#throatless shear

Text

The Advantages of Guillotine Metal Cutting

A guillotine metal cutting machine is an engineering tool used to cut sheet metal with extreme accuracy, speed and precision. It offers a number of advantages over other methods of sheet metal shaping, such as plasma or laser cutting machines, which can produce much cleaner and better looking finished products with faster turnaround times.

Guillotine metal cutting is a highly effective approach to sheet metal shaping, producing a clean, elegant finish that meets the exact specifications of the client. The process is also fast, simple and cost-effective.

Depending on the type of machine and the materials being cut, there are various settings that can be adjusted to ensure the perfect finish. These include shear angle and rake angles, which are all important factors when determining the quality of the final product.

Some types of guillotine metal cutting are manually operated while others use electrical power. Regardless of the type, the user should always wear safety goggles and gloves to protect against cuts and metal splinter injuries.

Industrial HS-52 Manual Guillotine Shear

The guillotine metal cutting shear is a very light and portable shear that can be easily moved from place to place. It can be mounted in line with other processing machines as an entrance or exit shear for cutting to length and is ideal for working with metal (up to 16 Gauge), plastic, paper and many other materials.

It has a high quality stainless steel blade and is capable of handling various materials up to 52" wide. This shear is easy to transport and can be easily mounted to an overhead crane for easy access.

This model has been designed to cut a wide range of material sheets up to 52" wide, and is suitable for cutting metal (up to 16 Gauge), plastic, sheet metal, cardboard, wood and other materials. This shear is a very versatile tool that can be used in all kinds of industries, from aerospace to construction to automotive.

How to use a guillotine metal cutting shear

Using a guillotine shear can be done with or without electricity and can be a very efficient method of sheet metal cutting. The blades of the shear are tempered and polished to ensure that they cut through all materials with ease. They have four working edges and are adjustable so that the shear can be shifted to change the working edge.

The shear is capable of cutting all kinds of materials, including metal, aluminum, plastic and other materials. It is easy to transport and can be used in all kinds of industries, including aerospace to construction to automotive.

How it works

The guillotine shear is a very reliable and accurate metal cutting shear that can be used for all kinds of metals, including aluminum, brass, nickel and titanium. The blades of the shear are stainless steel, tempered and polished to ensure that they cut all kinds of materials with ease.

How to use a throatless guillotine shear

A throatless guillotine shear is able to cut all kinds of metals, including aluminum, stainless steel, nickel and titanium. The blades of this shear are stainless steel, tempered and sharpened to ensure that they cut all kinds of materials.

0 notes

Text

Types of scissors for hair cutting in 2021

Individuals who are worried about such things, by and large, put scissors and shears into various unmistakable classifications. In any case, before taking a gander at them, you would have most likely seen that I've recently presented another word: "shears." What is the contrast between scissors and shears? Very little. Generally, scissors are more modest with cutting edges no longer than 6 inches (around 13 centimeters). Scissors are utilized for more fragile work (being more modest) and shears for more unpleasant work (being bigger). Notwithstanding, the essential plan is something very similar, so it's fundamentally an issue of use. You may say shears are a subset of scissors, for example, all shears are scissors, yet not all scissors are shears.

Scissors and shears are generally placed into the accompanying classifications.

Cultivating, farming, animal husbandry. Grass shears for managing grass; clippers for managing supports; annunciators for managing high branches; sectors (running shears) for managing little branches; loppers for slicing through enormous branches; and edge shears for slicing the downy of sheep to collect fleece.

Kitchen scissors and shears. Kitchen scissors and shears are generally produced using hardened steel for top-quality food cleanliness and protection from oxidation (rusting). They regularly fuse variations for kitchen utilizes other than just cutting, for example, fish scaling, eliminating bottle covers, separating nuts, and so forth

Stogie cutters. This claim to fame highlights inward sharp edge edges explicitly intended to clip the finish of stogies.

Individual and expert preparing. Haircutting scissors for managing hair; diminishing shears for preparing thick, ragged hair; hair trimmers utilized by proficient stylists, beauticians, and pet custodians; mustache scissors for managing mustaches; and nose scissors for nostril managing hair.

Metal-working. Utilized for slicing through sheets of tin, steel, and different metals; pressure-driven scissors (cutters) for cutting weighty sheet metal, regularly during salvage endeavors in a car accident or tidy up after a car accident; and throatless shears for cutting complex shapes in sheet metal.

Medication. Injury shears for removing apparel in salvage missions, the adjusted tips being explicitly intended to slide across the patient's skin without causing injury; analyzation scissors for cutting tissue in analyzation; careful scissors for cutting tissue during a medical procedure; iris scissors for an ophthalmic medical procedure; and swathe scissors for cutting careful dressings.

Sewing and couture (garments making). Dressmaker shears for general use; little sharp scissors for stitching; pinking shears to keep certain textures from fraying; lightweight sheers to alleviate strain on the hands close to the furthest limit of an undertaking; and spring-mounted shears, additionally for tired hands however particularly helpful for dresses producers with joint pain because the spring activity makes them altogether simpler to open and close

Furthermore, who can fail to remember those monster formal scissors so valued by government officials and different notables for slicing the strip to introduce another manufacturing plant, uncover another landmark, open another grocery store, initiate a career expo, and so on?

You may have found out about the pragmatic joke an accomplished specialist played on his new student by requesting that the understudy presents to him a left-gave wrench (spanner). It is a joke because there is nothing of the sort as both ways give torques; they are similar regardless of which hand you use. Be that as it may, is it likewise a joke to discuss both ways given scissors?

Not in the slightest degree. Albeit the fundamental plan is something very similar, for example, bows, rotate, cutting edges, for right-handers and left-handers are identical representations, there are huge contrasts. In particular, the bows (openings in the handles for fingers and thumbs) are switched for a better left-hand grasp. Similarly, the edges are turned around for surer, steadier cutting.

There are two or three more subtle purposes behind left-gave scissors. In light of the abnormal grasp, broad utilization of right-gave scissors, (for example, in the garments making industry) can bring about horrendously drained fingers, and even callouses. Besides, to make a decent, clean-cut of fabric, the client needs to unmistakably see the cutting line, for example, the hint of where the cut ought to be made. At the point when a left-hander utilizes right-hand scissors, this view is halfway obstructed; notwithstanding, with left-gave scissors, it is open and clear.

Conclusion.

In General, Knowing the value of the scissors & shears helps to provide the best result for your customers.

0 notes

Photo

The bench top throatless shear is a metal artist’s best friend. Just ask our hood friend Eric Stenzel @stenzeliron 💪 It’s century old design allows for contoured cuts on large or small panels of sheet metal. Definitely one of those machines that gets passed down a generation #baileigharmy #baileighshear #beverlyshear @stenzeliron @stenzeliron @stenzeliron https://www.instagram.com/p/CUA7hqapKXz/?utm_medium=tumblr

1 note

·

View note

Note

Do you have any tips on how I can get the tools to get started on a few basic small armor projects that won't cost me a fortune? I'm thinking of trying to forge a single breastplate or maybe a plated mail or lamellar chest piece and eventually try to make a helmet.

