Text

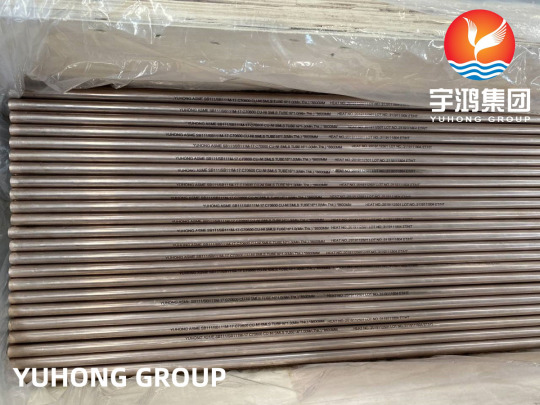

ASTM A269/ASME SA269 STAINLESS STEEL TUBE

ASTM A269/ASME SA269 stainless steel tube covers the nominal wall thickness grades of stainless steel pipe specified in the standard for general corrosion resistance and low or high-temperature applications. Usually applied as boiler, superheater, and heat-exchanger tubes.

ASTM A269/ASME SA269 STAINLESS STEEL TUBE PROVIDED BY YUHONG

ASTM A269/ASME SA269 Stainless Steel Tube

YUHONG GROUP provides the best ASTM A269/ASME SA269 Stainless steel tubes including seamless tubes, welded tubes, and U tubes.

TP304/TP304L/TP304H Stainless Steel Tube

FEATURES/CHARACTERISTICS OF ASTM ASTM A269/ASME SA269 STAINLESS STEEL TUBE

ASTM A269/ASME SA269 stainless steel pipe has good plasticity and low strength and hardness. At the same time, it has a certain toughness, but it is not ferromagnetic.

ASTM A269/ASME SA269 is not only resistant to oxidative acid medium corrosion, but also resistant to sulfuric acid, phosphoric acid, formic acid, acetic acid, urea, etc. if it contains Mo, Cu, and other elements. If the carbon content of this type of steel is less than 0.03% or contains Ti and Ni, its resistance to intergranular corrosion can be significantly improved.

0 notes

Text

ASTM A249/ASME SA249 STAINLESS STEEL TUBE

ASTM A249/ASME SA249 stainless steel tube covers nominal wall thicknesses welded and heavily cold-worked welded pipes made of the following materials

Various grades of austenitic steel for boilers, superheaters, heat exchangers, or condenser pipes.

ASTM A249/ASME SA249 STAINLESS STEEL TUBE PROVIDED BY YUHONG

ASTM A249/ASME SA249 Stainless Steel Tube

YUHONG GROUP provides the best ASTM A249/ASME SA249 Stainless steel tubes including welded austenitic alloy steel boiler tube, superheater and heat exchanger tube, and U bending tube.

TP304/TP304L Stainless Steel Tube

TP316/TP316L Stainless Steel Tube

ASTM A249 TUBING FEATURES

ASTM A249/ASME SA249 stainless steel tube has good plasticity, low strength, and hardness. At the same time, ASTM A 249 also has a certain toughness, but it is not ferromagnetic.

ASTM A249/ASME SA249 stainless steel tube is not only resistant to oxidative acid medium corrosion, but also resistant to sulfuric acid, phosphoric acid, formic acid, acetic acid, urea, etc. if it contains Mo, Cu, and other elements. If the carbon content of ASME SA249/ASTM A249 tubing is less than 0.03% or contains Ti and Ni, the resistance of this SS steel tube to intergranular corrosion can be significantly improved.

ASME SA249/ ASTM A249 TP304 SPECIFICATIONS

ASTM A249 Standard

ASTM A249/ASME SA249

Tube Type

Welded Tube

Finishes

Annealing Pickling, Bright Annealing

Outside Diameter

6 Up To 304.8 Mm

Thickness

0.5 Up To 6 Mm

Application

Heat Exchanger System

GRADES OF SPECIFICATION ASTM A249/SA 249

Grade

Specification

Stainless 304/304L, 304/304H

ASTM A249/SA249

Stainless 309S

ASTM A249/SA249

Stainless 310S

ASTM A249/SA249

Stainless 316/316L, 316/316H

ASTM A249/SA249

Stainless 317/317L

ASTM A249/SA249

Stainless 321/321H

ASTM A249/SA249

Stainless 347/347H

ASTM A249/SA249

ASME SA249/ ASTM A 249 TUBING CHEMICAL COMPOSITION

Grade

UNS

Composition, %

Design

C

Mn

P

S

Si

Cr

Ni

Mb

Ti

Nb

N

Cu

Ce

B

Al

TP304

S30400

0.08

2

0.045

0.03

1

18.0–20

8.0–11

. . .

. . .

. . .

. . .

. . .

. . .

TP304L

S30403

0.035

2

0.045

0.03

1

18.0–20

8.0–13

. . .

. . .

. . .

. . .

. . .

. . .

TP304H

S30409

0.04 – 0.1

2

0.045

0.03

1

18.0–20

8.0–11

. . .

. . .

. . .

. . .

. . .

. . .

TP310S

S31008

0.08

2

0.045

0.03

1

24.0- 26

19.0- 22

0.8

. . .

. . .

