぢ?.02mm/mMax. Moving speed120m/minSupport graphic formatPLT,AI,BMP,DST,DXF format (support for CORELDRAW, AI,PHOTOSHOP, AUTOCAD)Power Supply3P, AC 380V/50Hz/16A Main parts Applications Applicable and samples 1.Application Materials: Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc 2.Application Industries: BODOR Fiber Laser Cutting Machines are widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters,Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, GlassesFrame, Electronic Parts, Nameplates, etc. Packaging & Shipping Packaging and shipping 1)Packaging: Whole film packaging machine; anti-collision package edge; fumigation-free plywood wooden box and pallets with iron binding belt. 2)Shipping: We cooperate with SINOTRANS company whose experience in the ocean transportation will guarantee your machine safety. We also provide train transport, especially to Russia, Ukraine and other inland countries. 3)Payment: We support T/T, VISA, Mastercard payment terms with Alibaba Trade Assurance. Company Information Factory show Contact Please contact Lisa Whatsapp/Wechat/Phone : +86 158 3005 9372 customers visit China Co2 Laser Machine manufacturers website:http://www.changtaicnclaser.com/co2-laser-machine/

1 note

·

View note

Text

What Is PTFE Ball Valve?

What Is PTFE Ball Valve?

A PTFE ball valve is a crucial component of many industrial processes, allowing fluid or gas to flow through a valve that rotates 90 degrees and is sealed at both ends with solid sides. The durable design of this valve ensures that no leaks occur, and the material used is PTFE, which is the same as Teflon. In this article, we will discuss the manufacturing process and applications of a PTFE ball valve in various industries.

Manufacturing of PTFE Ball Valve

A PTFE ball valve manufacturer produces the valve body using a wide range of stainless steel and cast ductile iron materials. This material is commonly used in high-pressure and corrosive environments, serving as an alternative to metal valves. The PTFE-coated ball valve is used in petrochemical plants for flow control and transfer of chemicals. Apart from petrochemical processes, PTFE-coated ball valves can also be found in the manufacturing of fertilizers, pesticides, dyes, and pulp and paper processing plants.

Applications of PTFE Ball Valve

The PTFE ball valve is highly versatile, making it suitable for various industrial applications, including the pharmaceutical and food industries. For cryogenic applications, a PTFE ball valve is the preferred choice because of its high sealing capability and quick action. Its standard size and high strength make it an excellent choice for cryogenic applications.

PTFE is a versatile material that is resistant to chemicals and has no reaction with them. It is also an excellent choice for cookware, as metals like aluminum corrode easily when they come in contact with acids. Additionally, PTFE is not electrically conducting. Thus, PTFE is an excellent choice for hose linings, machine parts, and other components.

Advantages of PTFE Ball Valve

The advantages of PTFE are the high chemical resistance, low friction, and wide temperature range. These qualities make PTFE ideal for many industrial applications, including petrochemical, pharmaceutical, food processing, and cryogenic applications. Some PTFE ball valves are filled with glass fiber, carbon fiber, graphite, bronze, or glass, making them more durable and reliable.

In conclusion, the PTFE ball valve is an essential component of many industrial processes, and its reliability, durability, and ease of maintenance contribute to its popularity. The PTFE ball valve is versatile, making it suitable for various industrial applications, including the pharmaceutical and food industries. Its high chemical resistance, low friction, and wide temperature range make it an ideal choice for many applications.

MAN 7S35MC-MK7 Cylinder Liner from Decho Marine Services

Decho Marine Services (China) Tingting

+86 159-6706-1188

[email protected]

from Decho Marine Services

Decho Marine Services (China) Tingting

+86 159-6706-1188

[email protected]

0 notes

Text

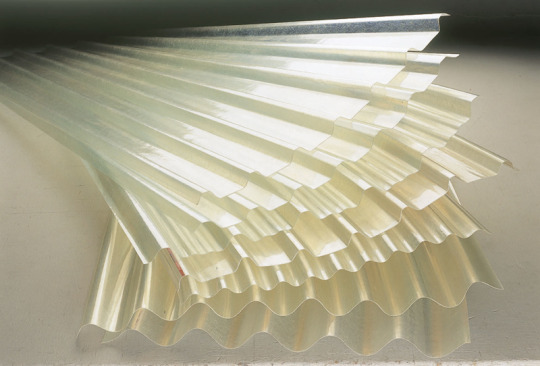

Global Fiber Reinforced Plastic Panels And Sheets Market Industry Analysis, Size, Share, Trends and Forecast 2032

Global Fiber Reinforced Plastic Panels and Sheets market was valued at USD 1,248.16 million in 2022 and is estimated to reach a value of 1,626.85 by 2028 with a CAGR of 4.4%.

