Text

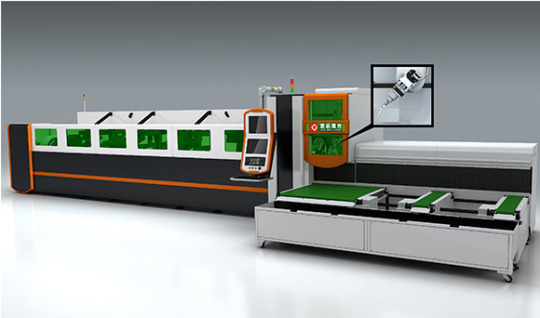

Overview of Heavy Duty Tube Laser Cutting Machine

We have launched the heavy-duty tube laser cutting machine, a large cutting machine, for processing super-long and super-heavy pipes. From automatic feeding to stable clamping, and finally to automatic receiving of the finished workpiece, the whole process can be fully automated. Save time and labor for you.

Application of Heavy Duty Tube Laser Cutting Machine

Application Of Heavy Duty Tube Laser Cutting Machine1

Construction machinery industry:

Many major load-bearing structures in construction machinery use ultra-long and ultra-thick channel steel I-beams and other pipes. The traditional plasma cutting and flame cutting methods have low processing efficiency and quality. But the fiber laser tube cutting machine can completely solve the problem of heavy pipe processing. In the future, laser tube cutting will gradually replace these methods.

Application Of Heavy Duty Tube Laser Cutting Machine2

Shipbuilding industry:

The automatic processing capability of the heavy-duty tube laser cutting machine can speed up the processing efficiency of the pipe components.

Application Of Heavy Duty Tube Laser Cutting Machine3

Steel structure industry:

Heavy-duty tube laser cutting machine can realize welding-free, making the product more stable.

Technical Data of Heavy Duty Tube Laser Cutting Machine

Model name

P35120

Workpiece length

0-12000mm

Tube dimeter range

20-350mm

Type of tube

Round tube, square tube, rectangular tube, oval tube, channel steel, I-beam, etc.

Single tube bearing weight

30kg/m

Laser source

IPG/nLIGHT/Raycus

Laser power

1500W-6000W

Positioning accuracy

±0.03mm

Rotational speed

70r/min

Support bevel cutting

Yes

Automatic deslagging

Option

Weld recognition

Option

Auto feeder

Standard chain loading and unloading system

Loading size

6* 12000mm

Auto feeder maximum weight

2.5T

Capacities

Material

1000W

1200W

1500W

2000W

2500W

3000W

4000W

Carbon steel

6

8

10

12

14

16

20

Stainess steel

4

5

6

8

10

10

12

Galvanized steel

3

4

5

6

8

8

10

Aluminum

3

3

4

5

6

6

10

Barss

2

2

3

4

5

5

8

Copper

1

1

2

2

3

3

4

Highlights of Heavy Duty Tube Laser Cutting Machine

Chain Drive Loading and Unloading System

The loading and unloading adopt chain drive mode, without manual intervention.

Intelligent Heavy-duty Chuck With Large Clamping Range

It adopts 3 heavy-duty pneumatic chucks with a maximum load of 500kg and a clamping range of 20-350 mm. The clamping pressure of the pneumatic chuck supports visual digital adjustment, which is precise and easy to control.

Servo Reducing Wheel Support System

Both the loading end and the unloading end are equipped with a servo reducing wheel support to increase the bearing capacity. At the same time, when the pipe type is switched, the adjusting wheel support adjustment can be quickly completed by inputting the pipe diameter data through the cutting system. No manual adjustment is required, and the operation is simpler and safer.