. . .

. . .

. . .

TP310H

S31009

0.04 – 0.1

2

0.045

0.03

1

24.0–26

19.0–22

. . .

. . .

. . .

. . .

. . .

TP310H

S31035

0.04 – 0.1

0.6

0.025

0.015

0.4

21.5–23.5

23.5–26.5

. . .

. . .

0.40- 0.6

0.20- 0.3

2.5- 3.5

. . .

0.002- 0.008

TP316

S31600

0.08

2

0.045

0.03

1

16.0–18

10.0–14

2.00–3

. . .

. . .

. . .

. . .

. . .

TP316L

S31603

0.035

2

0.045

0.03

1

16.0–18

10.0–14

2.00–3

. . .

. . .

. . .

. . .

. . .

TP316H

S31609

0.04 – 0.1

2

0.045

0.03

1

16.0–18

10.0–14

2.00–3

. . .

. . .

. . .

. . .

. . .

TP317

S31700

0.08

2

0.045

0.03

1

18.0–20

11.0–15

3.0–4

. . .

. . .

. . .

. . .

. . .

TP317L

S31703

0.035

2

0.045

0.03

1

18.0–20

11.0–15

3.0–4

. . .

. . .

. . .

. . .

. . .

TP321

S32100

0.08

2

0.045

0.03

1

17.0–19

9.0–12

. . .

Ti 5 × (C+N) min, 0.70 max

. . .

0.1

. . .

. . .

TP321H

S32109

0.04 – 0.1

2

0.045

0.03

1

17.0–19

9.0–12

. . .

4(C+N) min; 0.70 max

. . .

0.1

. . .

. . .

TP321H

S32654

0.02

2.0-4

0.03

0.005

0.5

24.0–25

21.0–23

7.0-8

. . .

. . .

0.45- 0.55

0.30-0.6

. . .

TP321H

S33228

0.04 – 0.08

1

0.02

0.015

0.3

26.0–28

31.0–33

. . .

. . .

0.60- 1

. . .

. . .

0.05 – 0.1

0.025

TP321H

S34565

0.03

5.0-7

0.03

0.01

1

23.0–25

16.0–18

4.0-5

. . .

0.1

0.40- 0.6

. . .

. . .

TP347

S34700

0.08

2

0.045

0.03

1

17.0–19

9.0–13

. . .

. . .

See Spec

. . .

. . .

. . .

TP347H

S34709

0.04 – 0.1

2

0.045

0.03

1

17.0–19

9.0–13

. . .

. . .

See Spec

. . .

. . .

. . .

TP348

S34800

0.08

2

0.045

0.03

1

17.0–19

9.0–13

. . .

. . .

. . .

. . .

. . .

. . .

Co 0.20, Ta 0.10

TP348H

S34809

0.04-0.10

2

0.045

0.03

1

17.0–19.0

9.0–13

. . .

. . .

. . .

. . .

. . .

. . .

. . .

Co 0.20, Ta 0.10

ASME SA249/ ASTM A 249 TUBING SIZE TOLERANCE

OD

WTH

L

ASTM A249

<25.4mm

±0.10mm

±10.00%

OD<50.8mm +3.0mm -0mm

≥25.4mm-38.1mm

±0.15mm

≥38.1mm-50.8mm

±0.20mm

≥50.8mm-63.5mm

±0.25mm

≥63.5mm-76.2mm

±0.30mm

OD≥50.8mm +5.0 -0mm

≥76.2mm-101.6mm

±0.38mm

≥101.6mm-190.5mm

+0.38mm -0.64mm

≥190.5mm-228.6mm

+0.38mm -1.14mm

WHAT IS ASME ASTM SA 249 STAINLESS STEEL TUBE?

ASME ASTM SA 249 stainless steel tubes are used in a variety of applications, including boiler, superheater, heat exchanger, and condenser systems. These a249 stainless steel tubes are manufactured through a welding process and are typically made from austenitic stainless steel, although other stainless steel grades may also be used.

The astm a249 tp304 specification outlines the requirements for the manufacturing, dimensions, mechanical properties, and testing of these welded stainless steel tubes. It provides guidelines for various aspects, including tube dimensions, tolerances, chemical composition, mechanical properties, and nondestructive testing methods.

The stainless steel tubes produced under the ASME ASTM SA 249 standard are designed to withstand high temperatures, corrosion, and pressure in demanding industrial environments. ASME sa249 are known for their excellent corrosion resistance, strength, and durability, making them suitable for applications where reliability and longevity are essential.

Common stainless steel grades used in ASME ASTM SA 249 tubes include 304, 304L, 316, 316L, 317, and 321. These grades offer varying levels of corrosion resistance, mechanical properties, and heat resistance, allowing for the selection of the most appropriate grade based on the specific application requirements.

Overall, ASME ASTM SA 249 stainless steel tubes meet stringent industry standards, ensuring that they are manufactured to the specified dimensions, quality, and performance criteria. These ASTM a249 tubings play a critical role in various industrial sectors, providing efficient and reliable solutions for heat exchanger tube manufacturers and fluid transportation systems.