In terms of primary factor, increasing consumption of composites from heavy truck and trailer market is primarily driving the market growth. As per the data released by FTR transportation intelligence states that, preliminary trailer orders surged in March to 36,200 units, an increase of 41% month-over-month and 29% year-over-year. According to FTR, trailer orders for the past 12 months have totaled 252,000 units. Polymer-reinforced composites provide better crash performance than traditional steel. The latter typically absorb only 35 J/kg of energy, while thermoset composites absorb almost twice as much. Thermoplastic composites absorb 5 to 6 times more energy than steel.

A Glimpse of Value Chain Process

Fiber preforms are manufactured through weaving, braiding, stitching, and knitting. Weaving is used in making both two-dimensional and three-dimensional fibers and is suitable for the manufacture of high-value and narrow-width products. It has its downsides, though. For one, weaving multilayer fibers is time-consuming and fairly more expensive. Also, it is difficult to create fabrics with fibers that are oriented to each other at anything other than 90-degree angles. Braiding is way better in that aspect as it allows for fibers to be aligned at 45 degrees to each other. Through two-step braiding, manufacturers can create right about any shape of preform. Knitting typically produces two-dimensional fabric, but the creation of multilayer fabric is possible with machines fitted with more than one needle bed.

Click Here To Request a Free Sample Report: https://analyticsmarketresearch.com/sample-request/fiber-reinforced-plastic-panels-and-sheets-market/57621/

Segmental Analysis

Based on type, the market is segmented into glass composite, carbon composite and others, while on the basis of end use the market is segmented into building and construction, trucks and trailers, recreational vehicles and others.

In terms of volume, glass composites held a share of 65.43% in 2022, Fiberglass reinforced plastic (GFRP), commonly known as fiberglass, is a synthetic composite material made from plastic and very fine fiberglass. This is the largest segment in the composites industry. FRP composites are relatively inexpensive composites compared to carbon and other metal fiber composites. For decades, this synthetic composite has been sought after for its high strength, light weight, and corrosion resistance. Due to its light weight and corrosion resistance, GRP products are in high demand in industries such as wind energy, aerospace, defense, construction and automotive. Developing countries, such as China and India, are expanding their infrastructure. This is expected to lead to the growth of the construction industry and boost the demand for FRP composites. The market for FRP composites is highly competitive, with suppliers with good access to technical and financial resources developing innovative products to offer competitors’ products before entering the market. We are focusing on it. Most of the major players in this market segment have their own R & D departments.

In terms of value, building and construction end user dominated the market with 69.44% in 2022, FRP panels and panels are widely used in applications such as roofing, interior wall panels and exterior facades in the building and construction industry. The global construction industry is growing at a remarkable rate. According to Oxford Economics, a global leader in forecasting and quantitative analysis, the construction industry is expected to grow at an average annual growth rate of 3.9% pa. Until 2030. This steady growth is expected to drive demand for wall panels and roofing solutions, thus driving demand for FRP panels and panels over the next few years. FRP panels and panels are widely used in the building and construction industry repair, brightness and water resistance. As a durable, dirt-resistant and impact-resistant composite material, it can be used in both commercial and residential environments. They are installed over existing wall materials such as concrete, creating a watertight installation and providing a new look for years to come. According to China’s National Development and Reform Commission, the Chinese government has approved 26 infrastructure projects with an estimated investment of $142 billion in 2019, expected to be completed in 2025.

Regional Analysis

Global FRP Panels and Sheets Market is primarily analyzed across North America, Europe, APAC, South America and Middle East and Africa.