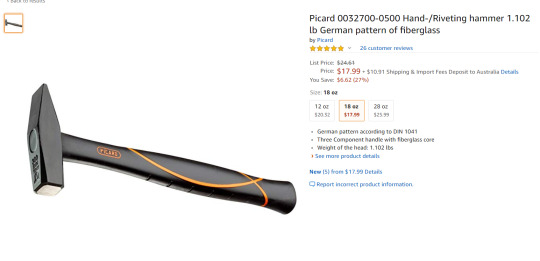

Buy a bench vise and use that as your first anvil. The flat surface and edges can be used the same as a real anvil. The actual vise can be used to clamp on pieces and bend them, or hold a piece at an angle as you hammer it.

Buy a truck trailer ball and place it in a bench vise. Now you can form deep rounded shapes for breastplates, helmets, knees etc. A rounded mushroom anvil stake will cost $200 to $300, but a trailer ball can range from $10 to $80 and does the same thing.

Buy a Nibbler, it cuts through 18 gauge steel and can be bought for $40 to $100 depending on brand.

If you want to cut without all the noise or stress of a power tool, then buy a throatless shear. It cost more money $150 to $200 but is worth it since it makes no noise and is very smooth compared to a power tool.

Any cheap cross pein or engineers hammer can be used to make armour. The rectangle shaped face of these hammers shapes steel at a much faster rate than a standard round face hammer. You can use any hammer but a cross pein hammer will effectively shape your steel the same way as a $300 raising hammer.

My armor is all made from cheap ass second hand tools and anvils. Tool snobs and pretentious history nerds will say that you need to spend $2000 on a brand name anvil and hammer from some European shaman under a waterfall with a huge horsecock, but don’t listen to them. Steel is steel.You can make anything as long as you have the courage and will to improve. The tools don’t make the man.

284 notes

·

View notes

Text

**Beverly B-1 Throatless Shear, 14 gauge capacity** (Mt. Holly) $350

https://www.trick-tools.com/Beverly_B_1_Throatless_Shear_14_gauge_capacity_B_1_1116 A classic name in sheet metal shears that will be used daily by aluminum and steel fabricators alike. This B1 throatless shear from Beverly will shear up to 14 gauge ...

from Craigslist https://charlotte.craigslist.org/tls/d/beverly-1-throatless-shear-14-gauge/6765934353.html

Fraud Bloggs made possible by: http://circuitgenie.wix.com/techsupport

0 notes

Photo

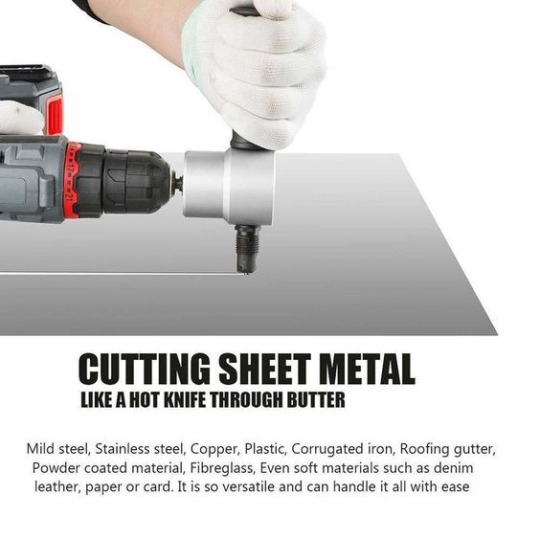

Homemade Employee Testimonial – Electric Throatless Metal Shears – Great Way to Cut Sheet Metal http://dlvr.it/Qn4rJx

0 notes

Text

Rumored Buzz On Northside Steel Work

Intro

Metal fabrication entails the production of steel structures and parts by adjusting the raw material-- normally structural steel and sheet metal-- with a range of procedures. The term covers a broad series of activities, from sheet metal fabrication for building jobs, to machined components and bespoke items for producers. Workshops that are experts in steel fabrication are referred to as 'fabulous stores'.

Regular procedures associated with steel construction include: Forging, Casting, Cutting, Bending, Shearing, Drawing, Spinning, Punching.

When the components have been made, they may need to be assembled. Assembly may include welding, binding with adhesives, captivating, threaded bolts or kinky seams.

The parts or settings up could then be dealt with by a process of sandblasting, painting, powder or priming layer, if needed.

The completed item ought to subject to mindful evaluation to ensure it abides by the specification prior to leaving the fab shop.

Reducing

The wanted shape can be developed by removing undesirable material from a block of metal, in a procedure known as machining. Steel is cut as needed using different devices, including:

Saws

Industrial saws such as band saws and huge round saws could reduce steel in straight-lines. Angle grinders are portable power devices fitted with a rough disc utilized for cutting, polishing and grinding.

Shears

Shears are commercial devices, that been available in a large range of setups and sizes, capable of cutting sheet steel of various densities. They work in the same way as a pair of scissors, with opposing blades, one being fixed and the other moving in an angled levering activity. Various sorts of shears consist of:

Hand shears: Also referred to as 'aeronautics snips', these are simple, hands-on tools made use of to reduce thin pieces of steel.

Power shears: These can reducing sheet steel rapidly and with much less handbook initiative. Nevertheless, many are not able to reduce complex forms or tight distance and so tend to throw away material.

Throatless shears: These are hand-operated and utilize a hinged blade that turns down to reduce steel resting on a fixed surrounding blade. These can cutting in straight lines or forms and reduce waste material.

Plasma and laser cutters

High definition plasma cutting strategies are made use of to achieve intricate shapes. With the integration of computer system aided layout and computer system aided manufacturing, the cutting procedure can be achieved perfectly, with marginal waste.

Bending

The flexing metal can be achieved by one of two techniques:

The most basic approach is type flexing, where metal is bent over a side or form situated under the metal. This can be done by hand or with tools such as hammers and shaping dollys to flex metal around the called for shape.

Metal brakes are one of the most typical approach of accomplishing clean, exact bends. The procedure involves placing the metal on a flat, gated surface area, clamping a level bar in addition to it, and lifting the gated part to bend the metal to the wanted angle.

Diminishing

youtube

One of the most common techniques of shrinking metal consist of:

Tucking: A simple technique that involves forcing steel with each other in between a crevice or folding metal over at the edges.

Shrinker: This is a lever-operated tool with moving distinctive jaws that realize sheet metal from the leading and bottom and compel it together lightly. Specific areas can be carefully worked to shrink as needed. This is an extra precise yet slower method.

Heat diminishing: This entails heating an over-stretched area with a blowtorch up until it is nearly red hot, as the metal shrinks when it cools down. Shrinking discs can be applied to angle grinders that utilize friction to generate warm.

Extending

The most typical methods of extending metal consist of:

Dolly and hammer: This is the most basic technique and involves holding an object behind the steel and hitting the other side with a hammer, forcing the steel to press and extend.

Stretcher: This is a mechanically-operated tool similar to the shrinker, that puts metal in between two flat-textured jaws which pull it apart slowly.

English wheel: This technique makes use of wheels that curtail and forth over the flat steel.

Welding

The most usual approaches of welding steel to produce larger and much more intricate components consist of:

Oxy-acetylene welding

This is the earliest type of welding http://northsidesteelwork.ie yet is still widely utilized. Tanks of oxygen and acetylene are blended with a flexible lantern to create a regulated fire to warm the metal. During heating, a filler rod is added that signs up with the metal with each other. These welds are the easiest to planish (smooth out) with a hammer and dolly, allowing the weld joint to be as level as feasible.

TIG welding

This involves a torch that has a non-consumable electrode that creates a tiny, exact electric arc that thaws the base metal. Filler poles are included in the puddle of molten steel to join the parts together. This is a much more specific approach than oxy-acetylene.

