#Aerospace 3D Printing Market Share

Text

Aerospace 3D Printing Market Surges with Rise in Lightweight Component Demand

Rapid prototyping in the aerospace sector and the increase in the utilization of light weight components is driving the Global Aerospace 3D Printing Market.

According to TechSci Research report, “Aerospace 3D Printing Market- Global Industry Size, Share, Trends, Competition, Opportunity, and Forecast, 2018-2030”. Global Aerospace 3D Printing market is growing because traditional materials are being replaced with new, lightweight, high-strength materials, which is an efficient way to achieve the goals of lowering emissions, using fewer materials, and improving fuel efficiency. The 3D printed components are highly used for rapid prototyping in the aerospace industry and the companies have started using engine components made from a 3D printed process. In addition to manufacturing expenses, maintenance costs can be decreased as well because 3D-printed parts require less maintenance.

Other than material expenses, the price of printing 10 pieces of the same product versus 10 pieces of ten distinct products is the same. The addictive manufacturing process is helping in making the components cost effective and light weight. All these factors are driving the growth of the global Aerospace 3D Printing Market during the forecast period.

To increase the usage of 3D-printed parts and components in more advanced aircraft and spacecraft, several aerospace OEMs are now funding extensive research programs. Additionally, the adoption of 3D-printed parts is expanding in the aftermarket sector since doing so could ease the strain on conventional supply networks. period. The advantages that 3D printing provides have made it more widely accepted in the aviation industry. With shorter lead times, lower prices, and more digitally flexible design and development techniques, 3D printing generates parts.

Both customers and manufacturers experience significant cost savings because of the adoption of 3D printing. However, the COVID-19 has impacted the industry as because of lockdowns and other curbs all the manufacturing process was hampered, and this has resulted in the decline in the growth of the market. However, in the forecast years the Global Aerospace 3D Printing Market will exhibit higher growth rate.

Browse more than XX market data Figures spread through XX Pages and an in-depth TOC on " Global Aerospace 3D Printing Market"

https://www.techsciresearch.com/report/aerospace-3d-printing-market/4028.html

The Global Aerospace 3D Printing Market is segmented based on application, material type, printer technology type, by region, and by company. Based on application, the market is further divided into aircraft, unmanned aerial vehicles, & spacecraft. Based on material, the market is bifurcated into alloys & special metals. On the basis of printer technology, the market is further segmented into SLA, FDM, DMLS, SLS, CLIP and others.

Some of the major companies operating in the Global Aerospace 3D Printing Market include:

Aerojet Rocketdyne Holdings Inc.

MTU Aero Engines AG

GE Aviation

Stratasys, Ltd.

The Exone Company,

Materialise NV

3D Systems, Inc

Hoganas AB

Envisiontec GmbH

EOS GmbH

These are the key players developing advanced technologies and launching new products to stay competitive in the market. Other competitive strategies include mergers with the research and development firms, new product developments, and marketing activities to increase customer outreach. These companies are also focusing on meeting the regulations of different regional governments and are also partnering with different defense research bodies to stay competitive in the market.

Download Free Sample Report

https://www.techsciresearch.com/sample-report.aspx?cid=4028

Customers can also request for 10% free customization on this report.

“In the next few years, 3D printing is anticipated to develop into a speedy method for producing low-volume parts that can be used in the mass manufacturing of the components of big metal and the process is also used in the prototyping of the component. The advancements and technological innovations in the industry is expected drive Global Aerospace 3D Printing Market growth” said Mr. Karan Chechi, Research Director with TechSci Research, a research-based global management consulting firm.

“Aerospace 3D Printing Market- Global Industry Size, Share, Trends, Competition, Opportunity, and Forecast, 2018-2030” has evaluated the future growth potential of Global Aerospace 3D Printing Market and provides statistics & information on market size, structure, and future market growth. The report intends to provide cutting-edge market intelligence and help decision makers take sound investment decisions. Besides, the report also identifies and analyzes the emerging trends along with essential drivers, challenges, and opportunities in the global Aerospace 3D Printing Market.

Browse Related Research

Micro Vsat Market

https://www.techsciresearch.com/report/micro-vsat-market/19239.html

Military Satellite Market

https://www.techsciresearch.com/report/military-satellite-market/19241.html

More Electric Aircraft Market

https://www.techsciresearch.com/report/more-electric-aircraft-market/19242.html

Nanosatellites and Microsatellite Market

https://www.techsciresearch.com/report/nanosatellites-and-microsatellite-market/19243.html

Contact

Mr. Ken Mathews

708 Third Avenue,

Manhattan, NY,

New York – 10017

Tel: +1-646-360-1656

Email: [email protected]

Web: https://www.techsciresearch.com

#Aerospace 3D Printing Market#Aerospace 3D Printing Market Size#Aerospace 3D Printing Market Share#Aerospace 3D Printing Market Trends#Aerospace 3D Printing Market Growth

0 notes

Text

#3D Printing In Aerospace And Defense Market#3D Printing In Aerospace And Defense Market size#3D Printing In Aerospace And Defense Market share#3D Printing In Aerospace And Defense Market trends#3D Printing In Aerospace And Defense Market analysis#3D Printing In Aerospace And Defense Market forecast

0 notes

Text

The aerospace 3D printing materials market is projected to reach USD 8.39 billion by 2027, at a CAGR of 25% from USD 2.75 billion in 2022. Demand for lightweight, cost-effective aircraft, as well as the need for rapid manufacturing of complex parts are expected to drive the aerospace 3D printing materials market forward.

The Fusion Deposition Modeling (FDM) segment is expected to dominate the aerospace 3D printing market in terms of printing technology. The ability of this technology to produce complex shapes with varying textures, thickness, and color is one of the main factors driving the segment's overall growth.\

North America is the largest region in the aerospace 3D printing materials market and is driven by the increasing adoption of 3D printing technology for the production of complex, lightweight 3D components Furthermore, aircraft component and aircraft manufacturers are shifting to 3D printing technology to produce low-volume parts, fueling the growth of the aerospace 3D printing market.

The key players in this market 3D systems Corporation (US), Stratasys, Inc. (Israel), Materialise N.V (Belgium), EOS GmbH (Germany), and Ultimaker B.V. (Netherlands). Continuous developments in the market—including new product launches, mergers & acquisitions, agreements, and expansions—are expected to help the market grow. Leading manufacturers of aerospace 3D printing materials market have opted for new product launches to sustain their market position.

#Aerospace 3D Printing Materials#Aerospace 3D Printing Materials Market#Global Aerospace 3D Printing Materials market#Aerospace 3D Printing Materials Market Overview#Aerospace 3D Printing Materials Research Report#Aerospace 3D Printing Materials Research Insights#Aerospace 3D Printing Materials business Research Report#Aerospace 3D Printing Materials Industry Trends#Aerospace 3D Printing Materials Market Share#Aerospace 3D Printing Materials Market Analysis#Aerospace 3D Printing Materials Market Growth#Demand for Aerospace 3D Printing Materials#Sales for Aerospace 3D Printing Materials

0 notes

Text

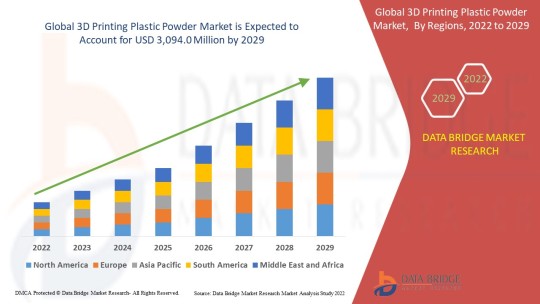

3D Printing Plastic Powder Market Size, Share, Trends and Forecast by 2029

This 3D Printing Plastic Powder market report has been prepared by considering several fragments of the present and upcoming market scenario. The market insights gained through this market research analysis report facilitates more clear understanding of the market landscape, issues that may interrupt in the future, and ways to position definite brand excellently. It consists of most-detailed market segmentation, thorough analysis of major market players, trends in consumer and supply chain dynamics, and insights about new geographical markets. The market insights covered in 3D Printing Plastic Powder report simplifies managing marketing of goods and services effectively.