ASTM A249 VS A269 STAINLESS STEEL TUBE

Applications: ASTM A249 tubes are primarily intended for general corrosion-resisting and low- or high-temperature service, including heat exchangers, condenser tubes, and other applications. ASTM A269 tubes, on the other hand, are specifically designed for general service applications requiring high corrosion resistance and mechanical properties.

Manufacturing Process: ASTM A249 tubing is produced through the welding process, while a269 tubing can be either welded or seamless. Seamless stainless steel tubes are typically preferred for high-pressure or critical applications.

Dimensional Tolerances: ASTM a249 tubing has more lenient dimensional tolerances compared to ASTM A269. A269 tubes have tighter tolerances for outside diameter, wall thickness, and length, ensuring greater precision and consistency.

Surface Finish: ASTM A269 specifies stricter requirements for the surface finish of tubes, particularly for applications where cleanliness and smoothness are important, such as in the pharmaceutical and food processing industries.

0 notes

Text

C70600 COPPER ALLOY STEEL TUBE

C70600 pipe/tube using UNS C70600 copper-nickel alloy is primarily used in seawater service as forged and machined valve and pump components, fittings, and hardware. The alloy UNS C70600 pipe is also used in applications where high corrosion resistance is required, and where chloride stress corrosion cracking prevention measures prevent the use of stainless steel. Just like UNS C71500, copper alloy UNS C70600 tubes are seamless Copper Nickel Alloy Tubes of standard specifications for Water Desalting Plants.

UNS C70600 COPPER NICKEL PIPE/TUBE SPECIFICATION

Model NO.

C70600 C71500

Standard

ASTM

Od

6.35-406mm

Wt

0.5-80mm

Length

1-6m or as the Customer requires

Transport Package

Standard Export Packing

Specification

Pure Cu99.9%

Trademark

Tongmao

origin

China

HS Code

7411101900

SB111 C70600 TUBE PROPERTIES

Copper or Alloy

Copper

Tin

Aluminum

Nickel incl Cobalt

Lead

lron

Zinc

Manganese

Arsonic

Antimony

Phosphonus

Chromium

Elements

C10100

99.99 min@0

002 max

0.0010 max

0005 max

0.0010 max

0.0001 max

0.00005 max

0.0005 max

0.0004 max

0.0003 max

0.0001 max

C10200

99.95 min_

C10300

99.95 minE

0.001-0.005

C10800

99.95 minF

0.005-0.012

C12000

99.90 min

0.004-0.012

C12200

99.9 min

0.015-0.040

C14200

99.40 min

0.15-0.50

0.015-0.040

C19200

98.5 min

0.8-1.2

0.20 max

0.01-0.04

C23000

B4.0- 86.0

0.05

0.05 max

remainder

C28000

59.0- 63.0

0.09

0.07 max

remainder

C44300

70.0-73.0

0.9 -1.2

0.07

0.06 max

remainder

0.02-0.06

C44400

70.0-73.0

0.9 -1.2

0.07

0.06 max

remainder

0.02 -0.10

C44500

70.0-73.0

0.9 -1.2

0.07

0.06 max

remainder

0.02 -0.10

C60800

remainder

5.0-6.5

0.1

0.10 max

0.02-0.35

C61300

remainder

0.20 -0.50

6.0-7.5

0.15 max

0.01

2.0-3.0

0.10max

0.20 max

0.015 max

C61400

remainder

6.0-8.0

0.01

1.5-3.5

0.20 max

1.0 max

0.015 max

C68700

76.0-79.0

1.8-2.5

0.07

0.06 max

remainder

0.02-0.06

C70400

remainder

4.8-6.2

0.05

1.3-1.7

1.0max

0.30-0.8

C70600

remainder

9.0-11.0

0.05

1.0-1.8

1.0 max

1.0 max

C70620

86.5 min

9.0-11.0

0.02

1.0-1.8

0.50 max

1.0 max

0.02 max

C.05 max

C71000

remainder

19.0-23.0

0.05/

0.50-1.0

1.0 max"

1.0 max

C71500

remainder

29.0-33.0

0.05/

0.40-1.0

1.0 max

1.0 max

C71520

65.0 min

29.0-33.0

0.02

0.40-1.0

0.50 max

1.0 max

0.02 max

C .05 max

C71640

remainder

29.0-32.0

0.05*

1.7-2.3

1.0 max"

1.5-2.5

C.06 max

C72200

remainder

15.0-18.0

0.054

0.50-1.0

1.0 max"

1.0 max

0.30-

UNS ALLOY C70600 PIPE HIGHLIGHTS

The properties of copper-nickel tube alloy C70600 are usually supplied as redrawn tubes in the annealed condition. The combination of strength and good ductility provides excellent formability for ASTM B111 tubes.

0 notes

Text

C44300 COPPER ALLOY STEEL TUBE

ASTM B111 C44300 tube is widely used in the surface condenser, heat exchanger, and evaporators. The C44300 tube offers high strength, excellent corrosion resistance, and good creep resistance at elevated temperatures.

