Photo

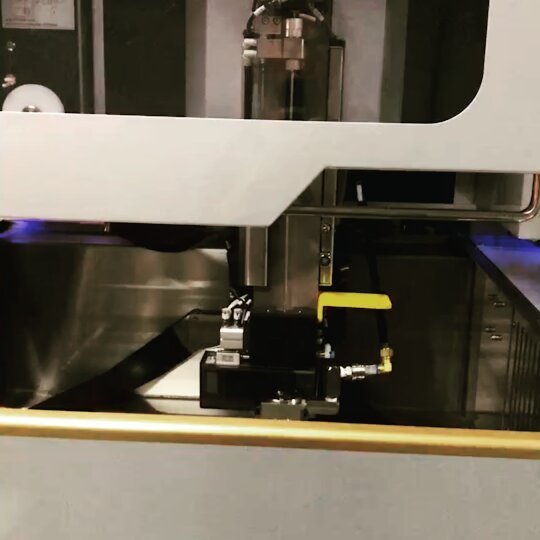

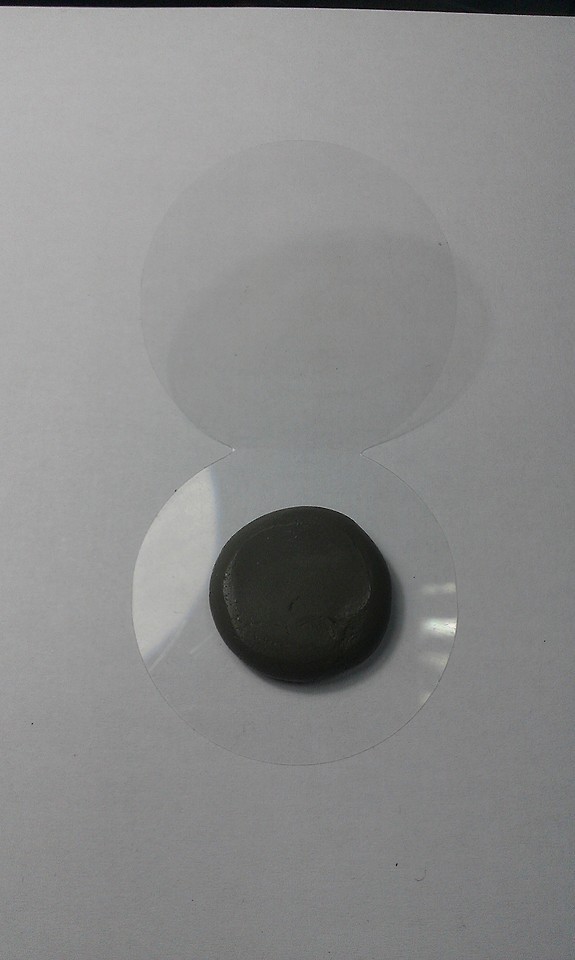

Waterjet Cutting Nozzle:

Runchang waterjet nozzle based on the latest tech of nanotechnology of tungsten carbide strengthened the resistant of focusing tubes, longer the life of working times. FYI:

1. The content of Cobalt is within 0.6%, density is around 15.9g/cm3.

2. Anti-stress between 2000Mpa-2400Mpa.

3. Super oxygen resistance, lower thermal expansion, high hardness, and density, surpassing other similar products considerably.

Runchang highly reliable waterjet nozzle is widely used in cutting metal, glass, granite, marble, stone so as to other construction materials, composite materials, bullet-proof materials, and other special material required shape of a cut forming, water cutting soft material, low melting point, flammable and explosive materials like bombs, oil tanks, etc.

Here attached a quotation sheet for Premium Nozzles with below details, FYI:

1. The Grade is TCF2005, up to 60,000psi and to 90,000psi over 120 hours.

2. Price: starting from $25 USD per nozzle.

3. Delivery: 5 business days door-to-door by DHL.

4. Lead time: no longer than 7 business days. Customized is the same.

Specialize in this field for over 25 years, we have a great capability and strict managing system to ensure you with Good Quality, Fast Delivery with Competitive Price.

PS: If you have a large demand, e.g. 200 tubes per month, the price can be way much cheaper than this, but High Quality and Good Service are always guaranteed here.

Should you have any questions, please do not hesitate to contact me. Samples will be sent for your evaluation!

Runchang Group.

Led by Peter Chen, P.hD.