Modular Mechanical Structure Of Side Rail

The large laser cutter adopts the side rail design and chuck suspension type fixing method, which can accommodate larger pipes. The machine tool structure adopts the modular design, which can realize segmental splicing installation and convenient installation and disassembly. Even if the length of the whole machine exceeds 24 meters, there are no restrictions on transportation.

https://www.goldenlaser.org/products/heavy-duty-tube-laser-cutting-machine/

0 notes

Text

Overview of Fiber Laser Tube Cutting Machine Flexible Manufacturing System

The integration of laser cutting and sorting will help customers achieve flexible planning, production tracking, and quality monitoring. While improving equipment utilization, it will reduce quality failures and manufacturing costs, shorten delivery cycles, and achieve intelligent and digital production mode.

The fiber laser tube cutting machine produced by our company has different types -- from 1000w fiber laser cutting machine to 8000w laser cutting machine -- each type sells at a different price.

Automated Workflow of Fiber Laser Tube Cutting Machine FMS

Step 1

Loading a bunch of round tubes to the auto feeder of the tube cutting machine, which has the advantage of high efficiency.

Step 2

Smart laser tube cutter equipped with fully electric floating support and auto-focusing laser cutting head to ensure high precision during cutting.

Step 3

After the copper pipe is cut, the customized receiving tract will receive the finished parts pipe, and then the pneumatic feeding fixture will feed it.

Step 4

Industrial robots will automatically clamp and clean workpieces.

Step 5

Industrial robots will palletize workpieces and can put more than 2000 tubes in one box.

Highlights of Fiber Laser Tube Cutting Machine FMS

Automatic Loading and Unloading System

The fully automatic loading and unloading system is controlled by the CNC system and seamlessly connected with the laser tube cutting machine to realize the hoisting and loading of the whole bundle of tubes. The control system intelligently divides and composes the tubes and the automatic conveying process. A pipe component is sent to the position to be inspected for automatic measurement, saving manual loading and unloading costs, and improving work efficiency.

Synchronous Processing Of Industrial Robot

The 3D industrial robot can carry out automatic feeding of unconventional length pipes and unloading of waste after cutting. At the unloading end, the industrial robot is matched with the crawler. It can visually recognize and automatically grab workpieces, and automatically palletize and store workpieces after classification.

Intelligent Operating System

It adopts bus control mode, supports touch screen operation mode, and has 7 intelligent management modules for planning, production, process, debugging, diagnosis, maintenance, and setting. It has its own tube material library and integrates a variety of tube splicing processes.

Full Stroke Chuck

No manual adjustment is required. Intelligent pressure feedback system automatically adjusts pressure according to different pipe diameters and thicknesses. Intelligent identification and clamping of various pipe materials, real-time monitoring and alarm, safe and efficient.

Application of Fiber Laser Tube Cutting Machine FMS1

Food processing pipeline

This is a German 150-year-old food company. According to customer requirements, a set of copper fast cutting and cleaning and packaging production lines is customized. Reached unattended, in line with German security levels.

https://www.goldenlaser.org/products/fiber-laser-tube-cutting-fms/

0 notes

Text

Overview of 3D 5-axis Laser Tube Cutting Machine

The swing cutting head of the three-dimensional 5 axis fiber laser pipe cutting machine can achieve 45-degree cutting. 5 axis 3D laser metal cutting machine can be used to produce H steel, I-beam, and other profiles and water-drop-shaped tube, concave, and other shaped tube cutting easily. As one of the best 3D laser cutting machine suppliers, Golden laser has high-quality 3D laser cutting machine and 5-axis laser cutting machine for sale, feel free to contact us and get 3D CNC machine price!

Golden Laser tube cutter with rotary laser head for bevel pipe cutting

Application of 3D 5-axis Laser Tube Cutting Machine

Application Of 3D 5-axis Laser Tube Cutting Machine1

Fitness equipment industry:

The bevel cutting of the 5-axis 3D 3d pipe metal cutting machine can significantly improve the splicing defects of the fitness equipment pipe fittings, so that the welding quality is better and the product surface is more beautiful.

Application Of 3D 5-axis Laser Tube Cutting Machine2

Automobile pipe fittings:

Through the beveled pipe fittings, there is no gap in splicing, and the sealing performance of the pipe fittings can be ensured after welding, which is very important for the internal oil and gas pipelines of automobiles.