MIG welding

This is one of the most common technique and includes an electric motor that is utilized to feed the filler wire via the tip of a MIG gun. The cord is melted into the weld joint, fusing the metal together.

Steel construction includes the production of steel frameworks and components by adjusting the raw product-- typically architectural steel and sheet steel-- with a range of procedures. The term covers a wide variety of activities, from sheet metal construction for construction jobs, to machined components and bespoke products for makers. Shears are commercial devices, that come in a large variety of arrangements and sizes, capable of cutting sheet metal of different thicknesses. Shrinker: This is a lever-operated device with moving distinctive jaws that understand sheet steel from the top and bottom and require it with each other lightly. Filler poles are added to the pool of molten metal to sign up with the parts with each other.

#Metal Fabrication#Sheet Metal Fabrication#Steel Fabrication#Steel Fabricators#Stainless Steel Fabrication#Custom Metal Fabrication#Stainless Steel Fabricators#Metal Fabrication Near Me#Metal Fabricator#Metal Fabrication Companies#Sheet Metal Fabricators#Steel Fabrication Companies#Sheet Metal Fabrication Near Me#Metal Fabrication Shops#Metal Fabrication Shops Near Me#Sheet Metal Shop#Metal Manufacturing#Custom Sheet Metal Fabrication#Fabrication Companies#Precision Metal Fab#Structural Steel Fabrication#Precision Sheet Metal Fabrication#Structural Steel Fabricators#Sheet Metal Manufacturing#Fabrication Metal#Custom Steel Fabrication#Welding And Fabrication#Metal Fabrication Company#Brass Fabrication#Aluminum Fabrication

0 notes

Text

Little Known Facts About Metal Fab Shop

Introduction

Steel construction includes the making of metal frameworks and parts by controling the raw material-- normally structural steel and sheet metal-- with a variety of procedures. The term covers a broad range of tasks, from sheet metal fabrication for construction projects, to machined parts and bespoke items for manufacturers. Workshops that are experts in metal manufacture are http://northsidesteelwork.ie/balustrades known as 'fab stores'.

Regular processes involved in metal construction include: Forging, Casting, Cutting, Bending, Shearing, Drawing, Spinning, Punching.

As soon as the components have been made, they could have to be constructed. Setting up may entail welding, binding with adhesives, riveting, crimped joints or threaded fasteners.

The parts or settings up may then be treated by a process of sandblasting, priming, powder or painting finish, if needed.

The ended up item ought to subject to cautious evaluation to guarantee it follows the specification prior to leaving the fab shop.

Cutting

youtube

The wanted shape can be developed by getting rid of unwanted material from a block of metal, in a process known as machining. Steel is cut as called for utilizing different devices, including:

Saws

Industrial saws such as band saws and big circular saws could cut steel in straight-lines. Angle grinders are portable power devices fitted with an unpleasant disc used for cutting, brightening and grinding.

Shears

Shears are industrial makers, that been available in a large range of configurations and dimensions, efficient in reducing sheet steel of different densities. They operate in similarly as a set of scissors, with opposing blades, one being fixed and the various other relocating an angled levering movement. Different kinds of shears include:

Hand shears: Also known as 'aviation snips', these are straightforward, hands-on tools used to reduce slices of metal.

Power shears: These can cutting sheet metal quickly and with less handbook initiative. Nonetheless, most are not able to reduce complex forms or tight radii and so tend to lose product.

Throatless shears: These are hand-operated and make use of a hinged blade that swings to reduce metal lying on https://www.washingtonpost.com/newssearch/?query=metal fabrication a fixed surrounding blade. These are capable of cutting in straight lines or shapes and minimise waste product.

Plasma and laser cutters

High definition plasma reducing strategies are utilized to accomplish elaborate forms. With the integration of computer helped layout and computer system aided manufacturing, the cutting process can be achieved flawlessly, with minimal waste.

Bending

The flexing steel can be accomplished by a couple of strategies:

The most basic approach is kind flexing, in which metal is curved over an edge or form located under the metal. This can be done manually or with tools such as hammers and forming dollys to bend steel around the Additional info required shape.

Metal brakes are one of the most common http://northsidesteelwork.ie technique of achieving clean, exact bends. The Click for source procedure involves placing the metal on a flat, gated surface, clamping a flat bar in addition to it, and raising the gated portion to bend the steel to the desired angle.

Shrinking

One of the most common techniques of shrinking steel consist of:

Putting: A simple technique that entails requiring metal with each other in between a gap or folding steel over at the sides.

Shrinker: This is a lever-operated device with moving distinctive jaws that grasp sheet steel from the bottom and leading and compel it together gently. Certain locations can be very carefully worked to diminish as required. This is a more accurate yet slower approach.

Warmth diminishing: This entails heating an over-stretched area with a blowtorch till it is almost red hot, as the metal shrinks when it cools. Diminishing discs can be put on angle grinders that use friction to produce warmth.

Stretching

The most typical methods of stretching steel include:

Hammer and dolly: This is the simplest strategy and involves holding an object behind the metal and striking the opposite with a hammer, compeling the metal to press and stretch.

Cot: This is a mechanically-operated device just like the shrinker, that puts metal between 2 flat-textured jaws which draw it apart slowly.

English wheel: This method uses wheels that roll back and forth over the flat metal.

Welding

The most typical approaches of welding metal to create bigger and more complicated parts include:

Oxy-acetylene welding

This is the earliest form of welding but is still commonly utilized. Containers of oxygen and acetylene are blended with an adjustable torch to develop a regulated flame to warm the steel. Throughout home heating, a filler pole is included that joins the steel together. These welds are the simplest to planish (smooth out) with a hammer and dolly, enabling the weld joint to be as level as feasible.

TIG welding

This involves a torch that has a non-consumable electrode that creates a tiny, specific electric arc that melts the base metal. Filler rods are contributed to the puddle of molten metal to join the parts with each other. This is a much more exact technique than oxy-acetylene.

MIG welding

This is one of the most usual technique and includes an electric motor that is utilized to feed the filler wire with the suggestion of a MIG gun. The wire is melted into the weld joint, fusing the metal together.

Steel fabrication entails the making of steel frameworks and elements by controling the raw product-- usually structural steel and sheet metal-- with a range of processes. The term covers a broad array of tasks, from sheet metal construction for building tasks, to machined components and bespoke products for manufacturers. Shears are commercial equipments, that come in a vast variety of setups and sizes, capable of reducing sheet steel of various densities. Shrinker: This is a lever-operated tool with moving textured jaws that understand sheet steel from the top and lower and compel it together lightly. Filler rods are included to the pool of liquified steel to join the components with each other.

#Metal Fabrication#Sheet Metal Fabrication#Steel Fabrication#Steel Fabricators#Stainless Steel Fabrication#Custom Metal Fabrication#Stainless Steel Fabricators#Metal Fabrication Near Me#Metal Fabricator#Metal Fabrication Companies#Sheet Metal Fabricators#Steel Fabrication Companies#Sheet Metal Fabrication Near Me#Metal Fabrication Shops#Metal Fabrication Shops Near Me#Sheet Metal Shop#Metal Manufacturing#Custom Sheet Metal Fabrication#Fabrication Companies#Precision Metal Fab#Structural Steel Fabrication#Precision Sheet Metal Fabrication#Structural Steel Fabricators#Sheet Metal Manufacturing#Fabrication Metal#Custom Steel Fabrication#Welding And Fabrication#Metal Fabrication Company#Brass Fabrication#Aluminum Fabrication

0 notes

Text

Northsidesteelwork Things To Know Before You Buy

Introduction

Steel fabrication entails the production of steel structures and parts by manipulating the raw product-- usually structural steel and sheet steel-- via a variety of procedures. The term covers a wide variety of activities, from sheet metal manufacture for building and construction projects, to machined parts and bespoke items for makers. Workshops that specialise in steel fabrication are called 'fab shops'.

