Text

How Vital Is Computer Keyboard?

Keyboard is the primary and most integrated external part of any computer. Despite the recent advances in mouse, on screen sparse graphics, and virtual specs, the keyboard remained central to human-computer interaction up to the present.

While all key-based text entry devices developed from the now ancient typewriter, the keyboard as a device for electromechanical data entry and communication, largely inherited the layouts and the utility of two devices: teleprinters or teletypes and keypunches.

Teleprinter-like devices were used as early as the 1870s to simultaneously type and transmit stock market text data from the keyboard across telegraph lines to stock ticker machines to be immediately copied and displayed onto ticker tape. Even much earlier, the first keypunch device was invented which soon evolved to include keys for text and number entry akin to normal typewriters by the 1930s. Electric typewriter keyboards were incorporated in the development of the earliest computers and also used in data entry onto magnetic tape and data output.

For most of the 20th century, the keyboard on the teleprinter played a strong role in point-to-point and point-to-multipoint communication while the keyboard on the keypunch device played a strong role in data entry and storage for just as long.

A basic computer keyboard nowadays functions as a peripheral input device that uses an arrangement of buttons or keys to act as mechanical levers or electronic switches. It has been the main input method for computers until supplemented by the computer mouse in the 1980s. In normal usage nowadays, a keyboard is used as a text entry interface for typing text, numbers, and symbols into application software such as a word processor, web browser or social media app.

Typically, keyboard keys or buttons produce characters that correspond to the symbol engraved or printed on them when pressed. In much recent computer technology, each button can produce a number of characters depending on the scan code of the software or the computer program. Most recent computer software can now run virtual keyboards on touchscreen computers.

The most commonly used type of keyboard nowadays are membrane waterproof keyboard Australia. They consist of a flexible, one-piece printed silicone membrane that has the key pattern printed directly on it. The underside of this membrane is printed with specialized ink that conducts electricity. When a user presses a key on a membrane, the upper layer makes contact with conductive traces located below the keyboard underneath a small air gap. This allows a very mild electrical current to flow, and that's what registers the keystroke.

Membrane waterproof keyboard in Australia are durable and water resistant. Being crafted using flexible, waterproof materials, they are resistant to liquid and dirt intrusion. Membrane keyboards are not just that practical but affordable as well.

A hip nowadays is a waterproof keyboard in Australia. It makes it easy to connect custom membrane QWERTY keypads to the USB keyboard port of personal computers thereby by converting contact closures to Windows compatible PC USB keyboard codes. This innovative waterproof keyboard in Australia allows customizing of membrane QWERTY keypad by using hard coated polyester films. These films allow unlimited textures ideal for environments that require germicide for a silky smooth feel to your keyboard.

0 notes

Text

Waterproof, washable keyboards that help prevent cross-contamination in medical offices & healthcare facilities, industrial computing, at the office, and even at home where a spill-proof keyboard and mouse can be very handy.

There’s no need to stress if you have a waterproof keyboard. They are resistant to spills, so you can wipe them down and carry them on. Some keyboards have a higher resistance rating than others. These ratings indicate the extent of a keyboard’s resistance to water, dust, and other foreign objects.

Here are some of the best waterproof keyboard.

SteelSeries Apex 3

The Steelseries Apex 3 offers impressive value but still has great performance and durability. This full-size gaming waterproof keyboard uses durable membrane switches with an expected life expectancy of around 20 million presses. You don’t get the click of mechanical keys, but they’re silent and contribute to the waterproofing. You also get a massive removable wrist rest to keep you comfortable for long gaming sessions.

One of the best features of this keyboard is the IP32 waterproof rating. A rating of IP32 means it won’t be affected by vertically dripping water, even if it’s tilted 15 degrees. The rating also means that the Steelseries Apex 3 is protected against dirt and dust getting inside. As a bonus, the Apex 3 also features 10-zone RGB lighting.

Logitech G213

The Logitech G213 is an affordable keyboard with many good features. It uses membrane keys that do a good job of replicating the feel of a fully mechanical switch. There are also media keys, a Game Mode switch, and a dedicated button to toggle the RGB lighting. There are five programmable RGB lighting zones, but the colors are subdued compared to many rivals.

This keyboard also has some handy features like a huge wrist rest and a long, braided cable. According to Logitech, the G213 has a spill resistance of 60 milliliters, so you won’t have to worry about dropping your drink on it. This keyboard is perfect if you want a gaming keyboard that doubles as an office keyboard.

Perixx PERIBOARD-517

The Periboard-517 looks like a regular office keyboard, but it takes waterproofing to another level. It’s IP65 certified, meaning it is protected from water and dust. You can even wash this keyboard, and it has holes at the bottom to drain the excess water. The only caveat is that users cannot get the USB port wet.

Apart from the IP65 certification, the Periboard-517 is a regular office keyboard available in black or full white. It’s tough and affordable, but more suited to a business setting. The membrane keys have an average response, and there isn’t any backlighting, programmable keys, or other features preferred by hardcore gamers.

Corsair K68 Mechanical Gaming Keyboard

The Corsair K68 is better for gaming, but costs double the price of the Periboard-517. It has Cherry MX Red switches with excellent feedback that is favored by top gamers. This keyboard is highly customizable when paired with the ICUE app. There’s per-key RGB lighting, and you can sync it with your mouse, monitor, and other devices. You can also set up macros for certain games to quickly access inventory items or initiate certain commands.

The K68 looks like a regular keyboard but comes with a wrist rest, media keys, and adjustable lighting. The IP32 rating makes it resistant to spills, and there’s silicone protecting the internals and drainage holes at the bottom. The Corsair K68 is durable and has outstanding gaming performance.

