Text

The Back Pressure Steam Turbine in Process Industries

In the fast-paced world of process industries, achieving efficiency and sustainability is paramount. Enter the back pressure steam turbine—a game-changer in energy utilization for industries. This blog explores the impact of the back pressure steam turbine in process industries on optimizing energy use.

Understanding Back Pressure Steam Turbines:

Tailored for applications needing both electricity and process heat, the back pressure steam turbine excels at tapping into high-pressure steam. Unlike traditional turbines, it does this by simultaneously generating electricity and releasing steam at lower pressures. This makes the back pressure steam turbine in process industries a go-to solution for Combined Heat and Power (CHP) needs.

Key Components and Working Principle:

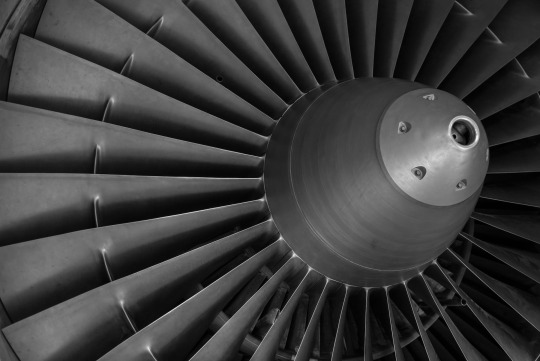

High-pressure steam flows into the back pressure steam turbine, interacting with blades to convert kinetic energy into mechanical power. This power then drives a generator, producing electricity. Unlike other turbines, the back pressure steam turbine releases steam at lower pressures, making it suitable for a variety of industrial processes requiring lower-pressure steam.

Advantages in Process Industries:

The back pressure steam turbine in process industries offers a range of benefits. It boosts energy efficiency by harnessing high-pressure steam that would otherwise be wasted. This not only leads to significant cost savings but also aligns with environmental objectives by curbing greenhouse gas emissions. The adaptability of the back pressure steam turbine allows seamless integration into diverse industrial processes, from chemical manufacturing to paper production and food processing.

Conclusion:

As industries push towards sustainability, the back pressure steam turbine stands out as a catalyst for positive change. Beyond cost savings and heightened efficiency, back pressure steam turbine in process industries plays a vital role in reducing the carbon footprint of industrial operations. The back pressure steam turbine’s adaptability and versatility position it as a cornerstone for a more sustainable and energy-efficient future in process industries.

Turtle Turbines is one of the most reputed steam turbine manufacturers from India for power generation, suitable for operation on the saturated and superheated steam boilers operating in various industries. Based in India, the company focuses on providing sustainable solutions for power generation and configurations to meet the needs of different applications. For more information please visit on www.turtleturbines.com

0 notes

Text

Applications of Steam Turbines in Various Industries

The applications of steam turbines in various industries are both diverse and indispensable, showcasing their crucial role in powering numerous industries. In the realm of power generation, steam turbines stand as stalwarts, converting thermal energy into mechanical power with unparalleled efficiency. Whether in fossil fuel or nuclear power plants, these turbines are the driving force behind electricity generation, meeting the escalating global demand for energy.

Beyond the realm of power plants, the maritime industry relies heavily on the applications of steam turbines for propulsion. From naval vessels to cargo ships, steam turbines provide a reliable and efficient means of harnessing power from boiled water, enabling ships to navigate vast oceans. This marine application underscores the adaptability and robustness of steam turbines in diverse operational environments.

The applications of steam turbines in various industries include the manufacturing sector, which benefits significantly from the applications of steam turbines. Industries ranging from paper mills to chemical plants integrate steam turbines into their processes, using them to drive machinery and facilitate smooth operations. The flexibility of steam turbines allows for customization, ensuring they meet the unique requirements of various manufacturing processes, thereby enhancing overall productivity.

Innovations in energy production have expanded the applications of steam turbines in various industries to unconventional realms. Geothermal power plants harness the Earth’s natural heat, utilizing steam turbines to convert thermal energy into electricity. This sustainable approach exemplifies the versatility of steam turbines in contributing to environmentally friendly and renewable energy solutions. Moreover, district heating systems in urban areas leverage steam turbines to distribute heat efficiently, further diversifying their applications and impact.

In conclusion, the applications of steam turbines in various industries reverberate across critical sectors, playing a pivotal role in powering economies and enhancing our daily lives. As technology advances, the adaptability and efficiency of steam turbines are likely to pave the way for even more innovative applications, solidifying their status as indispensable components in the diverse landscape of mechanical power generation.

Turtle Turbines is one of the most reputed steam turbine manufacturers from India for power generation, suitable for operation on the saturated and superheated steam boilers operating in various industries. Based in India, the company focuses on providing sustainable solutions for power generation and configurations to meet the needs of different applications. For more information please visit on www.turtleturbines.com

0 notes

Text

Harnessing Steam’s Potential: Back Pressure Steam Turbines

In the ever-evolving landscape of energy generation, one technology has quietly reshaped the way we harness steam’s potential for power and industrial processes: the Back Pressure Steam Turbine. This engineering marvel has revolutionized the world of power generation by efficiently converting steam into electricity, all while producing high-pressure steam for other industrial needs. In this blog, we’ll take a deep dive into the world of back-pressure steam turbines, exploring their working principles, applications, and the role they play in optimizing energy utilization.

