#3 Axis CNC Routers

Video

youtube

STARMACNC 3 heads cnc engraving machine with independent 120cm Rotary ax...

#youtube#STARMACNC 3 heads cnc engraving machine with independent 120cm Rotary axis for engraving The cnc router machine on website show: https://www

0 notes

Text

This 3 axis cnc router is perfect for any small or medium engineering organization. With its high precision accessories and all-metal structure, it is both durable and easy to use. The three-axis screw motor provides precise control and the electronic spindle speed adjustment makes it easy to get the perfect speed for your project.

The 3 axis cnc router is a versatile machine that can be used for mechanical tool engraving or laser engraving. It features high precision accessories, an all-metal structure, and a three-axis screw motor for precise control. The electronic spindle speed adjustment makes it easy to get the perfect speed for your project.

The 3 axis cnc router is a versatile and precise machine that is perfect for any engineering organization. With its high precision accessories, all-metal structure, and three-axis screw motor, it is both durable and easy to use. The electronic spindle speed adjustment makes it easy to get the perfect speed for your project.

For more information about 3 axis CNC router Manufacturers company in Pune visit our website: https://www.leymonn.com/product/3-axis-cnc-router.html

#3 Axis CNC Router#3 Axis CNC Router Manufacturer#3 Axis CNC Router in Pune#3 Axis CNC Router Manufacturer Company in Pune

0 notes

Text

An Ultimate Guide To CNC Conversion Kits

If you are an entrepreneur looking to grow your production business fast, CNC conversion kits are your best bet.

And if you’re looking to buy one, you’re at the right place, as CNC Conversion Plus is your one-stop shop for the best CNC conversion kits and everything CNC.

Our conversion kits will give your older machines a complete modern makeover; all you’ve got to do is power them on and let the magic happen.

#CNC conversion kit#mill CNC conversion kit#control packages#CNC turning machine#3-axis CNC machine#CNC router machine

0 notes

Text

EXPLORING THE 5 COOL PARTNER SELLER ELECTRONICS PRODUCTS-Part1

Exploring the 5 Cool Partner Seller Electronics Products

Prologue

Are you an electronics enthusiast looking to expand your electronics project repertoire? Want to take your skills to the next level by exploring new and exciting products? Look no further than our list of five cool electronics products from partner sellers!

Whether you’re interested in building your own smart home devices, experimenting with sensors, or creating your own robot, these products are sure to inspire you. They cover a lot of application areas, from loop detectors used to monitor vehicle count in parking garages to Arduino CNC shields used in CNC machines, from simple pulse sensors used to detect cardiovascular pulse signals from fingertip to RGB LED panel light used in smart home, these products are unique, compact, and functional. Not only are these products fun to build and use but they’re also designed to help you learn new skills and techniques along the way.

What’s more, these products all come from trusted partner sellers who are committed to developing high-quality products. They’re happy to provide technical support for customers who have questions, so you can be sure you’re getting the best in electronics.

So get ready to dive into the world of electronics and explore these five cool partner seller products. You’re sure to find something that piques your interest and takes your own electronics projects to the next level.

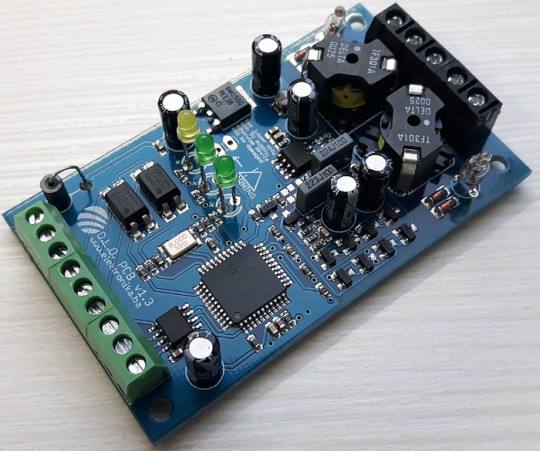

Inductive Loop Vehicle Detector by Elektronika-ba

Whether you need to monitor occupancy and count vehicles in parking garages, control vehicle access at door and barrier controls, or facilitate traffic light installations and traffic controllers, the inductive loop detector is the perfect solution. It can even detect the direction and speed of vehicle traffic, making it an invaluable tool for a variety of traffic-related applications. In addition, this device can function as a stand-alone speed trap and can be easily interfaced with Arduino.

We can also provide a pre-programmed PIC chip to meet your project requirements.

Specifications

Number of operating modes: 4

Tuning: Automatic

Detection type: Presence/Pulse

Presence time: Adjustable in 3 steps

Pulse duration: 250 ms / 500 ms

Signal filtering: Adjustable in 2 steps (NORMAL, HIGH)

Loop inductance: 20 uH — 1000 uH

Frequency range: 20 kHz — 145 kHz

Frequency selection: 2 combinations (LOW, HIGH)

Sensitivity: Maximum 0.0025% Δf/f, adjustable in 8 steps

Detection speed: 10 ms by default, adjustable

Start-up time: ~ 1 second per channel (or longer if the frequency is not stable)

Temperature range: -35°C — 120°C

Sensor protection: Galvanic isolation + gas discharge tube for lightning protection

Don’t settle for less — click here to learn more about the Inductive Loop Vehicle Detector and experience the compact, yet cool detector!