Data Bridge Market Research analyses that the 3D printing plastic powder market will witness a CAGR of 4.4% for the forecast period of 2022-2029 and is likely to reach at USD 3,094.0 million by 2029.

Download Sample PDF Copy of this Report to understand structure of the complete report @ https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-3d-printing-plastic-powder-market

Market Overview:

The rising demand for bio based plastics is the major factor accelerating the growth of the 3D printing plastic powder market. Furthermore, government support, advancements in different materials and technologies, growing demand from consumer electronic industry, and increasing application of 3D printing plastic also expected to drive the growth of the 3D printing plastic powder market. However, rising environment concern regarding disposal of 3D printed plastic products and dearth of acceptance among population will restrains the 3D printing plastic powder market, whereas, various governments are banning the usage of plastic will challenge 3D printing plastic powder market growth.

Some of the major players operating in the 3D Printing Plastic Powder market are 3D Systems, Inc, Arkema, Stratasys Ltd, EOS GmbH, CRP TECHNOLOGY S.r.l., Cyfuse Biomedical K.K., CELLINK GLOBAL, Anatomics Pty Ltd, EOS, ENVISIONTEC, INC., Materialise, Renishaw plc, SLM Solutions, FIT AG, Prodways Technologies (a subsidiary of Prodways Group), BOSON MACHINES, Advanced Solutions Life Sciences, LLC, Tinkerine Studios Ltd Oxford Performance Materials, Materialise, BASF SE, Evonik Industries AG, Clariant, HP Development Company, L.P., DuPont de Nemours, Inc., VEXMA TECHNOLOGIES PVT LTD, PolyOne Corporation, 3Dnatives, Protofab, Jariwala Robotics Private Limited among others.

Global 3D Printing Plastic Powder Market Scope

The 3D printing plastic powder market is segmented on the basis of type, application and end-user. The growth amongst the different segments helps you in attaining the knowledge related to the different growth factors expected to be prevalent throughout the market and formulate different strategies to help identify core application areas and the difference in your target market.

On the basis of type, the 3D printing plastic powder market is segmented into photopolymer, ABS and ASA, polyamide, PLA, polylactic acid and others.

The application segment of the 3D printing plastic powder market is segmented into prototyping and manufacturing.

The end-user segment of the 3D printing plastic powder market is divided into healthcare, aerospace and defense, automotive, electrical and electronics and other.

Browse More About This Research Report @ https://www.databridgemarketresearch.com/reports/global-3d-printing-plastic-powder-market

Table of Content:

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Global 3D Printing Plastic Powder Market Landscape

Part 04: Global 3D Printing Plastic Powder Market Sizing

Part 05: Global 3D Printing Plastic Powder Market Segmentation By Product

Part 06: Five Forces Analysis

Part 07: Customer Landscape

Part 08: Geographic Landscape

Part 09: Decision Framework

Part 10: Drivers and Challenges

Part 11: Market Trends

Part 12: Vendor Landscape

Part 13: Vendor Analysis

Browse Trending Reports:

Global Auto Injectors Market – Industry Trends and Forecast to 2029https://www.databridgemarketresearch.com/reports/global-auto-injectors-market

Global Specimen Retrieval Market – Industry Trends and Forecast to 2028https://www.databridgemarketresearch.com/reports/global-specimen-retrieval-market

Global Core Needle Biopsy Market – Industry Trends and Forecast to 2028https://www.databridgemarketresearch.com/reports/global-core-needle-biopsy-market

Global Autonomous Emergency Braking Market – Industry Trends and Forecast to 2030https://www.databridgemarketresearch.com/reports/global-autonomous-emergency-braking-market

About Data Bridge Market Research:

An absolute way to predict what the future holds is to understand the current trend! Data Bridge Market Research presented itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are committed to uncovering the best market opportunities and nurturing effective information for your business to thrive in the marketplace. Data Bridge strives to provide appropriate solutions to complex business challenges and initiates an effortless decision-making process. Data Bridge is a set of pure wisdom and experience that was formulated and framed in 2015 in Pune.

Data Bridge Market Research has more than 500 analysts working in different industries. We have served more than 40% of the Fortune 500 companies globally and have a network of more than 5,000 clients worldwide. Data Bridge is an expert in creating satisfied customers who trust our services and trust our hard work with certainty. We are pleased with our glorious 99.9% customer satisfaction rating.

Contact Us: -

Data Bridge Market Research

Email: – [email protected]

#3D Printing Plastic Powder Market#3D Printing Plastic Powder Market Growth#3D Printing Plastic Powder Market Demand

0 notes

Text

Additive Manufacturing Market Size, Share, Forecast, & Trends Analysis

additive manufacturing market is poised to soar to unprecedented heights, anticipated to burgeon to a monumental $228.8 billion by the year 2031, exhibiting a remarkable Compound Annual Growth Rate (CAGR) of 27.9% from 2024 to 2031.

Download free sample report here: https://www.meticulousresearch.com/download-sample-report/cp_id=5838?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=30-05-2024

The ascent of the additive manufacturing sector is propelled by an array of compelling forces, including the imperative to fabricate intricate components, slash manufacturing outlays, and curtail wastage. Additionally, advancements in product innovation and supply chain efficiency, coupled with the allure of seamless customization and mass production capabilities inherent in additive manufacturing, further catalyze this exponential growth trajectory. However, challenges loom in the form of limited build dimensions and the associated pre-processing and post-processing overheads, which could potentially dampen market expansion.

Yet, amidst these challenges lie untapped vistas of opportunity, particularly in the realms of 3D printing for functional end-use parts and the burgeoning domain of composite 3D printing. Nevertheless, concerns regarding intellectual property infringement and the scarcity of adept professionals threaten to impede the sector's growth.

Emerging trends paint a vivid picture of on-demand spare parts fabrication, heightened product personalization, and the integration of Artificial Intelligence (AI) into 3D printing workflows as prevailing themes in this dynamic landscape.

Browse in depth: https://www.meticulousresearch.com/product/additive-manufacturing-market-5838?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=30-05-2024

Delving deeper, the global additive manufacturing market is intricately segmented into offerings encompassing hardware, software, materials (encompassing plastics, polymers, metals, ceramics, composites, and other material variants), and services. Moreover, delineations based on form — spanning solid, liquid, and powder material categories — offer nuanced insights into the market's multifaceted composition. End-user segmentation further elucidates the market dynamics, encompassing a gamut of sectors ranging from consumer products, healthcare, and automotive to aerospace & defense, electronics & semiconductors, and beyond.

Unveiling the market's intricate tapestry, the hardware segment emerges as the dominant force, commanding a lion's share exceeding 60.0% of the global additive manufacturing arena. This preeminence is fueled by a confluence of factors, including the decentralization of production, on-demand manufacturing paradigms, and the concomitant streamlining of supply chains. Noteworthy is the hardware segment's pivotal role in facilitating the realization of highly tailored, bespoke products across diverse industry verticals.

Download request sample report here: https://www.meticulousresearch.com/request-sample-report/cp_id=5838?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=30-05-2024

Segmentation by form unveils a nuanced narrative, with solid materials dominating the landscape owing to their indispensable mechanical properties, whereas powder materials emerge as the harbinger of future growth, underpinned by their pivotal role in additive manufacturing processes.

Zooming out to a geographical perspective, Asia-Pacific emerges as the epicenter of additive manufacturing fervor, commanding a substantial share exceeding 36.0% of the global market. The region's ascendancy is underpinned by a confluence of factors, including burgeoning manufacturing activities, robust digitization initiatives, and a burgeoning startup ecosystem. Meanwhile, North America is poised to register the highest CAGR of 29.0%, propelled by the region's robust industrial landscape and a burgeoning appetite for customized 3D-printed products across diverse sectors.

Amidst this landscape of transformative change, key players including industry stalwarts such as 3D Systems Corporation, Arcam AB, Stratasys, Ltd., and a host of others stand at the vanguard, shaping the contours of tomorrow's manufacturing landscape through pioneering innovations and unwavering commitment to excellence.