0 notes

Text

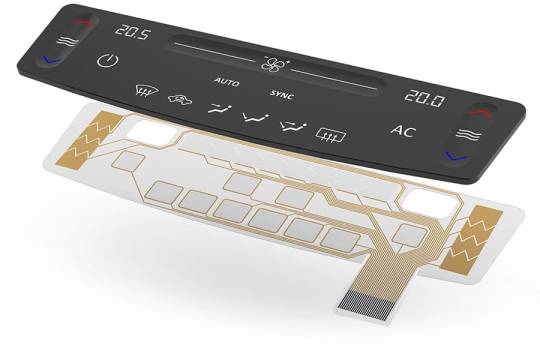

The Intellectual Operation of Comfort and Excellent Sensitivity Touch Switches

The electrical charge disturbs the switch’s own electrical charge upon touching a capacitive switches printing Australia causing a change in capacitance because of the change, the switch can identify when and where the touch occurred. A capacitive switch is a type of touch-controlled electrical switch that operates by measuring change in capacitance that works in the same manner as a typical capacitive smartphone. When touched the surface, a small electrical charge is transferred from body to the switch which subsequently causes a change in capacitance as the switch detects this change, responding with the appropriate command. A capacitive switch consists of three main layers, the graphic overlay, the circuit and the backer that overlay consists of the graphic artwork. This can also include windows, embossing, coatings, adhesives and selective texturing that will either be a flexible printed circuit or a printed circuit board as the backer is the final part. The capacitive switches printing may or may not include an adhesive that must bond to specific substrate and the most common materials used for overlays are plastic, acrylic and glass due to their durability and versatility.

Capacitive touch switches are widely used in aerospace, military equipment, medical instruments, intelligence control, commercial appliances, security products and others. As the capacitive touch interfaces are widely used. From the fields of consumer electronics, household appliances, car security system, light emitted lamps lighting decoration application, solar photovoltaic application, sound and mobile terminal gadgets. The major features of capacitive switches printing beautiful and aesthetically appealing appearance with strong graphic clarity and straight-forward design sealed design ensuring top performance and wear resistance. As the anti-fade and non-deformation with long life span on waterproof and anti-interference as no metal contact with simple structure and low cost in operation comfort in excellent sensitivity. It can realise intellectualisation and operate more conveniently and the reliability can replace in various panels such as metal keypads and membrane keypads. There are no mechanical components in a capacitive switch which resulting in a longer lifespan when compared to their mechanical counterpart additionally, the capacitive switches printing can withstand some of the harshest outdoor environments and if the intrusion of dirt, dust or moisture is a concern, capacitive is probably the best option for an electrical switch.

The key thing to remember about capacitive switches printing is that they require direct contact with a conductive object to operate which is why using a stylus typically won’t work unless it’s a capacitive stylus. Capacitive touch control switches can actually detect the touch of a finger through an insulating material shell such as tempered glass or plastic film that ensures the product’s sensitivity, stability, reliability id not changed. With ambient conditions and long-term use, it has the waterproof and anti-interference ability of capacitive switches printing that does not require the user to touch metal directly. These can eliminate potential safety hazard as the part of touch circuit is placed on the back of insulating material shell. It is easy to make a keypad sealed with the surroundings and has no any mechanical components which doesn’t wear out, long a lifespan and can reduce the later maintenance costs.

0 notes

Text

Things about Capacitive Switches

There are lots of things that people could be grateful for in a better life and way of living, it seems like everything today is one soft touch to happen. This is made possible by the capacitive switches printing. This has gained popularity in recent years as an alternative to membrane switches, mechanical switches, and other input device options. With no mechanical parts to wear down, a slim profile that can be applied to curved surfaces, and intricate backlighting options, the capacitive switches printing offer some more outrageous possibilities for the user interface.

What is a capacitive switch?

Since people are having natural electricity in the body, the capacitive switch can easily be changed just like how an electronic capacitor measure changes in capacitance values when a conductive object like a finger, or a body part, moves along the sensor. The changes in the value are interpreted and registered as an activation of the switch. A capacitive switch can contain a lot of functionality that is not be easily achieved with a normal membrane or even a mechanical switch. capacitive switches printing can have assertiveness sliders, sensitive locations in multiple figures such as a circle, and can have different stages of sensitivity for activation. You also can have choices like a nearness detector combined with a capacitive switch for further functioning advantages. As a capacitive switch is a sensor that senses via a non-conductive surface, thicker substrates can be used such as protection glass, or acrylic materials for a very strong switch. This can also give the capability for added gasketing for extreme environments. It is also possible to complete very complicated backlighting explanations with capacitive switch technologies.

How capacitive switch form?

Just like the membrane switch, the capacitive switch generally needs about layers to function. An overlay panel, a circuit layer, and a backing material are the three layers that form a capacitive switch. The graphical overlay could be any non-conductive material of various thicknesses including glass, polyester, polycarb, acrylic materials, and many other non-conductive materials. The circuit layer can be a thin plastic flex circuit, or a sensing pad laid out on a rigid printed circuit board. The backing material could be a metal back plate, glass, or plastic, or can be attached to the position of your product. It is also possible to have a flexible circuit on the inside of a sealed container with a graphic outside to make sure the safety of the electronics from harsh environments. Capacitive switch structures can be more complicated relying on backlighting opportunities or shielding conditions. However, with its very thin layer of formation, with the exact three layers alone, the construction can be applied easily to a curve surface. It can provide a long life span for no parts could move because of its compactness and even no wearing down. With its great effect, they have progressed dramatically over the past couple of years employing cost effective brands. in the coming years, expect that capacitive will give the technology advancement a better and greater result.

0 notes

Text

Add more to your prototypes

In the Printed Electronics Industry, which involves a number of interdisciplinary areas, product development cycles sometimes require the need for rapid prototyping or small production runs. Often this need is driven by milestones such as a proof-of-concept, the need to provide a working product demo to your client or you simply have a requirement for small quantities of high-quality graphic panels or labels.

Membrane switch overlay prototypes can also be produced as prototypes, which in essence is a small production run. The Graphic Overlay layer; The graphic overlay is the visual interface component of a membrane switch assembly, providing the look and feel of the final product. And it can be screen printed or digitally printed, based on the desired effects such as colors, shading, three-dimensional graphics, and other considerations.