SB111 C44300 TUBE SPECIFICATION

COUNTRY

STANDARD

NAME

ASTM

ASTM B111

Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule Stock

GB/T

GB/T8890

Seamless Copper Alloy Heat Exchanger Tubes

BS

BS2871

Copper and Copper Alloys Tubes

JIS

JIS H3300

Copper and Copper Alloy-Seamless Pipes and Tubes

DIN

JIS H3300

Wrought Copper and Copper Alloy Tubes for Condensers and Heat Exchangers

SB111 C44300 TUBE CHEMICAL COMPOSITION

Composition

Elements

Cu(1)

Pb

Sn(2)

Zn

Fe

As

(1)CU+ Sum of Named Elements 9.69 min.

(2)For tubular produts the minimum Sn content may be 0.9%

Min (%)

70

0.8

0.02

Max (%)

73

0.07

1.2

Rem

0.06

0.06

SB111 C44300 TUBE PHYSICAL PROPERTIES

Melting Point- Liquidus°F

1720

Melting Point. Solidus °F

1650

Density lb/coin. at 68°F

0.308

Specific Gravity

8.53

Electrical Conductivity% IACS at 68°F

25

Thermal ConductivityBtu/sq ft/ ft hr/°F at 68°F

64

Coefficient of Thermal Expansion 68-57210 to -6 power per °F (68- 572*F)

11.2

Specific Heat CapacityBtu/lb/F at 68°F

0.09

Modulus of Elasticity in Tensionksi

16000

Modulus of Rigidityksi

6000

SB111 C44300 TUBE HIGHLIGHTS

SB111 C44300 material has the following benefits: Durability – The structure and chemical composition of an SB111 C44300 make it durable. This kind of ASTM B111 tube can last up to 10 years, depending on where you are using them and the frequency of use.

WHAT IS THE DIFFERENCE BETWEEN SB111 C44300 TUBE AND THE SB111 C70600 PIPE?

The main difference between the SB111 C44300 tube and astm b111 c70600 lies in the material composition and their specific applications. Here are the key distinctions:

SB111 c44300 and c70600 Material Composition:

SB111 C44300 Tube: C44300 is a copper alloy pipe known as Admiralty Brass, which primarily consists of copper (Cu) with small amounts of zinc (Zn) and trace elements. It is a non-ferrous alloy with good corrosion resistance and excellent thermal conductivity.

SB111 C70600 Pipe: C70600 is a copper-nickel alloy known as 90/10 Copper-Nickel, which contains approximately 90% copper (Cu) and 10% nickel (Ni). It also includes small amounts of other elements such as iron (Fe) and manganese (Mn). This alloy offers high resistance to corrosion, particularly in marine environments, and has good mechanical properties.

C44300 and C70600 tubes Applications:

SB111 C44300 Tube: C44300 tubes are commonly used in heat exchangers, condensers, and other applications where efficient heat transfer and resistance to corrosion are required, such as heat exchanger pipes. They are suitable for use in both freshwater and seawater environments.

SB111 C70600 Pipe: C70600 pipes, due to their excellent corrosion resistance, are widely used in marine applications such as seawater cooling systems, shipbuilding, and offshore installations. They are specifically designed to withstand the harsh conditions of saltwater environments.

C44300 and C70600 Mechanical Properties:

SB111 C44300 Tube: Admiralty Brass (C44300) has good formability, making it easy to bend and shape during installation. It possesses moderate strength and can handle moderate pressures and temperatures.

SB111 C70600 Pipe: 90/10 Copper-Nickel (C70600) has higher strength compared to Admiralty Brass. It exhibits good mechanical properties, including high tensile and yield strength, making it suitable for applications requiring higher pressure and temperature ratings.

It is important to consider the specific requirements of the application, including the operating conditions, fluid characteristics, and corrosion resistance needed, when selecting between the SB111 C44300 tube and the SB111 C70600 pipe. Consulting the appropriate specifications and guidelines for the intended use is crucial to ensure the optimal choice of material.

WHAT ARE THE BENEFITS OF SB111 C44300?

SB111 C44300, also known as Admiralty Brass, offers several benefits in various applications:

Corrosion Resistance: C44300 exhibits excellent resistance to corrosion, making it suitable for use in both freshwater and seawater environments. This property ensures the longevity and reliability of components made from this alloy.

Thermal Conductivity: Admiralty Brass has high thermal conductivity, allowing for efficient heat transfer. This makes it ideal for heat exchangers, condensers, and other applications where effective thermal management is crucial.

Formability: c44300 tube is highly formable, making it easy to bend and shape during installation. This property facilitates the manufacturing process and enables the creation of intricate designs and configurations.

Reliability: Components made from SB111 C44300 are known for their durability and reliability. The alloy's mechanical properties provide sufficient strength and resistance to withstand moderate pressures and temperatures.

Cost-Effectiveness: Admiralty Brass is often considered a cost-effective choice due to its availability, relatively low material cost, and ease of fabrication. This makes it an attractive option for various industries.

0 notes

Text

ASTM B111/ ASME SB111 COPPER ALLOY STEEL TUBE

ASME SB111 C70600 Tube Copper-nickel alloy that resists seawater corrosion and has high antifouling properties against marine microorganisms. You can find ASTM B111 tubes using ASME SB111 alloy are widely used in shipbuilding repair, petrochemical, natural gas, and other marine engineering and related industries. ASME SB111 materials, like SB111 C7060, have good corrosion resistance, especially in seawater.