The Foundation: Steam as a Power Source

Steam has been a cornerstone of energy generation for centuries, dating back to the days of the Industrial Revolution. It’s versatility and capacity to store and transfer energy make it a valuable resource for power plants and industrial facilities.

The Back Pressure Steam Turbine Unveiled

A back-pressure steam turbine is a remarkable piece of engineering that capitalizes on the dual potential of steam. It operates by efficiently using high-pressure steam to produce both electricity and lower-pressure steam that can be directed to various industrial processes. This versatility is what makes it a game-changer in the world of power generation.

Applications Across Industries

Back-pressure steam turbines have found their niche in numerous industrial sectors:

Power Generation: They serve as the workhorses of electricity production, helping power plants efficiently convert steam into electrical energy.

Combined Heat and Power (CHP) Systems: Back-pressure steam turbines are integral in CHP systems, which simultaneously produce electricity and usable heat, resulting in exceptional energy efficiency.

Industrial Processes: In industries such as petrochemicals, paper, and food processing, these back-pressure steam turbines supply high-pressure steam for various operations, significantly contributing to energy optimization.

Efficiency and Sustainability

One of the key attributes of back-pressure steam turbines is their efficiency. They not only maximize energy conversion but also play a pivotal role in the sustainability of power generation. By optimizing energy utilization and reducing waste, they contribute to more environmentally friendly energy production.

Conclusion: Harnessing Steam’s Potential for a Brighter Future

The back-pressure steam turbines have redefined the way we utilize steam for power and industrial processes. It’s ability to efficiently produce electricity while supplying high-pressure steam for additional applications showcases its remarkable versatility. As the world pivots toward sustainable energy solutions, back-pressure steam turbines emerge as a vital component in the quest for greener and more efficient power generation. By harnessing steam’s potential to the fullest, it promises a brighter and more sustainable future for us all.

Turtle Turbines is one of the most reputed steam turbine manufacturers from India for power generation, suitable for operation on saturated and superheated steam boilers operating in various Industries. Based in India, the company focuses on providing sustainable solutions for power generation and configurations to meet the needs of different applications. For more information please visit on www.turtleturbines.com

0 notes

Text

Elevating Power: The Artistry of Steam Turbine Overhauling

In the dynamic arena of power generation, where the quest for efficiency never wanes, the meticulous craft and artistry of steam turbine overhauling takes center stage. This blog embarks on a journey to unravel the intricacies of this process, where engineering excellence isn’t just a requirement but a commitment to ensuring steam turbines operate at their zenith. Join us as we explore the art and science behind steam turbine overhauling, a true testament to precision and peak performance.

Understanding the Symphony of Overhauling

In the lifecycle of a steam turbine, wear and tear are inevitable companions. Enter the steam turbine overhauling process – a symphony of planning, disassembly, inspection, repair, and reassembly. At its core, this meticulous choreography aims to breathe new life into turbines, restoring them to optimal performance levels.

The Prelude: Meticulous Planning

Before the tools are wielded, planning takes center stage. Engineers pore over the turbine’s history, assessing its condition and identifying components in need of attention. This phase isn’t just a checklist; it’s a strategic roadmap, ensuring every nuance is considered to minimize downtime and maximize efficiency.

Disassembly: Crafting Precision

The disassembly phase of steam turbine overhauling is akin to a delicate dance, where each component is gracefully dismantled. Skilled hands navigate the labyrinth of blades, bearings, and seals with precision. The objective is clear: to expose the turbine’s inner workings for a thorough inspection and eventual restoration.

Component Inspection: Unveiling Secrets

In the spotlight of inspection, hidden flaws are revealed through advanced techniques like non-destructive testing. Damaged components are scrutinized, and a decision is made – repair or replace.

Upgrading the Score: Enhancing Efficiency

Engineering excellence in the steam turbine overhauling process doesn’t stop at restoration; it extends to strategic upgrades. Modern materials, innovative blade designs, and advanced control systems become part of the performance symphony. These upgrades not only rejuvenate the turbine but position it as a stalwart in the evolving landscape of power generation.

Reassembly: Crafting Harmony

Reassembly is where the symphony of the steam turbine overhauling process crescendos. Each component finds its place, aligning precisely with manufacturer specifications. It’s a meticulous endeavor, a testament to craftsmanship, where every bolt tightened contributes to the turbine’s harmonious operation.

Testing and Commissioning: The Grand Finale

The final act involves rigorous testing and commissioning. The turbine takes center stage for performance validation. This phase of the steam turbine overhauling process isn’t just about functionality; it’s about fine-tuning and adjusting, ensuring the turbine is not just restored but optimized for peak performance.

Conclusion: Orchestrating the Future of Power

In the grand theatre of power generation, steam turbine overhauling emerges as an orchestration of engineering excellence. It isn’t merely a maintenance routine; it’s a commitment to shaping the future of energy. The artistry of steam turbine overhauling ensures that these mechanical marvels continue to conduct the power symphony, playing a vital role in illuminating our world. Engineering excellence in steam turbine overhauling isn’t a task; it’s a dedication to the enduring power and potential of these machines, propelling us toward a future where power is not just generated but orchestrated with precision and artistry.