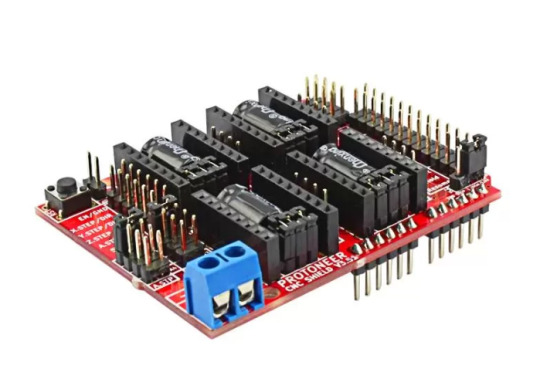

Arduino CNC Shield V3.51 by Protoneer

Designed by Protoneer, this kit is packed with features to ensure high precision control of your stepper motors, you can use it to easily build small CNC routers, DIY laser cutters, 3D printers, or any project that requires precise stepper motor control.

Our latest version 3.51 includes several enhancements to make assembly and installation even easier. We’ve added end-stop and probe signal filtering circuitry to eliminate false triggers and allow the use of unshielded cables for end-stops and probes. We’ve also increased the size of the solder pads for easier assembly and updated the probe pin labels to make installation a breeze.

With the Arduino CNC Shield Kit, you’ll have everything you need to build your own CNC router or mill with ease.

Features

Includes Noise Filers on all end stops and the probing pin. (New in V3.51)

GRBL 0.9 compatible. (Open source firmware that runs on an Arduino UNO that turns G-code commands into stepper signals https://github.com/grbl/grbl)

4-Axis support (X, Y, Z, A-Can duplicate X, Y, Z or do a full 4th axis with custom firmware using pins A4 and A3)

2 x End stops for each axis (6 in total)

Coolant enable

Uses removable Pololu A4988 compatible stepper drivers. (A4988, DRV8825 and others)(Not Included)

Jumpers to set the Micro-Stepping for the stepper drivers. (Some drivers like the DRV8825 can do up to 1/32 micro-stepping )

Compact design.

Stepper Motors can be connected with 4-pin molex connectors or soldered in place.

Runs on 12–36V DC. (At the moment only the Pololu DRV8825 drivers can handle up to 36V so please consider the operation voltage when powering the board.)

Don’t wait — click here to see more about the Arduino CNC Shield V3.51 and start your next project today!

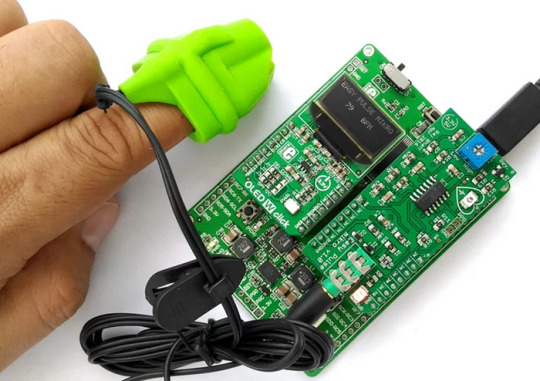

Easy Pulse Mikro by Embedded Lab

What’s more, the Easy Pulse Mikro is designed in the convenient Mikro bus form factor, making it easy to integrate with a wide range of mikroElektronika’s development boards. With all necessary instrumentation and amplification built right in, this powerful sensor provides a clean and precise analog PPG waveform output that’s routed to the AN pin of the mikroBus connector.

Whether you’re a hobbyist, student, or professional developer, the Easy Pulse mikro is the perfect tool for monitoring heart rate and other vital signs.

Click here to see more about the Easy Pulse mikro.

Features

Compatible with mikroBus socket.

Filtered and amplified analog PPG signal output

On-board potentiometer for adjusting amplifier gain, if needed (rotate clock-wise for increasing gain)

Onboard LED for indicating heartbeat. It flashes synchronously with the heartbeat on detecting the pulse from the fingertip.

2 notes

·

View notes

Text

What You Need To Know About The Different Types Of CNC Milling Machines?

In factories and workshops, getting things done quickly and accurately is really important. CNC milling machines are like the superheroes of technology because they're super precise and can adapt to different tasks. Let's explore the different kinds of machines that are helping industries come up with cool new stuff, making CNC milling easier to understand.

1. Vertical Mills:

- An easily accessible workpiece from above is made possible by the vertical axis used on vertical milling machines. Flat surfaces, slots, and pockets are frequently created using them. For tasks like mould production and prototyping, where accessibility and precision are important, vertical mills are perfect.