China has become the world’s largest producer of FRP. It is expected that the demand for fiberglass will soon surpass that of the United States and is becoming the largest market for demand and application of the global fiberglass industry. This is the world’s top fiberglass enterprise. The main reason for paying attention to the Asian market. Flue gas desulfurization, thermal power generation accounts for more than half of the global power generation, so coal will remain the main fuel for at least the next few decades. All thermal power plants will eventually have a scrubber and desulfurization system, and FRP is the most cost-effective material in this application. Its FGD (smoke gas desulfurization) future investment is mainly in Asia, not the United States and Europe, China will become the largest market for FGD systems, accounting for more than 40% of the world total.

Demand for FRP compound substances is increasing rapidly due to its properties such as lightweight; FRP is 70% lighter compared to various metals and provides high strength like that of metals. FRP composite materials are corrosion resistant and require much lesser maintenance than common metals, wood or embodied products. FRP composite material is non-conductive and non-magnetic.

FRP composite materials have impacted and even revolutionized several major markets such as the wind energy market. FRP composite materials are being used for the nacelles, spinner and turbine blades. The high strength and lightweight FRP composite materials based products allow for longer and wider blades resulting in high production of electrical energy in the wind farms. Apart from these drivers, the market also face challenges such as high cost, mean production velocity or power depth regarding compound materials.

Competitive Analysis

Some of the Major companies operating within the market are Brianza USA Corporation , Captrad Ltd , Crane Composites, Inc. (Crane CO.) , Dofrp (Miyabi FRP) , Hill & Smith Holdings PLC , Kal-Lite , Kalwall , Krempel GmbH , Panolam Industries International, Inc. , Redwood Plastics and Rubber

Read This Complete Strategic Report: https://analyticsmarketresearch.com/reports/fiber-reinforced-plastic-panels-and-sheets-market/57621/

Recent Development

In May 2021, Grupo Verzatec S.A. de C.V. acquired the Engineered Materials division from Crane Co. for US$360 million. The company manufactures fiber-reinforced plastic (FRP) composite panels through Crane Composites.

By Type

• Glass Composites

• Carbon Composites

• Others

By End Use

• Building and Construction

• Trucks and Trailers

• Recreational Vehicles

• Others

Global Fiber Reinforced Plastic Panels and Sheets Market: Regional Analysis

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Fiber Reinforced Plastic Panels and Sheets market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Global Fiber Reinforced Plastic Panels and Sheets Market: Estimation

Both the top-down and bottom-up approaches were used to estimate and validate the size of the market and to estimate the size of various other dependent sub-markets of various marketspaces. The key players in the markets are identified through secondary research, and their market contributions in different applications across regions and globally were determined through primary and secondary research. This entire process included the study of the annual and financial reports of the top market players and extensive interviews for key insights with industry leaders such as CEOs, VPs, directors, and marketing executives. All percentage shares, splits, and breakdowns were determined using secondary sources and verified through primary sources. All the possible parameters that affect the market covered in this research study have been accounted for, viewed in extensive detail, verified through primary research, and analysed to arrive at the final quantitative and qualitative data. This data has been consolidated, and detailed inputs and analysis from Analytics Market Research added before being presented in this report.

Frequently Asked Questions

• What is the market size and growth projections?

• What is the market size and growth projection for each of the market segments and sub-segments across Countries & Regions?

• What are the top performing segments, and countries / regions of each of the markets?

• What is the market size and growth rate across key countries / regions?

• How big is the global & regional market in terms of revenue and volume?

• How far market will grow in forecast period in terms of revenue and volume?

• What factors will influence demand and supply trends across each markets during the forecast period?

• What are the technology trends shaping various markets?

• Which country / region has more opportunities?

• What is the COVID-19 impact on the market and how long will it take to recover?

• Who are the key competitors of market Players?

• What are the market share (%) of Key Players?

• What are the Merger & Acquisition, New Product Launch, Recent Development within each of the Markets?

• What are PEST analysis, Ecosystem Analysis, Porter’s Five Forecast Analysis, Ansoff Matrix, and SWOT Analysis among other analyses for diverse markets?

