#Aircraft Carbon Brake Disc

Text

Friction Products Market Exploring Key Factors Influencing Growth and Competitive Landscape By 2024-2030 | GQ Research

The Friction Products market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global Friction Products market showcased a significant presence, boasting a valuation of USD 58 Million. This underscores the substantial demand for Friction Products technology and its widespread adoption across various industries.

Get Sample of this Report at https://gqresearch.com/request-sample/global-friction-products-market/

Projected Growth: Projections suggest that the Friction Products market will continue its upward trajectory, with a projected value of USD 86.4 Million by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 5.20 %, reflecting a steady and robust growth rate for the Friction Products market over the coming years.

Technology Adoption:

In the Friction Products market, technology adoption is pivotal for enhancing performance, durability, and safety across various applications. Manufacturers continually invest in advanced friction materials, bonding techniques, and manufacturing processes to meet the diverse requirements of industries such as automotive, aerospace, construction, and industrial machinery. Adoption of innovations such as ceramic composites, carbon-carbon materials, and friction modifiers enables the development of friction products with superior wear resistance, thermal stability, and frictional characteristics, addressing the evolving needs of end-users for reliable and high-performance friction solutions.

Application Diversity:

Friction products find application across a wide range of industries and end-uses, including braking systems, clutch assemblies, transmission components, and industrial friction materials. From automotive brake pads and aircraft braking systems to industrial clutches and friction discs, the versatility of friction products enables their adaptation to diverse operating conditions and performance requirements. Additionally, friction materials play a critical role in specialized applications such as wind turbine brakes, elevator systems, and railroad braking systems, highlighting their significance in ensuring operational safety and efficiency across various sectors.

Consumer Preferences:

Consumer preferences in the Friction Products market are influenced by factors such as reliability, performance, cost-effectiveness, and environmental sustainability. End-users prioritize friction products that offer consistent braking performance, minimal noise and vibration, and extended service life, particularly in safety-critical applications such as automotive braking systems. Preferences also extend to environmentally friendly friction materials with reduced heavy metal content, low dust emissions, and recyclability, aligning with regulatory requirements and consumer demand for eco-friendly solutions.

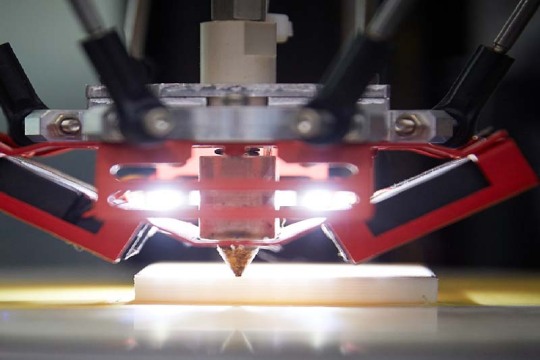

Technological Advancements:

Technological advancements drive innovation in friction product materials, formulations, and manufacturing processes, leading to improvements in performance, efficiency, and sustainability. Developments in nanotechnology, surface engineering, and composite materials enable the design of friction products with enhanced tribological properties, reduced weight, and improved thermal stability. Moreover, advancements in additive manufacturing (3D printing) and precision machining techniques facilitate the production of custom-designed friction components tailored to specific application requirements, accelerating product development cycles and enabling rapid prototyping of novel friction solutions.

Market Competition:

The Friction Products market is characterized by intense competition among global and regional manufacturers vying for market share and differentiation. Established players leverage their technological expertise, R&D capabilities, and brand reputation to maintain leadership positions, while emerging entrants focus on niche markets or specialized applications to gain traction. Pricing strategies, product quality, and aftersales support are key factors influencing purchasing decisions in this competitive landscape, prompting companies to invest in innovation, strategic partnerships, and market expansion initiatives to sustain competitive advantage.

Environmental Considerations:

Environmental considerations are increasingly important in the Friction Products market, given concerns over pollution, resource depletion, and regulatory compliance. Manufacturers prioritize the development of eco-friendly friction materials with reduced environmental impact, such as asbestos-free brake pads and low-metallic friction formulations. Additionally, efforts to optimize manufacturing processes, minimize waste generation, and recycle end-of-life friction products contribute to environmental sustainability and circular economy principles. By adopting cleaner production technologies and adhering to stringent environmental regulations, industry stakeholders mitigate the environmental footprint of friction product manufacturing and usage, promoting sustainable practices throughout the value chain.

Regional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

Akebono Brake

Nisshinbo

Bosch

Continental

GMP Friction Products

Tenneco

Shandong Longji

BorgWarner

Brembo S.p.A.

Aisin Seiki Co.Ltd.

The research report provides a comprehensive analysis of the Friction Products market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-friction-products-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731 Website - https://gqresearch.com/

#FrictionProducts#AutomotiveIndustry#IndustrialMachinery#Sustainability#ElectricVehicles#MarketAnalysis

0 notes

Text

Revolutionizing Precision by CNC Components Manufacturers

CNC (Computer Numerical Control) is a machining technology. Products are created by removing material from a so-called workpiece using various cutting tools. At the same time, the production process is automated by software – the tool or workpiece moves according to the code, and the machine operator performs only auxiliary operations, such as changing tools or setting the workpiece. CNC machining by CNC components manufacturers makes it possible to produce high-precision parts from a CAD (computer-aided design system) file with excellent physical and mechanical properties. Due to the high level of automation, CNC machining is competitive for single pieces & short runs, as well as for serial and mass production.

CNC manufacturing process

The CNC manufacturing process of a product can be broken down into four main steps:

1. An engineer designs a CAD model.

2. A technologist based on CAD/CAM software prepares a control program for the CNC machine.

3. The operator inserts the tool, and workpiece into the CNC machine and starts the control program.

4. The CNC machine performs all the processing operations – material removal.

CNC Machine Applications Industries

Aerospace

The aerospace industry encompasses all modes of air transport, from massive Airbus A380 aircraft that carry hundreds of passengers to spacecraft designed to fly to the International Space Station, the Moon, and even Mars. Aerospace technology is characterized by incredible precision that is difficult to achieve with conventional tools, which is why CNC machines by CNC-turned parts manufacturers were the perfect solution.

CNC in Aviation

The CNC machine plays a crucial role in the fast and accurate production of the parts that are used in the operation of every component of the aircraft. Such tools are used to create engine parts, cockpit equipment, aircraft skin, wings, and other parts.

CNC in the space industry

CNC is used at NASA, SpaceX, and Roscosmos enterprises to provide rockets with parts of any size and shape with incredibly high fitting accuracy. They produce spare parts for engines, computer equipment, parts for various systems, and spacecraft hulls.

Car

Car shop manager Rocky Helms has a lot of work to do. He oversees the workshop of the world-famous racing team Richard Childress Racing (RCR). The company's 24 employees work two shifts a day to produce the 170,000 parts needed to service the RCR.

The workshop itself occupies 7,000 square meters on a 210,000 square meter campus. Since its inception in 1969, RCR has played 17 championships and won more than 200 times in three NASCAR Major Series, including three Daytona 500 races (1998, 2007, 2018) and three Brickyard 400 races (1995, 2003, 2011).

To increase the production of cars and maintain maximum productivity in the workshop, the RCR is equipped with the latest material handling technologies, including the Roland MODELA MDX-540 benchtop mill.

According to Helms, the machine can do the work in 10 minutes that a person does in 10 hours. RCR uses Roland to mill engine and brake parts, wheel discs, and shock absorbers. The device is also used to create carbon fiber parts & to engrave identification numbers on parts.

Medical

In the space industry, it is customary to say: "There is no repair shop in space." The quality, precision, and reliability of each part must be impeccable because once it leaves the planet, it just has to work. The same applies to the medical field. If the prosthetic implant does not work properly, it affects the health and well-being of the patient. When the operation is complete, the part simply needs to function.

Global trends indicate that the need for medical implants will increase, as will the competition in the market. According to Seco Tools, about five major suppliers are vying for 85 percent of the orthopedic parts market, with more than 200 companies vying for the remaining 15 percent.

The manufacturing process of orthopedic implants includes cutting, grinding, 3D printing, and other operations on CNC devices by CNC machining parts factory. The machine performs roughing, finishing, milling, T-slot machining, chamfering, and deburring. The goal is to achieve the required surface finish, reducing the need for time-consuming manual processing. Five-axis milling and grinding machines provide advantages when working with complex shapes and contours of prosthetic implants. Thanks to CNC, the production time is significantly reduced & the accuracy is increased. Modern technology is capable of processing almost any material, including titanium and ceramics.

0 notes

Text

Aircraft Carbon Brake Disc Market Revenue, Future And Business Analysis By Forecast 2032

The global aircraft carbon brake disc market size is expected to have a positive outlook during the forecast period from 2022 to 2032. The global market is predicted to reach around US$ 1,136.23 Million in 2022 and is anticipated surge to a high of US$ 2,034.81 Million by the year 2032. The global aircraft carbon brake disc market was valued at around US$ 1,071.92 Million in 2021.

