Text

High Quality Rigid PP PE Plastic Waste Washing Line

The increasing demand for sustainable practices in the plastic industry has led to the development of advanced machinery designed to recycle plastic waste efficiently. One such innovation is the High Quality Rigid PP PE Plastic Waste Washing Line, offered by machinemg.com. This advanced washing line is specifically engineered to process and recycle polypropylene (PP) and polyethylene (PE) waste, turning discarded plastic into valuable raw materials for new products. Here’s an in-depth look at its features, benefits, and impact on the recycling industry.

Overview of the Washing Line

The High Quality Rigid PP PE Plastic Waste Washing Line is a comprehensive solution that handles the entire process of plastic waste recycling. It includes several stages, each designed to ensure that the plastic is thoroughly cleaned and processed. The major components typically include:

Shredding Unit: This unit breaks down large pieces of plastic waste into smaller, manageable pieces.

Pre-Washing System: This system removes large contaminants and reduces the burden on subsequent cleaning stages.

Washing System: Consisting of multiple washing tanks, this system ensures that all dirt, labels, and adhesives are removed from the plastic.

Rinsing System: This stage further cleans the plastic to remove any remaining contaminants.

Drying System: The cleaned plastic is then dried using centrifugal dryers or hot air drying systems to prepare it for further processing.

Sorting and Separation System: This final stage separates the plastic by type and quality, ensuring that only the highest quality material moves forward.

Key Features and Benefits

High Efficiency: The washing line is designed for high throughput, making it capable of processing large quantities of plastic waste efficiently. This is crucial for meeting the demands of recycling facilities.

Comprehensive Cleaning: The multiple stages of washing and rinsing ensure that the plastic is thoroughly cleaned, resulting in high-quality recycled material that can be used in various applications.

Energy Efficiency: Advanced technologies used in the washing line minimize energy consumption, reducing the overall operational costs and environmental impact.

Durability and Reliability: Made from high-quality materials, the washing line components are designed to withstand the rigors of continuous operation, ensuring long-term reliability and low maintenance costs.

Customization: machinemg.com offers customization options to cater to the specific needs of different recycling facilities, allowing for adjustments in capacity and functionality.

Environmental Impact

Recycling rigid PP and PE plastics using the High Quality Rigid PP PE Plastic Waste Washing Line significantly contributes to environmental sustainability. By converting plastic waste into reusable material, it reduces the amount of plastic that ends up in landfills and oceans. This not only conserves natural resources but also minimizes pollution and its harmful effects on wildlife and ecosystems.

Economic Benefits

Investing in a high-quality washing line can lead to substantial economic benefits for recycling businesses. The production of high-quality recycled plastic can be sold at a premium, and the efficiency of the washing line reduces operational costs. Furthermore, as regulatory pressures increase for sustainable practices, businesses equipped with advanced recycling technology will be better positioned to comply with environmental regulations and capitalize on market opportunities.

Conclusion

The High Quality Rigid PP PE Plastic Waste Washing Line from machinemg.com represents a significant advancement in the field of plastic recycling. Its comprehensive, efficient, and environmentally friendly design makes it an essential tool for modern recycling operations. By investing in such advanced technology, recycling facilities can enhance their processing capabilities, reduce environmental impact, and achieve greater economic returns. As the world continues to grapple with plastic waste, innovations like this washing line offer a promising solution for a more sustainable future.

#Plastic Waste Washing Line#wpc production line#wpc machine#wpc extrusion line#waste shredder machine#plastic crusher machine#wood plastic composite machine

0 notes

Text

youtube

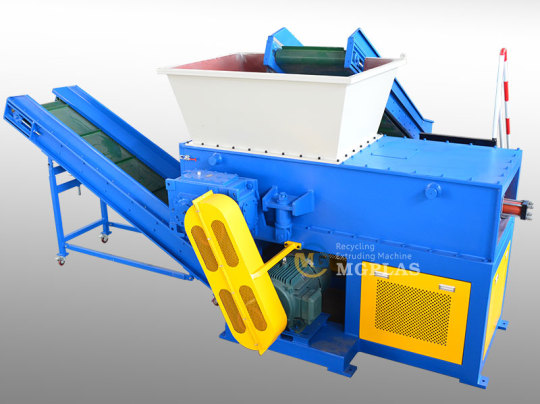

Double shaft plastic pallet shredding machine for recycling waste plastic pallets

Double shaft type plastic pallet shredding machine recycling waste plastic pallets.