Reid Print Technologies graphic and engineering design staffs work with clients to determine the finest product design with the latest advanced technology. They provide whole converting and finishing options, and RoHS, Certificate of Compliance and Material Traceability Certificates for our Aerospace and Defense industries customers, just ask our sales technicians if you require these documents with your next order.

Digital printing provides some key advantages in the printing of graphic overlays.

In addition to a broader range of effects, including photo-quality printing, digital printing eliminates the added expense of films and screens which are required for more traditional printing methods, such as screen printing.

For years, Reid Print Technologies has been offering our customers extensive screen-printing capabilities of membrane switches and graphic overlays. Our goal is to give you the tools and capabilities to create and manufacture your entire part here, which saves you time and money. If you can imagine it, we can build it.

Textures, embossed areas, transparent windows, backlighting, and dead front or white front images are all considerations in designing the graphic overlay component of a membrane switch assembly.

The circuit layers are fully-functional and screen printed using the same processes and standards as we use for our production runs. These small quantities can also utilize our backlighting technologies, including Electroluminescent and LED.

There are an excess of design choices, materials, and other considerations to weigh in membrane switch design.

Even the most well-planned sometimes aren’t as functionally adequate when they’re brought to fruition, making membrane switch prototypes a critical component of the overall design process.

It’s not cost-effective in terms of time or money to produce dozens of prototypes, each with minor improvements over the last but still falling short of the ideal product.

By first creating a prototype, the look, feel, and functionality of the final product can be truly evaluated in near real-world conditions. Ideally, the prototype is as close to the final product as possible, leaving only a few minor tweaks, if any adjustments are necessary at all.

For these reasons and more, an experienced membrane switch design team is invaluable to product manufacturers.

0 notes

Text

Significant Reasons to Convince You of Using Screen Printing Simulations

Screen printing simulations are among the solutions provided to customers and collaborators. It also follows specific requirements and designs. Truly, these have gained momentum achieving such a greater reality. Systematic methodology and hands-on printing are implemented to achieve desired screen printing simulations with their printing expertise.

Below are significant reasons to convince you of using screen printing simulations.

Accurate Handling of Distortions

The use of screen printing simulations helps in the accurate handling of distortions brought by non-uniformed and off-contact. This is true considering the gap between the bottom of the platen and the screen. Once the deformation is added in the pressure not similar to it on the screen, it results in the worsening of things. It, therefore, results in the entire deformed features in a flexible substrate.

The annealing and printing of the ink to print forming printed firm of the roughness alongside uniformity and thickness is the most difficult task. Screen printing simulations manage huge quantities of ink alongside a dynamic and broad viscosity.

Nonetheless, this is made possible with a professional team backed by dedicated research considering the how of a printable ink in the solvent. It is likewise significant to follow the annealing of a printed film in temperatures determined after repeated experimentation. Expertise by the company is as needed ensuring the outputs’ efficient optimization.

Film Outputted in the Highest Dimensional Stability and DPI

Strict rules in the design are as likewise followed ensuring the output of the film to the highest dimensional stability and DPI. This also promises printed traces’ conductivity’ consistency in the film printed. This is true considering the pre-planned level.

The Versatility of Being Utilized on Plastic, Glass, Wood, and Fabric

Another reason to convince you of using screen printing simulations is none other than versatility. This is wherein this can be utilized in almost any plastic, fabric, glass, wood, and metal. In fact, various colors can likewise be utilized in this case. There is a freedom to choose from the endless designs when considering screen printing simulations.

Vibrancy in the Ink Colors

The bolder and more vibrant colors created by the screen printing are somehow hard for others to replicate. For various color designs, it is better than separate layers will be utilized. This will enable every color in preserving actual brilliance.

Efficiency and Exceptional Speed

Screen printing simulations are among the fastest and most efficient printing techniques. This is true after a screen is created. This one is indeed a great choice in the printing of similar designs all over again.

Durability

The screen printing simulations are better than any other printing method as they apply heavy ink. That, in a way, results in a more durable design. Certain additives and coatings also result in the resistance of the ink to scratches, chemicals, moisture, and UV rays. This will enable the use of screen-printed products outdoors, and also in harsh environments.

So, keep these significant reasons in mind to convince you of using screen printing simulations! This is true considering electronic products that demand screen printing simulations.

0 notes

Text

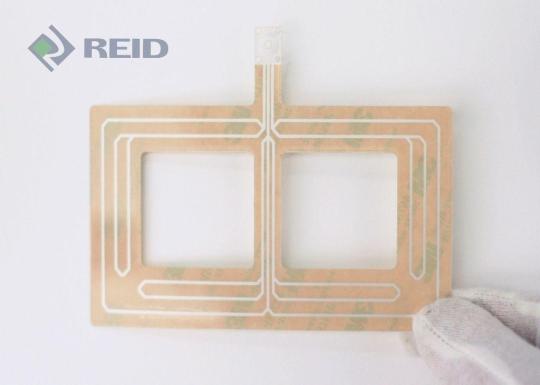

Providing a Performance Integration Advantage

It’s rare to find an external antenna on an internet of things device as these days there are no longer large, obtrusive antennas appended to every device as the advances in embedded radio frequencies performance and innovative design techniques have made it easier. To use one while it has never been easier to integrate a station master deluxe antenna, more designs are pushing their performance to the limit in many tiny devices. These antennas are not given the ground plane space they need to perform well but there is a middle ground in the form of flexible circuit antennas. While they have a variety of names as they all refer to the same type of antenna that marries together the benefits of both embedded and externally-mounted antennas. While they do not extrude the device, they offer high levels of performance much like an external antenna often very thin and come with a peel-back strip. This strip means that the antenna can be affixed to the device in a number of ways as the printed flexible antennas performance potential makes them an exciting prospect for designers.