Read Our More Blogs: https://www.linkedin.com/pulse/aluminum-honeycomb-panels-how-its-made-anamika-tawar

0 notes

Text

CHINA'S TOP PLASTIC INJECTION MOLD MANUFACTURER

Founded in 2006, EX MOULD Co., LIMITED Ltd’s the industry-leading supplier of custom Injection Moulding from China! With over 10 years of experience in manufacturing Plastic Molded Products, we provide professional Plastic Injection Mold Services from consulting, designing, and prototyping, to producing, being one of the top-grade injection mold makers and manufacturers for a wide range of industries.

Our injection molding process involves top-class and commercial-grade plastic end-use molded parts, custom prototypes, rapid injection molds, and more, while cost and time-efficient low or mass-volume production are always provided to customers around the world! Send us your drawings and inquiry now, we will give back you 100% quality guaranteed injection molds!

Rely on our multiple advanced machines and types of equipment, experienced design engineers, machinists, and skilled workers, we are able to offer you the widest range of custom Injection Molding services, including Clod Runner Mold, Hot Runner Mold, Insert Mold, Epoxy Mold, Silicone Mold, Blow Mold, Resin Mold and more, also a wide variety of certified materials (PLA, ABS, Nylon, PVC, Poly, Carbon Fiber, LDPE, PTFE, etc.) and surface finishes are available to meet your special requirements and demands.

CLICK HERE FOR MORE INFO »

1 note

·

View note

Text

How does biogas process organic fertilizer?

To process biogas residue into compost fertilizer residue, we can summarize the whole treatment technology as:Dehydration (separated solids - 15% can be used as fertilizer compost) → composting (composting a large amount of biogas residues into high-quality fertilizers) → granulation (making composted biogas residues into granules for easy sales and storage) → packaging, our company is professional organic fertilizer machine manufacturers, here is a brief introduction.

1. dehydrationDehydration of the digestate is essential because the transport distances are often too great. Producers can use solid-liquid separators to separate biogas residues into liquid (typically 1-6% dry matter) and fiber fractions (typically 20-40% dry matter)

2. Biogas plant biogas residue solid phaseComposting During composting, biogas residues are decomposed under the action of atmospheric oxygen. Composting of modern biogas waste is a multi-step, closely monitored process with measured inputs of water, air and carbon- and nitrogen-rich materials (making C:N ratios equal to values of 15–25:1).

The compost turning machine widely used in developing countries such as India, China, Nepal, etc. The whole process is assisted by crushing the digestate to size, keeping the oxygen concentration in the air above 15%, adding water and regularly ensuring proper aeration.

3. Granulation processThe granulation stage of biogas residue composting occurs after the compost crushing and screening process. The granulator is the key equipment in the production of biogas residue organic fertilizer, which directly determines the quality and appearance of the finished product. Common organic fertilizer granulators include: double-roll extrusion granulator, rotary drum granulator, disc granulator machine, new organic fertilizer granulator, new two-in-one organic fertilizer granulator, flat die granulator machine, ring die granulator, each granulator has its own production characteristics, and the fertilizer granulator machine price varies.

4. Packaging

The automatic packaging machine is a fully automatic packaging machine with functions of automatic weighing, automatic bagging, automatic filling, automatic bag delivery and automatic sealing.

0 notes

Text

Expert Guide for Fiber Laser Machine And Acrylic Engraving Machine in 2023

Fiber laser cutting technology is a new practice that is seen being commonly used in industries; it is the type of technology that works with a high-power technology that works in a way that directs a high-power laser to vaporize the materials and to create a cut edge. Various types of laser cutters are used in the industry, as China fiber laser machine suppliers are supplying different laser machines to users worldwide.

However, the primary laser cutting machine uses a laser to cut or engrave the desired materials. Laser cutters are considered extremely important because of their specific properties; their high speed and accuracy make them n option that is more of a mechanical cutting method.

With various models available in the market, it becomes tough to figure out which laser machine would suit your requirement the best. Thus, one must have detailed information about what to look for when considering a laser machine.

China is regarded as the best fiber laser machine manufacturer because they offer the finest appliances. Things to look for while purchasing a laser machine.