0 notes

Photo

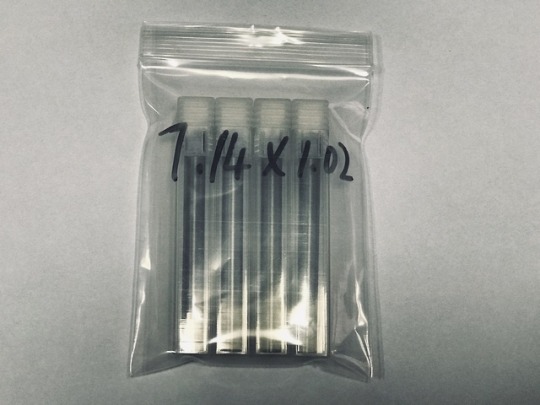

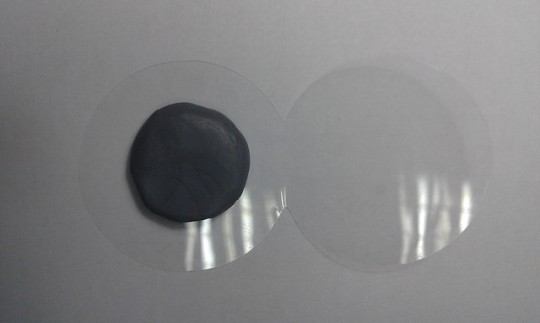

Waterjet Cutting Orifice:

Runchang Waterjet Type 94 NanoDiamond Orifice for pure water and abrasive cutting heads. Used in Runchang Cutting Heads. Comparable to Comadur type 27 orifice. Also, they were used in some KMT and Flow style cutting heads and water-only applications.

Runchang Waterjet Type 91 NanoDiamond Orifice for pure water and abrasive cutting heads. Used in Runchang Cutting Heads. Comparable to Comadur type 35 orifice. May also be used in some Flow International Waterjet style cutting heads among others.

NanoDiamond is a material new to the waterjet industry. It is made up of small diamond particles fused together to provide wear characteristics very similar to the single-crystal diamond orifices on the market today.

Resistance to impact damage is greatly increased however, as the material lacks the natural cleavage planes found in single-crystal orifices. As a man-made material, it is also much less expensive - up to half the price of a single-crystal diamond orifice - delivering you greater value.

Should you have any questions, please do not hesitate to contact me. Samples will be sent for your evaluation.

Runchang Group.

Led by Peter Chen, P.hD.

0 notes

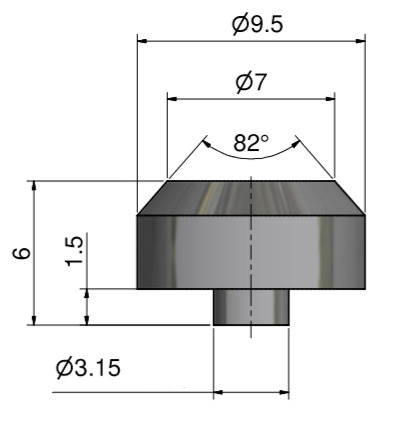

Photo

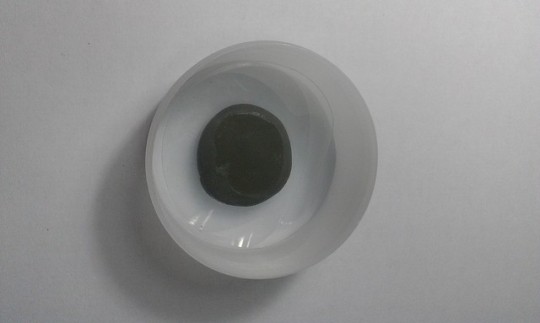

Tungsten Putty:

Tungsten putty that is soft and malleable so it can be changed into virtually any shape or broken off into small pieces. Use tungsten putty to easily add or remove weight right at fishing or derby competition.

3rd Edition just release! Developed by our R&D head Peter Chen, P.hD, the putties’ stick level is 2X than the last version, and it can be stretched considerably without tearing off any powder. Really smoothy and easily pinch into the exact size with your specific demand. It also helps increase its duration up to 450 hours of using without any de-coloring. Recyclable, Good for the environment.

"This stuff is great for adding design details while increasing weight at the same time. As others have noted, selective removal also allows for precise fine-tuning of overall weight last minute at weigh in" -- By a derby competition champion.

Tungsten Rig Putty Leading Sinker Weights For Carp Fishing Terminal Tackles.

Enclosed some photos for our main products for your review.

If you have any time, please pay a visit to us. I think a lot of items will match your interest, and really hope to establish business relationship with you!