Quick buy: https://www.meticulousresearch.com/Checkout/86948189?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=30-05-2024

Contact Us:

Meticulous Research®

Email- [email protected]

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

0 notes

Text

Additive Manufacturing with Metal Powders Market Size, Share, Trends, Demand, Industry Growth and Competitive Outlook

Additive Manufacturing with Metal Powders Market business report provides a profound overview of product specification, technology, product type and production analysis considering major factors such as revenue, cost, and gross margin. This market document consists of market analysis by regions, especially North America, China, Europe, Southeast Asia, Japan, and India, focusing top manufacturers in global market, with production, price, revenue, and market share for each manufacturer. Hence the report assists clients to take well-informed and crucial decisions in their respective industries, sectors, or companies. A reliable Additive Manufacturing with Metal Powders report also includes market drivers and market restraints that are derived from SOWT analysis.

The universal Additive Manufacturing with Metal Powders market research report will be favorable for new comers/new investors, propose investors, and private equity enterprises, analysts, and prudent business organizers, suppliers, manufacturers, and distributors, and end-use industries. In addition, this market report also endows with top to bottom estimation of the market with respect to income and developing business sector. Thus, Additive Manufacturing with Metal Powders report is a great source of an in-depth market analysis to prosper in this competitive environment. It showcases all the recent developments, product launches, joint ventures, mergers, and acquisitions by the several key players and brands that are driving the market.

Data Bridge Market Research analyses that the additive manufacturing with metal powders market will witness a CAGR of 22.1% for the forecast period of 2022-2029 and is likely to reach at USD 2.111,10 million by 2029.

Access Full 350 Pages PDF Report @

Additive manufacturing refers to associate industrial variant of 3D printing technology that manufactures 3D objects through 3D modeling package, machine instrumentality, and layering material. Additive producing with metal powders combines parts to fabricate objects from the 3D modeling information, usually layer-upon-layer. The technique is presently wide applied to supply dental restorations, medical implants, vehicles, aerospace, and different product.

Some of the major players operating in the additive manufacturing with metal powders market report are Allegheny Technologies Incorporated, American Axle & Manufacturing, Inc., American Chemet Corp., AMETEK Specialty Metal Products, Burgess-Norton Manufacturing Company, Carpenter Technology Corporation, Daido Steel Co, Ltd., Diamet Corporation, Dowa Holdings Co., Ltd., Erasteel SAS, F. W. Winter Inc. & Co., Federal-Mogul Holdings Corp., Fine Sinter Co., Ltd., GKN Sinter Metals, Inc., Hoeganaes Corp., H.C. Starck GmbH, Hitachi Chemical Company, Ltd., Hgans AB, JFE Steel Corp., Kennametal, Inc., Kobe Steel, Ltd., Kymera International, Miba AG, Norilsk Nickel, PMG Holding GmbH, Rio Tinto Metal Powders among other.

Table of Content:

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Global Additive Manufacturing with Metal Powders Market Landscape

Part 04: Global Additive Manufacturing with Metal Powders Market Sizing

Part 05: Global Additive Manufacturing with Metal Powders Market Segmentation by Product

Part 06: Five Forces Analysis

Part 07: Customer Landscape

Part 08: Geographic Landscape

Part 09: Decision Framework

Part 10: Drivers and Challenges

Part 11: Market Trends

Part 12: Vendor Landscape

Part 13: Vendor Analysis

Additive Manufacturing with Metal Powders Key Benefits over Global Competitors:

The report provides a qualitative and quantitative analysis of the Additive Manufacturing with Metal Powders Market trends, forecasts, and market size to determine new opportunities.

Porter’s Five Forces analysis highlights the potency of buyers and suppliers to enable stakeholders to make strategic business decisions and determine the level of competition in the industry.

Top impacting factors & major investment pockets are highlighted in the research.

The major countries in each region are analyzed and their revenue contribution is mentioned.

The market player positioning segment provides an understanding of the current position of the market players active in the Personal Care Ingredients

Browse Trending Reports:

Fluorocarbon Based Vacuum Grease Market

Hygiene Adhesives Market

Isoprene Market

Lubricant Anti Wear Agents Market

Oilfield Surfactants Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 888 387 2818

UK: +44 208 089 1725

Hong Kong: +852 8192 7475

Email: [email protected]

0 notes

Text

Brazil Industry 4.0 Market - Forecast(2024 - 2030)

Brazil Industry 4.0 Market Overview

Brazil Industry 4.0 Market size is forecasted to reach $6230.29 million by 2027, growing at a CAGR of 10.91% during the forecast period from 2022-2027. Industry 4. has become vital for all organizations owing to paradigm shift towards real time or near real-time process monitoring in the industrial sector. The growing emphasis towards high-speed machine-to-machine (M2M) communication on the factory floor coupled with the increasing investment in plant digitalization is set to drive the Brazil Industry 4.0 Market growth during the forecast period. In addition to this, adoption of various advanced technologies including augmented reality, cloud computing, enterprise resource planning, internet of things, robotics and others; across industry verticals such as oil and gas, transportation, energy, mining, utilities and so on, is set to drive system integration service market growth. Increasing penetration of industry 4.0 across the globe combining artificial intelligence, big data and analytics, 4G, 5G with operational technology as a part of addressing worker safety, optimizing field operations, and boosting maintenance productivity along with process efficiency in industrial environments is considered vital in driving the growth of Brazil industry 4.0 industry.

Report Coverage

The report: “Brazil Industry 4.0 Market Report– Forecast (2022-2027)” by IndustryARC, covers an in-depth analysis of the following segments in the Brazil Industry 4.0 Market.

By Offerings: Hardware, Software and Services (System Integration Services, Testing & Certification, Maintenance and Operational Services, Consulting and Others).

By Technology: Artificial Intelligence, Machine-to-Machine, Big Data and Analytics, Augmented Reality & Virtual Reality, Autonomous Robots, SCADA, Simulation, Horizontal and vertical System Integration, Cloud Computing, Cyber Security, Internet of Things (IoT), Digital Twin, Advanced human-machine interfaces (HMI), Additive Manufacturing (3D Printing) and Others.

By End-User: General Manufacturing, Transportations & Logistics, Medical & Pharmaceutical, Metal & Mining, Oil & Gas (Upstream, Midstream and Downstream), Automotive & Tire, Aerospace & Defence, Food & Beverage, Electronics & Semiconductors, Power (Power Generation, Power Distribution and Power Transmission), Construction, Agriculture (Seeding and Weeding, Monitoring, Fertilizer Application, Harvesting, Pruning, and Others), Water & Wastewater Treatment, Paper & Pulp, Chemical and Others.

Request Sample

Key Takeaways

Big Data & Analytics held a significant market share in 2021 and is estimated to be the fastest segment during 2022-2027, owing to the shift of Brazil towards Industry 4.0, with industries such as oil, gas, minerals, and agriculture through the adoption of big data & analytics.

The market of Brazil Industry 4.0 is estimated to witness a significant upsurge during the forecast period, owing to the increasing adoption of advanced technologies such as predictive maintenance, data analytics, digital twins, artificial intelligence and others in the Oil & Gas sector.

This industry is consolidated with top market players including Iastech Automação De Sistemas Ltda, Simatec Tecnologia em Automacao Ltda, Techplus Automacao, Automind Automação, Greylogix Brasil among others.

Brazil Industry 4.0 Market Segment Analysis - by Offerings

Brazil's Industry 4.0 market is segmented into Hardware, Software and Services, based on offerings. According to the Brazil Industry 4.0 Market report of IndustyrARC, the Hardware segment held the major market share in 2021 of $1659.71 million and is estimated to reach $2978.08 million in 2027, with a CAGR of around 10.19% during the forecast period 2022-2027. The growth of this segment is mainly driven by the increasing adoption of industry 4.0 across industries and a growing inclination toward digitalization along with increasing investment. Furthermore, Industry standards that achieve higher levels of security to enable connected solutions in the factory are driving the need for hardware security. This is expected to boost market growth. The increasing popularity and high penetration rate among the end-user industries play a major role in offering incentives to the market players to take various strategic steps. For instance, in February 2021, ABB introduced the SWIFTI cobot, which combines a payload of 4 kg and a reach of up to 580 mm with the advantages of safe collaborative operation and convenience of use. This will offer up new opportunities for increased efficiency in a variety of sectors ranging from manufacturing to logistics and beyond, allowing more organizations to embrace automation. Such developments fuel the growth rate Brazil Industry 4.0 Market in the forecast period 2022-2027.