The market is expanding as a result of carbon brake discs working as a feasible substitute for steel brakes and offering significant weight reductions when compared to the latter. Additionally, carbon brake discs are known to wear consistently and function better as the temperature rises. As a result, market valuation is likewise increasing over time and is predicted to continue growing in the upcoming years.

Due to its widespread use in takeoffs, landings, manoeuvring, halting, and landing aircraft, the global market for aircraft carbon brake discs is experiencing a significant increase in sales volume. To assure the safety of the flights, high carbon brake disc rotors are quickly being found; additionally, they are consumer parts that release the brakes simultaneously. The aircraft carbon brake disc is a cutting-edge brake mechanism, according to the analysts at FMI.

It is clear that aircraft carbon brake discs are lighter and have greater heat dissipation properties when compared to reinforced carbon brake discs made of steel. Additionally, it does not alter the high-temperature energy absorption properties. Therefore, it has been predicted that an important part of the aviation sector is the directional control of an aircraft during ground operations. As a result, the market for carbon brake discs for aircraft is anticipated to increase significantly during the given period.

Key Takeaways

The aircraft carbon fiber reinforced carbon brake discs are thicker as compared to the steel rotor used in the aircraft and are remarkably light. Attributed to this feature, the widespread adoption of a carbon brake disc in the aircraft industry is witnessed over the forecast period.

The aircraft carbon brake disc is capable of withstanding temperatures more than 50% higher than steel component brakes. In addition to that, it has been revealed while analyzing that the aircraft carbon brake discs are capable of withstanding2-3 times the heat of a steel brake in non-aircraft applications.

Overall lower costs are associated with the aircraft carbon brake discs since they require minimal maintenance. The minimum operating costs are combined with brake life improvement, lower consumption of fuel, and compact aircraft feasibility is driving the market size of aircraft carbon brake discs.

The ease of retrofitting by manufacturing and engineering technologies is expected to lower the costs for specific aircraft models. Therefore, aircraft carbon brake discs are highly preferred by aircraft manufacturers.

The surge in demand for air passengers has led to a surge in the demand for aircraft, which is further anticipated to drive growth in the aircraft carbon brake disc market over the assessment period.

While analyzing the aircraft carbon brake disc market, it has been identified that the market has gained significant traction over recent years owing to the excessive utilization of these discs in aircraft. The aircraft carbon brake disc market has been gaining popularity over the forecast period, due to its rapid usage in military and commercial aircraft for gliding, taking off, and landing. This aspect is witnessed to be the key growth prospect for the industry and has resulted in a considerable upsurge of demand in the carbon brake disc forum.

For more information: https://www.futuremarketinsights.com/reports/aircraft-carbon-brake-disc-market

Competitive Landscape

The manufacturers are focusing on capitalizing on improving the functionality of aircraft carbon brake discs for better handling of the ground procedures along with catering to the rising demand for safety for the air-passengers. The prominent key players are majorly focusing on product development and are also emphasizing offering certified products through quality brake systems with technological advances in order to increase their brand value.

In addition to that, various key players in the aerospace industry are anticipated to take stringent measures in order to mitigate steep falls in their revenues and demand, thereby propelling market expansion in the upcoming years.

More Insights into the Aircraft Carbon Brake Disc Market

North American region is expected to account for the largest market share over the recent years by accounting for a CAGR of around 5.1% throughout the forecast period. This region has been experiencing rapid growth in terms of aircraft production and is likely to dominate the market share for aircraft carbon brake discs in the upcoming years.

Key Segments in the Aircraft Carbon Brake Disc Market

By Material Type:

Carbon-Carbon

Carbon-Composite

By Aircraft Type:

General Aviation

Commercial Aircraft

Narrow Body Aircraft

Wide Body Aircraft

Regional Jets

Military Aircrafts

By Fit Type:

First Fit

Retro Fit

0 notes

Text

0 notes

Text

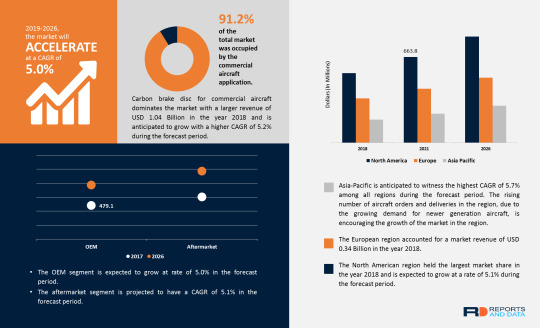

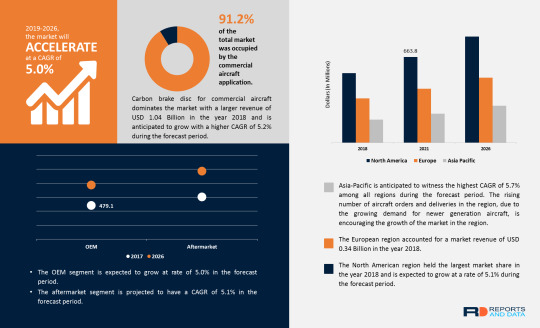

Global Aircraft Carbon Brake Disc to Make Huge Impact in near Future Basic Influencing Factors Driving the Industry 2019 – 2024

Industry Overview of Aircraft Carbon Brake Disc Market

The global Aircraft Carbon Brake Disc market research report studies market overview defining; definition, types, applications latest trends to identify the revenues and the progress of the market over the forecast period. The report offers preventive and premeditated management along with emphasizes the summary of the global Aircraft Carbon Brake Disc market along with classifications and market chain structures. It also highlights authorized statistics of the global Aircraft Carbon Brake Disc market.

Improvement approaches and plans are examined just as assembling procedures and cost structures are additionally investigated. This report likewise states import/trade utilization, free market activity Figures, cost, value, income and gross edges. The report centers around Global real driving Aircraft Carbon Brake Disc Industry players giving data, for example, organization profiles, item picture and determination, limit, generation, value, cost, income and contact data.

Aircraft Carbon Brake Disc is mounted in airplane wheel brake device, it is an important component which is usually used for takeoff, landing, gliding, turning and stopping the. It realizes brake and ensures the safety of a flight and is belonging to the consumable parts.

There are two kinds of airplane brake disc, powder metallurgy brakes and carbon brakes. It is the inevitable trend that carbon brakes, which have excellent mechanical properties, thermal physical properties and good friction and wear properties, will replace powder metallurgy brakes in the aviation industry.

Aircraft Carbon Brake Disc is an advanced technique in brake device. Compared to steel brakes, it is lighter, has better heat dissipation property, and does not reduce the energy absorption characteristics at high temperatures.

The global average price of Aircraft Carbon Brake Disc is in the decreasing trend, from 3701 USD/Unit in 2013 to 3473 USD/Unit in 2018. With the situation of global economy, prices will be in decreasing trend in the following five years.

The classification of Aircraft Carbon Brake Disc includes Commercial Brake Disc and Military Brake Disc. Commercial Brake Disc accounted for the largest share, about 90.63% of the overall Aircraft Carbon Brake Disc market, in 2018.

Get a Sample PDF Report: https://www.acquiremarketresearch.com/sample-request/50522/

Segmentation by product type: Commercial Brake Disc, Military Brake Disc

Segmentation by application: OEM, Aftermarket

The key manufacturers covered in this report: Safran, Meggitt, Honeywell, UTC Aerospace Systems, Xian Aviation Brake Technology, Chaoma Technology, Hunan Boyun New Materials, ...

The fundamental purpose of this Aircraft Carbon Brake Disc market report is to provide a correct and strategic analysis of the Profile Projectors industry. The report scrutinizes each segment and sub-segments presents before you a 360-degree view of the said market.It provides a deep insight into the industry parameters by accessing the market growth, consumption volume, the upcoming market trends, and the different prices variation for the forecast year.

The research methodology of the market involves both primary as well as secondary research data sources. It commits different factors affecting Aircraft Carbon Brake Disc industry such as market environment, various policies of the government, past data and market trends, technological advancements, upcoming innovations, market risk factors, market restraints, and challenges in the industry.

Inquiry before Buying Here @ https://www.acquiremarketresearch.com/enquire-before/50522/

The report grants knowledge on the accompanying pointers:

– Market Penetration: Comprehensive data on the items collection of the top players in the Aircraft Carbon Brake Disc market.

– Product Development/Innovation: Detailed knowledge on the forthcoming advances, R&D actions, and product dispatches in the Aircraft Carbon Brake Disc market

– Competitive Assessment: top to bottom appraisal of the market systems, geographic and business sections of the main players in the Aircraft Carbon Brake Disc market

– Market Development: Comprehensive data about developing markets. This report breaks down the market for a different area overall topographies

– Market Diversification: Exhaustive data about new items, undiscovered topographies, late advancements, and capital exposures in the Aircraft Carbon Brake Disc market

With tables and figures broken down on worldwide Global Aircraft Carbon Brake Disc market, this research gives key measurements on the condition of the business and is a profitable wellspring in direction and course for organizations and people intrigued by the market.