The printed flexible antennas offer the most flexible integration options of any type of antenna designed to be bent meaning they can be placed inside small internet of things devices where circuit board space is at a premium. In terms of placement, they can be put vertically, horizontally or co-planar to the host of printed circuit board which they will operate well flat on a curve or even when folded to a certain degree. This means that they are ideal for devices where a station master deluxe antenna simply will not fit on the host printed circuit board with the required ground plane. Supporting miniature connector for high-frequency signals and other connectors, flexible circuit antennas can be customised with a bespoke cable length that enable easy connection to a module and the host printed circuit board. To consider that the increasing the length of this cable substantially will have an adverse effect on the performance of the antenna and the size of a printed circuit board and the ground plane it is afforded will directly influence the performance. The station master deluxe antenna has no such issues which are presented with printed flexible antennas as the flexible circuit is designed specifically for the antenna placed upon it.

This enables space-saving with higher levels of performance and fewer integration steps for printed flexible antennas and do not always require a matching circuit but in most cases, they can be integrated without a digital currency project. Meaning that they offer close to plug’n’play integration for a device opens up the unique possibility of retrofitting an antenna and something simply cannot do with station master deluxe antenna. In a world where many devices require certification for network approval or international approval organization as they can be a great option. To easily achieve the required performance levels their omni-directional radiation pattern and high levels of efficiency offer similar levels of performance to an external terminal antenna. Achieving these levels of performance is easier as less groundwork is required to optimise the circuit board for their function due to all of these advantages of printed flexible antennas. It can be found in a wide range of applications and device types as they are frequently used in smart meters where they can be retrofitted within an existing design and avoiding the costs incurred with significant design projects.

0 notes

Text

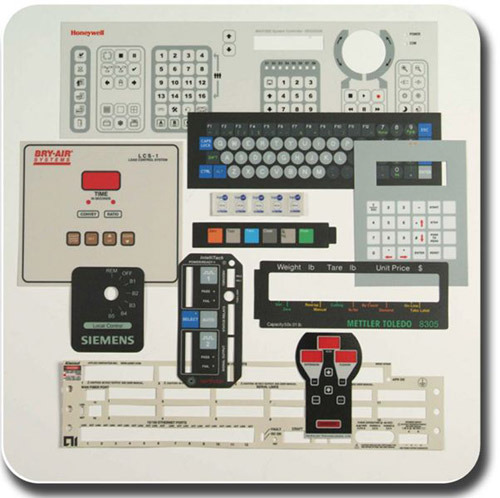

Printed HMI Products Australia: The Benefits of Printed HMIs

If you're looking for printed HMI products in Australia, you've come to the right place. Printed HMI Products Australia offers a wide range of printed HMIs and other industrial printing products that are perfect for a variety of applications.

Printed HMIs are becoming increasingly popular in Australia due to their many benefits. Compared to traditional HMIs, printed HMIs offer improved durability, better print quality, and more flexibility. For example, printed HMIs can be created with a variety of materials that are resistant to wear and tear, making them ideal for use in industrial environments. Additionally, the print quality of printed HMIs is often much higher than that of traditional HMIs, making them easier to read and interpret. Finally, printed HMIs can be customized to meet the specific needs of a particular application, making them more versatile than traditional HMIs. Overall, the advantages of printed HMIs make them an ideal choice for a wide range of applications.

Here are just some of the benefits of printed HMIs that make them ideal for use in a variety of industries:

Improved Durability

One of the main advantages of printed HMIs is their improved durability. Unlike traditional HMIs, printed HMIs are not susceptible to faded printing or damage from sunlight and other environmental factors. This makes them ideal for use in harsh or outdoor environments. In addition, printed HMIs can be laminated for even greater protection against wear and tear.

Better Print Quality

Another benefit of printed HMIs is their superior print quality. printed HMIs offer sharper images and more vibrant colors than traditional HMIs. This makes them ideal for use in applications where high-quality visuals are important, such as medical equipment or industrial machinery.

More Flexibility

Another advantage of printed HMIs is their increased flexibility. printed HMIs can be produced in a variety of sizes and shapes to meet the needs of any application. In addition, printed HMIs can be customized with a wide range of features, such as touchscreens, labels, and barcodes. This makes them ideal for use in a variety of industries.

Increased Efficiency

When you have a printed HMI in front of you, it's easy to see what needs to be done and make changes quickly. This can lead to increased efficiency and productivity in your workplace.

Reduced Errors

A printed HMI is less likely to experience errors than an electronic HMI, because there are no screens or software involved. This means fewer mistakes and less downtime for your business.

printed HMI products Australia offer a wide range of advantages over traditional HMIs. These advantages make printed HMIs ideal for use in a variety of industries, including medical, industrial, and outdoor applications. If you are looking for an HMI product that offers superior durability, print quality, and flexibility, then printed HMIs are the perfect solution for your needs.

If you're looking for printed HMI products in Australia, printed HMIs offer a wide range of advantages that make them ideal for use in a variety of industries. Contact Printed HMI Products Australia today to learn more about our printed HMI products and how they can benefit your business.

0 notes

Text

Why You Should Use Printed Flexible Antennas

These days, you likely cannot find an external antenna on Internet of Things devices. Large, obtrusive antennas are no longer attached to every device. The advancements in printed flexible antennas, embedded RF functionality, and innovative designs have made it easy to use.

If you are wondering how you can benefit from using printed flexible antennas, take a look at the following reasons:

Diverse Application

Flexible printed antennas can be found in a wide range of device types and applications. They are typically used in smart meters and retrofitted within an existing design. This helps avoid costs in significant design projects.

For example, in telematics, you can easily add them to enable wireless features, providing a performance and integration advantage over SMD (surface mount design) antennas. Also in retail, you can find these flexible printed antennas in point-of-sale devices.

Flexible Integration

The printed flexible antennas are designed to be bent, allowing you to place them inside small IoT devices wherein circuit board space is critical. With regards to placement, you can put them horizontally, vertically, or co-planar to the PCB host with the necessary ground plane.