Inquiry Before Buying

Brazil Industry 4.0 Market Segment Analysis - by Technology

By Technology, the Brazil Industry 4.0 Market is segmented into Artificial Intelligence, Machine-to-Machine, Big Data and Analytics, Augmented Reality & Virtual Reality, Autonomous Robots, SCADA, Simulation, Horizontal and vertical System Integration, Cloud Computing, Cyber Security, Internet of Things (IoT), Digital Twin, Advanced human-machine interfaces (HMI), Additive Manufacturing (3D Printing) and Others. Big Data and Analytics segment held the major market share in 2021 of $474.28 million and is estimated to reach $834.86 million in 2027, with a CAGR of around 9.84% during the forecast period. Brazil is gradually moving toward Industry 4.0, with industries such as oil, gas, minerals, and agriculture expected to be early adopters of Big Data services. According to Software.org, 21 to 24 percent of Brazilian small and medium-sized businesses believe digitization will aid in the development of more personalized products and services. Such high penetration of advanced technologies and inclination towards digitalization will give incentives to the market players to take various steps to expand their business. Hence, the above-mentioned factors will drive the growth of this market during 2022-2027.

Brazil Industry 4.0 Market Segment Analysis – by End-user

Based on end-user, the market is segmented into General Manufacturing, Transportations & Logistics, Medical & Pharmaceutical, Metal & Mining, Oil & Gas, Automotive & Tire, Aerospace & Defence, Food & Beverage, Electronics & Semiconductors, Power, Construction, Agriculture, Water & Wastewater Treatment, Paper & Pulp, Chemical and Others. The metal and Mining segment held the major Brazil Industry 4.0 Market share in 2021 of $434.20 million and is estimated to reach $831.47 million in 2027, with a CAGR of around 11.40% during the forecast period. The value of digital technology in the mining industry is growing as companies look for ways to reduce geological uncertainty, market volatility, and operational hazards. Big data analytics and the internet of things (IoT) offer a unique opportunity to rethink existing processes and create new value. The metal and mining industry is now involved in connecting previously unconnected operational technology (OT), devices and systems, and information technology (IT) for data exchange and operational efficiency via IT/OT convergence, integrated sales and operational planning, agile supply chain, digital EHS monitoring, and performance parameters. According to the Ibram association, the mining industry in Brazil will invest $40.4 billion by 2026. This will help to improve the mining business in Brazil and, eventually, the Industry 4.0 market in Brazil. Such factors will drive the growth of this market.

Schedule a Call

Brazil Industry 4.0 Market Drivers

Increasing proliferation of technologies like predictive maintenance, data analytics, digital twins, artificial intelligence and others in Oil & Gas sector fuels the growth:

Over the last few years, the oil & gas sector is undergoing a transition as leading players in this industry are adopting advanced technology to reshape their operating landscape and reap the benefits of improved productivity, higher efficiency, and increased cost savings. In order to decarbonize and optimize operations, the Brazilian O&G industry has started to take advantage of advanced technologies including cloud services, digital twins Internet of things (IoT) and Artificial Intelligence (AI), among other digital services. Apart from that, the adoption of video surveillance complemented by advanced analytics and machine learning to improve operational efficiency as well as health and safety in the O&G sector can be considered vital in driving the Brazil Industry 4.0 Market growth forward. For instance, in November 2021, Brazil’s Petrobras, the leading oil, natural gas and derivatives exploration, production and distribution company, announced the plan of investing $68 Bn from 2022-2026 to boost oil production in the subsea pre-salt area by leveraging the advanced technologies to fulfill the demand of the customers. Such steps create a positive impact on the growth of this market.

The burgeoning demand for establishing a digital infrastructure in the mining sector is accelerating the growth of this market:

The Brazilian mining industry is opting for technological innovation to remain competitive while driving safety and transparency standards. Mining is of major importance to the Brazilian economy, having more than 3,000 mines spread across the national territory. The Brazilian mining industry is facing significant challenges due to plummeting commodity prices, lessening global demand and increasing safety and security risks. To reduce the effect of such challenges, miners need to improve safety, scale operations, improve operational processes, and enhance production, thereby driving the need for new business models and operating models. Leading mining companies in Brazil are harnessing the high computing power of digital technologies, including cloud-enabled mobility, big data-powered analytics and the industrial Internet of Things (IoT). This in turn drives the growth of this market. Furthermore, the increasing usage of robotics and penetration of automation with assisted and remote-control equipment and autonomous drilling and related process in the mining industry, to deliver safer and more effective mining performance, is fueling the growth of this market. In June 2021, Japan’s ITOCHU Corporation announced signing an MoU with the Brazilian CSN Group with the aim of promoting decarbonization and digital transformation (DX) for Casa de Pedra iron ore mines in Brazil. Such events trigger the growth of this market.

Buy Now

Brazil Industry 4.0 Market Challenge

The lack of investments in digital infrastructure in Brazil is creating hurdles for the market growth

Even though the Brazil Industry 4.0 Market is growing rapidly, but the lack of investment for developing digital infrastructure in Brazil creates challenges for the growth of this market. The implementation of Industry 4.0 in Brazil is still a challenge owing to the lack of investment in IT infrastructure in the country. IT readiness and appropriate telecommunications infrastructure are necessary for Industry 4.0 to thrive across Brazil. The research conducted by CNI shows that the alarming point is that only 33% of companies in Brazil claim that no new investment is needed. Another survey report of CNI states that innovation benefits the production chain and the country, demonstrating impacting results for the companies involved and for the country's economy, but the reality in Brazil is approximately half of the companies are still considered industry 2.0. To shift it from industry 2.0 to industry 4.0, a huge amount of investment is required. Hence, the lack of investment creates challenges for this market.

Brazil Industry 4.0 Industry Outlook

Technology launches, acquisitions, Partnerships and R&D activities are key strategies adopted by players in the Brazil Industry 4.0 Market. In 2021, the market of Brazil Industry 4.0 industry outlook has been fragmented by several companies. The top 10 companies in the Brazil Industry 4.0 include

Iastech Automacao De Sistemas Ltda

Simatec Tecnologia em Automacao Ltda

Techplus Automacao

Automind Automacao

Greylogix Brasil

Icone Tecnologia e Automacao

Automaton Automacao

Company 8

Company 9

Company 10

Recent Developments

In June 2021, Schneider Electric, a global leader in digital transformation and energy management and automation, inaugurated a new industrial automation laboratory in Brooklyn, south of São Paulo which was made in partnership with Westcon Instrumentation Industrial to simulate the industrial internet of things (IIoT) and industry 4.0 applications with augmented reality demonstrations.

In May 2020, Siemens announced its partnership with GreyLogix to produce respirators in-house for use in healthcare facilities in Brazil to help fight the coronavirus. The equipment featured Siemens solutions, with emphasis on the controllers and HMIs of the SIMATIC line and the power supplies of the SITOP line, and at the same time, GreyLogix ensured that the equipment produced followed the necessary medical requirements.

In March 2020, Schneider Electric announced to invest in the Titled High-Performance Machine journey based on Industry 4.0, by providing a series of training and workshops to support machine manufacturers and end users who want to improve performance and productivity and reduce costs in production processes in Brazil.

#Brazil Industry 4.0 Market#Brazil Industry 4.0 Market Share#Brazil Industry 4.0 Market Size#Brazil Industry 4.0 Market Forecast#Brazil Industry 4.0 Market Report#Brazil Industry 4.0 Market Growth

0 notes

Text

Inconel Market Size, Share, Analysis, Growth, Key Players, Trend and Forecast to 2034

The global Inconel market reached around 22 thousand tonnes in 2023 and is expected to grow at a CAGR of 3.5% throughout the forecast period until 2034.