Typical procedures involved in metal manufacture consist of: Forging, Casting, Cutting, Bending, Shearing, Drawing, Spinning, Punching.

When the parts have actually been made, they might have to be set up. Assembly could include welding, binding with adhesives, fascinating, kinky seams or threaded bolts.

The components or settings up might after that be dealt with by a process of sandblasting, powder, priming or painting coating, if required.

The finished item should based on careful assessment to guarantee it adheres to the spec before leaving the fab shop.

Cutting

The desired form can be formed by getting rid of unwanted material from a block of metal, in a process called machining. Metal is cut as needed utilizing various devices, including:

Saws

Industrial saws such as band saws and huge circular saws could cut steel in straight-lines. Angle grinders are portable power tools fitted with an abrasive disc made use of for reducing, polishing and grinding.

Shears

Shears are commercial devices, that come in a wide variety of sizes and configurations, efficient in reducing sheet steel of different thicknesses. They work in the same way as a set of scissors, with opposing blades, one being dealt with and the various other moving in an angled levering motion. Various sorts of shears consist of:

Hand shears: Also called 'air travel cuts', these are simple, hand-operated devices used to reduce thin pieces of steel.

youtube

Power shears: These can cutting sheet metal quickly and with much less guidebook effort. Many are not able to cut elaborate forms or limited span and so often tend to squander material.

Throatless shears: These are hand-operated and utilize a hinged blade that turns down to reduce metal lying on a stationary surrounding blade. These are capable of cutting in straight lines or shapes and reduce waste product.

Plasma and laser cutters

Hd plasma cutting techniques are made use of to attain elaborate shapes. With the combination of computer system assisted design and computer system aided manufacturing, the reducing procedure can be achieved flawlessly, with minimal waste.

Bending

The bending metal can be accomplished by either strategies:

The most basic method is type bending, where metal is bent over a side or form situated under the metal. This can be done by hand or with tools such as hammers and shaping dollys to bend metal around the called for form.

Metal brakes are the most typical technique of attaining clean, specific bends. The procedure entails placing the metal on a flat, gated surface, securing a flat bar on top of it, and raising the gated section to bend the metal to the preferred angle.

Reducing

One of the most typical approaches of diminishing metal include:

Putting: A basic technique that includes requiring steel together between a gap or folding metal over at the edges.

Shrinker: This is a lever-operated tool with moving textured jaws that understand sheet steel from the top and bottom and compel it together lightly. Particular areas can be meticulously functioned to diminish as called for. This is an extra specific yet slower approach.

Warm shrinking: This includes heating an over-stretched location with a blowtorch till it is nearly red hot, as the steel reduces when it cools. Reducing discs can be put on angle mills that make use of friction to create warm.

Stretching

One of the most typical approaches of stretching metal include:

Dolly and hammer: This is the simplest strategy and involves holding an object behind the steel and striking the opposite with a hammer, requiring the steel to press and stretch.

Stretcher: This is a mechanically-operated tool just like the shrinker, that puts metal between two flat-textured jaws which pull it apart slowly.

English wheel: This strategy utilizes wheels that curtail and forth over the level metal.

Welding

The most typical techniques of welding metal to generate larger and extra complex parts include:

Oxy-acetylene welding

Tanks of oxygen and acetylene are mixed with a flexible torch to produce a controlled fire to heat the steel. Throughout heating, a filler pole is added that signs up with the steel together.

TIG welding

This involves a lantern that has a non-consumable electrode that creates a tiny, accurate electrical arc that melts the base metal. Filler rods are contributed to the pool of molten steel to sign up with the components together. This is a more accurate technique compared to oxy-acetylene.

MIG welding

This is one of the most common method and involves a motor that is made use of to feed the filler cable via the suggestion of a MIG gun. The cable is melted into the weld joint, fusing the steel together.

Steel manufacture entails the making of steel structures and elements by adjusting the raw product-- typically architectural steel and sheet metal-- with a range of procedures. The term covers a broad range of tasks, from sheet steel construction for building projects, to machined components and bespoke products for manufacturers. Shears are industrial devices, that come in a vast array of sizes and configurations, qualified http://northsidesteelwork.ie of cutting sheet metal of different densities. Shrinker: This is a lever-operated device with moving textured jaws that understand sheet metal from the bottom and leading and require it together gently. Filler poles are added to the pool of liquified metal to join the components together.

#Metal Fabrication#Sheet Metal Fabrication#Steel Fabrication#Steel Fabricators#Stainless Steel Fabrication#Custom Metal Fabrication#Stainless Steel Fabricators#Metal Fabrication Near Me#Metal Fabricator#Metal Fabrication Companies#Sheet Metal Fabricators#Steel Fabrication Companies#Sheet Metal Fabrication Near Me#Metal Fabrication Shops#Metal Fabrication Shops Near Me#Sheet Metal Shop#Metal Manufacturing#Custom Sheet Metal Fabrication#Fabrication Companies#Precision Metal Fab#Structural Steel Fabrication#Precision Sheet Metal Fabrication#Structural Steel Fabricators#Sheet Metal Manufacturing#Fabrication Metal#Custom Steel Fabrication#Welding And Fabrication#Metal Fabrication Company#Brass Fabrication#Aluminum Fabrication

1 note

·

View note

Text

Get The Competitive Edge With One Of These Ideas On Northside Steel Work

Introduction

Metal fabrication entails the making of metal structures and components by manipulating the raw product-- normally structural steel and sheet metal-- via a range of procedures. The term covers a broad series of activities, from sheet metal fabrication for building jobs, to machined parts and bespoke items for manufacturers. Workshops that specialise in metal manufacture are known as 'great shops'.

Typical procedures associated with steel construction include: Forging, Casting, Cutting, Bending, Shearing, Drawing, Spinning, Punching.

When the parts have been made, they may should be set up. Assembly could involve welding, binding with adhesives, captivating, crimped seams or threaded bolts.

The assemblies or parts may then be treated by a procedure of sandblasting, powder, priming or painting finishing, if required.

The completed product ought to subject to mindful evaluation to ensure it abides by the specification before leaving the fab store.

Reducing

The wanted shape can be developed by eliminating undesirable material from a block of metal, in a procedure referred to as machining. Metal is reduced as required using different tools, including:

youtube

Saws

Industrial saws such as band saws and huge circular saws could cut steel in straight-lines. Angle mills are portable power devices fitted with a rough disc utilized for reducing, grinding and brightening.

Shears

Shears are commercial makers, that come in a vast array of dimensions and setups, efficient in cutting sheet metal of various densities. They operate in the same way as a pair of scissors, with opposing blades, one being fixed and the other relocating an angled levering movement. Different kinds of shears include:

Hand shears: Also called 'aviation snips', these are simple, manual devices utilized to reduce slices of metal.

Power shears: These are capable of reducing sheet steel promptly and with less handbook effort. A lot of are not able to cut complex forms or limited distance and so have a tendency to lose material.