Plastic pallet shredding machine, with double shaft design, is used to reduce plastic pallets into smaller pieces through a mechanical shredding process. This double shaft shredding machine is designed to shear and cut the sturdy plastic pallets, which are typically made of high-density polyethylene (HDPE) or polypropylene (PP).

If any interest or enquiry, please contact us freely for machine details and best proposal quotation of the plactic pallet shredding machine.

Mr.Gram Gao

WhatsApp & WeChat: +86 137 7625 5760

[email protected] https://www.machinemg.com

Thanks a lot for your time to watch our videos.

Please subscribe our channel for coming videos of new machines and 1% discount.

0 notes

Text

Key Components of the PET Bottle Washing Line

Our innovative solutions are designed to efficiently clean and process PET bottles, ensuring high-quality recycled materials for a range of applications. Explore our PET Bottle Washing Lines to optimize your recycling efforts and promote environmental sustainability.

0 notes

Text

Enhance your plastic recycling efforts with our high-performance Plastic Crusher Machines at Machinemg.com. Our machines are designed to crush plastic waste into smaller, manageable pieces, facilitating easier recycling and processing. Explore our range of Plastic Crusher Machines to improve efficiency and sustainability in your recycling operations.

0 notes

Text

China Good Quality Rigid Plastic Shredder Machine for Sale: A Comprehensive Guide

In the modern era of industrial production, the demand for efficient and reliable plastic waste management solutions has never been higher. Among the leading solutions is the rigid plastic shredder machine, a critical asset for recycling and waste management facilities. For businesses seeking top-notch quality at competitive prices, machinemg.com offers exceptional rigid plastic shredder machines made in China. This article delves into the features, benefits, and reasons why investing in these machines can be a game-changer for your operations.

What is a Rigid Plastic Shredder Machine?

A rigid plastic shredder machine is specifically designed to process tough, durable plastic materials that are commonly used in a variety of industries. These machines can handle various plastic products, including pipes, drums, containers, and large molded parts, breaking them down into smaller, manageable pieces for recycling or disposal.

Key Features of Rigid Plastic Shredder Machines

High Durability:

Constructed with robust materials, these machines can withstand heavy-duty use, ensuring longevity and consistent performance.

Powerful Shredding Capability:

Equipped with strong, sharp blades, the shredder efficiently cuts through rigid plastics, significantly reducing their volume.

User-Friendly Design:

Designed for ease of use, these machines come with intuitive controls and safety features to protect operators.

Energy Efficiency:

Advanced engineering ensures that the machines use energy efficiently, reducing operational costs while maintaining high productivity.

Versatility:

Suitable for a wide range of plastic materials, making them an ideal choice for various industries.

Benefits of Using Rigid Plastic Shredder Machines

Environmental Impact:

By converting large plastic waste into smaller pieces, these machines facilitate recycling, reducing landfill waste and promoting a circular economy.

Cost Savings:

Recycling plastic waste on-site can significantly lower disposal costs and create a new revenue stream through the sale of shredded materials.

Space Efficiency:

Shredding reduces the volume of plastic waste, saving valuable space in storage and transportation.

Compliance:

Helps businesses comply with environmental regulations by managing waste responsibly and sustainably.

Why Choose machinemg.com?

Quality Assurance:

Machines from machinemg.com are manufactured to the highest standards, ensuring reliability and excellent performance.

Competitive Pricing:

Offering top-quality machines at competitive prices, making it a cost-effective solution for businesses of all sizes.

Expert Support:

The company provides comprehensive support, from choosing the right machine to installation and maintenance, ensuring a seamless experience.

Proven Track Record:

With a history of satisfied customers and successful installations, machinemg.com is a trusted name in the industry.

Conclusion

Investing in a high-quality rigid plastic shredder machine from machinemg.com is a smart move for businesses looking to enhance their waste management practices, improve efficiency, and contribute to environmental sustainability. With robust features, significant benefits, and the backing of a reputable supplier, these machines are a valuable addition to any industrial setup. Visit machinemg.com today to explore their range of shredder machines and take the first step towards a more efficient and eco-friendly operation.