Overview of Fiber Laser Cutting Technology:

Fiber laser cutters are the type of machines that use cutters that are based on high-powered optical lasers that are directed into the cutting surface. The residue is then blown away, and the cut or engraving is left behind. It is ideal to be used on organic materials like cards, leather, wood, etc. because these materials allow light absorption very quickly and can also be cut with the help of low-power lasers. However, in the case of metals, we see that metals require an extra high power because metals are reflective and heat conductive.

There are three main types of laser cutting machines, each based on certain specifications that make them specific to a particular application. There are types of lasers: carbon dioxide gas, crystal, and fiber lasers; each has its advantages and disadvantages. To find the right product, one needs to know about them in detail.

Carbon Dioxide Gas Laser Cutters:

These are the most common type of laser cutters available in the market as these are the first laser cutting machines that were marketed over twenty years ago. These are the machines that are ideally considered for cutting and engraving glass, plastics, foams, leather, wood, paper, card acrylic, etc. these are the machines that perform its task based on the use of carbon dioxide gas along with other gasses like helium and nitrogen.

It works in a way that the electrically stimulated gas mixture produces the laser beam. The lasers then reflect off mirrors within the laser cutters before they are focused and directed by a lens into a working surface. The primary type of carbon dioxide gas laser machine is usually 30w to 150w in power range; this is primarily sufficient for most leather and wood cutting and engraving tools. However, the high-power version for cutting metals can be in the 1000-3000w range.

Advantages:

These laser machines are ideal for cutting organics that are in the form of wood, leather, card, and rubber.

Low-power lasers are around 30-150w that, are adequate for most organic materials.

Carbon dioxide lasers leave a sharp cut edge on the metals or the specialized materials.

These are also preferred because they have a low upfront investment cost.

Disadvantages:

These laser-cutting machines are unsuitable for highly reflective metals as they cannot cope with the lasers reflected in the laser emitter.

Compared to the other laser cutters, they take twice as long as the fiber cutters.

They are also sensitive and fragile due to the placement of internal mirrors and glass tubing's.

These are the machines that usually need periodic aligning functions at their best.

They require regular maintenance and servicing to ensure that they function correctly.

Crystal Fiber Laser Cutters:

Crystal laser cutting machines have specific applications, especially in the kind of applications where high power and high intensity of focus are required. In the case of these laser machines, we see that the applications are mainly in the form of heavy industrial cutting of plastics, metals, and ceramics. They are now more common as the machines that are primarily seen to be used in the beauty and cosmetology industry as they work well for laser treatments that are done for hair and blemish removal.

In the case of these crystal laser-cutting machines, neodymium and neodymium yttrium aluminum garnet are the bases that work to generate the laser beam. These lasers are typically used where high energy and low repetition are required. In the case of crystal lasers like Nd YAG lasers, these are the lasers that are mainly used in places where very high power is needed.

Nd: YAG is the laser specially used to cut and weld steel in the automotive industry. Along with steel, it works over semiconductors and various alloys. In this case, the power range is mainly in the 1000-5000w range.

Advantages:

These lasers have a high intensity; thus, they are highly suitable for cutting through more robust and thicker materials.

They are also highly suitable for heavy industrial cutting as they can easily cut through stronger and thicker materials.

These are also very cheap as they provide upfront costs for laser machines.

Disadvantages:

They have a high operating cost due to the power consumption.

The high power leads to the quicker degradation of the parts, which requires frequent replacement and costly maintenance.

Fiber Laser Cutters:

These fiber laser cutting machines are the type of machines that first entered the market around 2008. They are proven to be much more beneficial than carbon dioxide-based laser machines. The applications of these machines include metals, organic materials, and even plastics.

Fiber laser cutting machines are solid-state lasers that use a seed laser that is amplified and magnified using optical fibers. These are a lot more efficient compared to carbon dioxide or crystal-based laser machines; the absence of moving parts helps in a way that reduces the need for maintenance.

The power range starts at around 20-30w in the case of desktop applications such as jewelry or fabric engraving and cutting, and it can go up to 4000w and beyond for metal-cutting standing machines. They can go higher further for large-scale industrial for Hispeed laser machine.

