#stenter for glass manufacturers

Text

Brückner on Techtextil in Frankfurt: 75 years of tradition and innovation

This year, the German family-run company is celebrating its 75th birthday. Today, more than 6000 BRÜCKNER lines around the globe produce textile products of all kinds. The product range of the textile machinery manufacturer is at least as diverse as the end products manufactured on it. BRÜCKNER's customers include manufacturers of industrial textiles, nonwovens, textile floor coverings, artificial turf, glass fabrics and, of course, classic apparel textiles.

Industrial textiles

In the field of coating and finishing industrial textiles, the world market leader offers the right unit for almost every process. Whether full-bath impregnation for aqueous media, one-sided full-surface or dot application of latex and acrylate pastes, foam or paste application via various roller and squeegee systems or the application of laminating adhesive - BRÜCKNER has a solution for every process. Numerous customers worldwide are very satisfied with their BRÜCKNER lines for coating or laminating abrasive cloth, airbags, roof membranes, blackout material, billboards, geotextiles or tarpaulins. In addition to the application units and coating lines, the portfolio also includes the right drying systems.

Nonwovens

These include, for example, the thermofusion ovens of the SUPRA-FLOW product line, which are mainly used in the nonwovens industry. Among other things, high-loft nonwovens for mattresses, insulation, comforters or upholstery, as well as lightweight nonwovens for the hygiene industry such as ADL nonwovens, topsheets or backsheets can be finished on the air-through thermofusion ovens. BRÜCKNER also offers air-through dryers for scrubbing nonwovens, kitchen towels, operating table covers, paper napkins and feminine hygiene products as well as high-speed spunlace lines for wipes, wet wipes and wet laid nonwovens. The POWER-FRAME stenter with proven split-flow technology is used for the thermal treatment of needle felts, high-temperature filters or geo- and agro-nonwovens. It is usually at the heart of the finishing process for classic garment textiles and is also ideal for drying and heatsetting after digital printing.

Floor coverings

Discover our expertise in coating, laminating and drying textile floor coverings for yourself. The DUOTHERM dryer deserves special mention here. It is the perfect solution for thermal treatment processes that require temperature separation between the upper and lower air. Like all BRÜCKNER lines, it can be heated with different media: Gas (direct or indirect), thermal oil, steam in low or high pressure versions, electric heating or various hybrid versions. Just recently, a BRÜCKNER line for drying single-sort floor coverings was equipped with a fully electrically heated DUO-THERM dryer. By operating this dryer with green electricity, the long-standing BRÜCKNER customer was offered the possibility of CO2- neutral production of tufted carpets.

Textile expertise made easy

The new ExperTex simulation tool is a calculation program that makes it possible for the first time in the world to digitally simulate textile drying, heat-setting and curing processes. In addition to the pure process simulation, a comprehensive calculation of consumption data (e.g. electrical and thermal energy required, production costs or the CO2 footprint) is integrated. The active process is automatically perfected using an optimization menu. The innovative algorithm simulates, analyzes and optimizes the entire range of possible setting parameters depending on the specified process, either for maximum production output or to reduce energy consumption. The new ExperTex program is browser-based and intuitive to use.

Visit BRÜCKNER at the TECHTEXTIL in hall 12.0, stand B54.

0 notes

Text

Industrial Brushes Market Dynamic Demand, Growth, Development and Challenges

Industrial Brushes Market: Overview

The increasing demand for industrial brushes from the manufacturing and automotive sectors stands as a key factor aiding in expansion of the global industrial brushes market. Rise in innovation have prompted the expansion in selection of fiber circles and brushes that keep laborers shielded from basic wire brush-related wounds. Thusly, makers in the modern brushes market are expanding their creation capacities for bristle circles and brushes, attributable for their potential benefits of usability and better execution.

Get Brochure of the Report @ https://www.tmrresearch.com/sample/sample?flag=B&rep_id=7110

The global industrial brushes market is classified on the basis of raw material, type, application, and regions. In terms of raw material, the market is classified into metal, nylon, polyester, fiber, and others (wool, rubber, and others). Based on type, the market is grouped into cylinder, wheel, machine, circular, disc, anti-static, industrial sweeping, comber, boiler, ESD, power brush, stenter, accumulator, ceramic, acid brush, and others. In terms of application, the market is categorized into automotive, aerospace & defense, construction & utility, pharmaceutical, textile, electrical & electronics, glass & ceramics, lithography & printing, packaging & labeling, industrial manufacturing, and others.

The report offers experiences into the market as far as development restrictions, drivers, challenges, and forthcoming chances. It likewise centers around the table of division, late advancements, and the rundown of players working in the field that will help increment incomes in the conjecture period. The report further illuminates the effect of the novel COVID pandemic on the worldwide enemy of static movies market and what procedures can be received to assist this market with creating huge incomes in the coming years.