2. Horizontal Mills:

- Horizontal milling machines have a spindle aligned horizontally, in contrast to vertical mills. These configurations are ideal for heavy-duty machining activities and batch production because they allow the cutting of numerous sides of a workpiece without requiring repositioning. Manufacturing sectors including aerospace, automotive, and marine are strongholds for horizontal mills.

3. Multi-Axis Mills:

- Advanced features of multi-axis milling machines include simultaneous movement along several axes. These devices have unmatched accuracy and productivity when it comes to carrying out intricate machining tasks. Multi-axis mills are essential in sectors like jewellery manufacture, medical, and aerospace because they can create complex geometries and shapes by adding extra axes of movement, such as rotational or tilting axes.

4. CNC Router Mills:

- To cut and shape wood, plastic, and other non-metallic materials, specialised milling machines known as CNC router mills are used. Signage, cabinetry, and woodworking businesses will find them perfect because of their big work envelopes and high-speed spindles. For small-scale producers, artists, and hobbyists, CNC router mills are great.

5. Benchtop Mills:

- Benchtop milling machines are compact and portable, making them ideal for small workshops, educational institutions, and prototype laboratories. Despite their diminutive size, these machines provide precision and adaptability that rival bigger industrial mills. Benchtop mills are popular among amateurs, DIY enthusiasts, and students learning the principles of machining.

CNC milling machines are available in a wide range of designs that satisfy a variety of industrial requirements, from vertical mills to multi-axis machining centres. Understanding the strengths and capabilities of each kind enables producers to pick the best machine for their individual applications, enabling innovation and efficiency in the ever-changing world of contemporary production.

Why choose HLH Rapid?

HLH Rapid is a remarkable team that combines the best of the West and East. It was founded by Vader Yu from China and Director James Murphy from the United Kingdom, both of whom have extensive industry expertise.

We help companies globally by promptly producing high-quality prototypes and parts. Our skills as well as expertise promote innovation, making it easier for businesses to develop new products swiftly.

We are pleased to provide a wide range of services, including rapid injection moulding, CNC machining, and numerous 3D printing technologies (such as SLA, SLS, and SLM), all in one stop.

To know more about cnc milling services, talk to our experts today by sending an email at [email protected] or visit our website: www./hlhrapid.com

0 notes

Text

Unlocking Precision: Understanding CNC Machine Configuration

CNC (Computer Numerical Control) machines have revolutionized manufacturing by automating and streamlining the production of intricate parts with unparalleled precision and efficiency. At the heart of every CNC machine lies its configuration – a carefully orchestrated combination of components and parameters that determine its capabilities and performance. In this blog, we'll delve into the essential elements of CNC machine configuration, shedding light on the key components that drive its functionality and versatility.

Machine Type: CNC machines come in various types, each designed for specific machining operations and applications. Common types include:

CNC Milling Machines: Used for cutting and shaping solid materials, such as metal, wood, and plastics, using rotating cutting tools.

CNC Lathes: Ideal for machining cylindrical parts by rotating the workpiece against stationary cutting tools.

CNC Routers: Employed for cutting and carving materials like wood, foam, and composites using computer-controlled routing heads.

CNC Plasma Cutters: Utilized for cutting metal sheets and plates using a high-velocity jet of ionized gas (plasma). Selecting the appropriate machine type depends on factors such as the desired machining operations, material types, part complexity, and production volume.

Axis Configuration: The axis configuration of a CNC machine refers to the number and orientation of its motion control axes. Common configurations include:

3-Axis Machines: Capable of moving along three linear axes (X, Y, Z) to perform 2D and 3D machining operations.

4-Axis Machines: Incorporate an additional rotary axis (typically A or B) for rotating the workpiece, enabling more complex machining operations and angular cuts.

5-Axis Machines: Feature two additional rotary axes (typically A and B or A and C), allowing for simultaneous movement and rotation in multiple directions, expanding the range of machining possibilities and enhancing precision.

Multi-Axis Machines: Combine three or more linear and rotary axes to achieve intricate machining capabilities, such as simultaneous milling, turning, and grinding. The axis configuration determines the machine's flexibility, precision, and suitability for specific machining tasks.

Control System: The control system is the brain of the CNC machine, responsible for interpreting the part design data (usually in the form of G-code) and translating it into precise movements and commands for the machine's motors and actuators. Key components of the control system include:

CNC Controller: The central unit that processes the G-code instructions and coordinates the motion of the machine axes.

Motor Drives: Power the machine's motors and provide precise control over their speed and position.

Feedback Systems: Include encoders and sensors that provide feedback on the position, velocity, and acceleration of the machine axes, ensuring accurate motion control.

Human-Machine Interface (HMI): Allows operators to interact with the CNC machine, input machining parameters, monitor the machining process, and troubleshoot any issues. Modern CNC machines may utilize proprietary control systems or industry-standard platforms such as Fanuc, Siemens, or Mitsubishi, each offering unique features and capabilities.