ASTM B111/ ASME SB111 TUBES PROVIDED BY YUHONG

ASTM B111/ ASME SB111 Copper Alloy Steel Tube

YUHONG GROUP provides the best ASTM B111/ ASME SB111 tubes including straight tube, U tube for heat exchanger, boiler, and superheater.

C70600 Copper Alloy Steel Tube

C71500 Copper Alloy Steel Tube

C44300 Copper Alloy Steel Tube

C12200 Copper SMLS Tube

68700 Copper Alloy Steel Tube

ASTM B111 TUBES FEATURES

The characteristics of ASTM B111/ ASME SB111 copper alloys are mainly good electrical and thermal conductivity and have a certain strength (higher than aluminum alloys and magnesium alloys). You can find ASTM B111/ ASME SB111 tubes widely used in electronic power and other fields with high electrical conductivity requirements, such as various electrodes, electrical contacts, and high-strength wires;

The ASTM B111/ ASME SB111 tubes are also used in fields with high heat dissipation requirements such as heat dissipation components or devices, such as molds, thermonuclear reactor radiators, air conditioning condenser pipes, etc.

ASTM B111/ ASME SB111 TUBES SPECIFICATIONS

ASTM B111 Specification

ASTM B111/ASME SB111

ASTM B111 Copper&Copper Alloy Tube Type

Condensers, Evaporators, Heat Exchangers

ASTM B111 Tube Size in Outside Diameter

Up to 3 1⁄8 in. [80 mm] inclusive

ASTM B111 Tubing Length

Up to 6 mater,custom cut lengths

ASTM B111 Heat Exchanger Tube Thickness

Up to 0.120 inch[3 mm] inclusive

ASTM B111/ ASME SB111 TUBES CHEMICAL COMPOSITION

UNS No.

ASTM B111 Copper&Copper Alloy Tube (%)

Cu

Ni Incl Co

Ti

Al

Lead Max

Fe

Zn

Mn

As

Other Named Elements

C44300

70.0-73.0

...

0.9-1.2

...

0.07

0.06 max

reminder

...

0.02-0.06

...

C68700

76.0-79.0

4.8-6.2

...

1.8-2.5

0.07

0.06 max

reminder

...

0.02-0.06

...

C70600

reminder

9.0-11.0

...

...

0.05

1.0-1.8

1.0 max

1.0 max

...

...

C71500

reminder

29.0-33.0

...

...

0.05

0.4-1.0

1.0 max

1.0 max

...

..,

C71640

reminder

29.0-33.0

...

...

0.05

1.7-2.3

1.0 max

1.5-2.5

...

C.06 max S.03

ASTM B111/ ASME SB111 TUBES TENSILE REQUIREMENT

UNS No.

Temper Designation

Tensile Strength

Yield Strengh

Elongation

Code

Name

min MPa

min MPa

in 50mm min%

C44300

O61

annealed

45

15

...

C68700

O61

annealed

50

18

...

C70600

O61

annealed

40

15

...

C70600

H55

light-drawn

45

35

...

C71500

O61

annealed

46

16

...

C71640

O61

annealed

72

50

15

C71640

HR50

light-drawn

63

25

...

ASTM B111 EQUIVALENT STANDARD

Product Description

ASTM B111

JIS H3300

DIN

Admiralty Brass Tube/Pipe

C44300

C4430T

DIN17660 CuZn28SnI

2.0470

Al-Brass Tube/Pipe

C67800

C6870T

DIN 17660 CuZn20Al2

2.0460

Copper Nickel 90/10 Tube/Pipe

C70600

C7060T

DIN 17664 CuNi10FeMn

2.0872

Copper Nickel 70/30 Tube/Pipe

C71500

C7150T

DIN17664 CuNi30MnFe

2.0882

ASTM B111 ASME SB 111 TUBES TYPICAL APPLICATIONS

ASTM B111 and ASME SB 111 are specifications that define the requirements for seamless copper and copper alloy tubes used in various applications. These ASTM b111 tubes are typically utilized in industries such as plumbing, HVAC (Heating, Ventilation, and Air Conditioning), refrigeration, and heat exchangers. Here are some typical applications of ASTM B111/ASME SB 111 tubes:

Plumbing Systems: Copper tubes specified under ASTM B111/ASME SB 111 are commonly used in plumbing systems for transporting water and other fluids. They are resistant to corrosion, have excellent heat transfer properties, and are relatively easy to install.

HVAC and Refrigeration: Copper asme sb111 tubes are widely employed in heating, ventilation, air conditioning, and refrigeration systems due to their excellent thermal conductivity. These tubes efficiently carry refrigerants, allowing for effective heat exchange and temperature regulation.

Heat Exchangers: ASTM B111/ASME SB 111 tubes find extensive use in heat exchangers where the transfer of heat between two fluids is required. Their high thermal conductivity ensures efficient heat transfer, making heat exchanger pipes suitable for applications in power plants, chemical processing plants, and industrial machinery.

Oil and Gas Industry: oil field tubing specified under these standards is used in the oil and gas industry for applications such as oil coolers and hydraulic lines. Their corrosion resistance and ability to withstand high pressures and temperatures make them suitable for these demanding environments.

Shipbuilding and Marine Applications: Copper asme sb111 tubes are employed in shipbuilding and marine applications due to their resistance to corrosion in seawater. They are used for various purposes, including piping systems, heat exchangers, and condensers.