Introduction:

Inconel, a family of superalloys known for their exceptional resistance to heat, corrosion, and oxidation, plays a crucial role in South Africa's industrial landscape. As industries across the country strive for enhanced performance and durability, the Inconel Market emerges as a key enabler of technological advancement and industrial efficiency. This article delves into the dynamics of the Inconel Market in South Africa, highlighting its applications, market trends, and impact on various sectors.

Industrial Applications and Demand:

Inconel alloys are widely utilized in industries that demand high-performance materials capable of withstanding extreme conditions. These superalloys are renowned for their strength at elevated temperatures, resistance to thermal creep deformation, and exceptional corrosion resistance. In South Africa, key industries such as aerospace, power generation, chemical processing, and marine engineering extensively employ Inconel to enhance the durability and reliability of critical components.

Click Here: https://www.chemanalyst.com/industry-report/inconel-market-4179

Aerospace and Power Generation:

In the aerospace industry, Inconel is essential for manufacturing jet engines, gas turbines, and exhaust systems. Its ability to maintain structural integrity at high temperatures and resist oxidation makes it invaluable for components exposed to intense heat and pressure. Similarly, in the power generation sector, Inconel alloys are used in gas turbines, heat exchangers, and boiler components, ensuring operational efficiency and longevity in high-temperature environments. As South Africa invests in expanding its aerospace capabilities and modernizing its power infrastructure, the demand for Inconel is poised to grow.

Chemical Processing and Petrochemical Industries:

Inconel's resistance to corrosive chemicals and high-temperature environments makes it a preferred material in chemical processing and petrochemical industries. It is used in reactors, distillation columns, piping systems, and valves, where exposure to harsh chemicals and elevated temperatures necessitates robust and reliable materials. With South Africa's focus on boosting its chemical and petrochemical production capacities, the Inconel Market is expected to witness significant growth.

Marine Engineering and Oil & Gas:

The marine engineering sector benefits from Inconel's resistance to seawater corrosion and biofouling, making it ideal for components such as propeller shafts, pumps, and valves. In the oil and gas industry, Inconel is used in drilling tools, downhole equipment, and offshore platforms, where materials are exposed to high pressures, corrosive environments, and extreme temperatures. South Africa's maritime activities and oil & gas exploration efforts further drive the demand for Inconel in these sectors.

Market Trends and Growth Drivers:

The Inconel Market in South Africa is influenced by several trends and growth drivers, including advancements in material science, increasing industrialization, and the need for high-performance materials in critical applications. The growing focus on renewable energy and the development of advanced manufacturing techniques, such as additive manufacturing (3D printing), also contribute to the expanding use of Inconel alloys in innovative applications.

Significant players in the Global Inconel market are ThyssenKrupp VDM, Aperam, Hitachi Metals, Haynes, Daido Steel, Sandvik, Bohler Edelstahl, Fushun Special Steel, Ritinox, Salomon'smetal, Altemp Alloys, Siddhagiri Metals & Tubes, City Special Metals Ltd, Aspirinox Alloys Inc, Steel Tubes India, Supreme Special Steels, Jayesh Metal Corporation, Kencotube, Tarang Steel, Navstar Steel, PM Metal, Jiangsu TISCO Hongwang Metal Products Co. Ltd, Yuhong Group, Shanghai Baogang Steel Manufacturing Co., Ltd., NINESTEEL, Qiyuan Steel, Shanghai Osaka Metal Material Group Co., and Others.

Click Here: https://www.chemanalyst.com/industry-report/inconel-market-4179

Challenges and Opportunities:

Despite its advantages, the Inconel Market in South Africa faces challenges such as high material costs, complex manufacturing processes, and competition from alternative high-performance alloys. However, strategic initiatives focused on research and development, technological advancements, and collaboration with industry stakeholders can mitigate these challenges. Additionally, exploring new applications and enhancing local production capabilities present significant opportunities for market growth and innovation.

Conclusion:

The Inconel Market in South Africa represents a vital segment within the industrial landscape, offering unparalleled performance and reliability across various high-stress applications. With its exceptional properties and wide-ranging industrial uses, Inconel contributes to the advancement of key sectors, including aerospace, power generation, chemical processing, and marine engineering. By capitalizing on market opportunities, addressing challenges, and fostering collaboration, South Africa can harness the full potential of the Inconel Market, driving industrial growth, technological innovation, and economic development in the region.

0 notes

Text

Diamond Tools Market - Global Growth, Share, Trends, Demand and Analysis Report Forecast 2031

The global diamond tools market is set to experience substantial expansion, with projections indicating a surge from the estimated US$13 billion mark at the end of 2024 to a staggering US$25 billion by 2031. This remarkable growth trajectory is attributed to a confluence of factors driving demand and innovation within the industry.

For more information: https://www.fairfieldmarketresearch.com/report/diamond-tools-market

Technological Advancements Propel Market Momentum

The diamond tools market has witnessed an unprecedented surge in growth owing to technological advancements in manufacturing processes. Innovations such as laser cutting and 3D printing have revolutionized the production of diamond tools, enhancing their precision, durability, and versatility across various industries including automotive, aerospace, and construction. This surge in technological prowess is expected to sustain market expansion in the forecast period.

Construction Boom and Automotive Revolution Drive Demand

Rapid urbanization, infrastructure development projects, and a burgeoning automotive sector are key drivers propelling the demand for diamond tools. In the construction industry, these tools are indispensable for cutting, drilling, and grinding applications, particularly for materials like concrete, stone, and ceramics. Similarly, the automotive industry's shift towards lightweight materials necessitates the use of diamond tools for precision machining, creating a surge in demand and driving market growth.

Key Growth Barriers and Opportunities

While the diamond tools market presents immense growth prospects, it is not devoid of challenges. High initial investments pose a barrier to entry for new players, along with environmental concerns surrounding the extraction and processing of raw materials. Intense competition further adds pressure on market players, leading to price wars and reduced profit margins. However, opportunities abound, particularly in the adoption of Industry 4.0 technologies, the rise of synthetic diamonds, and expansion into emerging markets, offering avenues for sustainable growth and market dominance.

Regulatory Landscape: Balancing Innovation with Responsibility

The regulatory environment plays a pivotal role in shaping the diamond tools market, with stringent regulations driving innovation in responsible diamond sourcing and safety standards. While regulations pose challenges such as increased production costs, they also pave the way for advancements in eco-friendly manufacturing practices and sustainable sourcing methods, positioning compliant companies for long-term success.

Fairfield's Ranking Board Highlights Market Dynamics

Fairfield's ranking board sheds light on key segments and regional frontrunners within the diamond tools market. Synthetic diamond abrasives maintain dominance, while polishing pads and discs spearhead the finishing category, and diamond pastes and suspensions lead the lapping-based segment. North America retains a strong presence, with Asia Pacific emerging as a powerhouse due to rapid industrialization and infrastructure development.

Leaders in Global Diamond Tools Space

Leading the charge in the global diamond tools space are industry stalwarts such as Hilti Group, Sumitomo Electric Industries, Husqvarna AB, and Saint-Gobain Abrasives Inc., among others. These companies leverage extensive product portfolios, global presence, and strategic alliances to maintain competitive positions and drive market growth.

0 notes

Text

Forecasting the Future: Market Trends and Share in the Aircraft Electrification Industry

The Aircraft Electrification Market is experiencing significant growth, with market statistics indicating a value of USD 6.0 billion in 2021 and a projected increase to USD 20.0 billion by 2030, reflecting a remarkable CAGR of 14.3% during the forecast period. This growth is primarily attributed to the rising adoption of cleaner and greener aircraft, advancements in advanced air mobility, and the exploration of alternative energy sources.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=31650461

Key Players: Major companies leading the aircraft electrification market include Honeywell International Inc. (US), GE Aviation (US), Safran (France), Thales Group (France), and Raytheon Technologies (US). These companies have established themselves as key players in the market and are driving innovation through various strategies.