Industrial Brushes Market: Competitive Analysis

Itemized profiles of makers in the mechanical brushes market have been given in the report to assess their financials, key item contributions, late turns of events, and methodologies. Some of the key strategies adopted by players include merger and acquisition, joint ventures, and others. There are major investments on product innovation and quality improvisation by other manufacturers in order to gain a competitive edge. List of players operating in the market include 3M, The Mill-Rose Company, Robert Bosch GmbH, Spiral Brushes Inc., Gordon Brush Mfg. Co. Inc., Unimade Industry Co. Limited, Tanis Brush, The Industrial Brush Company Inc., KOTI Group, Associated Industrial Brush Co. Ltd., and others.

To get Incredible Discounts on this Report, Click Here @ https://www.tmrresearch.com/sample/sample?flag=D&rep_id=7110

Industrial Brushes Market: Current Trends and Opportunities

Industrial brushes are seeing enormous interest in food and drug areas, chiefly for cleaning purposes Disk brush, round brush, and so on, are significantly requested in these enterprises. The worldwide food and refreshments (F&B) industry has seen sound development in the course of the most recent 10 years and this is required to proceed. Asia Pacific is the quickest developing area as far as shopper spending on food. North America, explicitly the United States and Canada, and Europe are the most adult retail showcases on the planet. The worldwide drug industry is encountering vigorous development since the most recent decade.

One of the key controlling elements for the modern brushes market is the unpredictability in crude material costs. Modern brushes are regularly produced using fibers produced using standard materials, including nylon, polypropylene, polyester, conductive, common filaments, tempered steel, metal, and gentle steel. A few materials, for example, treated steel just as gentle steel have excessive cost variances.

Industrial Brushes Market: Regional Analysis

The global market for industrial brushes is widespread into the regions of North America, Asia Pacific, Latin America, Europe, and the Middle East and Africa. Each region is further classified on the basis of nations. Among these, the market is dominated by Asia Pacific on account of the presence of major companies. Countries such as India, Japan, and China are the key revenue generators for this region. North America will also gain significant momentum while it remains at stagnant pace in terms of revenue generation.

Request For TOC @ https://www.tmrresearch.com/sample/sample?flag=T&rep_id=7110

About TMR Research:

TMR Research is a premier provider of customized market research and consulting services to business entities keen on succeeding in today’s supercharged economic climate. Armed with an experienced, dedicated, and dynamic team of analysts, we are redefining the way our clients’ conduct business by providing them with authoritative and trusted research studies in tune with the latest methodologies and market trends.

Contact:

TMR Research,

3739 Balboa St # 1097,

San Francisco, CA 94121

United States

Tel: +1-415-520-1050

0 notes

Text

Types of Process Heating Applications and Operations

Process heating finds its application in various type of industrial application across different industry verticals. Single manufacturing process involves different type of heat treatments. Hence, it’s important to understand which type of heating application is required in your processing. In layman’s language process heating is just generation of heat and transfer to product under process, however there are lot of technicalities involved based on type of product, time of manufacturing, desired output quality, intermediate processes and etc.

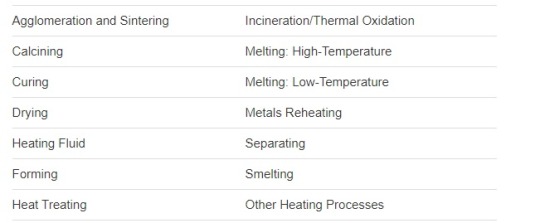

Process heating applications can be grouped into 14 key categories:

* Application of Process heating is not limited to only these 14 categories, there are endless potential application of process heating. Above categories are based on various study materials and our experience.

In this article we will try to cover 7 of them and other 7 will follow in upcoming articles.

Agglomeration and Sintering

Agglomeration and sintering is process of heating of a mass of fine particles below the melting point to form larger particles or solid parts. Sintering is normally used in the manufacturing of advanced ceramics and the production of specialty metals.

Application:

Metals Production

Equipment Type:

Various Furnace Types, Kilns, Microwave

Industry:

Metal

Ceramic

Calcining

Calcination is a process of heating a substance under controlled temperature and in a controlled environment. The process is done for decomposition of calcium carbonate to calcium oxide and carbon dioxide, through direct or indirect heating. Calcining is performed to improve the chroma, tinctorial strength, pigmentary texture, weather stability, light-fastness and thermal stability of pigment.

Application:

Lime Calcining

Equipment Type:

Various Furnace Types

Industry:

Cement

Wallboard

Pulp and Paper Manufacturing

Primary Metal

Curing

Curing process employed in polymer chemistry and process engineering applications that produces/increase the toughening or hardening of a polymer material by cross-linking of polymer chains. Curing is also used to speed up the cure of polyurethane rubbers and plastics, platinum silicone rubbers, epoxy resins and other type of materials. This process is usually performed in controlled heating environment. In the manufacturing of plastics, curing is the cross-linking reaction of a polymer, also common step in the application of coatings to metallic and non-metallic materials.