Tooling and Workholding: Tooling and workholding play a critical role in CNC machining, enabling the secure fixation of workpieces and the precise execution of machining operations. Key components include:

Cutting Tools: End mills, drills, inserts, and other cutting tools tailored to specific materials and machining operations.

Tool Changers: Automatic or manual systems for changing cutting tools during machining processes, reducing downtime and increasing productivity.

Workholding Devices: Vises, clamps, fixtures, and chucks that securely hold the workpiece in place during machining, ensuring stability and accuracy. Proper selection and setup of tooling and workholding solutions are essential for achieving optimal machining results and minimizing setup time.

CNC machine configuration encompasses a myriad of components and parameters that determine the machine's capabilities, performance, and versatility. By understanding the machine type, axis configuration, control system, and tooling/workholding options, manufacturers can select and configure CNC machines to meet their specific machining requirements and production goals. Whether producing precision parts for aerospace, automotive, or medical applications, CNC machines stand ready to unlock the potential of modern manufacturing with their unparalleled precision and efficiency.

0 notes

Text

How many ways CNC machine tool systems can be classified?

CNC (Computer Numerical Control) machining is a manufacturing process that utilizes pre-programmed computer software to control the movement and operation of machine tools. These machine tools can include lathes, mills, routers, grinders, and other types of equipment used for precision cutting, drilling, shaping, and finishing of different materials.

Since its inception in the 1950s, CNC machining has revolutionized the manufacturing industry and has become an integral part of various industries such as aerospace, automotive, medical, and more. With continuous advancements in technology and software capabilities, CNC machining continues to evolve, offering a wide range of options for manufacturers to choose from.

One way to classify CNC machine tool systems is based on their motion control technology. This includes three main categories: 2-axis, 3-axis, and multi-axis systems. Let's take a closer look at each of these categories and their subcategories:

2-Axis Systems

2-axis systems are the most basic type of CNC machine tool system, with only two axes (X and Y) controlled by the computer software. These systems are typically used for simple operations such as drilling, facing, and boring. They are commonly found in manual milling machines that have been retrofitted with CNC controls.

3-Axis Systems

3-axis systems have three axes (X, Y, and Z) controlled by the computer software, allowing for more complex operations such as contouring, pocketing, and slotting. These systems are commonly used in modern CNC milling and turning machines.

Multi-Axis Systems

Multi-axis systems have additional axes, usually referred to as A, B, and C, controlled by the computer software. This adds more flexibility and complexity to the machining process, allowing for operations such as 3D surface machining and simultaneous five-axis milling. Multi-axis systems are commonly used in high-precision industries such as aerospace and medical manufacturing.

CNC machining has become an integral part of various industries in Canada, such as aerospace, automotive, medical, and more. With continuous advancements in technology and software capabilities, CNC machining continues to evolve, offering a wide range of options for manufacturers to choose from.

One major advantage of using CNC machining is its ability to produce complex and precise parts with high accuracy and repeatability. This is especially beneficial in industries where quality and precision are crucial, such as aerospace and medical manufacturing.

CNC castings in Canada also play a significant role in the manufacturing process. Casting is a cost-effective method for producing large quantities of identical parts with complex shapes and designs. With the use of CNC machining, these castings can be further refined and finished to meet specific requirements, resulting in high-quality end products.

Moreover, CNC machining offers a faster and more efficient production process compared to traditional methods. With the use of computer software and automated processes, CNC machines can produce parts with minimal human intervention, reducing the risk of errors and increasing productivity.

In Canada, there are various companies that specialize in providing CNC machining services. These companies not only offer machining services but also provide expertise in design, engineering, and prototyping. This allows for a seamless production process from concept to final product.

Another benefit of CNC machining in Canada is its ability to work with a wide range of materials such as metals, plastics, and composites. With the use of different cutting tools and techniques, CNC machines can effectively handle different materials, making it a versatile option for manufacturers.

In addition to its advantages, CNC machining in Canada also contributes to the country's economy. With the growing demand for precision and high-quality products, the need for CNC machining services continues to rise, creating job opportunities and contributing to economic growth.

Furthermore, with advancements in technology, CNC machining in Canada continues to evolve and improve. New techniques and software are constantly being developed, allowing for even more complex and precise parts to be manufactured. This not only benefits the manufacturers but also the end consumers who can enjoy high-quality products at competitive prices.