Turtle Turbines is one of the most reputed steam turbine manufacturers from India for power generation, suitable for operation on saturated and superheated steam boilers operating in various Industries. Based in India, the company focuses on providing sustainable solutions for power generation and configurations to meet the needs of different applications. For more information please visit on www.turtleturbines.com

0 notes

Text

Steam Turbine Overhauling

In the world of power generation, steam turbines plays a very important role in many industries. Steam turbines converts the heat of pressurized steam into electricity. These mechanical marvels are essential in various industries, from electricity generation to petrochemical plants. However, like all mechanical systems, steam turbines require maintenance and rejuvenation. This is where steam turbine overhauling comes into play.

Understanding Steam Turbines

A steam turbine is a rotary mechanical device that extracts energy from high-pressure steam and converts it into mechanical work. The basic principle behind its operation is simple: high-pressure steam flows through a set of blades mounted on a rotating shaft. As the steam passes through these blades, it causes the shaft to spin, thus producing mechanical energy. This energy can then be used to drive generators and produce electricity. Steam turbines are subjected to extreme conditions, such as high temperatures and pressures, which can lead to wear and tear over time, therefore steam turbine overhauling is essential. This wear and tear can result in reduced efficiency and reliability. Steam turbine overhauling becomes necessary to restore these machines to their optimal working conditions.

The Overhauling Process

Steam turbine overhauling is a comprehensive process that involves several key steps:

Shutdown and Inspection: The first step is to shut down the turbine and inspect its various components. This includes checking the rotor, blades, casings, and internal components for signs of wear, corrosion, and damage.

Disassembly: The turbine is then carefully disassembled, and each component is inspected individually. Any damaged or worn parts are identified and replaced.

Cleaning: Thorough cleaning is a critical part of the steam turbine overhauling process. All components are cleaned to remove contaminants and deposits that may have accumulated over time.

Repairs and Replacements: Damaged parts are either repaired or replaced, depending on the extent of the damage. Skilled technicians may weld, re-machine, or recondition components to bring them back to their original specifications and quality.

Balancing: The rotor assembly is balanced to ensure smooth operation and prevent vibrations that can lead to premature wear.

Reassembly: After all necessary repairs and replacements are completed, the turbine is reassembled, and all components are reinstalled.

Testing: The overhauled turbine undergoes extensive testing to ensure that it meets performance and safety standards. This includes checks for alignment, vibration, and operational efficiency.

Alignment and Calibration: The turbine is aligned with its associated equipment and calibrated to ensure optimal performance.

Final Inspection: A final inspection is conducted to verify that the overhauled turbine is ready for operation.

Benefits of Steam Turbine Overhauling

Increased Efficiency: Steam turbine overhauling can significantly improve the efficiency of a steam turbine, resulting in increased power generation and cost savings.

Extended Lifespan: Properly overhauled steam turbines can last longer, providing a reliable source of power for years to come.

Reduced Downtime: Scheduled overhauls can minimize unplanned downtime and prevent costly breakdowns.

Safety Enhancement: Overhauling includes safety checks, ensuring that the turbine operates without risks to personnel or the environment.

Conclusion

Steam turbine overhauling is a vital process that breathes new life into these power generation workhorses. It is an art that combines engineering expertise, precision, and dedication to keep these machines running efficiently and reliably. As we continue to rely on steam turbines to generate electricity and power various industries, the significance of overhauling cannot be understated. It ensures that these mechanical marvels continue to serve us, silently turning steam into the energy that drives our modern world.

Turtle Turbines is a manufacturer of steam turbines for power generation, suitable for operation on the Low Pressure Saturated to High Pressure Superheated steam boilers operating in the process industry. Based in India, the company focuses on providing sustainable solutions for power generation and energy efficiency. Turtle Tubrines offers a range of steam turbines in various sizes and configurations to meet the needs of different applications and provides the Services for Installation, Commissioning and After Sales Services for the Steam Turbines. To know more about the products and services please visit www.turtleturbines.com

0 notes

Text

Steam Turbine Overhauling

In the world of power generation, steam turbines plays a very important role in many industries. Steam turbines converts the heat of pressurized steam into electricity. These mechanical marvels are essential in various industries, from electricity generation to petrochemical plants. However, like all mechanical systems, steam turbines require maintenance and rejuvenation. This is where steam turbine overhauling comes into play.

Understanding Steam Turbines

A steam turbine is a rotary mechanical device that extracts energy from high-pressure steam and converts it into mechanical work. The basic principle behind its operation is simple: high-pressure steam flows through a set of blades mounted on a rotating shaft. As the steam passes through these blades, it causes the shaft to spin, thus producing mechanical energy. This energy can then be used to drive generators and produce electricity. Steam turbines are subjected to extreme conditions, such as high temperatures and pressures, which can lead to wear and tear over time, therefore steam turbine overhauling is essential. This wear and tear can result in reduced efficiency and reliability. Steam turbine overhauling becomes necessary to restore these machines to their optimal working conditions.

The Overhauling Process

Steam turbine overhauling is a comprehensive process that involves several key steps:

Shutdown and Inspection: The first step is to shut down the turbine and inspect its various components. This includes checking the rotor, blades, casings, and internal components for signs of wear, corrosion, and damage.

Disassembly: The turbine is then carefully disassembled, and each component is inspected individually. Any damaged or worn parts are identified and replaced.