Advantages:

They are the fiber lasers that are 4-5 times faster than Nd YAG lasers and two times faster than carbon dioxide lasers with the same power.

These laser fibers are 30% more efficient for the use of laser energy. The other type of laser machine as they consume 20- 30% more power compared to carbon dioxide lasers.

These lasers are ideal even for reflective materials as these fiber lasers work a lot better than carbon dioxide lasers.

These laser machines usually come with fixed parts; they typically require less maintenance compared to carbon dioxide lasers with the same power level.

Disadvantages:

These fiber machines come at a higher price than carbon dioxide lasers.

Further Buying Considerations:

Along with knowing about the type of machines that are available in the market, their specifications, and applications, some other things need to be considered; these are in the form of things like;

Machine Type: For most users, choosing between carbon dioxide and fiberglass lasers is challenging.

Material:

Carbon dioxide-based lasers are mainly the type of lasers that are a usual choice in the case of organics and metals, especially in applications requiring a cleaner cutting edge. These machines are more efficient with thicker and more reflective metals.

Power:

One also needs to check for power, as typically, higher leverage means a faster and a reliable cut. Most lasers are available in higher powers, but these are the most efficient ones.

Bed Size:

The size of the cutting bed is also an essential thing that should note because these beds determine the size of the material; the desktop cutters can have variable bed sizes.

Support:

Carbon dioxide and Nd: YAG lasers are the type of lasers that tend to wear more than fiberglass lasers; thus, they frequently require maintenance and adjustment.

If you more detail for hispeed laser machine, So you just visit our blog page, here's the different laser machines guide and experiment.

#machine#fiber laser machine#acrylic engraving machine#hispeedlasermachine#cnc machines#2023 laser guide

1 note

·

View note

Text

CNC Metal Laser Cutting Machine

Fiber Laser Cutting Machine

Laser cutting can also produce high quality cut edges, usually without further cleaning, processing or finishing, thus reducing the need for secondary processing. Igolden laser, as leading manufacturer and supplier of fiber laser machines in China, will provide best quality and factory price laser cutting machine for metal sheets and tubes, including stainless steel, carbon steel, aluminium, copper, galvanized sheet, mild steel, corten steel, silver, gold, ect.

Flatbed CNC Sheet Metal Laser Cutting Machine is an ideal entry level laser cutter without any high purchase cost or training cost. With easy operation and simple maintenance, the flatbed fiber laser cutting machine provide users powerful cutting ability and efficiency. Therefore, it is a good choice for users to have an economical processing.

CNC Sheet Metal Laser Cutting Machine advantages

1. Simple operating system, to realize rapid cutting on the shape what you want on the metal material, like Steel, Iron, Aluminum Plate, Carbon steel, Stainless steel, Cooper, and galvanized sheet .

2. Independent electric control cabinet with strong and weak electric separation, to make your maintenance more convenient and safe.

3. Aviation aluminum alloy beam to ensure the running speed is up to 150m/min.

4. World-class components like guide rails and racks to guarantee the cutting accuracy.

5. The strong iron flatbed to keep the machine for 20 years without distortion.

6. When considering sheet metal laser cutting prices, laser cutting has a higher quality cutting edge, it saves money and time cost if we count all cost all.

Fiber laser cutter VS CO2 laser cutting machine

CO2 laser cutting machine is also a commonly used laser cutting machine for industrial purposes. But in actual use, there are big differences between a CO2 laser cutting machine and sheet metal laser cutting equipment. The differences mainly include the following aspects.

1. Laser generator

The CO2 laser generator is a kind of gas molecular laser. It uses CO2 gas as the medium and transmits the laser beam through reflective lenses. However, fiber laser cutting machines work with diodes and fiber optic cables for beam transmission. The reflective lenses in the CO2 laser technology have to act at a certain distance. While the CNC fiber laser is not subject to such limitations.

2. Electro-optical conversion rate

Fiber laser cutting system is the latest laser technology. Its solid-state laser generator is more efficient than a CO2 laser. The electro-optical conversion rate of a CO2 laser cutter is only 8%-10%. However, that rate of a fiber laser cutter can be as high as 30%. In other words, the overall energy consumption of a metal laser cutting machine is 3-5 times lower than that of a CO2 laser cutter. So the fiber laser machine is more energy-efficient.