In conclusion, CNC machining in Canada is a crucial aspect of modern manufacturing. Its ability to produce high-quality, complex parts with efficiency and precision makes it an essential process for various industries. As technology continues to advance, we can only expect CNC machining in Canada to become even more advanced and integral in the manufacturing process. So whether it's for cnc castings or general machining needs, Canada has a wide range of reputable companies that offer top-notch CNC machining services. So if you're looking for quality and reliable manufacturing solutions, look no further than CNC machining in Canada. With its numerous benefits and constantly evolving technology, it's clear that CNC machining is here to stay and will continue to play a vital role in the growth of Canada's economy. So don't hesitate to utilize this advanced manufacturing process for your business needs, and experience the advantages it has to offer first-hand. Choose CNC machining in Canada and take your production to the next level. Happy machining! So, whether you're in need of CNC castings in Canada or general machining services in Canada, be sure to consider utilizing CNC machining for high-quality and efficient results. From its early origins to its current advancements, CNC machining has proven to be a valuable asset for many industries and will continue to do so in the future. So why not take advantage of this technology and see how it can benefit your business today? Give CNC machining in Canada a try and witness its power for yourself.

0 notes

Video

youtube

STARMA 3 axis 4 axis cnc router 6060 Milling And Engraving Machine

#youtube#STARMA 3 axis 4 axis cnc router 6060 Milling And Engraving Machine Main specifications: 2.2kw water cooling spindle DSPA11 control system S

0 notes

Text

An Ultimate Guide To CNC Conversion Kits

If you are an entrepreneur looking to grow your production business fast, CNC conversion kits are your best bet.

And if you’re looking to buy one, you’re at the right place, as CNC Conversion Plus is your one-stop shop for the best CNC conversion kits and everything CNC.

Our conversion kits will give your older machines a complete modern makeover; all you’ve got to do is power them on and let the magic happen.

#mill CNC conversion kit#CNC conversion kit#control packages#CNC turning machine#3-axis CNC machine#CNC router machine

0 notes

Video

youtube

OEM CNC 3040 Pro Wood Router Manufacturer 3 Axis PCB Drilling Woodworking Machinery Custom Mini CNC Wood Router Machine

More details or free tutorials ,please contact on whatsapp :008618053182392/ [email protected], Our website : jxautocnc.com

0 notes

Text

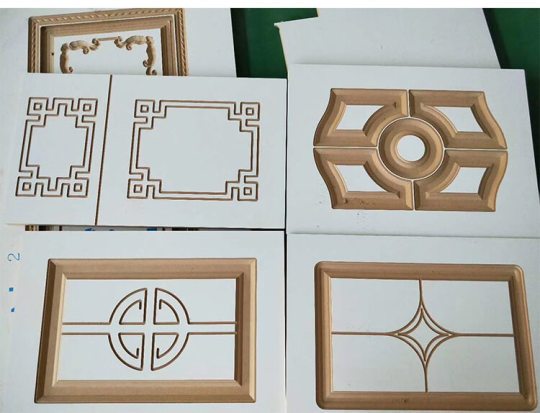

2023 Most Common Cnc Wood Router Machines For Sale #2

The CNC router is considered one of many kinds of tools which have CNC variants. The CNC Routers from Omni CNC often consist of three, 4, and 5 axis variants. The 4-axis CNC router has the flexibility to rotate across the vertical axis, and they're generally used in superior carvings and millwork.

In the world of CNC manufacturing, Purewords is a extensively known model. Although it is out there in quite so much of variants, including the 3018 and 3040, the CNC 3020 wood carving and engraving machine is now the favorite amongst woodworkers. The Sintron 3018 Pro CNC router kit’s ability to cut each horizontally and vertically makes it perfect for creating quite a lot of patterns, which is its most impressive characteristic. You can carve detailed graphics, signboards, and even 3D creations with this 3-axis CNC router. Your security is necessary to Sintron, thus for the 2020 mannequin, it created an enhanced adaptor.

All these features make Shapeoko 4 the perfect CNC for signal makers engaged on wood. The powerful spindle and motor combination can provide you a cloth removal rate of up to ninety five cubic inches of hardwood per minute if the slicing parameters are correctly chosen. This supplies wonderful accuracy and precision whereas making the machine sturdy sufficient to supply good chopping speeds.

Therefore, each in operation and maintenance, it's extra appropriate for model spanking new users. Woodworking engraving machines are widely used within the furnishings trade due to their excessive processing accuracy, easy operation, robust practicability, straightforward maintenance, and fast processing speed. Compared with different CNC machine tools, the fiber laser chopping machine can full the processing of assorted complex constructions. As long as any picture may be drawn on the pc, the machine can complete the processing without opening the mould and might produce the product immediately. That is, new merchandise could be developed rapidly and costs can be saved.

If you will work on greater projects, then you must go for the device that will give you a bigger working space. The wire mesh in the suction port of the water circulation air pump is used to stop international mud particles from getting into the pump physique. The filter mesh should be saved clear always to avoid clogging and reduce the pumping pace of the pump.

You have to connect the two Y-axis shafts, the gantry shaft, and the Z-axis slider utilizing a hex key and fasteners, which doesn't take a lot time. This is a significant level of victory for Onefinity in comparison with other desktop CNC routers. The Woodworker arrives as 4 separate pre-assembled elements, which helps you to full the whole meeting course of in half-hour. This offers you the choice to choose a router or spindle that most accurately fits the sort of work you do.