Cleaning: Thorough cleaning is a critical part of the steam turbine overhauling process. All components are cleaned to remove contaminants and deposits that may have accumulated over time.

Repairs and Replacements: Damaged parts are either repaired or replaced, depending on the extent of the damage. Skilled technicians may weld, re-machine, or recondition components to bring them back to their original specifications and quality.

Balancing: The rotor assembly is balanced to ensure smooth operation and prevent vibrations that can lead to premature wear.

Reassembly: After all necessary repairs and replacements are completed, the turbine is reassembled, and all components are reinstalled.

Testing: The overhauled turbine undergoes extensive testing to ensure that it meets performance and safety standards. This includes checks for alignment, vibration, and operational efficiency.

Alignment and Calibration: The turbine is aligned with its associated equipment and calibrated to ensure optimal performance.

Final Inspection: A final inspection is conducted to verify that the overhauled turbine is ready for operation.

Benefits of Steam Turbine Overhauling

Increased Efficiency: Steam turbine overhauling can significantly improve the efficiency of a steam turbine, resulting in increased power generation and cost savings.

Extended Lifespan: Properly overhauled steam turbines can last longer, providing a reliable source of power for years to come.

Reduced Downtime: Scheduled overhauls can minimize unplanned downtime and prevent costly breakdowns.

Safety Enhancement: Overhauling includes safety checks, ensuring that the turbine operates without risks to personnel or the environment.

Conclusion

Steam turbine overhauling is a vital process that breathes new life into these power generation workhorses. It is an art that combines engineering expertise, precision, and dedication to keep these machines running efficiently and reliably. As we continue to rely on steam turbines to generate electricity and power various industries, the significance of overhauling cannot be understated. It ensures that these mechanical marvels continue to serve us, silently turning steam into the energy that drives our modern world.

Turtle Turbines is a manufacturer of steam turbines for power generation, suitable for operation on the Low Pressure Saturated to High Pressure Superheated steam boilers operating in the process industry. Based in India, the company focuses on providing sustainable solutions for power generation and energy efficiency. Turtle Tubrines offers a range of steam turbines in various sizes and configurations to meet the needs of different applications and provides the Services for Installation, Commissioning and After Sales Services for the Steam Turbines. To know more about the products and services please visit www.turtleturbines.com

0 notes

Text

Steam Turbines in Paper Industry

The paper industry is an essential part of our everyday lives, providing us with the books we read, the packaging for our goods, and the tissues we use. Behind the scenes, the paper industry relies on various mechanisms to produce these goods efficiently. One such mechanism that plays a crucial role is the steam turbine. Steam turbines in paper industries are the beating heart of paper industries. These impressive machines are a type of rotary engine that convert steam energy into mechanical work. The process begins with water being heated to create steam, which is then directed through a series of turbines. As the high-velocity steam flows over the turbine blades, it causes them to spin, thus generating mechanical energy.

The Role of Steam Turbines in the Paper Industry

Power Generation: Steam turbines in the paper industry are primarily used for power generation. Paper mills require significant amounts of energy for various processes, such as pulping, refining, drying, and transportation. Steam turbines in paper industries provide a reliable source of electricity that can be harnessed to run machinery, lighting, and more.

Steam Generation: In addition to producing electricity, steam turbines in paper industry are essential for generating steam used in the paper-making process. This steam is used in the drying of paper, which is a critical step in production. Steam turbines in paper industries ensure a constant supply of high-pressure steam, helping maintain the quality and efficiency of paper production.

Cogeneration: Many paper mills employ a method called cogeneration, where steam turbines not only generate electricity but also produce heat. This heat is utilized in the drying process, reducing the need for additional energy sources and increasing overall energy efficiency.

Sustainability and Efficiency: The paper industry is under constant pressure to reduce its environmental footprint. Steam turbines in paper industry play a crucial role in helping paper mills become more sustainable and energy-efficient.

Steam turbines in paper industries offer several advantages in this regard:

Waste Heat Recovery: Steam turbines can recover and utilize waste heat from the paper-making process, further increasing energy efficiency and reducing waste.

Combined Heat and Power (CHP): By using steam turbines for both electricity generation and steam production, paper mills can minimize their environmental impact and reduce reliance on fossil fuels.

Renewable Energy Integration: Many paper mills are integrating renewable energy sources, such as biomass or waste-to-energy processes, into their operations. Steam turbines can adapt to these energy sources, making them a versatile choice for sustainable production.

Conclusion

As the industry continues to evolve, so too will the role of steam turbines, helping to shape a more sustainable and efficient future for paper manufacturing.

Turtle Turbines is a manufacturer of steam turbines for power generation, suitable for operation on the Low Pressure Saturated to High Pressure Superheated steam boilers operating in the process industry. Based in India, the company focuses on providing sustainable solutions for power generation and energy efficiency. Turtle Tubrines offers a range of steam turbines in various sizes and configurations to meet the needs of different applications and provides the Services for Installation, Commissioning and After Sales Services for the Steam Turbines. To know more about the products and services please visit www.turtleturbines.com

0 notes

Text

Cogeneration using Steam Turbines in Turkey’s Dairy Industry

Turkey is rapidly emerging as a key player in the dairy industry, with a growing number of dairy plants scattered across the country. One of the critical aspects of dairy production is milk processing, which demands a substantial amount of energy. To address this energy challenge and reduce operational costs, many dairy plants in Turkey have turned to innovative solutions like cogeneration, which combines electricity and heat production.