Runchang Group.

Led by Peter Chen, P.hD.

0 notes

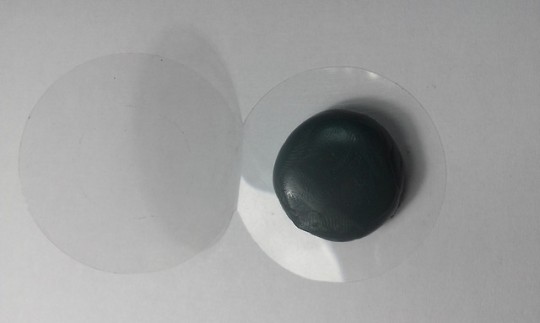

Photo

Tungsten Carbide Balls & Tungsten Balls:

Tungsten carbide ball, also called cemented carbide ball, is made of WC and a binder phase Co or Ni. Tungsten carbide ball production starts by having the raw metals sintered into blanks. After pressing into sintered blanks, tungsten carbide ball will often have a band like a satellite.

We then make use of precision machining for high tolerance ground as per each customer’s unique specifications. In addition, we use complete virgin Tungsten Carbide material with our creative production technology which leads to high-performance tungsten carbide ball.

Tungsten Carbide Ball - Process

The manufacturing process of tungsten carbide ball is summarized like this: Pulverizing as formula → mixing → satin extrude → granulating → pressing → molding → vacuum sintering → rough grinding → fine grinding → clean → polish as per our client's preferences → inspection → packing and warehousing.

Tungsten Carbide Ball’s Common Grades

Tungsten carbide ball grades are YG6, YG8, YG6X, YG13, YN6, YN9, YN12, YT5, and YT15.

Tungsten Carbide Ball Features

Tungsten carbide ball feature high hardness, wear resistance, rust free and anti-bending. They can directly replace any application of a steel ball. Usually, tungsten carbide ball is produced with a grade YG6 and with a hardness of HRA91.0 and density at 14.9g/cm3.

Tungsten Carbide Ball Precision

Tungsten Carbide Ball precision is G3, G5, G10, G15, G16, G24, G25, G48, G50, G100, G200, G300, G500, G1000, G2000, and G3000.

Tungsten Carbide Ball Standard Diameters

Tungsten carbide ball is available in diameters ranging from 0.3mm to 100mm.

Specific diameters are: 0.3mm, 0.4mm, 0.5mm, 0.7mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 1.588mm, 1.6mm, 1.98mm, 2.0mm, 2.2mm, 2.5mm, 2.75mm, 3.0mm, 1/8", 3.5mm, 3.75mm, 3.8mm, 4.0mm, 4.5mm, 3/16", 5.0mm, 6.0mm, 1/4", 6.5mm, 7.0mm, 7.5mm, 5/16", 8.0mm, 8.5mm, 9.0mm, 9.5mm, 3/8", 10.0mm, 10.5mm, 11.0mm, 7/16", 12.0mm, 12.5mm, 1/2", 13.0mm, 13.5mm, 14.0mm, 9/16", 14.5mm, 15.0mm, 5/8", 16.0mm, 16.5mm, 17.0mm, 11/16", 17.5mm, 18.0mm, 18.5mm, 19.0mm, 3/4", 19.5mm, 20.0mm, 20.5mm, 21.0mm, 21.5mm, 22.0mm, 7/8", 22.5mm, 23.0mm, 23.5mm, 24.0mm, 24.5mm, 25.0mm, 1", 1 1/8", 30.0mm, 1 1/4", 1 3/8", 35.0mm, 38.0mm, 1 1/2", 40.0mm, 1 5/8", 1 3/4", 45.0mm, 1 7/8", 50.0mm, 2", 60.0mm, 3", 4"

Tungsten Carbide Ball - State Condition. FYI:

1. Sintered tungsten carbide ball with satellite/belt.

2. Rough grinding tungsten carbide ball, without satellite/belt.

3. Grinding tungsten carbide ball.

4 High precision tungsten carbide ball.

5. Fine grinding tungsten carbide ball and polish.

6. Tungsten Carbide Ball - Applications

7. Tungsten carbide ball is widely used in many applications such as precision bearings, instruments, meters, pend production, spraying machines, water pumps, machinery accessories, sealing valves, brake pumps, oil deposits, hydrochloric acid laboratory, hardness testers, fishing weights, weighting blocks, ornaments, and precision machining.

Runchang Group.

Led by Peter Chen, P.hD.

0 notes