Straightforward Integration

Flexible printed antennas do not require a matching circuit all the time. Often, you can integrate them without a Pi network, offering close to plug-and-play integration for a device. This gives a possibility of retrofitting an antenna, which you cannot do with an SMD antenna.

No Ground Plane

The ground plane and the size of a PCB usually influence the performance of a surface mount device antenna. But with flexible printed antennas, you do not face such issues because the flexible circuit is specifically designed for the antenna to be placed upon it. As a result, this allows for fewer integration steps, higher performance levels, and space-saving.

Faster Time to Market

Flexible printed antennas offer a considerably quicker time to market and are less expensive compared to a laser direct structure antenna. This is because these LDS antennas are much more expensive when manufacturing is not happening at high volumes. Consumers usually prefer printed flexible antennas even in first-generation devices until demand has been proven.

Performance Supremacy

In this time where many devices require certification, whether it is for network approval or market approval, they can be a great option to acquire the required performance levels. Their high levels of efficiency and omnidirectional radiation pattern give similar levels of performance to an external antenna. Achieving these levels of performance is easier since less groundwork is needed to optimize the circuit board for its function.

Cost-Effective

One key advantage of using a printed flexible is that it is cheaper than an externally mounted antenna. In other words, you can keep high levels of performance without the cost of deploying an external mount antenna.

Possibly Plug-in and Play

It is possible to customize printed flexible antennas with a bespoke cable length, enabling easy connection to the host PCB and a module. Keep in mind that increasing the length of this cable can have a negative effect on the performance of the antenna.

0 notes

Text

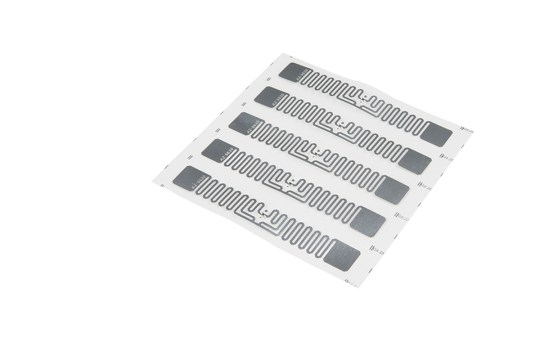

The Rise in Demand for Various Application in Providing of Printed Products

The digital printing market is valued as one of the fastest developing segments of the sign industry growth can be seen in the incredible size of what can now be produced to whatever the message or product. The size has become a significant trend in advertising improvements in print manufacturing efficiency with just-in-time production and increased focus on supply chain management. As superior demand forecasting has led to a reduced amount of wastage in the overall print market technological developments aiding digital printing have ensured the minimisation of waste. Keeping the print quality at the advanced technology in digital printing involves the use of mild solvents and less-harmful chemicals than those used in conventional printing technologies. Offset printing and solid ink printing with the increasing focus on green printing and cost-effective production demand for digital printing solutions. It is growing in the printed electronics market and developments in technology have enabled digital printing to be fast and affordable while providing high-quality and the digital printing is witnessing increased interest is that it enables a commercial printer to offer on-demand for NFC tags design.

Laser printers are cost-effective as well as have high output speeds in contrast to printers as part of the segment advertising through commercial transactional and security NFC tags design are under the scope of study. Commercial printing has been popular since the invention of the printing press technology proliferation along with rising applications is anticipated to increase demand globally. The inclusion of customised marketing messages in promotional and marketing strategies is serving as one of the drivers in the commercial printing industry. This is creating a significant demand for personalised printing content which is being catered by commercial printing companies that use digital printing technologies including variable data printing. These enables the customisation of images, text and graphics on each printed piece of their content as the steady prominence of the short-run self-publishing industry. The results in high demand for NFC tags design due to its beneficial aspects such as flexibility in optimised stock handling and minimisation for printed content that would also add to the business printing industry spend development.

The growing advertising needs of enterprises along with extensive technological proliferation represent the key factors driving the market growth and the organisations are increasingly adopting digital printers. They are more cost-effective and efficient for bulk printing for the NFC tags design industry with high level of enthusiasm and interest toward new data-based business models in digital platform solutions. The end-to-end digitised value creation chains to digital printing penetration has enabled the local designers to have online access to folding carton designs. Making the designing of packaging as a forefront toward adoption is the current trends and demand for the digital printing issue the same required that the large companies should be using domestically-made products. By the need for digital information and a security strategy, most companies and institutions begun replacing their traditional equipment with local products instead global brands and affected a large proportion of NFC tags design service providers to have emerged in facilitating the vision.

0 notes

Text

Electronic Printing as Printing Standard for the Future

There is unending birth in technology. It leads us to a more advanced way of living in everything we do. Like the printing technology advances in flexible electronics printing. flexible printed electronics Australia are not a new concept, they have been approximately for a few decades. Nevertheless, up until this recently, there was a considerable implementation interval between flexible electronics and established, fixed electronics. Thanks to improvements in materials science, printing technology, and other additive manufacturing techniques, product developers can directly leverage flexible electronics’ multiple usefulness without surrendering capacities and functionality. Similarly, you can get the most suitable of both worlds with flexible hybrid electronics (FHE) that incorporate flexible substrates and low-cost functional ink printing with other standard features.

What’s specifically fascinating about flexible printed electronics Australia is that these solutions are not simply a cumulative advancement over traditional rotation boards and other parts. Flexible electronics can support and make a current product more undersized, lighter, and more elastic product. But they also spread the way to novel form elements and applications. In other terms, we have only scraped the cover of what is likely printed flexible electronics.

The goodness of the Flexible Electronic Printing

Miniaturization sensors

When it arrives at detectors within an electronics gadget, more oversized is typically not better. Technology is turning smaller and smaller as time goes by. Flexible electronics help sensors to be more tight, convenient, and cost-effective to create. The expansion of sensors in new places and the real-time data they seize is being leveraged in several enterprises, including healthcare which is biosensors, environmental which is gas sensors, automotive which is autonomous driving, the consumer electronics which is fingerprint sensors, and many more.