One of the cornerstones of cogeneration in dairy plants is the utilization of a back pressure steam turbine. This technology allows the plants to efficiently generate electricity while harnessing waste heat for various processes, including milk pasteurization and drying, milk products such as milk powder, cheese, etc. By implementing cogeneration using steam turbines in Turkey’s dairy industry, dairy plants can significantly improve their energy efficiency and reduce their environmental footprint.

The cost of natural gas plays a pivotal role in the feasibility of cogeneration using steam turbines in Turkey’s dairy industry. With fluctuating natural gas prices, dairy plants need to carefully assess the economics of combined heat and power (CHP) systems. However, when natural gas prices are favorable, CHP systems can provide dairy plants with a reliable and cost-effective means of energy production, making them less dependent on external energy sources.

In conclusion, the dairy industry in Turkey is adapting to the evolving energy landscape with the implementation of cogeneration systems and back-pressure steam turbines. While the natural gas price fluctuations pose a challenge, the long-term benefits of increased energy efficiency, reduced operating costs, and a reduced carbon footprint make these solutions increasingly attractive for dairy plants. This transition towards sustainable energy practices will not only benefit the dairy industry but also contribute to a greener and more sustainable future for Turkey.

Turtle Turbines is a manufacturer of steam turbines for power generation, suitable for operation on the Low Pressure Saturated to High Pressure Superheated steam boilers operating in the process industry. Based in India, the company focuses on providing sustainable solutions for power generation and energy efficiency. Turtle Turbines offers a range of steam turbines in various sizes and configurations to meet the needs of different applications and provides the Services for Installation, Commissioning and After Sales Services for the Steam Turbines. To know more about the products and services please visit www.turtleturbines.com

0 notes

Text

Heat Rate of a Back Pressure Steam Turbines in CHP

Cogeneration, often referred to as Combined Heat and Power (CHP), is a highly efficient energy generation approach that has gained prominence in recent years. One critical component in cogeneration systems is the heat rate of a back pressure steam turbine. Understanding this parameter is essential for optimizing energy production and minimizing wastage.

The heat rate of a back-pressure steam turbine is a measure of its thermal efficiency. It represents the amount of heat energy required to produce a unit of electricity and the simultaneous generation of useful thermal energy. A lower heat rate signifies greater efficiency, making the cogeneration system more economically attractive. In essence, it allows the system to extract more energy from the same input.

Cogeneration systems equipped with back-pressure steam turbines are well-suited for industries and facilities with a high demand for both electricity and thermal energy. They are commonly employed in manufacturing plants, district heating, and even large commercial buildings. The ability to simultaneously produce electricity and heat from a single fuel source not only reduces energy costs but also decreases greenhouse gas emissions.

In conclusion, the heat rate of a back-pressure steam turbine is a crucial factor in the success of cogeneration systems. By enhancing thermal efficiency, these systems can significantly reduce energy wastage and improve overall sustainability. As industries and businesses increasingly focus on energy efficiency and environmental responsibility, cogeneration with efficient back-pressure steam turbines stands out as a compelling solution for the future.

Turtle Turbines is a manufacturer of steam turbines for power generation, suitable for operation on the Low-Pressure Saturated to High-Pressure Superheated steam boilers operating in the process industry. Based in India, the company focuses on providing sustainable solutions for power generation and energy efficiency. Turtle Turbines offers a range of steam turbines in various sizes and configurations to meet the needs of different applications and provides the Services for Installation, Commissioning and After Sales Services for the Steam Turbines. To know more about the products and services please visit www.turtleturbines.com

0 notes

Text

Heat Rate of a Back Pressure Steam Turbines in CHP

Cogeneration, often referred to as Combined Heat and Power (CHP), is a highly efficient energy generation approach that has gained prominence in recent years. One critical component in cogeneration systems is the heat rate of a back pressure steam turbine. Understanding this parameter is essential for optimizing energy production and minimizing wastage.

The heat rate of a back-pressure steam turbine is a measure of its thermal efficiency. It represents the amount of heat energy required to produce a unit of electricity and the simultaneous generation of useful thermal energy. A lower heat rate signifies greater efficiency, making the cogeneration system more economically attractive. In essence, it allows the system to extract more energy from the same input.

Cogeneration systems equipped with back-pressure steam turbines are well-suited for industries and facilities with a high demand for both electricity and thermal energy. They are commonly employed in manufacturing plants, district heating, and even large commercial buildings. The ability to simultaneously produce electricity and heat from a single fuel source not only reduces energy costs but also decreases greenhouse gas emissions.

In conclusion, the heat rate of a back-pressure steam turbine is a crucial factor in the success of cogeneration systems. By enhancing thermal efficiency, these systems can significantly reduce energy wastage and improve overall sustainability. As industries and businesses increasingly focus on energy efficiency and environmental responsibility, cogeneration with efficient back-pressure steam turbines stands out as a compelling solution for the future.