A CNC machine can only do what it is instructed to do by the software program that controls it. Check whether a dust collection system is supplied or whether one could be easily connected to it. Woodworking does not require very high torque however having a high RPM can let you cut quicker.

And widely utilized in vintage furnishings, European furniture and different furnishings industries. This 1325 CNC wood router is also called cheap CNC router, low-cost CNC machine or reasonably priced CNC machine by users for its decrease procurement and upkeep costs. From the processing path, this is also a three-axis engraving machine. The operator can full the machine operation independently.In addition, the procurement cost is low, and upkeep and repair are comparatively simple.

CNC wood router machine

Motors are most commonly stepper motors, but servos are a higher performance choice. In fact they will swell sufficient to cause accuracy issues for the CNC Router. For that reason, aluminum, steel, or phenolic are generally found on larger finish machines. A wooden spoilboard may then be connected atop the robust table below. A router table may also be made from an expendable material like MDF.

#CNC wood router machines#CNC machine wood router#CNC router wood#CNC wood router machine#CNC wood router machines for sale

1 note

·

View note

Text

ATC CNC Router for Wood Cutting and Engraving

Woodworking ATC (automatic tool changer) CNC router is a type of machine that is used to automate woodworking processes and increase efficiency. This type of router is equipped with an automatic tool changer, which allows for the rapid and precise changing of cutting tools during the routing process.

ATC Wood CNC Router

In the world of woodworking, precision, efficiency, and versatility are paramount. Enter the Automatic Tool Change (ATC) Wood CNC Router – a cutting-edge solution that revolutionizes woodworking processes. This comprehensive guide is your key to understanding the capabilities and benefits of ATC Wood CNC routers. From exploring the fundamentals of ATC technology to uncovering its diverse applications in woodworking, this guide equips you with the knowledge to optimize your woodworking operations and unleash your creativity.

It can be equipped with 6, 8, 10, 12 tools according to the different production process requirements of customers. There are two tool change modes for inline tool change and disc tool change. Widely used, including engraving, milling, chamfering, side milling, drilling, cutting, grooving, etc.

An Automatic Tool Change (ATC) Wood CNC Router is a sophisticated machining tool equipped with a tool magazine and a mechanism for automatically changing cutting tools during the machining process. Unlike manual tool changes, which require operator intervention and downtime, ATC routers streamline production by seamlessly switching between different tools as needed, enhancing efficiency and productivity.

Product Recommend

Linear ATC CNC Router with Oscillating Knife Cutting

3d Atc Auto Tool Changer Wood Woodworking Machine

Wood CNC Router Rotation Head With Rotation Table

Atc CNC Router Wood Carving Machine with Pinch Roller

ATC Linear CNC Wood Machine for Sale

3 Axis Swing Head ATC CNC Router Woodworking Machine

Linear ATC CNC Router Woodworking Machine

Atc CNC Router With Automatci Tool Changer

ATC CNC Router With Automatic Tool Changer

Step into a world of limitless possibilities with our state-of-the-art Woodworking ATC CNC Router with Tool Changer. Designed to revolutionize your woodworking experience, this cutting-edge machine combines precision, efficiency, and versatility to bring your creative visions to life like never before.

Unparalleled Precision

Experience woodworking at its finest with the Woodworking ATC CNC Router’s exceptional precision. Equipped with advanced technology and high-precision components, this machine ensures every intricate detail of your designs is flawlessly executed. From intricate carvings to intricate joinery, achieve perfection with ease.

Automatic Tool Changer

Say goodbye to time-consuming manual tool changes. Our Woodworking ATC CNC Router comes with an Automatic Tool Changer (ATC) that allows seamless and efficient transitions between different cutting, carving, and shaping tools. This feature not only saves you valuable time but also enables uninterrupted workflow, maximizing productivity.

Versatility Redefined

With the Woodworking ATC CNC Router’s tool-changing capabilities, you can explore a wide range of woodworking applications. Whether you’re crafting fine furniture, intricate cabinetry, decorative moldings, or even intricate wood engravings, this machine empowers you to push the boundaries of your creativity with ease.

Efficient Workflow

Boost your efficiency and optimize your workflow with the Woodworking ATC CNC Router. Its user-friendly interface and intuitive controls make operation effortless, allowing you to focus on unleashing your creativity. The machine’s rapid cutting speed, coupled with the automatic tool changer, ensures quick turnarounds and seamless production.

Enhanced Material Compatibility

The Woodworking ATC CNC Router is designed to accommodate a variety of materials, expanding your woodworking capabilities. From hardwoods to softwoods, plywood to MDF, this machine delivers exceptional results on various materials, enabling you to tackle diverse woodworking projects with confidence.

Reliable and Durable

Invest in a woodworking machine that stands the test of time. Our Woodworking ATC CNC Router is built with durability and reliability in mind. The robust construction and high-quality components ensure consistent performance, minimizing downtime and maximizing your return on investment.