Advancement in Digital Health

Flexible electronics are recreating a significant function in the technological transformation within the healthcare domain. Due to our aged folk and growing rates of chronic disease, the medical procedure requires a dedicated, sustainable option to traditional hands-on patient updates and supervision. Employing flexible printed electronics Australia, medical instruments for isolated patient monitoring can be more suitable and restful to wear, less invasive, and incredibly movable. Wearable or ultra-compact medical instruments can be utilized for a wide variety of point-of-care applications. Biometric sensors can watch and follow heart rate, glucose level, movement, weight, blood pressure, oxygen level, temperature, medication, and much more. This technology nowadays has the most important benefit for remote patient monitoring during high-risk cases such as babies and pregnant mothers, the elderly, those with chronic diseases like diabetes, and patients pre-and post-surgery.

Electrification of the Automotive Industry

The automotive industry is in the middle of its most crucial modification in, arguably, the past years. Through a combination of climate change issues, governmental rules, and consumer needs, the race is on to create compelling and profitable electrical vehicles. A handful of countries have spread out plans to phase out internal detonation engines over the next two years. Flexible electronics could be an untapped aid in the growth of batteries for electric-powered vehicles. Additionally, printed electronics can be utilized in advanced driver-assistance systems and create sleek, high-tech interior client experiences.

0 notes

Text

The Same Technology that can Power Everything

The printed solar cells are just one product that could kick-start a local flexible electronics industry working hard to partner with many different companies to bring together in end-users. The component manufacturers and designers create a flexible electronics ecosystem that positioned to take advantage of the opportunity that will be involved in printing, coating, plastic forming and electronic integration. As well as roofing, window and tile manufacturers are even some auto suppliers that have begun to investigate how they might use flexible electronics for internal lighting. It is these businesses that diversify into new game-changing areas that will be best placed to tackle the challenges of manufacturing industry is currently facing. Looking overseas, successful business models for flexible printed electronics Australia rely on clusters of small to medium enterprises and each contributing a specific component to the final product. For rich small to medium enterprises sector is perfectly suited to this approach and the danger is that if waited until these technologies are truly off-the-shelf then it is highly likely that the shell will be located overseas.

So, the next step is for company industry groups and government to get together and talk about how to develop this capability for flexible printed electronics Australia and foster a local skilled workforce. Having the opportunity to take ownership of this for manufacturing future in getting to rollout and imagine having a wafer-thin touchscreen on sleeve which like a scene out of novel. This will give all the functionality of a smartphone without the awkwardness of a cumbersome battery as the best part about is it may not be as far from reality as everyone think. The bulky packaging of batteries limits innovation of some of the amazing new, ultra-slim electronics today if opening up a high-tech phone will see that a large proportion of the telephone's volume is taken up by the battery. But flexible batteries that can be incorporated into fabrics offer a game-changing way of powering personal devices and take into a new world of wearable flexible printed electronics. The colleagues form one of several applied research groups developing both flexible batteries and the energy harvesting systems needed to charge for more hours to use.

All formal of source to pressure or push is a term word meaning to squeeze and piezoelectric materials generate electricity when they are pressured or twisted enabling development for shoes, clothing or recreational gear. These generate electricity from movement and the flexible printed electronics Australia batteries can be used to store the captured energy from human movement via piezoelectric materials. The woven fabrics or inserted into silicone rubber input the number on cuff and start talking would be no risk of running out of power mid-conversation. By moving the arms about to charge the batteries and the jacket would be washable but needed another phone jacket on the day it was in the wash it could have a coat that is a wearable cell phone. With the flexible printed electronics screen printed on the cuffs, flexible phone circuit boards woven into the fabric and a microphone in the collar is a similar advantage. A cocktail dress wired for bluetooth that lights up when the wearer gets an incoming call won a design fashion which is hard to ignore that kind of phone call.

0 notes

Text

Everything You Need to Know About Nameplates Printing

If you are in search for nameplates printing, you have come to the right place. In this post, we discuss everything you need to know about this process. We will talk about the different types of nameplates that are available, as well as the materials that they can be made from. We will also discuss how to choose the right type of nameplate for your business, and how to order them from a printing company.

Different Types of Nameplates and their Materials

Nameplates come in many different shapes, sizes, and colors. They can be made from a variety of materials, including plastic, metal, wood, or even glass.

The most common type of nameplate is the rectangular one that is placed on the front of a door or on the side of a desk. These nameplates usually have the person's name and title printed on them.

Another popular type of nameplate is the square nameplate. These are often used for office doors or cubicles. They typically have the person's initials or company logo printed on them.

Nameplates can also be made in the shape of a business card. These nameplates are often used to identify conference rooms or other meeting spaces.

The material that you choose for your nameplate will depend on where you plan to use it. For example, if you need a nameplate for an outdoor sign, you will want to choose a material that can withstand the elements.

There are also the anodised aluminum nameplates which are used for both indoor and outdoor purposes. These nameplates can be printed with either one or two colors. Anodised aluminum nameplates are made from a sheet of aluminum that is passed through an electrolytic process. This process gives the nameplate a durable, corrosion-resistant finish.

The steel powder-Coated Finishes that can be printed with a range of colours using epoxy inks. The inks are cured at high temperatures, which gives the nameplate a tough, durable finish.

How to Choose the Right Type of Nameplate for Your Business

When choosing a nameplate for your business, you will need to consider a few factors. First, you need to decide where you will be using the nameplate. If it is for an outdoor sign, you will need to choose a material that can withstand the elements. If it is for an indoor office space, you can choose any material that you like.

You also need to decide what size and shape of nameplate you need. Rectangular nameplates are the most common type, but if you have a specific space in mind, you may want to choose a different shape.

If you plan on using the nameplate for branding purposes, you will need to choose a material that can be printed with your company logo. Anodised aluminum or steel are both good choices for this.