#wpc production line#wpc machine#Plastic crusher machine#Waste shredder machine#Plastic shredder machine

0 notes

Text

Enhance your plastic recycling efforts with our high-performance Plastic Crusher Machines at Machinemg.com. Our machines are designed to crush plastic waste into smaller, manageable pieces, facilitating easier recycling and processing.

0 notes

Text

Good Quality WPC Wall Cladding Production Line

Explore the future of manufacturing with our advanced WPC production line at Machinemg.com. Our state-of-the-art equipment is designed to revolutionize the wood-plastic composite industry, offering unparalleled efficiency, precision, and sustainability.

0 notes

Text

Our state-of-the-art equipment is designed to revolutionize the wood-plastic composite industry, offering unparalleled efficiency, precision, and sustainability. Discover how our WPC production line can transform your business and elevate your products to new heights of excellence.

0 notes

Text

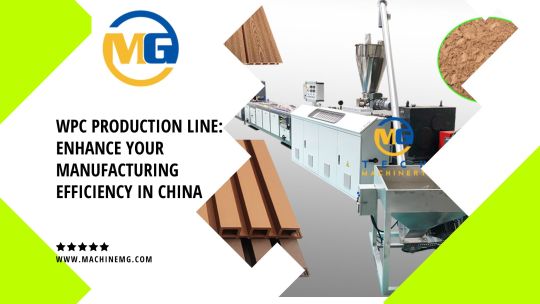

WPC Production Line: Enhance Your Manufacturing Efficiency in China

In recent years, the demand for Wood-Plastic Composite (WPC) products has surged globally, driven by their eco-friendly nature, durability, and versatility. China, as a leading manufacturing hub, offers cutting-edge WPC Production Lines that empower businesses to meet this escalating demand efficiently. This article explores the significance of WPC Production Lines in China and how they can enhance manufacturing efficiency.

Understanding WPC Production Lines

WPC Production Lines are sophisticated manufacturing systems designed to produce high-quality Wood-Plastic Composite materials. These lines integrate various processes, including material mixing, extrusion, shaping, cooling, and finishing, to create WPC boards, profiles, and other products.

Advantages of WPC Production Lines in China

1. Advanced Technology Integration

Chinese WPC Production Lines feature state-of-the-art technologies such as twin-screw extruders, automatic control systems, and precision tools. This integration ensures consistent product quality, uniformity, and customization capabilities.

2. High Production Capacity

With China's robust manufacturing infrastructure, WPC Production Lines can operate at high speeds and volumes, meeting large-scale production requirements. This scalability is vital for businesses catering to diverse market demands.

3. Cost Efficiency

Chinese WPC Production Lines offer cost-effective solutions due to competitive labor costs, efficient supply chains, and optimized production processes. This affordability enhances profitability and competitiveness in the global WPC market.

4. Quality Assurance

Leading WPC Production Lines in China adhere to stringent quality standards and certifications, ensuring that manufactured products meet industry specifications and customer expectations. This focus on quality strengthens brand reputation and customer trust.

5. Innovation and Customization

Chinese manufacturers continually innovate WPC Production Line technologies, offering customizable solutions to suit specific product designs, sizes, colors, and performance requirements. This flexibility enables businesses to differentiate their offerings and stay ahead in the market.

Key Components of WPC Production Lines

Material Handling Systems: Efficient handling of raw materials such as wood fibers, plastic resins, additives, and colorants is crucial for consistent WPC quality.

Extrusion Units: Twin-screw extruders with precise temperature and pressure control ensure uniform mixing, melting, and shaping of WPC materials.

Cooling and Sizing Equipment: Rapid cooling and accurate sizing mechanisms maintain product dimensions, surface finish, and structural integrity.

Surface Treatment and Finishing: Surface embossing, sanding, coating, and other finishing processes enhance WPC aesthetics, durability, and weather resistance.

Automation and Control Systems: Automated controls, sensors, and monitoring devices optimize production parameters, reduce waste, and enhance operational efficiency.

Conclusion

Investing in WPC Production Lines in China offers significant advantages for manufacturers seeking to streamline production, improve product quality, and expand market reach. The combination of advanced technologies, cost efficiency, quality assurance, and customization capabilities makes Chinese WPC Production Lines a strategic choice for enhancing manufacturing efficiency in the dynamic WPC industry.

1 note

·

View note