Application:

Coating

Polymer Production

Enameling

Equipment Type:

Various Furnace Types

Ovens

Kilns

Lehrs

Infrared

UV

Electron Beam

Induction

Industry:

Ceramics

Stone

Glass

Primary Metals

Chemicals

Plastics and Rubber

Drying

Drying process is performed to eliminate or remove moisture, water and other solvents from the material under processing through direct or indirect heating. Drying is very common application found in almost all type of industries such as stone, clay, glass industries, food processing, sand, textile, pharmaceutical, chemical and ceramic are only few of them. There are several types of dryer’s present operation in batch and/or continuous mode like Conventional Dryers, Microwave Dryers, Radio Frequency Dryers, Infrared Dryers, HOT AIR Dryer – Stenter, Tunnel Dryers, Pneumatic/ Flash Dryer, Drum Dryers, Spray Drying, Contact Drying- Steam Cylinders/Can, Fluid Bed Dryers, Rotary Dryers and etc.

Application:

Water, Moisture and Organic Compound Removal

Equipment type:

Fuel-Based Dryers

Hot Air/steam

Infrared

Resistance

Microwave

Radio-Frequency

Industry:

Stone

Clay

Glass Industries

Food Processing

Sand

Textile

Pharmaceutical

Chemical

Ceramic

Petroleum Refining

Agricultural

Pulp and Paper

Fluid Heating

In process of fluid heating the temperature of a liquid or gas increased, to achieve the complete or partial vaporization of the fluid, and is performed for a wide range of purposes in many industries, including chemicals, food processing, and petroleum refining. In chemical manufacturing, fluids are heated in both batch and continuous processes to induce or moderate a chemical reaction. Food processing applications include cooking, fermentation, and sterilization. In petroleum refining, fluid heating is used to distil crude oil into several component products.

Application:

Food Preparation

Chemical Production

Reforming

Distillation

Cracking

Hydro-treating

Equipment Type:

Various Furnace Types

Reactors

Resistance Heaters

Microwave

Infrared

Fuel-based Fluid Heaters

Immersion Heaters

Application:

Agricultural and Food

Chemical Manufacturing

Petroleum Refining

Forming

Forming operations, such as extrusion and molding, use process heating to improve or sustain the workability of materials. Examples include the extrusion of rubber and plastics, the hot-shaping of glass, and plastic thermoforming.

Application:

Extrusion

Molding

Equipment Type:

Various Ovens and Furnaces

Industry:

Rubber

Plastics

Glass

Heat Treating

Hardness, strength, flexibility, and the reduction of residual stresses are achieved by heat treating the material in controlled heating and cooling environment. Heat treating processes need the accurate control of temperature over the heating cycle. Heat treating is used extensively in metals, glass, ceramic and plastic industry for tempering and annealing.

Application:

Hardening

Annealing

Tempering

Equipment Type:

Various Fuel-Based Furnace Types

Ovens

Kilns

Lehrs

Laser

Resistance

Induction

Electron Beam

Industry:

Primary Metals

Fabricated Metal Products

Glass

Ceramic

Plastic

Part 2 of covering remaining 7 applications will be covered in our next article by that time you can increase your knowledge by visiting http://kerone.com/blog.

0 notes

Text

Brückner & Texfina – Two strong partners innovating for decades

Texfina in Peru (founded in 1947) and Brückner in Germany (founded in 1949) can both look back on impressive success stories spanning more than seven decades. The two family-run companies are pioneers with innovative power.

In difficult times, Texfina has put the 3rd Brückner line into operation!

Texfina began with hand-knitted sweaters made by the great-grandmother of the current managing directors, which were exchanged for food at the market. Subsequent generations turned Texfina into one of the world's leading manufacturers of knitwear.

Excellent specialists and advanced machinery as well as several patents are the basis of the company's success: Texfina supplies customers worldwide with tailor-made textiles that can be made hydrophobic, antibacterial, dirt-repellent or with UV protection. With the help of efficient management systems and IT, Texfina strives for ecological sustainability and promotes employee commitment through a progressive organizational culture.

Brückner is the technological market leader and system supplier for the dry finishing of textiles, technical textiles and nonwovens. Operating worldwide and owner-managed, with 75 years of tradition and experience, Brückner not only develops, produces, and sells systems for coating and finishing apparel textiles, technical textiles, glass fiber, nonwovens and floor coverings, but has also been developing systems for heat-recovery and exhaust air purification for many years. The focus is always on the highest possible productivity with the lowest possible energy consumption.

Texfina recently put the 3rd Brückner stenter with vertical chain into operation. The new machine from the Peruvian company, which is certified to OEKO TEX Standard 100, has 11 compartments and an air/air heat-recovery system.

A very homogeneous air flow, perfect temperature distribution and very low specific energy consumption are standard features of all Brückner machines. Precisely reproducible finishing results thanks to complete automation and recipe management in the system, which Texfina uses almost exclusively for heat-setting sports and performance wear, complete the picture. Chains, chain rails and pin bar carriers are extremely robust and low-maintenance, helping to make this machine a particularly sustainable investment. A pre-wash compartment before the fabric enters the stenter ensures better fabric quality and reduced emissions.

Raul Saba (President Texfina) is extremely satisfied with the cooperation: "The team of Brückner technologists did an excellent job, recognized our needs and configured the machine optimally. It is an enrichment for our production and a guarantee for the quality of our products."

Regina Brückner (CEO Brückner): "We are delighted about the trustful cooperation with this successful customer. The cooperation with Texfina promises sustainable success and forward-looking results for both sides."

0 notes