For compiling the report, data has been derived from a number of paid and unpaid sources such as presentations, white papers, journals, and press releases. It offers in-depth information obtained through extensive primary and secondary research methods. The information has been further assessed using various effective analytical tools. Therefore, the report provides a 360-degree view of market.

Read Complete Report With TOC: https://www.acquiremarketresearch.com/industry-reports/aircraft-carbon-brake-disc-market/50522/

At last, It includes the methodical description of the various factors such as the Aircraft Carbon Brake Disc market growth and a detailed information about the different company’s revenue, growth, technological developments, production and the various other strategic developments.

If you have any special requirements, please let us know and we will offer you the report as you want.

0 notes

Text

Aircraft Carbon Brake Disc Market Study, Competitive Strategies, Key Manufacturers, New Project Investment and Forecast till 2026

Aircraft Carbon Brake Disc Market Study, Competitive Strategies, Key Manufacturers, New Project Investment and Forecast till 2026

The market research report on the Global Aircraft Carbon Brake Disc Market published by Reports and Data has been formulated through a series of extensive primary and secondary research and further verified and validated by industry experts and professionals. The well formulated research report aims to provide the readers a better understanding of the industry and help them formulate strategic…

View On WordPress

#Aircraft Carbon Brake Disc Analysis#Aircraft Carbon Brake Disc Industry#Aircraft Carbon Brake Disc Market#Aircraft Carbon Brake Disc Market Forecast#Aircraft Carbon Brake Disc Market Growth#Aircraft Carbon Brake Disc Market Insight#Aircraft Carbon Brake Disc Market Research#Aircraft Carbon Brake Disc Market Share#Aircraft Carbon Brake Disc Market Trends#Aircraft Carbon Brake Disc PDF Report#Aircraft Carbon Brake Disc Research#Competitive Analysis

0 notes

Text

Aircraft Carbon Brake Disc Market 2019 – Huge Growth Opportunities and Expansion by 2025 | Research Informatic

The Aircraft Carbon Brake Disc Market research report covers a wide range of industry elements and components, as well as providing up-to-date and accurate market data. It depicts the regional growth trends as well as potential opportunities. It provides a comprehensive analysis of the market's primary segments through the use of charts and figures. The information in the report has been confirmed by a number of credible sources, including newspapers, magazines, journals, and other reliable sources. The Aircraft Carbon Brake Disc Market research report helps to achieve revenues and tremendous benefits in the future by presenting an unbiased overview of the market.

Visit: https://researchinformatic.com/reports/aircraft-carbon-brake-disc-market/77

Key Competitors

The report provides information that will help stakeholders evaluate investment suitability and market players acquire opportunities for partnerships, collaboration, and agreements.

Here is the list of some of the key players:

Safran

Meggitt

Honeywell

UTC Aerospace Systems

Xi`an Aviation Brake Technology

Chaoma Technology

Rubin Aviation Corporation JSC

Hunan Boyun New Materials

Beijing Beimo Gaoke Friction Material

Yantai Luhang Carbon Materials

SGL Group

Lantai Aviation Equipment

Mersen

Beijing Baimtec Material

Market Assessment

The Aircraft Carbon Brake Disc Market research report examines the market environment and demand from 2019 to 2026. It examines the current state of the market and its future prospects on a global and country level. The research report sheds light on various aspects of the industry by analyzing the market using value chain analysis.

Get Sample Report: https://www.researchinformatic.com/sample-request/77

Market Segmentation

The market is divided into four categories: product, type, application, and geography. Segmentation makes it easy to understand the market and acknowledge the information in the precise manner.

By Material Type (Carbon-Carbon, Carbon-Composite)

Fit Type (First Fit, Retro Fit), Aircraft Type (General Aviation, Military Aircrafts)

Sales Outlook (OEM Sales, Aftermarket)

Geographical Segmentation

The Market is segmented into South America, North America, Asia and Pacific region, Middle East and Africa, and Europe, based on regional distribution.

Enquire Now: https://www.researchinformatic.com/inquiry/77

Synopsis of the report

The report analyzes regional growth trends and future opportunities

A detailed analysis of each segment provides relevant information

The data gathered in the report is researched and verified by analysts

The report gives realistic information on supply, demand, and future projections.

Contact Us:

George Miller

1887 Whitney Mesa

Dr. Henderson, NV 89014

+1 775 237 4147

https://researchinformatic.com

#Aircraft Carbon Brake Disc Market#Aircraft Carbon Brake Disc Market Future#Aircraft Carbon Brake Disc Market Insight#Aircraft Carbon Brake Disc Market Share#Aircraft Carbon Brake Disc Market Opportunity

0 notes

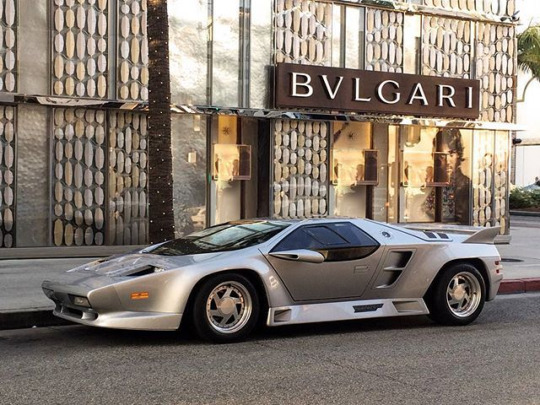

Photo

Lamborghini Reventon

Number 20 of only 20 produced, this Lamborghini Reventón is among the most exclusive, radical automobiles the company has ever built, the boldest of statements coming as it does from the folks who brought you the Miura, the Countach and the Diablo.

Based on the extraordinarily successful Murciélago LP640, the Reventón departs with all-new exclusive composite carbon-fiber body panels, inspired by the F-22 Raptor fighter jet, over its carbon-fiber and steel main structure. A prominent central peak and large forward-facing air intakes dominate the car’s visage, the latter ensuring optimal airflow to the front carbon-fiber brake discs and black 6-piston calipers. In the classic Lamborghini fashion established by the legendary Countach and a feature of every 12-cylinder Lambo since, the doors open upward. Another pair of large air intakes dominate the Reventón’s side sills, the driver side feeding air to the engine oil cooler and the passenger side channeling air beneath the floor to the voluminous rear diffuser. A longer tail and a larger speed-activated rear spoiler add to the Reventón’s aerodynamic edge over the Murciélago. Like the F-22, there is not a single flat plane in the entire shape, but a series of angles that emphasize the car’s high-speed mission.In addition to its swoopy body, the Reventón’s machined billet aluminum fuel-filler cap, exhaust outlet, bi-xenon/LED headlights, LED tail lights and gloss-black wheels with carbon-fiber blades all contribute to the Reventón’s extreme exclusivity.

The Reventón’s interior is every bit as unique, showing off Nero Perseus leather and Olive Verde Alcantara upholstery covering carbon-fiber seats, and a new instrument cluster made of carbon-covered billet aluminum and sheltering three aircraft-style Thin Film Transistor screens in place of analog readouts. These can be configured to show all driver information in two different layouts, one patterned after contemporary aircraft design and another using round analog-style readouts for those who prefer more conventional instrumentation. Distinctive arrow design patterns are punched into the Alcantara inserts in the seats, carpets and headliner, a motif repeated in the tail-light design. White thread decorates the black leather upholstery and is used for the Reventón logos stitched into the door panels and the Lamborghini insignias decorating the headrests. Other interior surfaces are trimmed in highly polished carbon fiber as standard fitment, namely the dash inserts, steering wheel lower rim, console plate and passenger grab handle.

Bold styling always leads the way in designing the latest raging bull, but no Lamborghini is complete without a brilliantly engineered drivetrain and chassis, and the Reventón lives up to its unique status in both categories. Visible beneath the Reventón’s arrow-motif back glass, its 6.5L V-12 engine comes straight from the Murciélago, but a dash of tuning has raised output by 10 ponies to 641 HP. Mated to the paddle-shifted E-Gear 6-speed transmission, the Reventón’s V-12 accelerates the car to 60 MPH in 3.4 seconds on the way to its 211 MPH top speed.

85 notes

·

View notes

Text

Aircraft Carbon Brake Disc Market Size, Trends and Future Growth Predictions till 2026

The latest research, Aircraft Carbon Brake Disc market allows companies and individuals learn more about the yesteryears, present and potential buyers in the Aircraft Carbon Brake Disc market for the forecast period, 2019 to 2026. Most importantly, the study enables business owners to understand and make better business decisions by pinpointing the current demands and needs of the consumers. The collection of data with an aim to offer clarity on consumer behaviour in a particular region where the Aircraft Carbon Brake Disc market players operate makes the report more valuable. Apart from this, the study evaluates the competitors in a specific country. Another critical aspect that is covered by this literature on Aircraft Carbon Brake Disc market is the effective assessment of small marketing campaigns.