Unmatched Customer Support:

We are committed to providing exceptional customer support throughout your woodworking journey. Our team of experts is available to assist you with any queries, technical support, or training needs, ensuring a smooth and seamless experience with our Woodworking ATC CNC Router.

Applications of ATC CNC Router Machine

The applications of ATC Wood CNC routers span a wide range of woodworking disciplines and industries. In furniture manufacturing, ATC routers excel at producing custom cabinetry, decorative panels, intricate carvings, and complex joinery with precision and efficiency.

Artistic woodworking thrives with ATC routers, allowing craftsmen to explore creative designs, sculptures, and intricate patterns with ease and precision.

ATC Wood CNC routers offer a multitude of benefits for woodworking professionals and businesses. Firstly, they significantly reduce setup times and tool changeovers, maximizing uptime and throughput. This results in faster production cycles and shorter lead times, ultimately increasing profitability and competitiveness in the market.

Moreover, ATC routers enhance versatility by enabling the use of a wide range of cutting tools, including end mills, drills, saw blades, and specialty tools. This versatility allows woodworkers to tackle diverse projects with varying requirements, from intricate carving and engraving to precision cutting and shaping.

Furthermore, ATC technology improves accuracy and consistency by eliminating human error associated with manual tool changes. This ensures uniformity in finished products and minimizes waste, leading to higher quality and customer satisfaction.

Key Considerations when Choosing an ATC Wood CNC Router

Selecting the right ATC Wood CNC Router is vital to ensure optimal performance and productivity. Here are some essential factors to consider:

a. Machine Size and Work Area: Assess your workspace and determine the appropriate machine size and work area to accommodate your woodworking projects.

b. Spindle Power and Speed: Consider the type of wood materials and cutting requirements you will be working with. Choose a machine with an adequate spindle power and speed range to achieve desired results efficiently.

c. Tool Magazine Capacity: Evaluate the tool magazine capacity of the ATC Wood CNC Router. Ensure that it can accommodate the range and quantity of cutting tools you typically use for your projects.

d. Control System and Software: Look for a machine with a user-friendly control system and compatible software. The software should support your design needs and provide ease of use for programming and toolpath generation. e.Continuation:

e. Machine Durability and Build Quality: Consider the durability and build quality of the ATC Wood CNC Router. Look for machines constructed with robust materials and components that can withstand the demands of continuous use.

f. Support and Training: Ensure that the manufacturer or supplier provides comprehensive support and training for the machine. This will help you maximize the capabilities of the ATC Wood CNC Router and troubleshoot any issues efficiently.

g. Budget and Return on Investment (ROI): Determine your budget and evaluate the potential return on investment. While ATC Wood CNC Routers may require a significant initial investment, their efficiency and productivity gains can lead to long-term cost savings and improved profitability.

ATC Wood CNC Routers offer a multitude of benefits and applications for woodworkers and manufacturers in the woodworking industry. Their automatic tool changing capability, versatility, precision, and efficiency make them indispensable tools for creating intricate designs, producing custom woodworking projects, and streamlining production processes. By considering key factors when choosing a machine and implementing proper maintenance, woodworkers can harness the full potential of an ATC Wood CNC Router to achieve exceptional results and stay at the forefront of the woodworking industry.

0 notes

Text

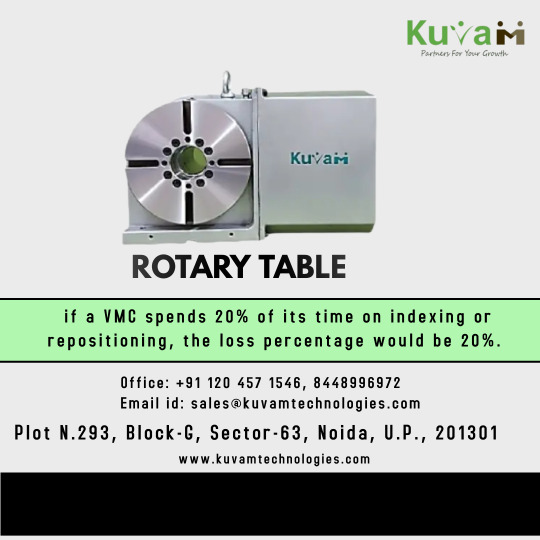

6 Things About CNC Rotary Table You May Not Have Known

CNC Rotary tables are generally ordinarily mounted "level", with the table turning around an upward hub, in a similar plane as the shape of an upward processing machine. A substitute arrangement is to mount the rotational table on its end (or mount it "level" on a 90° point plate), with the goal that it turns into an event hub. In this setup a tailstock can likewise be utilized, hence holding the workpiece "between focuses."

CNC Rotary Table are a type of work positioning device that is used in CNC machining centers. They are used to precisely position components at the desired angle to do multi-face operations in a single setup.