Electrical Applications: Copper tubes specified under ASTM B111/ASME SB 111 are also used in electrical applications where their excellent electrical conductivity is required. They are used in busbars, conductors, and other components of electrical systems.

It is important to note that the specific application of ASTM B111/ASME SB 111 tubes may vary depending on the alloy composition and specific requirements of the industry or application. Copper alloy tube manufacturers and engineers typically select the appropriate copper alloy and tube dimensions based on the intended use and the operating conditions of the system.

0 notes

Text

INCOLOY 825/N08825 NICKEL ALLOY PIPE/TUBE

Incoloy 825/UNS N08825 seamless pipe uses nickel-iron-chromium alloy with additions of molybdenum and copper. The chemical composition of the Incoloy 825 tube is designed to provide exceptional resistance to many corrosive environments.

INCOLOY ALLOY 825 SEAMLESS PIPE SPECIFICATION

Rod

Sheet

Strip

Pipe

Wire

Fittings

ASME SB408

ASTM A 240/A480

ASME SB409

ASTM B 163, ASME SB 163

ASTM B408 & ASTM B 564

ASTM B366

ASME SB564

ASME SA 240/SA 480

ASME SB906

ASTM B 407/B 829, ASME SB407/SB 829

ASME Code Case1325

ASME SB366

BS3076 NA15

ASTM B409/B906

ASME Code Case 1325

ASTM B514/B 775, ASMESB 514/SB 775

ASME Code Case1949

BS3075 NA15

BS 3072NA15

ASME Code Case 2339

ASTM B 515/B 751, ASME SB 515/SB751

IS0 9723

SEW 47

BS 3073NA15

ASME Code Case 1325 and 1983, BS3074NA15. SEW 470

IS0 9724

Vdtuv 412 8434, DIN 17460, EN 10095

SEW 470, Vdtuv 412& 434, DIN 17460EN 10028-7 & EN10095

Vdtuv 412 & 434, ISO 6207. DIN 17459

IS09725

INCOLOY 825 MATERIAL MECHANICAL PROPERTIES

Alloy state

Tensile strength N / mm2

Yield strength PO 2N / mm2

Elongation 5%

Brinell hardness HB Max

N08825 Hot Finished

517

172

30

200

N08825 Cold Finished

586

241

30

300

INCOLOY 825 MATERIAL PHYSICAL PROPERTIES

Incoloy 825 Pipe, Alloy 825 Tubing Physical properties

Density / Specific Gravity

8.1 kg / dm3

0.30 Ib / in3

Melting point

1370-1400℃

Incoloy 825/N08825 tube is similar to alloy 800 pipe but has improved resistance to aqueous corrosion. It has excellent resistance to both reducing and oxidizing acids, to stress-corrosion cracking, and to localized attacks such as pitting and crevice corrosion. Alloy 825 tubing is especially resistant to sulfuric acids and phosphoric acids. The Incoloy 825 seamless pipe using nickel steel alloy is used for chemical processing, pollution-control equipment, oil and gas well piping, nuclear fuel reprocessing, acid production, and pickling equipment.

https://www.nickelalloytubes.com/products/incoloy-825n08825-nickel-alloy-pipe-tube.html

0 notes

Text

INCOLOY 800/N08800 NICKEL ALLOY PIPE/TUBE

Incoloy 800 is a solid solution strengthened alloy of nickel, chromium, and iron with small additions of aluminum and titanium. ASTM B163 B407 ASME SB163 SB407 N08800 Incoloy 800 Seamless Tubing is particularly useful for high-temperature equipment in the petrochemical industry because the alloy doesn't form the embrittling sigma phase after long time of exposure at 1200°F (649°C). Excellent resistance to chloride stress-corrosion cracking is another important feature of alloy 800 tube/pipe.

INCOLOY 800/N08800 NICKEL ALLOY PIPE/TUBE EQUIVALENT SPECIFICATION

Country

Body

Grade

USA

UNS

N08800

France

AFTER

Z8NC 32.21

GB

BS

NA 15

Germany

DIN

1.4876

INCOLOY 800 PIPE/TUBE PHYSICAL PROPERTIES

Properties

Metric Units

Density

7,940 kg /m3 @ 20℃

Melting Range

1357-1385. ℃

Electrical Resistivity

0.989 micro-ohm. m @ 20℃

Specific Heat

460y / kg. ℃@ 20℃

Mean Coefficient of Expansion

14. 4x10 / ℃ @ 20℃

Thermal Conductivity

11. 5W / m. @ 20℃

Curie Temperature

-115℃

Modulus of Elasticity

Tension

196.5 Gpa @ 20℃

Torsion

73.4 Gpa @ 20℃

Poisson's Ratio

0 . 339 @ 20℃

UNS N08800/ALLOY 800 SEAMLESS TUBE CHEMICAL COMPOSITION

Element

Incoloy 800

Incoloy 800H

Incoloy 800HT

Nicke

30.00-35.00

30.00-35.00

30.00-35.00

Chromium

19.00-23.00

19.00-23.00

19.00-23.00

Iron

39.50 min

39.50 min

39.50 min

Carbon

0.10 max

0.10 max

0.10 max

Aluminum

0.15-0.60

0.15-0.60

0.25-0.60

Titanium

0.15-0.60

0.15-0.60

0.25-0.60

Aluminum + Titanium

0.30-1.20

0.30-1.20

0.30-1.20

ASTM Grain Size

Not Specified

5 or Coarser

Incoloy 800 Tubes are designed to resist Oxidation and Carburization. The general corrosion resistance is excellent. Incoloy alloy 800 pipe is a widely used material of construction for equipment that must have high strength and oxidation resistance, carburization, and other harmful effects of high-temperature exposure.