Key manufacturers in the market include Safran, United Technologies Corporation, Honeywell International Inc., Meggitt PLC, SGL Carbon, and Parker Hannifin, among others. Yantai Luhang Carbon Materials Technology Co. Ltd., Beijing International Aeronautical Materials Corporation (BIAM), Xi’an Aviation Brake Technology Co., Ltd., and Shaanxi Lantai Aviation Equipment Limited are key raw material suppliers in the market.

Download FREE PDF Sample copy of this research report at: https://www.reportsanddata.com/sample-enquiry-form/1716

Scope of the Report:

The recent study on the Aircraft Carbon Brake Disc Market aims at illuminating the performance of the Aircraft Carbon Brake Disc industry for the forecast period 2019 to 2026. Importantly the research digs deep into the competitive landscape where major vendors and new entrants are trying to keep up with the cut-throat competition worldwide. A thorough analysis of how technology is influencing the developments in the Aircraft Carbon Brake Disc Market forms an important part of the overall research.

Segments covered in the report:

For the purpose of this report, Reports and Data have segmented the global the aircraft carbon brake disc market on the basis of application, sales, and region:

Application Outlook (Revenue, USD Million; 2016-2026)

• Commercial Aircraft

• Military Aircraft

Sales Outlook (Revenue, USD Million; 20176-2026)

• OEM Sales

• Aftermarket

Regional Outlook (Revenue, USD Million; 2016-2026)

• North America

o U.S.

o Rest of North America

• Europe

o France

o UK

o Germany

o Rest of Europe

• Asia Pacific

o China

o Rest of Asia Pacific

• Rest of the World

o Brazil

Buy Now: https://www.reportsanddata.com/checkout-form/1716

Apart from this, the study assesses the weaknesses and strengths of the major market players operating across different regions. Analysis of prominent trends from past and future that is actively contributing to the growth of the Aircraft Carbon Brake Disc industry further plays an eminent role in helping business owners plan effective business strategies. Evaluation of various aspects such as import and export status, distribution channel, supply chain management, profit and gross margin is explained extensively in the report.

The research provides answers to the following key questions:

• What is the estimated market size of the Aircraft Carbon Brake Disc Market for the forecast period, 2019 to 2026? What will be the growth rate during the estimated period?

• What are the major driving forces likely to influence the competitive landscape of the Aircraft Carbon Brake Disc industry?

• Who are the prominent vendors operating in the Aircraft Carbon Brake Disc Market and what according to them are the winning strategies to remain ahead in the competition?

• What are the trends likely to influence the progress of the market over the coming years?

• What type of challenges and threats can hinder the progress of the Aircraft Carbon Brake Disc industry worldwide?

• What type of opportunities is in store for in store for the major vendors during the estimated period?

Read More: https://www.reportsanddata.com/report-detail/aircraft-carbon-brake-disc-market

#Aircraft Carbon Brake Disc market#Aircraft Carbon Brake Disc market Trends#Aircraft Carbon Brake Disc market Size

0 notes

Photo

Like all large jetliners, the Boeing 787 Dreamliner has a brake unit on each of the eight wheels of the main landing gear assemblies. On other aircraft, though, the brakes are powered by the hydraulics system where hydraulic actuators push the brakes against the wheel. To save weight which improves the fuel burn and payload, on the Dreamliner the brakes are powered by electrical actuators to press the carbon brake discs against the wheel. By dispensing with hydraulic actuators and the associated hydraulic lines and accumulators associated with the braking system, the Boeing 787-8 saves 141 lbs and the larger 787-9 saves 244 lbs. With electrical wiring replacing hydraulic lines, it's also faster to replace the brake units if needed. Built-in monitoring systems allow engineers to monitor brake performance closely giving a real time measurement of disc wear. The electric brakes on the 787 are produced by Safran Landing Systems and are the first application of this technology on a production commercial aircraft. Safran is a French company formerly known as Messier-Bugatti-Dowty and is the largest manufacturer of aircraft landing gear sets in the world. Final assembly of the 787 landing gears takes place at Safran's facilities in Everett, Washington, and Toronto, Ontario, before delivery to the 787 production lines in Seattle and Charleston. This particular 787 is N828AA, a -9 variant built at the Boeing Charleston line and delivered to American in June 2017. #avgeek #aviation #aircraft #planeporn #KDFW #DFW #DallasFortWorth #Texas #airport #planespotting #instaplane #Boeing #787 #AmericanAirlines #N828AA #Dreamliner #instagramaviation #splendid_transport #instaaviation #aviationlovers #aviationphotography #flight #AvGeeksAero #AvgeekSchoolofKnowledge #AvGeekNation (at DFW Airport) https://www.instagram.com/p/CWPkH5NL8eS/?utm_medium=tumblr

#avgeek#aviation#aircraft#planeporn#kdfw#dfw#dallasfortworth#texas#airport#planespotting#instaplane#boeing#787#americanairlines#n828aa#dreamliner#instagramaviation#splendid_transport#instaaviation#aviationlovers#aviationphotography#flight#avgeeksaero#avgeekschoolofknowledge#avgeeknation

9 notes

·

View notes

Text

How It’s Made Index(S01~S10)

How It’s Made是由 Discovery Channel 制作一款王牌节目,又被翻译为制造的原理或造物小百科, 本片从2001年推出至今,涵盖了几乎所有的制造技术 ,非常适合机械专业和对此感兴趣的同学。希望大家享受这趟制造的艺术之旅!

第一季推出时间为2001-01-06至2001-03-31

S01E01 Aluminum foil, Snow Boards, Contact lenses, Bread. 铝箔,雪橇板,隐形眼镜,面包

本集看点:铝锭是如何一步步用轧制工艺压制成像纸一样薄的铝箔的;

S01E02 Compact Discs; Mozzarella Cheese; Pantyhose; Fluorescent Tubes. 光碟,奶酪,女式连袜裤,荧光灯管

本集看点:CD光盘是怎么从模具注塑出来的;玻璃管的热弯,以及荧光灯复杂的自动化制程;

S01E03 Toothpicks; Acrylic Bathtubs; Helicopters; Beer. 牙签,玻璃纤维增强塑料浴缸 ,直升机,啤酒

本集看点:牙签的制作,是类似于螺钉,是先用木材做成木板再切割而成;塑料的吸塑制程,玻璃纤维+树脂强化制程;碳纤维制作的飞机支架;

S01E04 Hearing Aids; 3-D Puzzles; Rubber Mats; Toilets 助听器,三维拼图,胶垫,抽水马桶

本集看点:用模具制作陶瓷的加工制程;

S01E05 Copy Paper; Jeans; Computers; Plate Glass 复印纸,牛仔裤,电脑,平板玻璃

本集看点: 浮法平板玻璃的制作过程;

S01E06 Nails and Staples; Safety Glasses; Fabrics; Bicycles 钉子,护目镜,布匹,自行车

本集看点:一卷钢丝的艺术之旅;透明塑胶模具的高亮抛光;线全自动编制成布;自行车架的焊接与喷涂工艺;

S01E07 Kayaks; Safety Boots; Electronic Signs; Cereals 皮划艇,安全靴,电子招牌,麦片粥

本集看点: 热塑性塑料的成型方法加工,不需要压力,只需要加热和摇晃即可;LED制成的大型广告或体育比赛显示屏

S01E08 Trucks; Adhesive Bandages; Computer Circuit Boards; Liquors 卡车,创口贴,计算机电路(PCB),酿酒(威士忌)

本集看点:SMT和波峰焊制程(单面器件),目前手机等产品已经主要使用回流焊制程;

S01E09 Steel; Apple Juice; Aircraft Landing Gear; Cosmetics 钢铁,苹果汁,起落架,化妆品

本集看点:钢铁是怎样练成的;车削和铣削加工,喷砂工艺,外观电镀处理;

S01E10 Holograms; Package Printing; Skin Culture; Canned Corn 全息摄影,包装盒,皮肤培植,罐装玉米

本集看点:还是不懂的全息摄影和底片冲洗;

S01E11 Plastic Bags; Solar Panels; Plastic Gasoline Containers; Hockey Sticks 塑料袋,太阳能电池板,塑料汽油桶,曲棍球棍

本集看点:塑料袋通过聚乙烯吹膜制程制作;吹塑制作塑料桶;

S01E12 Aluminum Screw Caps; Chocolate; Pills; Pasta 铝瓶盖,巧克力,药丸,面食

本集看点:铝合金的拉伸制程;

S01E13 Bicycle Helmets; Aluminum; Car Brakes; Lithium Batteries 自行车头盔,铝,汽车刹车,锂电池

本集看点:聚苯乙烯发泡注塑;电解铝制程,制作成铝锭;电池是怎么卷出来的;