Honeywell International Inc.: Honeywell International Inc. operates across four segments and is renowned for its expertise in engineering and manufacturing high-performance navigation and sensor products. With a focus on aerospace products and services, Honeywell offers a technologically advanced portfolio that includes auxiliary power units, propulsion engines, environmental control systems, and wireless connectivity services, among others.

General Electric Company (GE): GE, an industrial giant, operates through its Industrial and Financial Services segments. In the aerospace sector, GE focuses on developing innovative solutions, such as the inertial navigation system used by the US Marine Corps and satellite communication systems for leading companies like Boeing. Collaborations, such as the partnership with NASA for developing inverters for large commercial electric aircraft, underscore GE's commitment to innovation.

Safran: Safran, a French multinational, specializes in aircraft engines, aerospace components, and defense systems. Its subsidiary, Safran Electronics & Defense, offers cutting-edge technologies for civil and military applications. Safran is actively developing new technologies aligned with market demands, including next-generation aircraft engines, 3D printing, and more electric aircraft components, to reduce fuel consumption and enhance performance.

Inquiry Before Buying: https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=31650461

In summary, the Aircraft Electrification Market is witnessing robust growth, driven by increasing environmental concerns and technological advancements. Key players are leveraging strategic initiatives to capitalize on emerging opportunities and drive innovation in this dynamic market landscape.

About MarketsandMarkets™

MarketsandMarkets™ has been recognized as one of America's best management consulting firms by Forbes, as per their recent report.

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

Contact:

Mr. Aashish Mehra

MarketsandMarkets™ INC.

630 Dundee Road, Suite 430, Northbrook, IL 60062

USA: +1-888-600-6441

Email: [email protected]

0 notes

Text

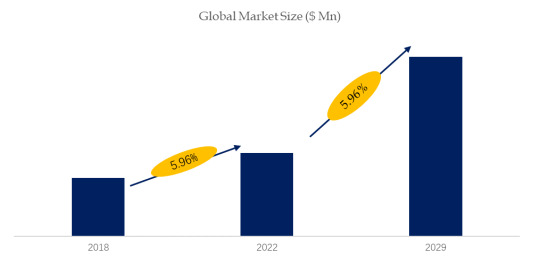

Scandium Metal, Global Market Size Forecast, Top 5 Players Rank and Market Share

Scandium Metal Market Summary

According to the new market research report “Global Scandium Metal Market Report 2023-2029”, published by QYResearch, the global Scandium Metal market size is projected to reach USD 0.16 billion by 2029, at a CAGR of 11.8% during the forecast period.

Figure. Global Scandium Metal Market Size (US$ Million), 2018-2029

Above data is based on report from QYResearch: Global Scandium Metal Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

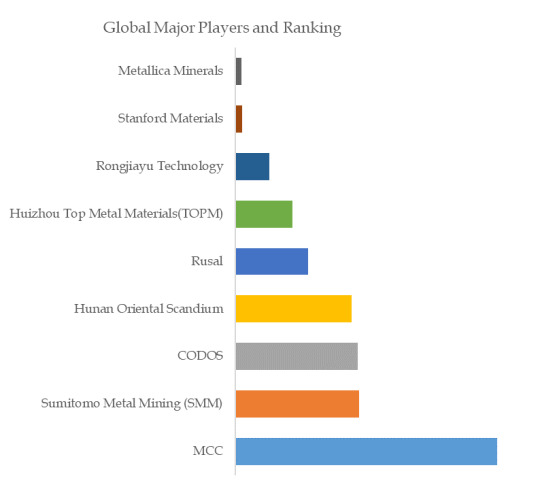

Figure. Global Scandium Metal Top 5 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

Above data is based on report from QYResearch: Global Scandium Metal Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

According to QYResearch Top Players Research Center, the global key manufacturers of Scandium Metal include MCC, Sumitomo Metal Mining (SMM), CODOS, Hunan Oriental Scandium, Rusal, Huizhou Top Metal Materials(TOPM), Rongjiayu Technology, Stanford Materials, Metallica Minerals, , etc. In 2022, the global top five players had a share approximately 59.0% in terms of revenue.

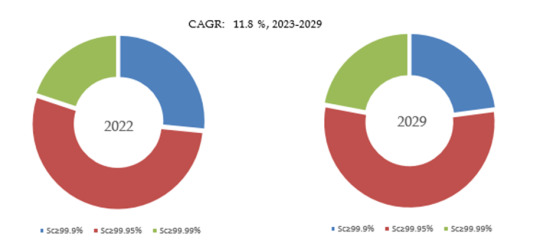

Figure. Scandium Metal, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global Scandium Metal Market Report 2023-2029.

In terms of product type, currently Sc≥99.95% is the largest segment, hold a share of 26.6%.

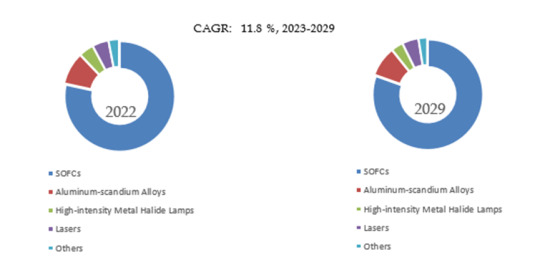

Figure. Scandium Metal, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global Scandium Metal Market Report 2023-2029.

In terms of product application, currently SOFCs is the largest segment, hold a share of 78.4%.

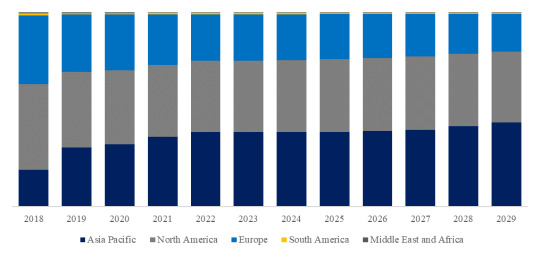

Figure. Scandium Metal, Global Market Size, Split by Region

Based on or includes research from QYResearch: Global Scandium Metal Market Report 2023-2029.

Market Drivers:

Aerospace Industry Demand: The aerospace industry's growing demand for lightweight and high-strength materials drives the demand for scandium metal, which is used as an alloying element to enhance the properties of aluminum-based alloys. Scandium-aluminum alloys offer significant weight savings and improved performance in aerospace applications, such as aircraft frames and structural components.

Solid Oxide Fuel Cells (SOFCs): Scandium is used as a dopant in the electrolyte material of solid oxide fuel cells (SOFCs) to improve their conductivity and efficiency. As the demand for clean energy solutions grows, particularly in stationary power generation and portable applications, the demand for scandium in SOFCs is expected to increase.

Emerging Technologies: Scandium finds applications in emerging technologies such as additive manufacturing (3D printing), where scandium-aluminum alloys offer unique properties for producing lightweight and complex components. Additionally, scandium is used in high-intensity discharge lamps, lasers, and other advanced electronic devices, driving demand from the technology sector.

Strategic Metal Status: Scandium's classification as a strategic metal by various governments and international organizations, due to its critical importance in key industries like aerospace, defense, and clean energy, drives efforts to secure and develop domestic sources of scandium, stimulating market growth.

Restraint:

Limited Supply: Scandium is relatively rare in the Earth's crust and is typically found in low concentrations in various mineral deposits, making its extraction and production challenging and costly. The limited availability of commercial-scale scandium sources constrains market growth and leads to supply chain uncertainties.

High Production Costs: The high production costs associated with scandium extraction, purification, and processing present a significant barrier to market expansion. The complex and energy-intensive processes required to produce pure scandium metal contribute to its high price, limiting its widespread adoption in industrial applications.

Price Volatility: Scandium prices are subject to significant volatility due to fluctuations in supply and demand dynamics, as well as speculative trading activities. Price instability and uncertainty make it challenging for end-users to plan and budget for scandium-containing products, potentially dampening market growth.