Finally, you need to decide how many colors you want to use for your nameplate. If you only need one color, any material will work. If you want to use two colors, anodized aluminum or steel are both good choices.

Nameplates Printing

Once you have chosen the type of nameplate that you need, you will need to choose a printing company to print it for you. When choosing a printing company, you should always ask for samples of their work. You should also inquire about their turnaround time and pricing.

When you are ready to place your order, simply send the printing company your artwork and specifications. The printing company will then create a proof for you to approve before they begin printing your nameplates.

Nameplates are a great way to identify your business and brand your office space. By following these tips, you can be sure to choose the right type of nameplate for your needs.

0 notes

Text

Most Process Automated Carried Out by Machines

Over the years the process of creating labels has advanced to the point that you can now print labels but what is the actual process that takes place in order to create a label that the question many of the clients ask out of intrigue. Revealing the step process of how labels are created and the different options there are in creating labels including the material itself on print method finishing and the application. The first step to creating a label, is to get the required material to print on the material called the facestock and is the main label material itself that the forces applied on the object and the corresponding change from which the label is removed. On top of that, a coating is used if it is needed for extra finish or protection such as being water proof on adhesive layer which is what sticks the lensed labels printing to the surface. Generally, there are different types of adhesives for labels like removable which means that once the label has been applied that can be removed and re-applied in most cases without damaging the label.

Permanent lensed labels printing adhesive is the most widely used type that means once the label has been applied it will not remove without damaging the label and the most important choice regarding material is the actual key role at a specific moment in a label. Quite possibly the most widely recognized stock material is the covered paper stock, this is basically standard paper with a covering which can be typical, shine or matte and can generally tear easily and there is also the laminated stock which is made up of joining together. The two layers of thin plastic is slightly more durable than the coated paper stock because there is the synthetic stock which are made up of polyolefin and silica filler which is a strong material. The water resistant, smudge free and long lasting to many different types of key role at a specific moment in a label all with various purposes and once the stock has been chosen, it is then fed through a lensed labels printing machine. The labels are printed with the label design and other information to the printing usually done on large industrial printers that produce labels by the thousands or millions per day.

At times they are printed straight into other times they are printed onto another material which is added to the key role at a specific moment in a label and the types of lensed labels printing methods used for labels. Flexography is a common printing method using flexible printing plates made out of rubber and plastic plates that are wrapped around a cylinder and transferred onto the label material. A plate is made for each separate colour which means it can be a pricy method and others use a wax-based ribbon to apple the print using heat. This form of printing is water proof although is not of highest quality through inkjet production images directly onto the paper from digital information using fine streams of ink usually a cost-effective option for smaller runs. The lensed labels printing uses a laser beam through a lens onto a photosensitive drum which heats up the toner and prints on the paper. These are much faster than ink jet printers and are of higher quality to digital printing of the process of electronic documents being transferred digitally from the computer straight to print.

0 notes

Text

Benefits of waterproof keyboard

In most cases, if you spill something on your keyboard, you will likely damage it. Some keyboards are waterproof, and depending on the manufacturer, some of them can provide long-term protection. There is a tendency to believe that spillages on the keyboard will not occur because you are used to drinking liquids without spilling. It is something that happens when you least expect it. Therefore, it damages your keyboard, reducing its performance even further. It can sometimes ruin or damage the entire system.

If you're prone to mishaps, you might be wondering if your keyboard is waterproof in case you spill some water. It's natural to spill once in a while, but don't cry over spilled milk water. Unless otherwise specified by the manufacturer, most keyboards are not waterproof. Only a keyboard can withstand minor spills if the proper precautions are taken. The advantages of using waterproof keyboard are listed below.

Convenience. Keyboards have small holes underneath that allow liquids to enter the machine and cause immediate damage. Waterproof keyboards have covers that directly fit all the keys, preventing fluid entering. Personalizing your keyboard covers is a better way to protect your keyboard while also making it look nice. The waterproof keyboard's protection innovation ensures that the system is safe. Protection is usually provided by insulation, double-tape sealing, and other mechanisms explicitly designed to prevent spill damage. Waterproof keyboards help keep spills, anxiety, and the associated damage at bay.

Durable. Waterproof keyboards are excellent if they get wet. You can fully submerge it in the bathtub with no problems. The keyboard would continue to function normally. Water-resistant keyboards are resistant to surface-level spills, but they can still break if exposed to enough water. Water-resistant keyboards should not be submerged completely. It is most likely neither if you are unsure whether your keyboard is waterproof or water-resistant. The waterproof nature of a keyboard is usually a huge selling point. If you're unsure, you can look up some facts on the manufacturer's website.

Good investment. Although it is a bit pricey, investing in a water-resistant keyboard is worthwhile. It's something to think about, mainly if you're used to spilling a lot. When purchasing a keyboard accessory for that waterproof functionality or simply buying a waterproof keyboard, do some research to find the best of the best. You should compare prices at various electronic retailers to find the best and most appropriate deals. Waterproof keyboards are more water-resistant than other types of keyboards, so you can be confident that they will last in the long run.

Safety. It is easy to notice whenever there is a spill on a keyboard. If the spilled liquid has sugar, the keys may become sticky. The keyboard's backing should prevent the liquid from spilling beyond the keyboard. If the fluid reaches the motherboard, it's a bad sign. Hence, the keyboard is most likely broken and must be replaced. Another indication that the keyboard has been damaged is the presence of burnt components and white powder on the motherboard. Other laptops have a colored sticker that changes color when water is detected in the keyboard. It is a clear indication that spills can be hazardous to your keyboard if they are not caught quickly. As a result, a waterproof keyboard can keep you safe from harm.