Turtle Turbines is a manufacturer of steam turbines for power generation, suitable for operation on the Low-Pressure Saturated to High-Pressure Superheated steam boilers operating in the process industry. Based in India, the company focuses on providing sustainable solutions for power generation and energy efficiency. Turtle Turbines offers a range of steam turbines in various sizes and configurations to meet the needs of different applications and provides the Services for Installation, Commissioning and After Sales Services for the Steam Turbines. To know more about the products and services please visit www.turtleturbines.com

0 notes

Text

Cogeneration using Steam Turbines in Turkey’s Dairy Industry

Turkey is rapidly emerging as a key player in the dairy industry, with a growing number of dairy plants scattered across the country. One of the critical aspects of dairy production is milk processing, which demands a substantial amount of energy. To address this energy challenge and reduce operational costs, many dairy plants in Turkey have turned to innovative solutions like cogeneration, which combines electricity and heat production.

One of the cornerstones of cogeneration in dairy plants is the utilization of a back pressure steam turbine. This technology allows the plants to efficiently generate electricity while harnessing waste heat for various processes, including milk pasteurization and drying, milk products such as milk powder, cheese, etc. By implementing cogeneration using steam turbines in Turkey’s dairy industry, dairy plants can significantly improve their energy efficiency and reduce their environmental footprint.

The cost of natural gas plays a pivotal role in the feasibility of cogeneration using steam turbines in Turkey’s dairy industry. With fluctuating natural gas prices, dairy plants need to carefully assess the economics of combined heat and power (CHP) systems. However, when natural gas prices are favorable, CHP systems can provide dairy plants with a reliable and cost-effective means of energy production, making them less dependent on external energy sources.

In conclusion, the dairy industry in Turkey is adapting to the evolving energy landscape with the implementation of cogeneration systems and back-pressure steam turbines. While the natural gas price fluctuations pose a challenge, the long-term benefits of increased energy efficiency, reduced operating costs, and a reduced carbon footprint make these solutions increasingly attractive for dairy plants. This transition towards sustainable energy practices will not only benefit the dairy industry but also contribute to a greener and more sustainable future for Turkey.

Turtle Turbines is a manufacturer of steam turbines for power generation, suitable for operation on the Low Pressure Saturated to High Pressure Superheated steam boilers operating in the process industry. Based in India, the company focuses on providing sustainable solutions for power generation and energy efficiency. Turtle Turbines offers a range of steam turbines in various sizes and configurations to meet the needs of different applications and provides the Services for Installation, Commissioning and After Sales Services for the Steam Turbines. To know more about the products and services please visit www.turtleturbines.com

0 notes

Text

Turtle Turbines: Revolutionizing the Energy Field with Payback Technology

In a world where energy efficiency and sustainability are becoming increasingly critical, innovative technologies are emerging to reshape the way we harness power. Among these innovations, Turtle Turbines has emerged as a game changer in the power and energy field with its revolutionary payback technology. This technology promises not only to reduce energy costs but also to enable consumers to recoup their investment within a remarkably short time frame.

Unveiling the Power of Turtle Turbines

Turtle Turbines has made waves in the energy sector with its advanced turbines that are designed to generate clean and sustainable energy. These turbines are compact and efficient making them suitable for various applications, including commercial and industrial settings. However, what truly sets Turtle Turbines apart is its unique payback technology.

The Payback Promise

Turtle Turbines’ payback technology is a game changer for businesses. It works on a simple yet brilliant premise: the energy generated by Turtle Turbines not only powers facility but also earns you money by feeding surplus energy back into the grid.

Smart Grid Integration: The turbines are connected to the grid through advanced technology that allows them to seamlessly integrate into the existing energy infrastructure.

Energy Savings: With the surplus energy you supply, your energy bills start to decrease significantly. In fact, in many cases, they turn into credits.

Fast Payback: What makes Turtle Turbines truly remarkable is the speed at which you can recoup your investment. The energy savings you accumulate through this payback technology enable you to recover the cost of your turbine within just a few years.

Benefits of Turtle Turbines

The introduction of Turtle Turbines and its payback technology has brought several benefits to the power and energy field:

Cost-Efficiency: Businesses can save substantial amounts on their energy bills, and the initial investment in Turtle Turbines can be recouped quickly.

Energy Independence: With Turtle Turbines, you have a reliable source of clean energy, reducing your vulnerability to power outages and energy price fluctuations.

Grid Support: By contributing surplus energy to the grid, you support the stability and resilience of the energy infrastructure.

Return on Investment: The rapid payback technology ensures that your investment in Turtle Turbines provides a tangible return within a few years, making it a financially sound choice.

Embracing a Sustainable Future

Turtle Turbines and its payback technology are leading the way in transforming the energy landscape. By harnessing clean sources while providing consumers with the means to recover their investment quickly, this innovative solution is contributing to a more sustainable and economically viable future.

The adoption of payback technology not only empowers consumers but also represents a significant step towards reducing our collective carbon footprint. As we look towards a future with increasing energy demands, Turtle Turbines stands out as a game changer in the power and energy field, offering both economic and ecological benefits to those who embrace it.

Turtle Turbines is one of the most reputed steam turbine manufacturers from India for power generation, suitable for operation on the saturated and superheated steam boilers operating in various Industries. Based in India, the company focuses on providing sustainable solutions for power generation and configurations to meet the needs of different applications. For more information please visit on www.turtleturbines.com

0 notes

Text

Maintenance of Back Pressure Steam Turbines

Maintenance of back-pressure steam turbines is a crucial aspect of ensuring their longevity and optimal performance. Steam turbines are widely used in various industries, including power generation and manufacturing, where they play a key role in generating electricity and providing process heat. To maximize the efficiency and reliability of these turbines, regular and proper maintenance is essential.