Rotary tables can be interpolated as the 4th Axis Rotary table For VMC with machines X, Y, and Z axes to enable machining of profiles such as cam machining, blade machining, and helical grooves - which would be otherwise out of reach with a standard 3 axes machining center. The table must be able to accommodate the workpiece and provide enough support to ensure precision and accuracy.

When selecting a rotary table, there are a few guidelines to keep in mind.

First, consider the size of the component you need to work with.

Second, check for the amount of swing required.

Third, check the center height of the table.

Fourth, for a multi-spindle table, check the center distance between the spindles.

Finally, in vertical conditions, if the length of the component is more than 100 mm, it is recommended to use a tailstock support.

When selecting a rotary table, you must take into consideration the clamping torque required for the operation.

To do this, you must first determine the machining forces required and the distance from the center where the operation will take place.

Then, calculate the torque that will be applied during machining (Torque = Force x Distance).

The machining torque should be within the Clamp torque capacity of the Table. Finally, you must check for the type of clamping required (Hydraulic or Pneumatic).

Select the component and fixture based on weight.

The weight should be within the capacity of the rotary table.

With tail stock, the support load capacity of the rotary table in vertical conditions will become equal to the horizontal load capacity.

To achieve the required accuracy, you need to check the indexing accuracy of the component and convert it to mm at the diameter where the operation is to be carried out.

NOTE: Higher accuracy of +/- 5” can be achieved by using an additional high-resolution encoder mounted on the table axis.

When choosing a machine, you should take into account its capacity and the size of the area in which it can operate.

You should also make sure that the machine will be able to handle the weight of the rotary table and any additional equipment.

The selection of the most suitable machine guard is based on the avoidance of fouling with the rotary table or sheet guard.

Following the mounting of the latter on the machine bed, it is essential to check for any fouling of the guard with the machine guard.

If fouling occurs, then the rear motor-mounting table can be used, provided there is sufficient space between the machine table and sheet guard when the latter is in its extreme right-hand position.

When selecting a controller, you should first check if it's capable of handling the 4th and 5th axis rotary tables for single-axis and two-axis tables respectively.

If not, we can suggest a stand-alone controller that can still perform the necessary operations even if it doesn't have continuous interpolation with the machine axes.

In some cases, controllers are only capable of 4 regular axes but the 5th axis can still do indexing.

At Kuvam Technologies Pvt Ltd, we pride ourselves on being able to provide our customers with the Direct Drive Rotary Table and its accessories that best suit their needs. If you need assistance in selecting the right product for your project, please do not hesitate to contact us at [email protected] and we will be more than happy to help you.

0 notes

Text

edge banding machines

China CNC router for sale - Roctech have advanced technology for Cabinet CNC center,cnc router cabinets,3/4/5 axis CNC machine,Roctech already have 15 years experiences of cnc router technology.cnc drilling machines

1 note

·

View note

Text

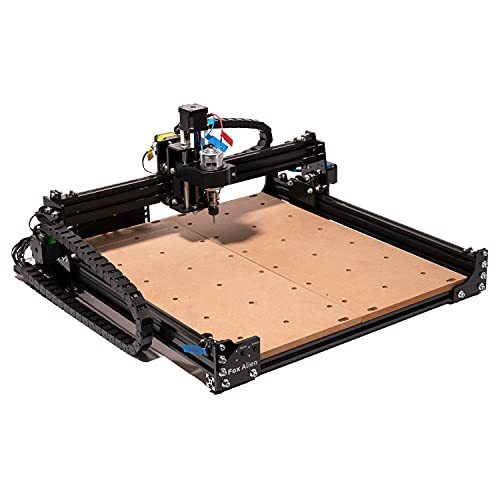

FoxAlien Masuter 4040 CNC Router Machine 3-Axis Engraving Milling

- Brand and Manufacturer: FoxAlien

Features

- Masuter 4040 is a budget-friendly CNC router with huge workspace of 400 x 380 x 55mm (15.75" x 14.96" x 2.16"). It utilizes a 60W spindle as well as NEMA17 stepper motors. Max moving rate is 2000mm/min and pin rate array is 0 ~ 10000.

- The control board is equipped with an upgraded 32-bit chip which works a lot more effective and also secure. It likewise sustains attachments such as offline controller, 300W spindle and power components. (Add-ons offered separately)

- Masuter 4040 is qualified to engrave, cut as well as pierce lots of kinds of material such as wood, MDF, acrylic and material etc. Suggested setups: speed-1000mm/ minutes; deepness per pass-0.2 mm; plunge rate-200mm/ minutes.

- House function and Emergency-Stop button are incorporated on the machine. The machine will certainly go to house with just push the button.

- Almost all are pre-assembled. It takes about 20-30mins to totally setting up. The machine works with Grbl software. It sustains Windows XP/7/10, Linux as well as Mac OS.

Maker Info

- Model: Masuter 4040

Item Info

- Size: 26.38 x 23.62 x 11.81 inches

Read the full article

0 notes