https://www.nickelalloytubes.com/products/incoloy-800-n08800-nickel-alloy-pipe-tube.html

0 notes

Text

INCOLOY 800HT/N08811 NICKEL ALLOY PIPE/TUBE

Incoloy 800HT (N08811 1.4959 ) High-temperature alloy has high-temperature hot corrosion and high-temperature abrasion resistance. The Incoloy alloy 800HT pipe can work long-term above 600 ℃ under certain stress conditions.

INCOLOY ALLOY 800HT PIPE EQUIVALENT SPECIFICATION

Country

Body

Grade

USA

UNS

N08800

France

AFTER

Z8NC 32.21

GB

BS

NA 15

Germany

DIN

1.4876

INCOLOY ALLOY 800HT PIPE PHYSICAL PROPERTIES

Properties

Metric Units

Density

7,940 kg /m3 @ 20℃

Melting Range

1357-1385. ℃

Electrical Resistivity

0.989 micro-ohm. m @ 20℃

Specific Heat

460y / kg. ℃@ 20℃

Mean Coefficient of Expansion

14. 4x10 / ℃ @ 20℃

Thermal Conductivity

11. 5W / m. @ 20℃

Curie Temperature

-115℃

Modulus of Elasticity

Tension

196.5 Gpa @ 20℃

Torsion

73.4 Gpa @ 20℃

Poisson's Ratio

0 . 339 @ 20℃

INCOLOY ALLOY 800HT PIPE CHEMICAL COMPOSITION

Element

Incoloy 800

Incoloy 800H

Incoloy 800HT

Nicke

30.00-35.00

30.00-35.00

30.00-35.00

Chromium

19.00-23.00

19.00-23.00

19.00-23.00

Iron

39.50 min

39.50 min

39.50 min

Carbon

0.10 max

0.10 max

0.10 max

Aluminum

0.15-0.60

0.15-0.60

0.25-0.60

Titanium

0.15-0.60

0.15-0.60

0.25-0.60

Aluminum + Titanium

0.30-1.20

0.30-1.20

0.30-1.20

ASTM Grain Size

Not Specified

5 or Coarser

INCOLOY ALLOY 800HT PIPE MECHANICAL PROPERTIES

Incoloy 800H/N08810 Nickel Alloy Pipe/Tube

Yield Strength

Tensile Strength

Elongation

Mpa

Mpa

%

Incoloy 800, 800H, 800HT

Hot Finished Annealed

170

450

30

Incoloy 800

Cold Worked. Annealed

205

520

30

INCOLOY ALLOY 800HT PIPE HIGHLIGHTS

ASTM B163 B407 ASME SB163 SB407 N08811 Nickel Alloy Seamless Tubes Pipes Incoloy 800HT Seamless Tubing can be used at temperatures up to about 1100°C (2010°F). In order to have the best ductility, the 800HT pipe should be used above 700°C (1290°F).

https://www.nickelalloytubes.com/products/incoloy-800ht-n08811-nickel-alloy-pipe-tube.html

0 notes

Text

INCOLOY 800H/N08810 NICKEL ALLOY PIPE/TUBE

Incoloy 800H is a slightly modified version of Incoloy 800 with the 800H grade possessing higher creep and rupture strength. The modification of incoloy alloy 800H pipe is possible because of the closely controlled carbon content and modified heat treatment.