本季资源链接:

magnet:?xt=urn:btih:e1ec692441019f65979f29e09bc9f84b3bdf563e&dn

第二季推出时间为2002-09-07至2002-12-07

S02E01 Eyeglass Lenses; Granite; Potato Chips; Microprocessors 眼睛镜片,花岗石板,薯片,微处理器

本集看点:塑胶镜片的抛光和AR镀膜;芯片的封装制程;

S02E02 Honey; Fiber-Optics; Bricks; Pipe Organs 蜂蜜,光纤,砖块,管风琴

本集看点:玻璃管拉丝成为光纤;

S02E03 Personal Watercraft; Wine; Office Furniture; Ice Skates 水上摩托,葡萄酒,办公家具,溜冰鞋

S02E04 Winter Jackets; Animation; Mushrooms; Gold Rings 冬季夹克衫,动画片,蘑菇,金戒指

本集看点:用 熔模铸造工艺制作魔戒;

S02E05 Hydroponic Lettuce; Construction Wood; Recycling; Fishing Flies 水培莴苣,建筑木材,垃圾回收,假蝇饵

本集看点:完全工业化种菜;

S02E06 Diamond Cuttings; Wood Doors; Paintballs; Newspapers 切割钻石,木门,彩色球,报纸

S02E07 Carpets; Drinking Water; Laser Eye Surgery; Acoustic Guitars 地毯,饮用水,激光眼科手术,吉他

S02E08 Fiberglass Boats; Clothes Dryers; Bubble Gum; Fireworks 玻璃纤维艇,干衣机,泡泡糖,焰火

本集看点:玻璃纤维+树脂制作的船体上盖;钢板制作圆筒;

S02E09 Steel Safes; False Teeth; Airplanes; Maple Syrup 保险箱,假牙,轻型飞机,枫糖浆

本集看点:来了,玻璃纤维+树脂制作的飞机机身;

S02E10 Gummies; Aluminum Cans; Fish Farming; Bronze Sculptures 花色软糖,易拉罐,养鱼,青铜雕塑

本集看点:可口可乐,来一罐!

S02E11 Aluminum Pots and Pans; Artificial Limbs; Peanut Butter; High Intensity Light Bulbs 旋压铝制品,假肢,花生酱,高光灯泡

本集看点:用旋压而非拉伸制作的铝合金罐子和盖子,两种方式各有优势;

S02E12 Cars; Grocery Carts; Rapid Tooling and Prototyping; Collectible Coins 小汽车,购物车,快速模具成型,纪念币

本集看点:钣金的加工制程,电阻焊;3D打印树脂零件,浇铸工艺及其模具制作;银币复杂的图案转移过程;

S02E13 Ball Bearings; Electrical Wires; Lost Wax Process Casting; Automated Machines 轴承,电线,熔模铸造,自动化机器

本集看点:钢球的制造过程(冲压+研磨); 熔模铸造的金属铸造件, 熔模本身也是通过模具制造的;极其舒适的全自动化制造过程合集;

本季资源链接:

magnet:?xt=urn:btih:543050ad51e44c744d235680efec5db2693724f7&dn

第三季推出时间为2003-10-01至2003-12-30

S03E01 Pre-inked Stamps; Cranberries; Cotton Yarn; Road Signs 原子章,酸果,棉纱,交通标志

本集看点:丝印网板的制作过程;

S03E02 Combination Locks; Pottery; Recreational Vehicles; Erasers 字码锁,陶器,休闲拖车,橡皮擦

本集看点:如何用模具制作陶罐;

S03E03 Wheel Loaders; Vegetable Oil; Hand Tools; Cotton Swabs 轮式装运机,植物油,手动工具,棉签

S03E04 Temporary Metal Fences; Asphalt Shingles; Polystyrene Products; Hard Candies 金属栅栏,沥青屋面板,泡沫板,花式硬糖

本集看点:泡沫发泡制程;

S03E05 Horse-drawn Carriages; Artificial Eyes; Dog and Cat Food; Mirrors 老式马车,假眼,猫粮和狗粮,镜子

S03E06 Yogurt; Candles; Neon Signs; Bookbindings 酸奶,蜡烛,霓虹灯,装订

S03E07 Prepared Mustard; Violins; Nuts and Bolts; Toilet Paper 芥末,小提琴,螺母螺帽,卫生纸

本集看点:螺杆的滚丝螺纹制程,螺母是钢丝在高温下压制而成的,螺母的螺纹后加工CNC制成;

S03E08 Fresh Cut Flowers; Adhesive Tape; Tofu; Lottery Tickets 鲜花,胶带,豆腐,彩票

S03E09 Inflatable Watercraft; Couscous; Modelling Dough; Wicker Products 充气筏,蒸粗麦粉,玩具胶泥,柳条编织

S03E10 Wind Generators; PVC Gloves; Thermo-Formed Glass; Fire Trucks 风力发电机,塑胶手套,热塑玻璃,消防车

本集看点:手工让平板玻璃热成型成精美盘子;

S03E11 Radiators; Hatchery Chicks; Filo Pastry; Cross-Country Skis 汽车散热器,孵蛋机,薄生面片,滑雪撬

S03E12 Electric Baseboard Heaters; Moulded Pulp Containers; Chicken; Video Games 电加热器,纸浆(鸡蛋)托盘,鸡肉,电脑游戏

本集看点:钣金连续冲压过程;

S03E13 Fire Fighter Boots; Garden Tools; Automated Machines; Gypsum Board 防火靴,园艺工具,自动化机械,石膏板

本集看点:新一期极其舒适的自动化流水线;

本季资源链接:

magnet:?xt=urn:btih:724f7b0bbf3278e4eec84db6c0373551017fb874&dn

第四季推出时间为2005-01-04至2005-03-29

S04E01 Plastic Bottles & Jars; Mail; Eggs; Handcrafted Wooden Pens 塑料瓶,邮件分拣,鸡蛋,木柄定制钢笔

本集看点:塑料瓶的吹塑制程(舒适);鸡蛋是怎么生产的;

S04E02 Plastic Injection Moulds; Automotive Oil Filters; Filing Cabinets; Blown Glass 塑料注塑模具,汽车滤油器,档案柜,吹塑玻璃

本集看点:塑料注塑模具的加工制程:CNC加工、EDM电极加工,以及双色注塑过程;钣金柜子的加工制程;美女是如何吹玻璃的;

S04E03 High-Precision Cutting Tools; Stained Glass; Semi-Trailers; Recorders 钻头,拼花玻璃,拖车,木直笛

本集看点: 涡流加热,通过热处理后软化或硬化金属;

S04E04 Conga Drums; Metal Plating; Buttons; 康茄鼓,金属电镀,纽扣

本集看点: 金属电镀制程;

S04E05 Grinding Wheels; Compost; Window Blinds; Milk 砂轮,堆肥,百叶窗,牛奶

S04E06 Brushes & Push Brooms; Blackboards; Smoked Salmon; Zippers 木刷子,黑板,熏鲑鱼片,拉链

本集看点: 毛刷组装时的金属U型倒扣固定住刷毛;

S04E07 3D Commercial Signs; Hardwood Floors; Corrugated Polyethylene Pipe; Mattresses 立体标牌,硬木地板,聚乙烯管,床垫

本集看点: 大型塑胶型材的成型过程;弹簧的制作过程;

S04E08 Ceramic Tiles; Nuts; Steel Forgings; Skateboards 瓷砖,果仁,炼钢,滑板

本集看点: 炼钢和轧钢;

S04E09 Car Engines; Flour; Recliners; Envelopes 轿车引擎,面粉,活动躺椅,信封

S04E10 Plastic Cups & Cutlery; Special Effects Makeup; Gold; Harps 塑料杯和餐具,特技化妆,黄金,竖琴

本集看点: 热成型一次性塑料杯;简单一些的塑料管型材制作过程;金锭的制作过程;

S04E11 Countertop Laminate; Frozen Treats; Children's Building Blocks; Detergents 表面压片,雪糕,儿童积木,清洁剂

S04E12 Architectural Moldings; Pulleys; Industrial Rubber Hose; Sheet Vinyl Flooring 装饰嵌条,滑轮,橡皮管,树脂地板

S04E13 Putty Knives; Garage Doors; Electric Motors; Wool 油灰刀,车库活动门,电动机,毛料衣物

本季资源链接:

magnet:?xt=urn:btih:0e69c6104b7c64173fa6ef64df6d7a801dd95f6f&dn

第五季推出时间为2005-09-07至2005-11-29

S05E01 Paving Asphalt; Marshmallow Cookies; Loudspeakers; Electronic Door Locks 沥青石料,葵糖饼干,高音喇叭,电子门锁

S05E02 Wood Burning Stoves; Orthoses; Ballet Slippers; Buses 木炭火炉,矫正鞋具,芭蕾舞鞋,公共汽车

S05E03 Robotic Arms; Tattoos; Sanitary Napkins; Concrete Pipes 机械手,纹身,卫生巾,水泥管

S05E04 Hockey Gloves; Snack Cakes; Remoulded Tires; Wastewater Treatment 曲棍球手套,点心蛋糕,轮胎翻新,污水处理