One primary aspect of the maintenance of back-pressure steam turbines is the inspection and cleaning of critical components. Over time, deposits and contaminants can accumulate on the turbine blades and nozzles, reducing its efficiency. Routine inspections and cleaning help prevent these issues and ensure that the turbine operates at its peak efficiency.

Another critical element of the maintenance of back-pressure steam turbines involves monitoring and maintaining the lubrication system. Proper lubrication is vital to reduce wear and friction within the turbine’s moving parts, ultimately prolonging its lifespan. Routine checks and oil changes are necessary to prevent any potential damage and ensure that the turbine operates smoothly.

Regular alignment and balancing are also essential in the maintenance of back-pressure steam turbines. Misalignment or imbalance can lead to increased vibrations, which can ultimately cause damage to the turbine and related equipment. Routine checks and adjustments can help avoid these problems.

Finally, safety checks and adherence to maintenance schedules are imperative for the maintenance of back-pressure steam turbines. Ensuring that maintenance is conducted as per manufacturer’s recommendations and industry standards is crucial for preventing accidents and ensuring the longevity and reliability of these critical assets. Properly maintained back-pressure steam turbines not only reduce operational costs but also contribute to overall energy efficiency and sustainability, making them a key component in various industries’ energy infrastructure.

Turtle Turbines is a manufacturer of steam turbines for power generation, suitable for operation on Low-Pressure Saturated to High Pressure Superheated steam boilers operating in the process industry. Based in India, the company focuses on providing sustainable solutions for power generation and energy efficiency. Turtle Turbines offers a range of steam turbines in various sizes and configurations to meet the needs of different applications and provides the Services for Installation, Commissioning, and after Sales Services for the Steam Turbines. To learn more about the products and services please visit www.turtleturbines.com

0 notes

Text

Turtle Turbines: Revolutionizing the Energy Field with Payback Technology

In a world where energy efficiency and sustainability are becoming increasingly critical, innovative technologies are emerging to reshape the way we harness power. Among these innovations, Turtle Turbines has emerged as a game changer in the power and energy field with its revolutionary payback technology. This technology promises not only to reduce energy costs but also to enable consumers to recoup their investment within a remarkably short time frame.

Unveiling the Power of Turtle Turbines

Turtle Turbines has made waves in the energy sector with its advanced turbines that are designed to generate clean and sustainable energy. These turbines are compact and efficient making them suitable for various applications, including commercial and industrial settings. However, what truly sets Turtle Turbines apart is its unique payback technology.

The Payback Promise

Turtle Turbines’ payback technology is a game changer for businesses. It works on a simple yet brilliant premise: the energy generated by Turtle Turbines not only powers facility but also earns you money by feeding surplus energy back into the grid.

Smart Grid Integration: The turbines are connected to the grid through advanced technology that allows them to seamlessly integrate into the existing energy infrastructure.

Energy Savings: With the surplus energy you supply, your energy bills start to decrease significantly. In fact, in many cases, they turn into credits.

Fast Payback: What makes Turtle Turbines truly remarkable is the speed at which you can recoup your investment. The energy savings you accumulate through this payback technology enable you to recover the cost of your turbine within just a few years.

Benefits of Turtle Turbines

The introduction of Turtle Turbines and its payback technology has brought several benefits to the power and energy field:

Cost-Efficiency: Businesses can save substantial amounts on their energy bills, and the initial investment in Turtle Turbines can be recouped quickly.

Energy Independence: With Turtle Turbines, you have a reliable source of clean energy, reducing your vulnerability to power outages and energy price fluctuations.

Grid Support: By contributing surplus energy to the grid, you support the stability and resilience of the energy infrastructure.

Return on Investment: The rapid payback technology ensures that your investment in Turtle Turbines provides a tangible return within a few years, making it a financially sound choice.

Embracing a Sustainable Future

Turtle Turbines and its payback technology are leading the way in transforming the energy landscape. By harnessing clean sources while providing consumers with the means to recover their investment quickly, this innovative solution is contributing to a more sustainable and economically viable future.

The adoption of payback technology not only empowers consumers but also represents a significant step towards reducing our collective carbon footprint. As we look towards a future with increasing energy demands, Turtle Turbines stands out as a game changer in the power and energy field, offering both economic and ecological benefits to those who embrace it.

Turtle Turbines is one of the most reputed steam turbine manufacturers from India for power generation, suitable for operation on the saturated and superheated steam boilers operating in various Industries. Based in India, the company focuses on providing sustainable solutions for power generation and configurations to meet the needs of different applications. For more information please visit on www.turtleturbines.com

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India.

0 notes

Text

Maintenance of Back Pressure Steam Turbines

Maintenance of back-pressure steam turbines is a crucial aspect of ensuring their longevity and optimal performance. Steam turbines are widely used in various industries, including power generation and manufacturing, where they play a key role in generating electricity and providing process heat. To maximize the efficiency and reliability of these turbines, regular and proper maintenance is essential.

One primary aspect of the maintenance of back-pressure steam turbines is the inspection and cleaning of critical components. Over time, deposits and contaminants can accumulate on the turbine blades and nozzles, reducing its efficiency. Routine inspections and cleaning help prevent these issues and ensure that the turbine operates at its peak efficiency.