Regulatory Challenges: Regulatory hurdles, including environmental regulations, permitting requirements, and trade restrictions, can hinder the development of scandium mining projects and the establishment of a reliable supply chain, limiting market access and availability.

Opportunity:

Recycling and Secondary Sources: Expanding efforts to recover scandium from recycled materials, industrial byproducts, and secondary sources present opportunities to supplement primary production and alleviate supply constraints. Advances in recycling technologies and processes could make scandium more accessible and economically viable.

Research and Development: Continued research and development efforts focused on scandium metallurgy, extraction techniques, and alloy development can lead to technological advancements and cost reductions, unlocking new applications and market opportunities for scandium metal.

Strategic Partnerships and Investments: Collaboration between governments, industry players, and research institutions to invest in scandium exploration, mining, and processing projects can help diversify the supply chain, mitigate risks, and ensure a stable and sustainable supply of scandium metal to meet growing demand.

Market Education and Awareness: Increasing awareness among end-users, manufacturers, and investors about scandium's unique properties, applications, and strategic importance can stimulate market demand and investment, driving growth in the scandium metal market.

About The Authors

Yang Min - Lead Author

Email: [email protected]

Yang Min is a market senior analyst specializing in chemical materials. Yangmin has 8 years’ experience in chemical materials market analysis, and focuses on chemical materials and API. He engaged in the development of technology and market reports and is also involved in custom projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Plastic Market Trends: A Comprehensive Analysis

The global Plastic Market is poised for significant growth in the coming years, according to a study conducted by Next Move Strategy Consulting. Projections indicate that the market size is expected to reach USD 831.54 billion by 2030, with a compound annual growth rate (CAGR) of 4.8%. This substantial growth reflects the increasing demand for plastic across various industries, driven by factors such as urbanization, industrialization, and technological advancements.

Request for a sample, here: https://www.nextmsc.com/plastic-market/request-sample

In this comprehensive analysis, we delve into the current trends shaping the plastic market landscape, providing insights into key factors influencing its trajectory and exploring the implications for stakeholders across the value chain.

Sustainable Initiatives Driving Market Transformation:

One of the prominent trends in the plastic market is the growing emphasis on sustainability. With rising environmental concerns and regulatory pressure, stakeholders across the value chain are actively seeking sustainable alternatives to traditional plastics. Biodegradable polymers, recycled plastics, and bio-based materials are gaining traction as companies strive to reduce their carbon footprint and mitigate plastic pollution. Innovative packaging designs, eco-friendly manufacturing processes, and circular economy models are increasingly adopted to promote sustainability in the plastic market.

The shift towards sustainable practices is driven by various factors, including consumer demand for environmentally friendly products, government regulations aimed at reducing plastic waste, and corporate initiatives to enhance brand reputation and mitigate risks associated with environmental liabilities. Companies are investing in research and development to innovate new materials and technologies that offer comparable performance to traditional plastics while minimizing environmental impact. Additionally, partnerships and collaborations across industries are facilitating knowledge sharing and technology transfer, accelerating the adoption of sustainable solutions in the plastic market.

Technological Innovations and Material Advancements:

Advancements in material science and manufacturing technologies are revolutionizing the plastic market. From lightweight and durable plastics for automotive and aerospace applications to high-performance polymers for electronics and medical devices, continuous innovation is driving product differentiation and market competitiveness. Nanotechnology, 3D printing, and smart materials are opening new avenues for customization and efficiency in plastic manufacturing. Additionally, digitalization and automation are optimizing production processes, enhancing quality control, and reducing time-to-market for plastic products.

The convergence of digital technologies, such as artificial intelligence, internet of things, and big data analytics, with traditional manufacturing processes is enabling predictive maintenance, real-time monitoring, and agile production capabilities in the plastic industry. These advancements enhance operational efficiency, minimize downtime, and improve product quality, thereby increasing competitiveness and profitability for plastic manufacturers. Furthermore, technology-driven solutions enable customization and personalization of plastic products to meet diverse customer requirements, driving innovation and market growth.

Regulatory Landscape and Policy Implications:

The plastic market is subject to evolving regulatory frameworks and policies aimed at addressing environmental concerns and promoting sustainability. Governments worldwide are implementing measures to reduce single-use plastics, encourage recycling, and promote the adoption of alternative materials. Extended producer responsibility (EPR) schemes, plastic bans, and eco-labeling initiatives are reshaping market dynamics and influencing consumer preferences. Compliance with regulatory requirements and alignment with sustainability goals have become imperative for businesses operating in the plastic industry.

Regulatory compliance entails significant challenges for plastic manufacturers, including investment in technology upgrades, adoption of sustainable practices, and development of alternative materials. However, proactive engagement with regulators, industry associations, and other stakeholders can mitigate compliance risks and unlock opportunities for innovation and market differentiation. Companies that embrace sustainability as a core business strategy and integrate environmental considerations into their operations are better positioned to navigate regulatory challenges and sustain long-term growth in the plastic market.

Consumer Trends and Market Dynamics:

Changing consumer preferences and evolving lifestyles are influencing demand patterns in the plastic market. Increasing urbanization, rising disposable incomes, and growing awareness about health and safety are driving demand for packaged food, beverages, and consumer goods, thereby fueling the growth of the plastic packaging segment. Moreover, the proliferation of e-commerce platforms and the rise of online retail are creating opportunities for innovative packaging solutions that ensure product integrity, convenience, and sustainability. Understanding consumer behavior and catering to shifting preferences are crucial for businesses to stay competitive in the dynamic plastic market landscape.

Consumer demand for sustainable and eco-friendly products is a key trend shaping the plastic market. As awareness of environmental issues grows, consumers are increasingly inclined to choose products that minimize their carbon footprint and reduce plastic waste. This trend is driving demand for biodegradable, compostable, and recyclable packaging solutions, as well as products made from recycled or renewable materials. Companies that prioritize sustainability in their product offerings and marketing strategies can capitalize on this growing market segment and gain a competitive advantage in the plastic market.

Efficacy of Plastic Market Segmentation Strategies:

Segmentation is becoming increasingly crucial in the plastic market to effectively target diverse consumer groups with tailored products and messaging. By analyzing demographics, psychographics, and behavioral patterns, companies can identify specific market segments with unique preferences and needs. Segmentation allows businesses to develop customized product offerings, pricing strategies, and marketing campaigns, thereby maximizing customer engagement and loyalty. Moreover, segmentation enables companies to allocate resources efficiently, optimize distribution channels, and enhance overall market penetration. As competition intensifies in the plastic market, effective segmentation strategies can provide businesses with a competitive edge and drive sustainable growth.

Impact of pandemic on Plastic Market Dynamics:

The pandemic has had a profound impact on the plastic market, influencing consumer behavior, supply chain dynamics, and regulatory frameworks. With heightened hygiene concerns and increased demand for single-use plastics, the pandemic has driven a surge in plastic packaging for essential goods such as food, pharmaceuticals, and personal protective equipment (PPE). However, the pandemic has also exposed vulnerabilities in global supply chains, leading to disruptions in raw material availability and logistics. Moreover, concerns about plastic pollution have intensified as the pandemic has led to a proliferation of disposable plastics, including face masks and gloves. As the world navigates the post-pandemic recovery phase, the plastic market must adapt to changing consumer preferences, regulatory requirements, and sustainability imperatives.

Influence of Social Media and Digital Marketing on Consumer Behavior:

Social media and digital marketing platforms are increasingly shaping consumer perceptions and purchasing decisions in the plastic market. With the proliferation of smartphones and internet connectivity, consumers have access to a wealth of information and online reviews that influence their product choices. Social media platforms such as Instagram, Facebook, and YouTube serve as powerful channels for brand engagement, storytelling, and influencer marketing in the plastic industry. By leveraging social media analytics and data-driven insights, companies can identify trends, monitor brand sentiment, and engage with consumers in real-time. Additionally, digital marketing strategies such as search engine optimization (SEO), content marketing, and email campaigns enable companies to reach target audiences effectively and drive traffic to their websites or online stores. As digitalization continues to reshape consumer behavior, businesses must embrace digital marketing strategies to enhance brand visibility, build customer relationships, and drive sales in the competitive plastic market.