S05E05 Ambulances; Dining Room Tables; Diatonic Accordians; Acrylic Awards 救护车,餐桌,手风琴,有机玻璃工艺品

S05E06 Alkaline Batteries; Wheelchairs; Flutes; Cowboy Boots 碱性电池,轮椅,长笛,牛仔靴

本集看点: 学习一下最常见类型电池的制作原理;

S05E07 Golf Balls; Furniture Handles; Parking Meters; Room Dividers 高尔夫球,门扣,停车计时器,房间屏风

S05E08 Suits of Armour; Street Light Poles; Bent Hardwood; Membrane Switches 铁盔甲,电灯杆,弯曲硬木,薄膜开关

本集看点: 可以看到锅仔片的结构原理;

S05E09 Sulkies; Bagpipes; Yule Logs; Fishing Lures 单座两轮马车,风笛,圣诞节原木形大蛋糕,假鱼饵

S05E10 Goalie Pads; Lapel Pins; Cardboard Boxes; Crystal Wine Glasses 守门员护具,衣襟徽章,纸盒,水晶杯

S05E11 Cement; Caskets; Soft Drinks; Glider Rockers 水泥,棺材,饮料,摆动式摇椅

S05E12 Kitchen Knives; Mannequins; Socks; Hypodermic Needles 厨刀,人体模型,纱袜,针头

S05E13 Electrical Panels; Kites; Eyeglass Frames; Toothbrushes 配电板,风筝,眼镜架,牙刷

本季资源链接:

magnet:?xt=urn:btih:997cae2b195f96293de6b35858cc50fdc73431f3&dn

第六季推出时间为2006-01-04至2006-03-29

S06E01 Three-Wheeled Vehicles; Baseball Bats; Artificial Bonsais; Trombones 三轮摩托,棒球棍,盆景,长号

S06E02 Springs; Pavers; Pianos; 弹簧,路砖,钢琴

本集看点: 各种弹簧的全自动制作过程;

S06E03 Ropes; Billiard Tables; Sailboards; Cymbals 绳索,台球桌,帆板,铙钹

S06E04 Seatbelts; Windows; Wax Figurines; Hot Air Balloons 安全带,塑钢窗,小蜡像,热气球

S06E05 Air Filters; Billiard Cues; Ice Sculptures; Suits 空气过滤器,台球杆,冰雕,西服

S06E06 Escalator Handrails; Highlighters; Guitar Strings; Wigs 自动扶梯扶手,荧光记号笔,吉他弦,假发

S06E07 Traditional Bows; Coffee Machines; Mascots; Hammocks 传统的弓,咖啡机,吉祥物,吊床

S06E08 Fiberglass Insulation; Wooden Ducks; Gumball Machines; Exhaust Systems 玻璃纤维隔层,木鸭子,口香糖球售卖机,排气管

S06E09 Chains; Bagels; Vinyl Records; 链条,硬面包圈,唱片

S06E10 Windshields; English Saddles; Butter; Post Clocks 挡风玻璃,英式马鞍,黄油,柱钟

本集看点: 夹层玻璃的制作过程;

S06E11 Individual Transporters; Canoes; Electric Guitars 双轮代步车,雪松独木舟,电吉它

S06E12 Residential Water Heaters; Air Bags; Jelly Beans; Ice Resurfacers 宅用热水器,气囊,胶质软糖,冰面修整器

S06E13 Amphibious Vehicles; Putters; Model Ships; Drumheads 水陆两用车,高尔夫球杆,轮船模型,鼓面

本季资源链接:

magnet:?xt=urn:btih:2575f1794b6554ba85b38125e673a95ecb7bb668&dn

第七季推出时间为2006-09-05至2007-03-30

S07E01 Footballs; Electric Guitar Amplifiers; Marbles; Airplane Propellers 橄榄球,吉它扩音器,玻璃球,飞机螺旋桨

本集看点: 精美的艺术品玻璃球;先锻造再CNC成型的结构件;

S07E02 Engine Blocks; Jawbreakers; Drum Shells; Drums 引擎铸模,硬球糖,爵士鼓

本集看点: 引擎的模具制造和浇铸过程;

S07E03 Lighters; Fossils; Hockey Pucks; High-Pressure Cylinders 打火机,化石,冰球,高压钢瓶

本集看点: 铝合金的多次拉伸成型过程;

S07E04 Balloons; Wallpaper; Frozen French Fries; Incandescent Light Bulbs 气球,墙纸,炸薯条,白炽灯泡

S07E05 Matches; Carousel Horses; Fine Porcelain; Fuel Tanks 火柴,旋转木马,细瓷,汽油箱

S07E06 Glass Cookware; Soap Bars; Steel Drums; Firefighter Uniforms 玻璃炊具,肥皂,铁皮鼓,防火服

S07E07 Crayons; Wooden Kayaks; Lawnmowers; Gold Chains 蜡笔,木伐子,割草机,金项链

S07E08 Inflatable Safety Devices; Braille Typewriters; Carbon-Fibre Cellos 安全气囊,盲人打字机,碳纤维大提琴

S07E09 Carbon-Fibre Masts; Fortune Cookies; IMAX Projectors; Roller Chains 碳纤维桅杆,好运饼干,IMAX 放映机,滚子链

S07E10 Firefighter Helmets; Nautical Compasses; Packaging Tubes; Hand Saws 消防员头盔,罗盘,包装软管,手锯

S07E11 Halogen Bulbs; Cellulose Insulation; Aluminum Ladders; Bamboo Fly Rods 卤素灯,纤维绝缘层,铝梯,竹制飞蝇钓竿

S07E12 Drill Bits; Photo Booths; Stamps 钻头,照相亭,邮票

S07E13 Yacht Wheels; Braided Rugs; Automobile Thermostats; Chisels 游艇方向盘,编织毯,汽车调温器,凿子

本季资源链接:

magnet:?xt=urn:btih:06d33183a0f6ea98b8a64257d73ae0ce870082c6&dn

第八季推出时间为2007-01-02至2007-04-03

S08E01 Motorcycles; Clay Pipes; Drumsticks; Whistles 摩托车,水泥管,鼓槌,哨子

S08E02 Glass Bottles; Hacksaws; Goalie Masks 玻璃瓶,钢锯,守门员面具

本集看点: 极其舒适的玻璃瓶模具制造和吹制成型制程;

S08E03 Lacrosse Sticks; Frozen Fish Products; Flashlights; Paintbrushes 长柄曲棍球杆,油炸冻鱼肉,手电筒,油漆刷

S08E04 Deep Cycle Batteries; Tins; Optical Lenses 蓄电池,白铁罐,光学镜头

本集看点: 镜头的打磨抛光制程,以及多层镜片结构;

S08E05 Pistons; Paint Rollers; Parachutes; Chimneys 活塞,油漆滚筒,降落伞,烟筒

本集看点: 先锻压成型再CNC的典型结构件;由钢板卷成圆筒的典型制程,提前制作倒钩结构进行预固定,自动化制程不需要;

S08E06 Fishing Reels; Miniature Houses; Kitchen Mixers 渔线轮,迷你房屋,厨房搅拌器

S08E07 Photographs; Fur Tanning; Welding Electrodes; Electric Violins 照片,毛皮制革,电焊条,电子小提琴

S08E08 Horseshoes; Dishwashers; Graphite Fly Rods; Pizza 马蹄铁,洗碗机,石墨飞蝇钓竿,比萨饼

S08E09 CO2 Cartridges; Pretzels; Scissor Lifts; Skating Rinks 二氧化碳弹药筒,椒盐卷饼,剪式提升机,滑冰场

S08E10 Pro Hockey Sticks; Bronzed Shoes; Treadmills; Computers 职业曲棍球棍,古铜色婴儿鞋,跑步机,掌上电脑

S08E11 Handcuffs; Caulking Compound; Propane Tanks; Forensics 手铐,堵缝剂,丙烷罐,法医学面部再造

本集看点: 上下焊接的冲压铝罐制程;

S08E12 Fur Coats; Hearses; Outdoor Lighting Fixtures; Golf Tees 毛皮大衣,灵车,室外照明器材,高尔夫球座

S08E13 Manhole Covers; Range Hoods; Artificial Logs; Snowmobiles 下水道井盖,抽油烟机,人造原木,雪地摩托

本集看点: 简单一些的金属铸造制程;

本季资源链接:

magnet:?xt=urn:btih:c04d9b7696663c9326761cf99038907f5db5f089&dn

第九季推出时间为2007-09-21至2008-04-06

S09E01 Solid Tires; Cheesecake; Canoe Paddles; Globes 实心轮胎,奶酪蛋糕,独木舟短桨,地球仪

S09E02 Boomerangs; Barbeques; Pinball Machines; Strobe Lights 回力镖 ,烧烤炉具,弹球机,闪光灯

S09E03 Wooden Bowls; Chainsaws; Stackable Potato Chips; Jet Compressor Blades 木圆盆,链锯,马铃薯片,喷气压缩机叶片