Another critical element of the maintenance of back-pressure steam turbines involves monitoring and maintaining the lubrication system. Proper lubrication is vital to reduce wear and friction within the turbine’s moving parts, ultimately prolonging its lifespan. Routine checks and oil changes are necessary to prevent any potential damage and ensure that the turbine operates smoothly.

Regular alignment and balancing are also essential in the maintenance of back-pressure steam turbines. Misalignment or imbalance can lead to increased vibrations, which can ultimately cause damage to the turbine and related equipment. Routine checks and adjustments can help avoid these problems.

Finally, safety checks and adherence to maintenance schedules are imperative for the maintenance of back-pressure steam turbines. Ensuring that maintenance is conducted as per manufacturer’s recommendations and industry standards is crucial for preventing accidents and ensuring the longevity and reliability of these critical assets. Properly maintained back-pressure steam turbines not only reduce operational costs but also contribute to overall energy efficiency and sustainability, making them a key component in various industries’ energy infrastructure.

Turtle Turbines is a manufacturer of steam turbines for power generation, suitable for operation on Low-Pressure Saturated to High Pressure Superheated steam boilers operating in the process industry. Based in India, the company focuses on providing sustainable solutions for power generation and energy efficiency. Turtle Turbines offers a range of steam turbines in various sizes and configurations to meet the needs of different applications and provides the Services for Installation, Commissioning, and after Sales Services for the Steam Turbines. To learn more about the products and services please visit www.turtleturbines.com

0 notes

Text

In the heart of Southeast Asia, Thailand’s edible oil industry has long been a cornerstone of the nation’s agricultural landscape. With a rich history of palm and vegetable oil production, it plays a vital role in both domestic consumption and international trade. However, in recent years, the industry has faced a significant challenge in the form of increasing power prices, prompting a search for innovative and sustainable energy solutions.

Enter biomass fuel and the magic of cogeneration. Biomass fuel, such as wood chips and residues from the agricultural sector, has emerged as a renewable energy source, significantly reducing the industry’s carbon footprint. The ingenious integration of steam turbines powered by biomass fuel has allowed Thailand’s edible oil industry to embrace cogeneration, a system where both electricity and usable heat are simultaneously produced. This dual-purpose approach optimizes energy output, helping the industry offset the impact of increasing power prices while maintaining environmental sustainability.

Cogeneration powered by biomass fuel is not only a cost-effective solution but also a powerful tool in reducing greenhouse gas emissions. It aligns with Thailand’s commitment to combating climate change and supporting a greener future. Thailand’s edible oil industry’s adoption of this innovative energy generation model not only enhances its energy self-sufficiency but also sets an inspiring example for other sectors in Thailand and beyond to explore similar sustainable energy solutions.

The increasing power prices may have posed a challenge for Thailand’s edible oil industry, but it has responded with a forward-thinking strategy. By incorporating biomass fuel and steam turbine cogeneration, the industry has proven that it is possible to meet rising energy demands sustainably while reducing environmental impact. As Thailand’s edible oil sector pioneers this approach, it points the way forward for other industries to follow suit, driving a more energy-efficient and eco-conscious future.

Turtle Turbines is one of the most reputed steam turbine manufacturers in India for power generation, suitable for operation on the saturated and superheated steam boilers operating in various Industries. Based in India, the company focuses on providing sustainable solutions for power generation and configurations to meet the needs of different applications. For more information please visit on www.turtleturbines.com

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India. For more information visit now https://turtleturbines.com

0 notes

Text

Nestled in the heart of Southeast Asia, Myanmar’s distillery industry has long been a symbol of the nation’s rich cultural heritage and economic vitality. However, the industry has grappled with a persistent challenge – the lack of reliable power availability. In response to this pressing issue, an innovative solution has emerged, heralding a new era for the distillery sector – the integration of biomass fuel and steam turbine technology.

Biomass fuel, derived from agricultural waste and organic materials, has emerged as a beacon of hope for Myanmar’s distillery industry. By harnessing the power of steam turbines fueled by biomass, distilleries are now able to generate their electricity, thereby significantly enhancing power security and mitigating the impact of the unreliable power grid. This integration not only addresses the challenge of power scarcity but also promotes sustainable practices within the industry, reducing its carbon footprint and contributing to a more eco-friendly future.

The amalgamation of biomass fuel and steam turbine technology aids in enhancing power security through biomass fuel integration and marks a significant step towards a more self-sufficient and resilient distillery sector in Myanmar. By relying less on the unpredictable power grid and embracing sustainable energy sources, distilleries are safeguarding their operations against the adverse effects of power shortages. Moreover, this transition serves as a testament to the industry’s commitment to environmental stewardship, paving the way for a more sustainable and secure energy future for Myanmar’s distillery landscape.

Turtle Turbines is one of the most reputed steam turbine manufacturers from India for power generation, suitable for operation on saturated and superheated steam boilers operating in various Industries. Based in India, the company focuses on providing sustainable solutions for power generation and configurations to meet the needs of different applications. For more information please visit www.turtleturbines.com

Turtle Turbines is one of the most reputed Steam Turbine Manufacturers In India. For more information visit now https://turtleturbines.com

0 notes