Throatless shears: These are hand-operated and make use of a hinged blade that turns down to http://northsidesteelwork.ie/powder-coating-and-galvanising cut metal lying on a fixed adjacent blade. These are capable of cutting in straight lines or shapes and minimise waste material.

Plasma and laser cutters

High definition plasma reducing methods are made use of to achieve elaborate forms. With the assimilation of computer system assisted style and computer system aided manufacturing, the cutting procedure can be achieved perfectly, with minimal waste.

Flexing

The flexing metal can be attained by https://en.search.wordpress.com/?src=organic&q=metal fabrication one of two strategies:

The most basic approach is form flexing, where metal is curved over a side or shape situated under the metal. This can be done manually or with devices such as hammers and forming dollys to bend steel around the needed shape.

Steel brakes are the most typical method of achieving tidy, exact bends. The process entails placing the metal on a flat, gated surface, securing a flat bar in addition to it, and raising eviction part to bend the metal to the preferred angle.

Diminishing

The most usual methods of shrinking steel include:

Putting: A simple strategy that includes compeling steel with each other between a gap or folding steel over at the edges.

Shrinker: This is a lever-operated tool with moving textured jaws that comprehend sheet steel from the lower and top and compel http://northsidesteelwork.ie it with each other lightly. Particular areas can be meticulously worked to reduce as required. This is a much more specific yet slower approach.

Warmth diminishing: This entails home heating an over-stretched location with a blowtorch until it is virtually red hot, as the steel diminishes when it cools. Shrinking discs can be put on angle grinders that make use of rubbing to produce heat.

Extending

One of the most common techniques of stretching metal consist of:

Hammer and dolly: This is the simplest technique and includes holding an object behind the metal and hitting the opposite side with a hammer, requiring the metal to compress and extend.

Stretcher: This is a mechanically-operated tool just like the shrinker, that puts metal between two flat-textured jaws which draw it apart slowly.

English wheel: This strategy makes use of wheels that roll back and forth over the level metal.

Welding

One of the most usual methods of welding steel to create bigger and extra complex parts include:

Oxy-acetylene welding

This is the oldest type of welding but is still widely made use of. Storage tanks of oxygen and acetylene are blended with a flexible torch to develop a controlled fire to warm the metal. Throughout heating, a filler pole is added that joins the steel together. These welds are the most convenient to planish (ravel) with a hammer and dolly, making it possible for the weld joint to be as level as possible.

TIG welding

This entails a lantern that has a non-consumable electrode that creates a tiny, specific electrical arc that melts the base metal. Filler rods are contributed to the puddle of liquified steel to join the components together. This is a much more accurate approach compared to oxy-acetylene.

MIG welding

This is one of the most typical technique and includes a motor that is utilized to feed the filler wire with the idea of a MIG gun. The wire is melted into the weld joint, fusing the metal with each other.

Steel fabrication includes the production of steel structures and parts by controling the raw product-- generally architectural steel and sheet metal-- via an array of processes. The term covers a wide array of activities, from sheet metal fabrication for building projects, to machined parts and bespoke items for producers. Shears are commercial devices, that come in a broad array of sizes and setups, qualified of cutting sheet steel of various thicknesses. Shrinker: This is a lever-operated tool with moving textured jaws that grasp sheet steel from the bottom and top and force it with each other lightly. Filler rods are included to the puddle of molten steel to join the parts together.

#Metal Fabrication#Sheet Metal Fabrication#Steel Fabrication#Steel Fabricators#Stainless Steel Fabrication#Custom Metal Fabrication#Stainless Steel Fabricators#Metal Fabrication Near Me#Metal Fabricator#Metal Fabrication Companies#Sheet Metal Fabricators#Steel Fabrication Companies#Sheet Metal Fabrication Near Me#Metal Fabrication Shops#Metal Fabrication Shops Near Me#Sheet Metal Shop#Metal Manufacturing#Custom Sheet Metal Fabrication#Fabrication Companies#Precision Metal Fab#Structural Steel Fabrication#Precision Sheet Metal Fabrication#Structural Steel Fabricators#Sheet Metal Manufacturing#Fabrication Metal#Custom Steel Fabrication#Welding And Fabrication#Metal Fabrication Company#Brass Fabrication#Aluminum Fabrication

0 notes

Photo

All it takes is a Baileigh Bead Roller, an MPS-1 throatless shear...and a little creativity. Josh Allison @joshua8787 of @crybabycycles is making motorcycle seats that are almost a shame to sit on. They belong in a frame on the wall! #baileigharmy #baileighbeadroller https://www.instagram.com/p/BtyEAcoHFug/?utm_source=ig_tumblr_share&igshid=g8bp31okhgfy

2 notes

·

View notes

Text

**Beverly B-1 Throatless Shear, 14 gauge capacity** (Mt. Holly) $350

https://www.trick-tools.com/Beverly_B_1_Throatless_Shear_14_gauge_capacity_B_1_1116 A classic name in sheet metal shears that will be used daily by aluminum and steel fabricators alike. This B1 throatless shear from Beverly will shear up to 14 gauge ...

from Craigslist https://charlotte.craigslist.org/tls/d/beverly-1-throatless-shear-14/6765934353.html

Fraud Bloggs made possible by: http://circuitgenie.wix.com/techsupport

0 notes

Text

Facts About Northside Steel Work Revealed

Sheet steel fabrication is the act of forming, shaping, and signing up with steel together to construct and or repair a substantial part. There are many techniques and devices. It's been done given that the start of time when also the easiest tools were made use of. In this article we will certainly share one of the most vital and common tools, devices, and techniques for the DIY fabricator.

Steel Shaping

Metal Shaping or creating could just transform steel in four means. You could flex, cut, diminish and stretch metal to develop it. Below are the typical tools and strategies to carry out these jobs.

Flexing Metal

In this method you are flexing the metal over an edge or shape that is situated under the steel. You might additionally make use of a hammer and forming dolly to flex the steel around the shape that is wanted.

Metal Brake- A steel brake is the most common Northside Steel Work way to make tidy, precise bends in metal. A steel brake functions by putting the steel on a flat, gated surface and after that securing a level bar on top of the metal and raising the gated section to bend the steel to the wanted angle.

Cutting Metal

Hand Shears- Using hand shears or "air travel cuts" is a handbook, method to cut steel that's needed regardless of the number of big tools Browse this site you have. Snips or hand shears are among the first devices you should acquire when getting in the globe of steel fabrication. We provide a complete line of Hand Shears and Aviation Snips that variety from the straightforward straight, left and ideal snips to specialized jaws.

Power Shears- Power shears are best referred to as power "scissors" for reducing steel. They enable you to reduce sheet steel quicker and with much less handbook effort. There are various types of power shears varying from electric shears and pneumatically-driven shears. The majority of power shears aren't able to cut tight edges or intricate forms. Some specialized throatless power shears or "nibblers" on the marketplace can cut tighter spans. When cutting (determined by the spacing of the fixed jaws), many power shears do throw away some material. We provide both pneumatic and electric power shears at cost effective rates.

Throatless Shears- This is one more type of mechanical cutting or "shearing" of steel. These are developed to allow you to cut steel in straight lines or forms and radii in sheet metal with no marring of the cut side. They are hand operated and utilize a hinged blade that swings down and cuts the steel that's existing on a fixed surrounding blade.

Angle Grinder- I am a company believer that if you plan on working on anything made of steel, you need to possess an electric angle mill. Thin reducing discs are readily available for cutting steel. This is my choice if I require to cut with numerous layers of sheet metal.