Application Of 3D 5-axis Laser Tube Cutting Machine3

Pipe processing industry:

Compared with traditional pipe cutting machines, the five-axis 3D CNC laser cutting machine has a wider range of processing capabilities and scope, so it can seize the opportunity in the fiercely competitive external processing field.

Technical Data of 3D 5-axis Laser Tube Cutting Machine

Model name

P2060A-3D

Workpiece length

0-6000mm

Tube diameter range

20-200mm

Type of tube

Round tube, square tube, rectangular tube, oval tube, channel steel, I-beam, etc.

Single tube bearing weight

25kg/m

Laser source

IPG/ nLIGHT/ Raycus fiber laser generator

Laser power

1500W-60001W

Positioning accuracy

±0.03mm

Rotational speed

120r/min

Support bevel cutting

Standard

Loading size

800mm*800mm*6000mm

Auto feeder maximum weight

Capacities

Material

1000W

1200W

1500W

2000W

2500W

3000W

4000W

Carbon steel

6

8

10

12

14

16

20

Stainless steel

4

5

6

8

10

10

12

Galvanized steel

3

4

5

6

8

8

10

Aluminum

3

3

4

5

6

6

10

Brass

2

2

3

4

5

5

8

Copper

1

1

2

2

3

3

4

Highlights Of 3D 5-axis Laser Tube Cutting Machine

Bevel Cutting

The maximum angle of the swing angle axis is ±160°; the maximum operating speed is 170m/min, and the maximum acceleration is 1.2G. There is no gap in pipe splicing.

Rapid Cutting

The pipe does not need to be moved when cutting the contour with a small figure, only the cutting head swings for rapid cutting.

Floating Support System

During the pipe cutting process, the support automatically adapts to the change of the pipe rotation posture. Ensure more stability during pipe processing.

Full Stroke Pneumatic Chuck

The chuck is made of high-bearing steel with high sealing performance and good dynamic performance. The maximum speed can reach 120r/min. When changing cutting materials, there is no need to adjust the jaws.

Welding Machine Body

The thickness of the welded plate of the machine bed is up to 25 mm and the weight is up to 7 tons. Stable and not easily deformed.

Samples of 3D 5-axis Laser Tube Cutting Machine

https://www.goldenlaser.org/products/3d-5-axis-laser-tube-cutting-machine/

0 notes

Text

Types of Fiber Laser Tube Cutting Machine

Smart Laser Tube Cutting Machine

Smart Laser Tube Cutting Machine, a type of CNC tube cutter, can realize fully automatic production, including automatic feeding, cutting, receiving, and sorting.

Small Tube Laser Cutting Machine

Small Tube Laser Cutting Machine is designed for small and thin thickness tube processing. Minimum size, maximum production rate.

3D 5-axis Laser Tube Cutting Machine

3D 5-axis Laser Tube Cutting Machine has swing cutting head so it can achieve 45-degree cutting. Give your special-shaped pipe or profile cutting more possibilities.

Cost-Effective Laser Tube Cutting Machine

Cost-Effective Laser Tube Cutting Machine is an affordable, practical, versatile tube laser cutter machine. If you expect to get profits with a low cost tube laser, this is a good choice.

Round Tube Laser Cutting Machine

Round Tube Laser Cutting Machine is special for processing round tube type pipes. Please choose it for high precision and high-efficiency work.

Heavy Duty Tube Laser Cutting Machine

Heavy Duty Tube Laser Cutting Machine is suitable for processing super-long and super-heavy pipes. Save time and labor for you.

Fiber Laser Tube Cutting Machine FMS

Fiber Laser Tube Cutting Flexible Manufacturing System will help you realize flexible planning, production tracking, and quality monitoring. Combined with your other equipment, it will reduce quality failures and manufacturing costs, shorten the delivery cycle, and realize Industry 4.0 in pipe processing.