3. Cutting ability

Fiber laser has the property of short wavelength, thus improving the absorption of the beam by the cutting material. The fiber laser beam is more suitable for transmission in the fine and soft fiber. So it is more flexible and easier to maintain than the CO2 laser transmission with mirror reflection. A 3KW fiber laser cutting machine is equivalent to a 4-5KW CO2 laser cutting machine in terms of cutting capacity and speed. So the metal laser cutter can greatly reduce operating costs. 4. Maintenance cost As a CO2 laser cutter has a complex laser structure, its subsequent maintenance cost is relatively high. The CO2 laser cutting system requires regular cleaning, and the reflective lenses also require frequent cleaning and calibration. Due to the CO2 gas purity, you need to maintain the resonant cavity regularly. However, a CNC metal laser cutter doesn’t require the above maintenance, saving a large amount of cost.

4. Application

Fiber laser cutting machine is mainly for metal cutting, such as mild or carbon steel, stainless steel, aluminum and its alloys, brass, copper, titanium, etc. While the Co2 CNC laser cutting machine is good at cutting non-metallic materials. It is now a solution to cut or engrave acrylic, wood, MDF, glass, etc.

0 notes

Text

G-Arm C-Arm Compatible X-Ray Transparent Jackson Frame Spinal Operating Table

HE-608-M(Jackson) Side column operating table is a high-end operating table for functional upgrades and improvements based on the HE-608-M The use of advanced micro-computer control and electric hydraulic transmission system, unique product structure, simple operation, safe and reliable quality has reached the international level, unique end column design, modular bed combination, excellent X-ray space, more suitable for orthopaedic thoracic surgery, Department of renal sur-gery and departments that need to be used in conjunction with C-arm X-ray machines

Jackson table is a specially designed table to be used in spine surgeries. It can be used to perform a perform a variety of spinal surgeries in supine, prone, lateral positions in a safe manner.

The carbon fiber table frame is placed over the patient, and the patient-table construct is sandwiched together with this frame. The frame is locked. Now both frame and the table hold the patient rigidly.

Not only this, the Jackson table for prone positioning allows the abdomen to hang entirely free of any pressure.

This is very beneficial during surgery as it reduces blood loss and pressure related issues, especially in patients with a large belly.

The rotational feature of the table allows the surgeon to carry spinal fusions without the need for patient repositioning.

With the advancement of science and technology, the strengthening of machining capabilities, and the improvement of design and manufacturing levels, the operating bed industry has developed rapidly. After years of steady development, Howell Medical has improved product quality, expanded production capacity, and introduced various advanced equipment. The company's products not only have a broad market in China but also are exported to many countries and regions around the world, winning the satisfaction and trust of global customers with their quality and price.

WhatsApp +8615146602893

Please write down your demand and we will send you quotation within 24h!

0 notes

Text

China carbon fiber aluminum honeycomb sandwich panel suppliers

China carbon fiber aluminum honeycomb sandwich panel suppliers About Us Headquartered in Foshan, China, Guangdong Xinhemate Building Materials Co., Ltd (鈥榅inhe鈥? implements its engineering excellence through a wide range of customized interior and exterior products and services: Ceilings and claddings, facade and canopies. Xinhe meets the challenges posed by creative architectural design in the state-of-the-art production facilities in China鈥檚 dedicated industrial zone with a team of more than 25 years experienced, qualified , trained and motivated workforce. Equipped with advanced computer numeric control (CNC) machines that imported from German and Swizz, these facilities and people ensure complex design specifications are implemented as per schedule. Xinhe is always doing her best to meet the increasing needs and requirements of the global building and construction industry. In pursuit of excellence, Xinhe has developed and implemented a quality management system in compliance with the ISO 9001:2008 standards. We are looking forward to establish the long term business relationship with all of our agents and distributors, architects, consultants, contractors, construction company, wholesales and business partners who have interested in our products and services.China carbon fiber aluminum honeycomb sandwich panel suppliers website:http://www.aluminumdecorations.com/

0 notes