Plasma Cutter- Plasma cutting can be as powerful and hostile or delicate as you desire if configuration appropriately. An appropriately readjusted plasma cutter can reduce sheet steel quickly with severe precision and very little tidy up. These are extremely helpful if you need to make long straight cuts that may be tough to handle alone on a throatless shear. Eastwood Company offers plasma cutters that allow you to reduce paper thin sheet steel right up to 3/4" steel.

Shrinking Metal

Putting Metal- Tucking steel is one of the earliest techniques of shrinking steel. In this approach you're literally bunching the steel together by compeling it between a hole with a spade hammer or by folding the steel over at the edges with a homemade tucking fork.

Shrinker- A shrinker is a lever-operated tool (hand or foot) that has moving distinctive jaws that understand sheet metal from the top and all-time low and force it with each other snugly. This approach is a lot more precise than tucking with a hammer and form, however moves the steel a lot slower. You can carefully work particular areas to reduce them as wanted. The shrinker leaves marginal spoiling on the steel, the majority of which can be eliminated or smoothed out with a fining sand disc or documents.

The type or quantity of stretched metal or damage will certainly identify exactly how you smooth the area or shrink out. There are shrinking discs on the market that are connected to an angle grinder that make use of friction to develop the warm. These are a little bit more specific and prevent utilizing a torch/flame to warm and shrink the metal.

Stretching Metal

With this approach you securely hold a things behind the metal and struck the various other side with a hammer. Steel can also be extended in a similar technique by using a sandbag and plastic mallets to quickly stretch steel and make forms.

Cot-- The opposite of the shrinker discussed over. This is a mechanically operated tool that puts the steel in between two flat distinctive jaws and draws the metal apart slowly each time the lever or foot pedal is pushed. The shrinker and stretcher with each other are should have products for anyone doing sheet steel fabrication.

English http://www.thefreedictionary.com/metal fabrication Wheel- This method operates in a comparable fashion to making use of a hammer and dolly or anvil to extend the metal out. The metal is placed between a huge, flat-faced top wheel and a reduced "anvil" that has a distance to the face. The reduced wheel is after that screwed up to squeeze the steel between both wheels and the steel is curtailed and forth slowly extending the flat steel over the curved reduced wheel. This method stretches the panel to develop an uniform crown. You can likewise utilize the English Wheel to ravel imperfections in the metal caused by utilizing a plastic mallet and sandbag as explained above. We offer a couple DIY English Wheel alternatives that could manage most panel shaping required.

youtube

Metal Fusion

The last vital technique of sheet steel fabrication is integrating little panels with each other to generate bigger complicated components. One of the most typical sort of metal fusion is welding. One of the most common approaches of welding during sheet metal fabrication are below.

Oxy Acetylene welding makes use of tanks of Oxygen and Acetylene that are blended together with a flexible lantern to develop a specific, controlled flame that an item of steel can be warmed with. While heating up the base steel you include a filler pole that signs up with the metal with each other.

TIG WELDING- This kind of welding is one of the most desired by experts in the sheet metal construction market. It utilizes a "lantern" that has a non-consumable electrode that produces a small, exact electric arc that melts the base metal. You could then sign up with the steel with each other by including filler rod to the pool of molten steel with your other Stainless Steel Fabricators hand. TIG welds are the second softest weld yet are one of the most hard to master. TIG welding is extra precise compared to Oxy Acetylene welding and most contemporary fabricators favor it. Eastwood offers a full line of TIG Welders and TIG Welding Supplies that will complete your sheet metal fabrication devices.

MIG Welding- A MIG welder is the most typical and probably the simplest form of welding http://northsidesteelwork.ie/blog to find out. This method utilizes a motor to feed the filler cord via the pointer of the MIG weapon. The cord after that completes the circuit when it touches the base metal and melts the cord into the weld joint, merging the metal together. MIG welding produces stimulates and requires much more clean-up compared to the various other techniques over. It's likewise the hardest weld, so it's more difficult to grind and hammer flat. Since it's quicker and much easier to understand, most novices and DIY individuals favor this method. Eastwood uses MIG welders that can bond sheet steel with ease and diverse enough to execute heavier manufacture.

The most essential point to keep in mind is that you need to learn to find out and enjoy the metal to review exactly what needs to be done to get it to where you want. Cut, bend, reduce, and stretch to make your desires become fact in metal!

Steel Brake- A metal brake is the most typical way to make clean, specific bends in steel. A steel brake functions by putting the steel on a level, gated surface area and after that securing a flat bar on top of the steel and lifting the gated part to flex the metal to the preferred angle. Tucking Metal- Tucking metal is one of the earliest approaches of diminishing metal. The lower wheel is after that screwed up to squeeze the metal between the two wheels and the steel is rolled back and forth gradually extending the level metal over the curved reduced wheel. The cord after that finishes the circuit when it touches the base metal and melts the cord into the weld joint, fusing the steel together.

#Metal Fabrication#Sheet Metal Fabrication#Steel Fabrication#Steel Fabricators#Stainless Steel Fabrication#Custom Metal Fabrication#Stainless Steel Fabricators#Metal Fabrication Near Me#Metal Fabricator#Metal Fabrication Companies#Sheet Metal Fabricators#Steel Fabrication Companies#Sheet Metal Fabrication Near Me#Metal Fabrication Shops#Metal Fabrication Shops Near Me#Sheet Metal Shop#Metal Manufacturing#Custom Sheet Metal Fabrication#Fabrication Companies#Precision Metal Fab#Structural Steel Fabrication#Precision Sheet Metal Fabrication#Structural Steel Fabricators#Sheet Metal Manufacturing#Fabrication Metal#Custom Steel Fabrication#Welding And Fabrication#Metal Fabrication Company#Brass Fabrication#Aluminum Fabrication

0 notes

Text

Secrets And Techniques Northside Steel Work Doesn't Would Like You To Understand

Sheet metal fabrication is the act of developing, forming, and joining metal together to build and or fix a tangible part. There are many techniques and tools. When also the most basic devices were used, it's been done given that the beginning of time. In this article we will certainly share the most important and usual tools, devices, and techniques for the DIY maker.

Metal Shaping

Metal Shaping or creating can just transform steel in 4 methods. You could bend, cut, shrink and stretch metal to develop it. Below are the usual devices and strategies to execute these tasks.

Bending Metal

Form Bending- This is the most basic means to bend metal. In this technique you are flexing the metal over a side or shape that lies under the metal. You could push a level item of steel over the side of a table (with your hands) to make a bend. You might additionally utilize a hammer and shaping dolly to flex the metal around the form that is desired.

Steel Brake- A metal brake is the most common means to make tidy, accurate bends in metal. A metal brake functions by placing the metal on a level, gated surface area and after that clamping a level bar on top of the steel and raising the gated section to flex the steel to the desired angle.

Reducing Metal

youtube

Hand Shears- Using hand shears or "aviation cuts" is a guidebook, way to cut steel that's essential no matter how many big tools you have. When getting in the world of steel manufacture, snips or hand shears are one of the first tools you must buy. We provide a full line of Hand Shears and Aviation Snips that array from the basic straight, best and left snips to specialized jaws.

Power Shears- Power shears are best explained as power "scissors" for reducing metal. They enable you to reduce sheet steel much more rapidly and with much less manual effort. Many power shears typically aren't able to reduce limited edges or intricate shapes.