Inquire before buying, here: https://www.nextmsc.com/plastic-market/inquire-before-buying

Collaboration and Innovation in the Plastic Market Ecosystem:

Collaboration and innovation are essential drivers of growth and competitiveness in the plastic market ecosystem. As the industry faces complex challenges related to sustainability, regulatory compliance, and technological disruption, collaboration among stakeholders is paramount to finding holistic solutions. Cross-sector partnerships between manufacturers, suppliers, recyclers, policymakers, and non-governmental organizations (NGOs) facilitate knowledge exchange, resource sharing, and collective action towards common goals. Open innovation platforms and incubators foster collaboration and co-creation of innovative solutions to address pressing challenges in the plastic market, such as plastic waste management, material innovation, and product design. By working together, stakeholders can leverage complementary expertise, pool resources, and accelerate the transition towards a more sustainable and resilient plastic market ecosystem.

Conclusion:

The plastic market is characterized by dynamic trends, evolving consumer preferences, and transformative technological advancements. To thrive in this rapidly changing landscape, businesses must adapt to emerging challenges and seize opportunities for innovation, collaboration, and sustainability. By embracing sustainable practices, leveraging technological innovations, and understanding consumer behavior, companies can position themselves for long-term success in the plastic market.

Moreover, effective segmentation strategies, awareness of the impact of COVID-19, integration of digital marketing, and collaboration across the ecosystem are essential for navigating complexities and driving growth in the plastic market. As stakeholders work together to address environmental concerns, regulatory requirements, and societal expectations, the plastic industry can contribute to a more sustainable and prosperous future for generations to come.

#plastic market#materials and chemicals#innovations#market trends#global market#industry analysis#business insights

0 notes

Text

Additive Manufacturing Market Size, Share, Forecast, & Trends Analysis

Additive Manufacturing Market Size, Share, Forecast, & Trends Analysis

additive manufacturing market is poised to soar to unprecedented heights, anticipated to burgeon to a monumental $228.8 billion by the year 2031, exhibiting a remarkable Compound Annual Growth Rate (CAGR) of 27.9% from 2024 to 2031.

Download free sample report here: https://www.meticulousresearch.com/download-sample-report/cp_id=5838?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=28-05-2024

The ascent of the additive manufacturing sector is propelled by an array of compelling forces, including the imperative to fabricate intricate components, slash manufacturing outlays, and curtail wastage. Additionally, advancements in product innovation and supply chain efficiency, coupled with the allure of seamless customization and mass production capabilities inherent in additive manufacturing, further catalyze this exponential growth trajectory. However, challenges loom in the form of limited build dimensions and the associated pre-processing and post-processing overheads, which could potentially dampen market expansion.

Yet, amidst these challenges lie untapped vistas of opportunity, particularly in the realms of 3D printing for functional end-use parts and the burgeoning domain of composite 3D printing. Nevertheless, concerns regarding intellectual property infringement and the scarcity of adept professionals threaten to impede the sector's growth.

Emerging trends paint a vivid picture of on-demand spare parts fabrication, heightened product personalization, and the integration of Artificial Intelligence (AI) into 3D printing workflows as prevailing themes in this dynamic landscape.

Browse in depth: https://www.meticulousresearch.com/product/additive-manufacturing-market-5838?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=28-05-2024

Delving deeper, the global additive manufacturing market is intricately segmented into offerings encompassing hardware, software, materials (encompassing plastics, polymers, metals, ceramics, composites, and other material variants), and services. Moreover, delineations based on form — spanning solid, liquid, and powder material categories — offer nuanced insights into the market's multifaceted composition. End-user segmentation further elucidates the market dynamics, encompassing a gamut of sectors ranging from consumer products, healthcare, and automotive to aerospace & defense, electronics & semiconductors, and beyond.

Unveiling the market's intricate tapestry, the hardware segment emerges as the dominant force, commanding a lion's share exceeding 60.0% of the global additive manufacturing arena. This preeminence is fueled by a confluence of factors, including the decentralization of production, on-demand manufacturing paradigms, and the concomitant streamlining of supply chains. Noteworthy is the hardware segment's pivotal role in facilitating the realization of highly tailored, bespoke products across diverse industry verticals.

Download request sample report here: https://www.meticulousresearch.com/request-sample-report/cp_id=5838?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=28-05-2024

Segmentation by form unveils a nuanced narrative, with solid materials dominating the landscape owing to their indispensable mechanical properties, whereas powder materials emerge as the harbinger of future growth, underpinned by their pivotal role in additive manufacturing processes.

Zooming out to a geographical perspective, Asia-Pacific emerges as the epicenter of additive manufacturing fervor, commanding a substantial share exceeding 36.0% of the global market. The region's ascendancy is underpinned by a confluence of factors, including burgeoning manufacturing activities, robust digitization initiatives, and a burgeoning startup ecosystem. Meanwhile, North America is poised to register the highest CAGR of 29.0%, propelled by the region's robust industrial landscape and a burgeoning appetite for customized 3D-printed products across diverse sectors.

Amidst this landscape of transformative change, key players including industry stalwarts such as 3D Systems Corporation, Arcam AB, Stratasys, Ltd., and a host of others stand at the vanguard, shaping the contours of tomorrow's manufacturing landscape through pioneering innovations and unwavering commitment to excellence.

Quick buy: https://www.meticulousresearch.com/Checkout/86948189?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=28-05-2024

Contact Us:

Meticulous Research®

Email- [email protected]

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

0 notes

Text

Revolutionizing Industries: The Expansive Realm of 3D Printing Filament Market

3D Printing Filament Market was valued at US$ 1,069.7 million in 2023 and is projected to reach US$ 4,989.5 million by 2031, growing at a CAGR of 21.36% from 2024 to 2031.

This comprehensive research study on the global 3D Printing Filament market gives detailed insights into the sector, offering a detailed analysis of market trends, prominent drivers, and future growth prospects. In order to make wise business decisions, it gives readers an extensive understanding of the market environment. Furthermore, the report covers several aspects, such as estimated market sizing, strategies employed by leading companies, restraining factors, and challenges faced by market participants.

Request our market overview sample now:

Market Forecast and Trends

The report's precise market forecasts and identification of emerging trends will allow readers to foresee the industry’s future and outline their tactics for the following years accordingly. Understanding market trends can help in gaining a competitive edge and staying ahead in a fast-paced business environment.

Regional and Segment Analysis

The study on the global 3D Printing Filament market will aid industry participants find high-growth regions and profitable market segments through region-specific and segment-by-segment analysis. This information helps in implementing better marketing strategies and product lineups to meet the preferences and needs of various target audiences. The major regions covered in this comprehensive analysis include North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa.

Investment and Expansion Opportunities

The research report supports strategic decision-making by revealing prospective areas for investment and business growth in the global 3D Printing Filament market. This report is a great tool for finding markets that are foreseen to grow substantially for aiding readers who want to expand into new and untapped markets or launch new products.

Competitive Analysis

The research report comprises an in-depth competitive analysis, which profiles major market competitors and evaluates their tactics, weaknesses, and market shares. These key players employ top business strategies, such as partnerships, alliances, mergers, acquisitions, product innovations, and product development, to establish a competitive advantage. Industry participants may use this information to measure their business against rivals and develop winning strategies for distinguishing themselves in the market.

Why Buy This Report?

Obtain an in-depth understanding of market trends and growth catalysts.

Utilize precise market forecasts for informed decision-making.

Outperform competitors through extensive competitive analysis.

Identify and leverage profitable regional and segment prospects.

Strategically plan investments and expansions in the global 3D Printing Filament market

The major players in the 3D Printing Filament Market are:

Höganäs AB

3D Systems Corporation

General Electric

Arkema S.A

Royal DSM N.V

Stratasys, Ltd.

Evonik Industries AG

ExOne

Arcam AB

Elevate Your Business Strategy! Purchase the Report for Market-Driven Insights

https://www.kingsresearch.com/enquiry/3d-printing-filament-market-536