S09E04 Steel Wool; Ranges; Carved Candles; Slot Machines 钢丝棉,炊具系列,雕刻蜡烛,老虎机

S09E05 CCD Semiconductors; Airline Meals; Paper Cups; Trumpets CCD半导体,航空餐,纸杯,小号

本集看点: 先进制程之相机CCD感应芯片制作过程;

S09E06 Padlocks; Hair Clippers; Wooden Shoes; Synthetic Leather 挂锁,电推剪,木鞋,人造革

S09E07 Racing Shells; Stainless Steel Sinks; Leather; Pedal Steel Guitar 划艇,不锈钢水池,皮革,踏板钢铁吉他

S09E08 Swords; Pontoons; Grandfather Clocks; Fuses 剑,浮船, 落地大摆钟,保险丝

S09E09 Bumpers; Lighting Gels and Camera Filters; Steam-Powered Models; Candy Canes 保险杠,滤色片,蒸汽模型,苔杖糖

S09E10 Umbrellas; Outboard Motors; Silver Cutlery; Tape Measures 雨伞,舷外马达,银制餐具,卷尺

S09E11 Scalpels; Oil Paints; British Police Helmets; Ice Axes 手术刀,油画颜料,英国警察头盔,冰斧

S09E12 Bacon; Snowblowers; Luxury Cars 熏肉,扬雪车,豪华轿车

S09E13 Automatic Transmissions; Silver Miniatures; Hot Air Balloon Baskets; Darts 自动变速器,银制微型复制品,热气球吊篮,飞镖

本季资源链接:

magnet:?xt=urn:btih:a9aa449eda3eeaa8d9e9d91996dde5510940630f&dn

第十季推出时间为2008-06-11至2008-09-03

S10E01 Magnets; Cooked Ham; Silver Teapots; Crash Test Dummies 磁铁,火腿,银制茶壶,撞击测试人体模型

本集看点: 用线圈磁化的磁铁;对于收口的茶壶,内芯位置冲压模具应该是用可变形的橡胶;

S10E02 Curling Stones; Refrigerators; Aluminum Baseball Bats; Opalescent Glass 冰壶,冰箱,铝制棒球棍,乳白玻璃

S10E03 Levels; Hot Dogs; Abrasive Grains; Sandpaper 水平尺,热狗,抛光粉,砂纸

S10E04 Ice Cream Treats; Wooden Golf Clubs; Aircraft Wings; Car Battery 冰淇淋,木制高尔夫球杆头,飞机机翼,车用蓄电池回收

S10E05 Automotive Fuel Pumps; Cricket Bats; Change Machines; Ductile Iron Pipe 汽车燃油泵,板球,纸币找换机,球墨铸铁管

S10E06 Wooden Barrels; Fire Hydrants; Automotive Seats; Cathode Ray Tubes 木桶,消防栓,汽车座椅,阴极射线管

本集看点: 老式CRT电视是如何制作的;

S10E07 Stainless Steel; Football Helmets; Resin Figurines; Laboratory Glassware 不锈钢,橄榄球头盔,树脂小塑像,实验室玻璃器具

本集看点: 不锈钢轧制制程;玻璃管的热切割制程;

S10E08 Fire Extinguishers; Doughnuts; Shock Absorbers; Banjos 灭火器,甜甜圈,减震器,班卓琴

S10E09 Dress Forms; Boat Propellers; Duvets; Faucets 女装人体模型,小艇螺旋桨,羽绒被,水龙头

本集看点: 注塑的融模,再进行浇铸;

S10E10 Bronze Bells; Wooden Airplane Propellers; Charcoal Briquettes; Gas Log Fireplaces 铜钟, 木制螺旋桨, 木炭和煤气炉

S10E11 Ice Cream Cones; Tent Trailers; Shoe Polish; Pliers 折叠刀, 皂石, 变压器和传统雪鞋

S10E12 Steel Shipping Drums; Police Whistles; Miniature Train Wagons; Glass Blocks 油桶, 警笛, 微型车厢和玻璃垫块

S10E13 Pocket Knives; Soapstone Products; Electric Pole Transformers; Snowshoes 蛋筒, 篷式挂车, 鞋油和钳子

本季资源链接:

magnet:?xt=urn:btih:3e5cd2ae716c8363111416709f962ae68ec36a60&dn

7 notes

·

View notes

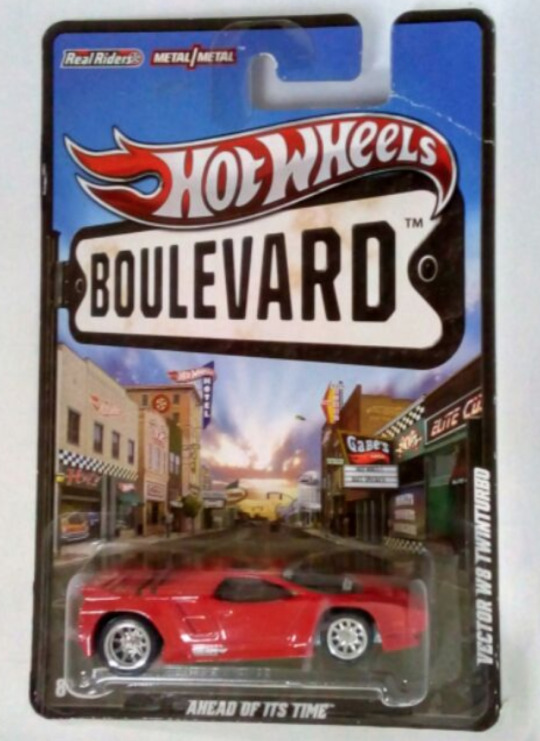

Photo

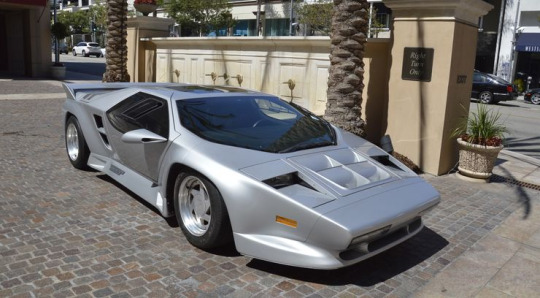

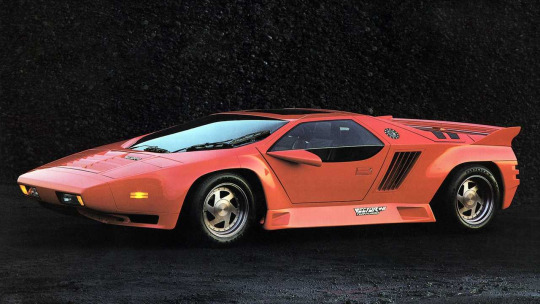

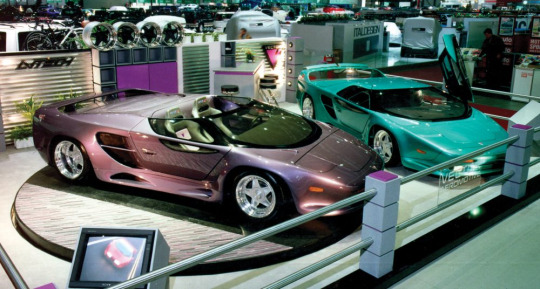

Casting Call: Vector W8

First off, I’d like to apologize for the fact that I’ve not been updating my Tumblr lately. I’ve been busy at work and haven’t had time to write something. To make up for this... I’m writing quite possibly one of my longest posts yet.

By popular demand, this is the casting you chose on Instagram for me to document: the Vector W8. Grab some popcorn, a drink or some music... and enjoy the read. This is also in some ways a car that time forgot, but it’s not a concept car... but I can break the rules because I made them.

When it comes to cars of the ‘80s, there is a debate as to what the best car of the era was. Many say it would be either the Lamborghini Countach or the Ferrari Testarossa. But I have something that is neither of those things. Today, we’re going to take a trip down memory lane and explore the car that attempted to elevate a small company to the dizzying heights of the supercar realm. This... is the Vector W8.

First, here’s a bit of background. The W8 was manufactured by a company known as Vector Motors, then known as Vector Aeromotive. The company was founded in 1971 as Vehicle Design Force by Gerald “Jerry” Wiegert in Wilmington, California; we’ll get to the full history of Vector in a post in the near future because it is honestly very interesting.

In essence, the W8 was a highly refined version of the Vector W2, one of the company’s initial prototypes (the “W” in the name stood for “Wiegert”). Wiegert wanted to put the W2 into production, but an economical downturn prevented him from doing so. However, by the ‘80s, Wiegert had eventually secured enough capital through public stock offerings and even various lawsuits, allowing him to chase his dream: to build his ultimate sports car, designed and built by his own company.