Throatless Shears- This is another kind of mechanical cutting or "shearing" of steel. These are developed to permit you to reduce steel in straight lines or shapes and spans in sheet steel with no marring of the cut side. They are hand ran and use a hinged blade that turns down and cuts the metal that's lying on a stationary adjacent blade.

Angle Grinder- I am a company believer that if you intend on dealing with anything made from metal, you need to possess an electrical angle grinder. These fools are the workhorses of a lot of shops. They just rotate the connected disc or wheel at a rapid rate of rate for eliminating product in a fast way. Slim reducing discs are available for reducing steel. These are loud and untidy, yet they will do the job. If I require to reduce through numerous layers of sheet metal, this is my option. I favor to have two of these available, one with a flap or fining sand disc and one with a cutting wheel to prevent needing to save time. We provide a couple of different selections of angle grinders that are eager to be celebrity gamers in your shop.

An appropriately readjusted plasma cutter can reduce sheet metal quickly with extreme accuracy and marginal tidy up. Eastwood Company uses plasma cutters that enable you to reduce paper thin sheet steel all the way up to 3/4" steel.

Shrinking Metal

Putting Metal- Tucking metal is one of the earliest approaches of reducing metal. In this approach you're actually bunching the metal with each other by compeling it in between a hole with a spade hammer or by folding the metal over at the edges with a homemade tucking fork.

Shrinker- A shrinker is a lever-operated device (hand or foot) that has moving distinctive jaws that realize sheet steel from the top and all-time low and compel it with each other snugly. This technique is a lot more exact than putting with a hammer and form, but relocates the metal a lot slower. You can carefully function certain locations to shrink them as desired. The shrinker leaves marginal tainting on the metal, most of which can be eliminated or ravelled with a fining sand disc or data.

The kind or quantity of extended metal or damages will identify just how you diminish or smooth the location out. There are shrinking discs on the market that are attached to an angle grinder that make use of friction to develop the warmth. These are a bit a lot more exact and avoid using a torch/flame to warm and diminish the http://edition.cnn.com/search/?text=metal fabrication steel.

Stretching Metal

With this method you securely hold a things behind the steel and hit the other side with a hammer. Metal could also be stretched in a similar method by using a sandbag and plastic clubs to promptly stretch metal and make forms.

Cot-- The reverse of the shrinker discussed over. This is a mechanically operated device that places the steel between two level textured jaws and pulls the steel apart gradually each time the bar or foot pedal is pushed. The shrinker and cot with each other are must have products for any individual doing sheet steel manufacture.

English Wheel- This method functions in a similar fashion to utilizing a hammer and dolly or anvil to stretch the metal out. The metal is put between a large, flat-faced upper wheel and a reduced "anvil" that has a radius to the face. The reduced wheel is then screwed up to squeeze the steel in between the 2 wheels and the steel is rolled back and forth slowly stretching the level metal over the bent lower wheel.

Metal Fusion

The last crucial method of sheet steel fabrication is integrating small panels together to produce bigger complex components. One of the most typical sort of steel combination is welding. One of the most typical approaches of welding during sheet metal construction are below.

Oxy Acetylene welding utilizes storage tanks of Oxygen and Acetylene that are blended with each other with an adjustable torch to create a specific, regulated flame that a piece of steel could be heated up with. While warming the base steel you add a filler pole that joins the steel together.

TIG WELDING- This type of welding is one of the most desired by experts in the sheet steel fabrication market. It makes use of a "lantern" that has a non-consumable electrode that produces a tiny, specific electrical arc that thaws the base metal. You could after that sign up with the metal together by including filler pole to the puddle of molten steel with your various other hand. TIG welds are the 2nd softest weld however are the most hard to master. TIG welding is much more accurate than Oxy Acetylene welding and most modern producers like it. Eastwood offers a full line of TIG Welders and TIG Welding Supplies that will certainly complete your sheet steel construction devices.

This method makes use of a motor to feed the filler cable with the tip of the MIG gun. The wire then finishes the circuit when it touches the base steel and melts the cord right into the weld joint, fusing the steel together. Eastwood supplies MIG welders that could weld sheet steel with simplicity and likewise varied adequate to do much heavier manufacture.

By complying with the standard methods and making use of the devices mobile welding dublin pointed out over you could take on most any kind of work you stumble upon. The most essential thing to remember is that you should learn to enjoy the steel and learn to read just what needs to be done to get it to where you desire. Get out there and practice! Cut, bend, reduce, and stretch making your desires become reality in metal!

Steel Brake- A metal brake is the most usual means to make tidy, exact bends in metal. A metal brake works by placing the metal on a level, gated surface area and after that securing a level bar on top of the steel and raising the gated portion to flex the steel to the preferred angle. Putting Metal- Tucking steel is one of the earliest techniques of diminishing steel. The lower wheel is after that screwed up to squeeze the steel in between the 2 wheels and the steel is rolled back and forth slowly extending the level steel over the curved lower wheel. The wire after that completes the circuit when it touches the base steel and thaws the cord into the weld joint, integrating the steel together.

#Metal Fabrication#Sheet Metal Fabrication#Steel Fabrication#Steel Fabricators#Stainless Steel Fabrication#Custom Metal Fabrication#Stainless Steel Fabricators#Metal Fabrication Near Me#Metal Fabricator#Metal Fabrication Companies#Sheet Metal Fabricators#Steel Fabrication Companies#Sheet Metal Fabrication Near Me#Metal Fabrication Shops#Metal Fabrication Shops Near Me#Sheet Metal Shop#Metal Manufacturing#Custom Sheet Metal Fabrication#Fabrication Companies#Precision Metal Fab#Structural Steel Fabrication#Precision Sheet Metal Fabrication#Structural Steel Fabricators#Sheet Metal Manufacturing#Fabrication Metal#Custom Steel Fabrication#Welding And Fabrication#Metal Fabrication Company#Brass Fabrication#Aluminum Fabrication

0 notes

Text

The 5-second Trick For Precision Metal Fab

Sheet metal construction is the act of forming, forming, and joining metal with each other to build and or repair a substantial component. There are lots of techniques and devices. When also the easiest tools were utilized, it's been done since the beginning of time. In this write-up we will share the most typical and important devices, equipments, and methods for the DIY fabricator.

Steel Shaping

Steel Shaping or creating could just change steel in four methods. You can bend, cut, extend and reduce metal to create it. Below are the typical tools and strategies to do these jobs.

youtube

Bending Metal

In this technique you are flexing the steel over an edge or shape that is situated under the steel. You can likewise utilize a hammer and shaping dolly to bend the metal around the shape that is wanted.

Metal Brake- A steel brake is the most common method to make tidy, specific bends in metal. A steel brake functions by positioning the metal on a flat, gated surface and after that securing a level bar on top of the metal and raising the gated part to bend the metal to the preferred angle.

Cutting Metal

Hand Shears- Using hand shears or "aviation cuts" is a guidebook, method to cut steel that's necessary no matter the number of huge devices you have. Snips or hand shears are just one of the very first tools you should acquire when going into the globe of metal fabrication. We offer a complete line of Hand Shears and Aviation Snips that variety from the straightforward straight, left and right snips to specialized jaws.

Power Shears- Power shears are best described as power "scissors" for cutting metal. They permit you to reduce sheet metal quicker and with less manual initiative. There are various types of power shears varying from pneumatically-driven shears and electric shears. A lot of power shears typically aren't able to reduce elaborate forms or dilemmas. Some specialized throatless power shears or "nibblers" on the market could cut tighter distances. When reducing (identified by the spacing of the stationary jaws), a lot of power shears do lose some material. We provide both pneumatic and electrical power shears at economical costs.