Finished Parts Tube Laser Cutting Machine

Finished Parts Tube Laser Cutting Machine has faster speed and higher precision to meet your needs in cutting finished fittings.

Unique design for finished pipe fittings cutting & hole making.

https://www.goldenlaser.org/products/

0 notes

Text

Stainless Steel Tube - Laser Cutting Machine Be Applied

Tube Laser Cutting Machine For Stainless Steel

Stainless steel is a group of iron-based alloys that contain a minimum of approximately 11% chromium. Stainless steel pipe components are widely used in sanitary fittings, kitchenware, appliance brackets, surgical instruments, food manufacturing, and other industries. Thanks to high precision, high speed, and diversified functions, more and more manufacturers choose automatic stainless steel tube laser cutting machines. As one of the leading stainless steel laser cutting machine manufacturers in China, Golden laser provides the best quality CNC stainless steel pipe cutting machine/cutter at a competitive price. Our company's machines, for example, small CNC cutting machine, can provide good stainless steel laser cutting services to meet the requirements of the production.

Stainless Steel

What are the advantages of steel tube laser cutting machines compared with traditional saw blades?

✔ No burrs on the cutting section, no need for secondary processing and grinding.

✔ Diversified cutting technology can meet the processing requirements of different types of pipes.

✔ High efficiency. Continuous, large-scale processing will reduce the processing cost of the workpiece.

✔ The CNC system of steel pipe cutting machine is convenient and flexible.

https://www.goldenlaser.org/laser-cutting-machine-stainless-steel.html

0 notes

Text

Copper Tube - Laser Cutting Machine Be Applied

Copper is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. Last year, we customized a laser solution for our Germany client in the food packing industry. Please view this video about intelligent & automatic fiber laser tube cutting production line for copper tube cutting and packing.

And feel free to contact us and get auto copper tube laser cutting machine price!

https://www.goldenlaser.org/laser-cutting-machine-copper.html

0 notes

Text

Brass Tube - Laser Cutting Machine Be Applied

Brass is an alloy of copper and zinc. Brass has long been a popular material for decoration for its bright gold-like appearance, e.g. for drawer pulls and doorknobs. It is still commonly used in applications where low friction and corrosion resistance is required, such as locks, hinges, gears, bearings, ammunition casings, zippers, plumbing, hose couplings, valves, and electrical plugs and sockets. The price of the brass laser cutting machine provided by our company is proper. Welcome to your consultation!

In addition to brass tubes, what other materials can the fiber laser tube cutting machine cut?

Stainless steel, mild steel, iron, carbon steel galvanized, copper, alloy, aluminum, etc.

https://www.goldenlaser.org/laser-cutting-machine-brass.html

0 notes

Text

Aluminum Tube - Laser Cutting Machine Be Applied

Aluminum is a silvery-white, soft, non-magnetic, and ductile metal in the boron group. In recent years, aluminum tubes have been widely used in metallurgy, machinery, petrochemical, electronics, atomic energy, medical, agriculture, aerospace, and defense industries. Golden laser has superior quality automatic aluminium/aluminum pipe/tube cutting machine for sale. The price of our CNC aluminum bar/circle cutting machine provided by our company is competitive. Welcome to your consultation!

Due to the development of the modern automobile industry, aerospace industry, military, etc., and the improvement of personalization, the requirements for small aluminum profiles, quantity, variety, and quality are getting higher and higher. Therefore, the processing requirements for aluminum tube components are getting higher and higher. Our company's machines can provide good aluminum laser cutting services to meet the requirements of the production test.

Why Golden Laser's fiber laser tube cutting machines?

With multiple cutting processes – cutting off, beveled cutting, and punching.

Automatic loading of round pipes, saving labor and time.

With automatic slag removal function, improving the surface quality of the workpieces.

High processing efficiency, 3 times that of the sawing machine.

https://www.goldenlaser.org/laser-cutting-machine-aluminum.html

1 note

·

View note