INCOLOY ALLOY 800H PIPE EQUIVALENT SPECIFICATION

Country

Body

Grade

USA

UNS

N08800

France

AFTER

Z8NC 32.21

GB

BS

NA 15

Germany

DIN

1.4876

INCOLOY ALLOY 800H PIPE PHYSICAL PROPERTIES

Properties

Metric Units

Density

7,940 kg /m3 @ 20℃

Melting Range

1357-1385. ℃

Electrical Resistivity

0.989 micro-ohm. m @ 20℃

Specific Heat

460y / kg. ℃@ 20℃

Mean Coefficient of Expansion

14. 4x10 / ℃ @ 20℃

Thermal Conductivity

11. 5W / m. @ 20℃

Curie Temperature

-115℃

Modulus of Elasticity

Tension

196.5 Gpa @ 20℃

Torsion

73.4 Gpa @ 20℃

Poisson's Ratio

0 . 339 @ 20℃

INCOLOY ALLOY 800H PIPE CHEMICAL COMPOSITION

Element

Incoloy 800

Incoloy 800H

Incoloy 800HT

Nicke

30.00-35.00

30.00-35.00

30.00-35.00

Chromium

19.00-23.00

19.00-23.00

19.00-23.00

Iron

39.50 min

39.50 min

39.50 min

Carbon

0.10 max

0.10 max

0.10 max

Aluminum

0.15-0.60

0.15-0.60

0.25-0.60

Titanium

0.15-0.60

0.15-0.60

0.25-0.60

Aluminum + Titanium

0.30-1.20

0.30-1.20

0.30-1.20

ASTM Grain Size

Not Specified

5 or Coarser

INCOLOY ALLOY 800H PIPE MECHANICAL PROPERTIES

Incoloy 800H/N08810 Nickel Alloy Pipe/Tube

Yield Strength

Tensile Strength

Elongation

Mpa

Mpa

%

Incoloy 800, 800H, 800HT

Hot Finished Annealed

170

450

30

Incoloy 800

Cold Worked. Annealed

205

520

30

INCOLOY ALLOY 800H PIPE HIGHLIGHTS

Incoloy 800H(UNS N08810) pipe has a restricted carbon content range of 0.05 to 0.10%, which is in the upper portion of that of Incoloy 800 tube and is annealed at 1149 to 1177℃ (Incoloy 800 is annealed at 983 to 1038℃). These differences impart Incoloy 800H pipe to have higher stress rupture and creep properties than Incoloy 800.

https://www.nickelalloytubes.com/products/incoloy-800h-n08810-nickel-alloy-pipe-tube.html

0 notes

Text

HIGH TEMPERATURE ALLOY FLANGE

High-temperature alloy flanges are mainly used in aerospace and energy fields.

HIGH-TEMPERATURE FLANGE PROVIDED BY YUHONG

As a professional forged flange supplier in China, YUHONG GROUP provides the best ASTM A182/ASME A182 High-temperature alloy flange with material grades F22, F5, F9, F91, etc.

HIGH-TEMP FLANGE FEATURES

The superalloy of high-temp flange has excellent high-temperature strength, good oxidation resistance, and hot corrosion resistance.

And our high-temperature flange has good fatigue properties, fracture toughness, and other comprehensive properties.

https://www.nickelalloytubes.com/products/high-temperature-pipe-tube-flange.html

0 notes

Text

HIGH TEMPERATURE ALLOY FITTING

High-temperature alloy refers to a class of metal materials based on iron, nickel, and cobalt that can work for a long time at high temperatures above 600 °C and under certain stress. Using high-temp alloy known as "superalloys," the alloy hose fittings are mainly used in aerospace and energy fields.

HIGH-TEMP ALLOY HOSE FITTINGS PROVIDED BY YUHONG

YUHONG GROUP provides the best ASTM A234/ASME A234 High-temperature alloy hose fittings with material grade WP5, WP9, WP11, etc.

HIGH TEMPERATURE ALLOY PIPE FITTINGS FEATURES

The superalloy has excellent high-temperature strength, good oxidation resistance, and hot corrosion resistance.

And alloy pipe fittings have good fatigue properties, fracture toughness, and other comprehensive properties.

https://www.nickelalloytubes.com/products/high-temperature-alloy-pipe-tube-fitting.html

0 notes

Text

HASTELLOY FLANGE

As Hastelloy is a corrosion-resistant nickel alloy, the Hastelloy flanges are widely used in the oil and gas industry.

HASTELLOY FLANGE PROVIDED BY YUHONG

Hastelloy flanges are often utilized in chemical processing applications where acid chlorides, solvents, formic and acetic acids, acetic anhydride, wet chlorine gas, hypochlorites, chlorine solutions, and phosphoric acid are used.

As one of the leading industrial flanges manufacturers in China, Yuhong Group can do ASTM B564/ASME SB564 Hastelloy Flange with material grades including Hastelloy C22 flanges, Hastelloy C276 flanges, Hastelloy B2 flanges, Hastelloy B3 flanges, etc.

HASTELLOY FLANGE FEATURES

The Hastelloy flange has high resistance to uniform corrosion, excellent localized corrosion resistance, and excellent resistance to stress corrosion cracking.

Ease of welding and fabrication.

https://www.nickelalloytubes.com/products/hastelloy-pipe-tube-flange.html

0 notes

Text

HASTELLOY FITTING

Hastelloy is a corrosion-resistant nickel alloy that contains other chemical elements such as chromium and molybdenum. Thus, the Hastelloy pipe fittings have high-temperature resistance and excellent corrosion resistance. Hastelloy C276 pipe/tube fittings are one of the Hastelloy grades used in the oil and gas industry.

HASTELLOY TUBE FITTING PROVIDED BY YUHONG

Hastelloy pipe Fitting is often utilized in chemical processing applications where acid chlorides, solvents, formic and acetic acids, acetic anhydride, wet chlorine gas, hypochlorites, chlorine solutions, and phosphoric acid are used.

Yuhong Group can do ASTM B366/ASME SB366 Hastelloy tube fittings with material grade Hastelloy C22, Hastelloy C276, Hastelloy B2, Hastelloy B3, etc.

HASTELLOY PIPE FITTING FEATURES

Hastelloy tube fittings have high resistance to uniform corrosion, excellent localized corrosion resistance, and excellent resistance to stress corrosion cracking.

Ease of welding and fabrication.

https://www.nickelalloytubes.com/products/hastelloy-pipe-tube-fitting.html

1 note

·

View note