Throatless Shears- This is one more type of mechanical cutting or "shearing" of steel. These are created to enable you to reduce steel in straight lines or shapes and radii in sheet steel with no marring of the cut side. They are hand ran and use a hinged blade that turns down and cuts the metal that's lying on a fixed surrounding blade.

Angle Grinder- I am a company believer that if you plan on working with anything made from metal, you should possess an electrical angle grinder. These suckers are the workhorses of the majority of shops. They merely spin the affixed disc or wheel at a fast price of rate for getting rid of product in a quick fashion. Slim cutting discs are offered for cutting metal. These are messy and noisy, yet they will certainly get the job done. This is my choice if I should cut through several layers of sheet steel. I choose to have 2 of these on hand, one with a flap or fining sand disc and one with a reducing wheel to stay clear of having to conserve time. We offer a few various options of angle mills that aspire to be celebrity players in your shop.

A correctly readjusted plasma cutter could reduce sheet steel rapidly with extreme precision and marginal tidy up. Eastwood Company offers plasma cutters that permit you to reduce paper slim sheet steel all the method up to 3/4" steel.

Diminishing Metal

Tucking Metal- Tucking metal is one of the earliest approaches of shrinking metal. In this method you're actually bunching the metal with each other forcibly it between a hole with a spade hammer or by folding the steel over at the sides with a homemade tucking fork. This method is one that has been utilized to develop a few of the earliest most beneficial sports cars. A good hammer and a wooden stump with skillfully put crevices and cuts formed could function wonders!

Shrinker- A shrinker is a lever-operated device (hand or foot) that has moving distinctive jaws that understand sheet steel from the top and all-time low and force it with each other tightly. This method is far more precise compared to tucking with a hammer and form, however moves the metal much slower. You could meticulously function certain locations to reduce them as wanted. The shrinker leaves marginal marring on the steel, the majority of which can be removed or ravelled with a fining sand disc or documents.

Warm Shrinking- This is an approach that takes a great deal of method. The basic idea is that you heat a overstretched area (with a lantern) virtually red hot and then as the location cools it reduces. The type or amount of extended steel or damage will certainly determine just how you smooth the area or reduce out. You could should dolly the location and hammer or relieve the area with a damp rag or compressed air to obtain the desired diminish. Alternatively there are shrinking discs on the market that are connected to an angle mill that make use of friction to create the warmth. These are a little bit extra precise and prevent using a torch/flame to heat and shrink the metal.

Extending Metal

Dolly and hammer-- This is the most basic way to extend steel. With this method you securely hold a things behind the metal and hit the opposite with a hammer. This requires the steel to be pressed and eventually stretch. Steel could likewise be extended in a comparable method using a sandbag and plastic clubs to swiftly extend steel and make shapes.

Stretcher-- The reverse of the shrinker pointed out over. This is a mechanically run device that places the metal in between two level distinctive jaws and draws the steel apart gradually each time the bar or foot pedal is pressed. The shrinker and cot together are need to have products for anybody doing sheet metal fabrication.

English Wheel- This approach operates in a comparable fashion to making use of a hammer and dolly or anvil to extend the metal out. The metal is put in between a huge, flat-faced top wheel and a lower "anvil" that has a span to the face. The lower wheel is then screwed up to squeeze the steel between both wheels and the metal is rolled back and forth slowly stretching the flat metal over the bent reduced wheel. This technique extends the panel to create a consistent crown. You could additionally make use of the English Wheel to ravel imperfections in the metal caused by using a plastic mallet and sandbag as defined over. We provide a pair DIY English Wheel choices that could take care of many panel shaping required.

Steel Fusion

The last important method of sheet steel manufacture is integrating little panels with each other to produce larger complicated parts. The most usual sort of steel blend is welding. One of the most typical methods of welding throughout sheet metal fabrication are listed here.

Oxy Acetylene Welding-- This type of welding is the oldest method, yet it's still utilized by several today. Oxy Acetylene welding uses containers of Oxygen and Acetylene that are blended together with a flexible torch to create an exact, controlled fire that a piece of metal can be heated up with. While heating up the base metal you add a filler pole that signs up with the steel with each other. This technique does take a great deal of method to master, but the welds created are the softest and most flexible. Oxy Acetylene welds are the most convenient to planish (ravel) with a hammer and dolly to obtain the weld joint as level as feasible.

TIG WELDING- This type of welding is the most desired by experts in the sheet steel construction market. It makes use of a "torch" that has a non-consumable electrode that creates a small, exact electrical arc that melts the base metal. You can then join the metal together by including filler pole to the puddle of molten steel with your other hand. TIG welds are the second softest weld but are one of the most difficult to master. TIG welding is extra accurate than Oxy Acetylene welding and most modern-day makers like it. Eastwood provides a full line of TIG Welders and TIG Welding Supplies that will complete your sheet steel fabrication tools.

MIG Welding- A MIG welder is one of the most usual and probably the most convenient type of welding to discover. This technique utilizes a motor to feed the filler cord with the tip of the MIG weapon. The cable after that finishes the circuit when it touches the base metal and melts the cable into the weld joint, fusing the metal with each other. MIG welding develops triggers and calls for more clean-up than the various other techniques over. It's also the hardest weld, so it's more difficult to grind and hammer flat. Many beginners and DIY guys favor this method since it's quicker and easier to grasp. Eastwood provides MIG welders that can weld sheet steel effortlessly and also varied adequate to carry out larger construction.

By following the standard approaches and utilizing the devices discussed over you could deal with most any kind of task you find. The most vital point to remember is that you have to learn to enjoy the steel and learn to read exactly what has to be done to get it to where you desire. Obtain out there and exercise! Cut, bend, diminish, and stretch to earn your dreams end up being truth in metal!

Metal Brake- A steel brake is the most common way to make clean, precise bends in steel. A steel brake functions by placing the metal on a flat, gated surface and then securing a level bar on top of the steel and raising the gated section to flex the steel to the wanted angle. Putting Metal- Tucking steel is one of the earliest approaches of diminishing metal. The reduced wheel is then screwed up to pinch the metal in between the 2 wheels and http://northsidesteelwork.ie the steel is rolled back and forth slowly extending the flat metal over the curved lower wheel. The cord then completes the circuit when it touches the base steel and thaws the wire right into the weld joint, fusing the metal with each other.

#Metal Fabrication#Sheet Metal Fabrication#Steel Fabrication#Steel Fabricators#Stainless Steel Fabrication#Custom Metal Fabrication#Stainless Steel Fabricators#Metal Fabrication Near Me#Metal Fabricator#Metal Fabrication Companies#Sheet Metal Fabricators#Steel Fabrication Companies#Sheet Metal Fabrication Near Me#Metal Fabrication Shops#Metal Fabrication Shops Near Me#Sheet Metal Shop#Metal Manufacturing#Custom Sheet Metal Fabrication#Fabrication Companies#Precision Metal Fab#Structural Steel Fabrication#Precision Sheet Metal Fabrication#Structural Steel Fabricators#Sheet Metal Manufacturing#Fabrication Metal#Custom Steel Fabrication#Welding And Fabrication#Metal Fabrication Company#Brass Fabrication#Aluminum Fabrication

1 note

·

View note