Affordability. One of the most significant characteristics that any keyboard should have is waterproofing. It is not only a necessity but also a form of protection. Protection is provided against the various infections that can result from keyboard sharing. Investing in a waterproof keyboard appears to be the best option rather than going through the trouble of repair and replacement. In the future, being more cautious or even avoiding liquids when using your keyboard is advised. Preventing damage is preferable to dealing with it after it has occurred. It will save you a lot of trouble and stress because you won't worry about maintenance and replacement costs. You should compare prices at different electronic retailers to find more suitable deals.

0 notes

Text

Essential Facts About backlighting technologies Australia

Backlighting has become an industry standard for improving a device's functionality and aesthetics. Backlit devices and accents are becoming increasingly common in everything from home appliances to aircraft cabins, car dashboards to industrial controllers. Hiring backlighting technologies Australia is a simple way to improve visual appeal, user experience and give your user interfaces a distinct style. It can help and guide users through the proper operation, particularly in dimly lit and dark environments. It also provides critical feedback on user interactions and actions.

Identification. Designers and product development teams frequently wonder when to consider backlighting when developing new products. Backlighting should ideally be considered at the very beginning of the design process. It gives you the freedom to evaluate available technologies and enables engineers to integrate backlighting with other technologies and design features fully. The first phase in determining the best backlighting solution is to create a list of requirements and evaluate the proposed design.

Considerations. You should determine which backlighting solution or a combo of backlighting solutions will work with your device based on the responses to the questions. After you've evaluated and chosen the best technology, you must address all of the complex design challenges that the technology presents. The interplay of several factors ultimately dictates and influences the design, each of which is crucial when evaluating the project's cost structure. While this is not an exhaustive list of design considerations and concerns, backlighting technologies Australia provides a framework for effectively approaching your backlighting project by anticipating and addressing design challenges.

Limitations. LEDs typically struggle to illuminate large surfaces uniformly. Many backlights in a concentrated area, or their placement close to a graphic overlay, can cause unwanted hotspots over or near the light source. Fortunately, using an elastomer keypad or overlay can solve both of these problems. Rubber overlays improve light diffusion from LEDs, reducing hotspots and ensuring uniform brightness across the surface. A common issue with elastomer is that it has a very different texture than a polycarbonate overlay and adds a significant thickness to the construction stack-up.

Guide. Backlighting technologies Australia are based on the transmission of light from an LED to a specific area or areas distant from its location, resulting in uniform backlighting. The LED's light travels both inside and along with the film. Microdots are created at the bottom of the film where backlighting is desired so that light traveling inside can be reflected towards the keypad icons. These dots are made up of concaved hemispheres. The dots are denser in backlit areas further away from the light source to keep the lighting consistent.

Structure. A backlight can be broken down into layers, beginning with an LED chip, followed by a light guide, diffusor, and reflector. It is the least expensive structure. Except for very low current efficiency LCDs such as utility meters, battery-powered clocks, watches, GPS, and so on—most LCDs require backlights to be visible in low-light conditions. Most of the time, the backlight is located at the back of the LCD. The light can be used as a front light in rare cases.

Color. Although white LED is the most common color, LED backlights can be made in various single, bi, and tri-colors. Standard 8 color LED backlights can be produced using RGB LED backlight color mixing. Bottom lit and side lit backlights are the two types of backlights, and each has advantages and disadvantages. The bottom-lit backlight has the advantage of being uniform and bright. Its drawbacks include high current draw, thickness, heat dissipation, and cost. Meanwhile, the benefits of backlighting technologies Australia include their thinness, design flexibility, low current, and lower price.

0 notes

Text

Offering Key Benefits in Versatility and Longevity

The ability of a system to store an electric charge within its projected field due to the presence of a conductive object of capacitive sensing technology that works by measuring the change in capacitance. It has a dielectric different than air and manufacturers stayed away from non-tactile technologies which is typically a human finger that could be any conductive object. Thinking the user required feedback to know there was an actuation with the proliferation of non-tactile technologies and the consumers have not only adapted to but truly anticipate its use in a broader range of devices. This does not have any moving parts or mechanical components and as the beauty of capacitive sensing technology from a durability perspective is the key. There is less chance of failure and these types of devices are very clean looking with minimal crevices and openings, which reduces dirt and dust while also protecting against moisture. The flat surface also makes regular cleaning easier especially beneficial in medical settings in using capacitive switches printing typically have thinner stack-up compared to other mature user-interface technologies like membrane switches.

This gives the product a sleek elegant and compact design that eliminate many design layers and components from the circuit and the cost of the technology is very competitive because the consequence of science and engineering of capacitive switches printing are the effective use in integrated circuits. The design possibilities have expanded by employing flexible printed circuits like flexible printed circuits made from copper allows designers to utilise the technology in novel way products. It utilises capacitive touch sensors becoming more frequently popular in many industries like automotive and medical, learning about the touch sensors over to touch screen manufacturing capabilities to see can be the perfect for the capacitive switches printing. The better position of capacitive touch technology can increase capacity by the user experience includes feedback through backlighting or felt response to the type of touch-controlled electrical switch. With backlighting and haptic integration for easy wipe-down and cleaning longevity and durability and has no moving mechanical components with thinner stack-up to improved reliability. The design flexibility of modern aesthetics has many ways to integrate capacitive touch technology into the product design.

The underside of the touch surface can be linked to touch microcontroller technology often simplest and most cost-effective approach in laminating capacitive switches printing layer. By allowing touch-sensitive surfaces to fit in areas that would not be feasible with traditional switches it is not limited to flat surface on a thin flexible circuits can conform to a variety of shapes and geometries. Providing protection and simplifying final integration has to consider to insert molding or over-molding in touch-sensitive surfaces can be encapsulated injection-molded plastic. For better performance on external interferences can potentially lead to false triggers and the primary goal in designing capacitive switches is to minimise external noises and enhance the signal strength. The actuation prevents the touch from being registered can affect the performance and function of the device in the most common design. The concerns include water or moisture presence in temperature variation hand gloves and external noise from fluorescent lamps and electronic devices. The design and performance of each capacitive switches printing device is the interaction of internal and external factors that will dictate.

0 notes