Design inspiration for the W8 (and by extension the W2) came from this green car: the Alfa Romeo Carabo (Hot Wheels actually did a model of this way back when). Its sleek, futuristic and aerodynamic design was perfect for Wiegert, especially with the aerospace theme the company was going for in the ‘80s.

Combining the sleek looks of the Carabo with the geometry and technology of fighter jets of the time like the F-15 Eagle, F-16 Fighting Falcon and F/A-18 Hornet, Wiegert and chief designer David Kostka set out to create what would be quite possibly the most insane supercar of the ‘80s, and probably still is now: the Vector W8. The term “Aeromotive Engineering” was used to describe the process of manufacturing this car, for the car used the newest and most advanced aerospace materials when manufacturing the W8.

The car passed the mandatory DOT crash tests and emissions tests. It used a semi-aluminum monocoque chassis which was epoxy bonded and riveted using 5000 aircraft-specification rivets with an aluminum honeycomb floorpan. The body was made mainly of carbon fiber and Kevlar. The car featured scissor doors, like a Lamborghini.

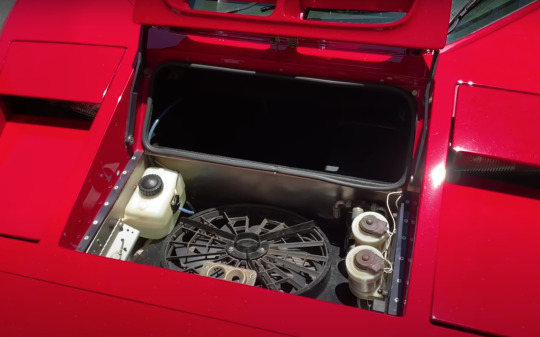

The beating heart of the W8 was this: a highly-modified aluminum resleevable 6.0L Rodeck twin-turbocharged racing V8 with variable boost pressure. The engine produced 625 horsepower and made 649 lb⋅ft (880 N⋅m) of torque at 4,900 rpm at 8 psi of boost pressure, and as if the Rodeck V8 couldn’t get any more ridiculous, it featured TRW forged pistons, Carrillo stainless steel connecting rods, stainless steel valves and roller rocker arms, a forged crank, a dry-sump oiling system with three separate filters and braided stainless steel hoses with anodized red and blue fittings. This engine sounded mad; click here to hear a Vector starting up and revving.

Yes, you heard that correctly; variable boost. The boost for both turbochargers was adjustable from 8 to 14 psi through a dial in the interior. And speaking of which, let’s talk about that next; because, if you thought the engine was already mad enough, the interior is on a whole other level.

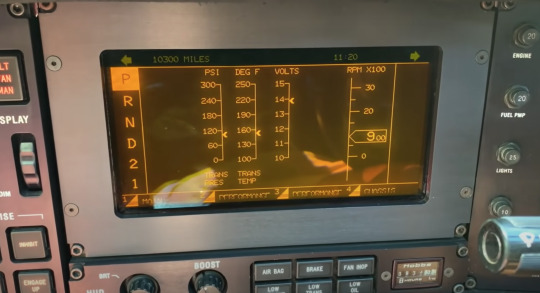

As you can see, the interior of the W8 is mad. Fighter jet-inspired screen? Check. A million buttons everywhere? Check. Gauges? ...no check. And hang on... is that what I think it is? A Turbo-Hydramatic 425 transmission?

Yep, that’s right, and that just makes the car a lot more insane; this ridiculously powerful 6.0L Rodeck V8 was mated to a 3-speed Turbo-Hydramatic 425 automatic transmission. Next to it on the right was the handbrake, sort of shaped like the throttle on a fighter jet. Due to the placement of the transmission and the handbrake, the driver side doorsill is very, very wide, making it a bit tough for the driver to get in and out of the car. You will also notice that there are buttons on top of the gear stick. I’ll get to those now.

As if this car couldn’t get any more ridiculous. This is the screen of the Vector W8, with four different settings (controlled with those four buttons), marked “Main”, “Performance”, “Performance” again and “Chassis”. This is the “Main” screen, showing the odometer, fuel gauge, speedometer and tachometer.

This is the first “Performance” screen, showing engine temperature, oil pressure and temperature, the tachometer reading and various other metrics.

The third screen was the second “Performance” screen, showing the transmission pressure (because it had a torque converter) and transmission temperature as well as battery voltage.

The last screen was the “Chassis” screen, which showed a picture of the W8 which updated in real time when a door was opened, when the engine compartment was opened and so on.

On the other side, you will notice that the W8 doesn’t actually have a partition between the driver and passenger side footwells. So it is a little awkward. This car also has no glovebox; in its place is a... CD changer?

Yes, that’s right. The car came with an in-car stereo... and a Sony CDX-A2001 ten-disc CD changer which graced the entire right side of the car’s already insane instrument panel. This was a nice innovation, although it did came with one drawback; no passenger-side airbags. Good luck if you get into a crash riding shotgun.

Back to the interior though. It was upholstered in premium leather and suede, with electrically adjustable leather Recaro seats and featured a premium air-conditioning system. Some driving amenities such as power steering were excluded. The seating position for the driver was made slightly towards the center for better drivability.

The rear of the W8 was dominated by lines, and the rear sightline... wasn’t very good, mainly because of that gigantic wing. The license plate holder is located on the left and apparently may have been an afterthought. “TWINTURBO” is seen gracing the back.

The car also features a trunk which is just behind the engine.

As for the front... oh, right, the headlamps. They’re not pop-up... they’re pop-DOWN.

The car also has a storage cubby up front, although really, it wasn’t much.

Also gracing the front were windshield wipers, as you would expect on practically every other car. However, there wasn’t just one, nor was there just two: there were THREE. A moonroof was also standard. It also had sliding side windows like a race car, as well as power-adjustable side mirrors.

The logo on the side of the car was the only thing that really gave any indication as to what manufacturer it was.

The car had unique six-spoke “turbine” wheels fitted to Michelin XGT Plus tires; the car used 255/45ZR-16s in the front and very, very strange 315/40ZR-16s in rear. These wheels were apparently of a bespoke design made to the driver’s specifications.

In terms of suspension, the W8 featured double A-arms up front and De Dion tube suspension at the rear, located by four trailing arms that stretched all the way forward to the firewall. The W8 used 13-inch vented disc brakes with Alcon aluminum 4-piston calipers.

In terms of performance, the Vector shined; it claimed to be able to do 389 km/h (242 mph) and a 0-60 mph (0-97 km/h) time of 3.9 seconds. These numbers were never officially tested, but if true, these are very impressive numbers for the time. Okay, enough about the W8’s performance and figures; let’s get to the part you’ve been waiting for, the history.

The W8 was first introduced in 1988 with a sticker price of about $185,000, priced within striking range of European competitors like the Lamborghini Diablo.

One high profile owner of a W8 was this man: Andre Agassi, although he ended up giving the car a bit of a bad rap. Agassi had insisted that his car be delivered before it was fully prepared; Vector agreed to this on the condition that Agassi not drive it and keep it in storage as the car was adjusted for the various emissions regulations in place. Agassi did not listen and drove it and ended up burning the rear carpeting due to an overly hot exhaust system; Agassi ended up requesting for a refund, which was ultimately granted. I’ll let you decide who’s at fault here.

Car And Driver magazine also tested the W8, but couldn’t complete testing because all three cars they were sent somehow managed to break down in different ways, leading to even more bad publicity. However, not all is bad as Road and Track magazine waxed lyrical about the Vector, praising practically every aspect of the W8’s performance.

Vector was still going strong in 1993, selling W8s; however, Wiegert was already planning for a successor. That successor was to be known as the AWX-3, better known as the WX-3 (Hot Wheels also made a model of this one too), where the name stood for Avtech Wiegert eXperimental, 3rd generation.

I’ll get into more details of the WX-3 in a later blog when I receive my WX-3 from the United States. Production of the W8 ultimately came to a halt in 1993 as Wiegert attempted to put the WX-3 into production; however, as the company was engaged in a hostile takeover by a Bermuda-based Indonesian company known as MegaTech, production never resumed and Vector entered a sharp decline. I’ll get into the rest of that history in another post.

In total, twenty-two cars were produced; seventeen of which were customer cars and five of which were prototypes. The car is now worth over $1 million today; so, if for some reason you ever see a car that looks like this on the roads, drop everything and take as many pictures as you can, because you have just seen one of only twenty-two Vector W8s. Okay, now that we’ve gotten all that out of the way, let’s get to the reason why you’re here.

This... is the Hot Wheels version of the Vector W8. Named the Vector W8 Twinturbo in the Hot Wheels lineup, this casting was first introduced in the 2012 HW Boulevard series in the Ahead Of Its Time sub-series. This casting was designed by Manson Cheung.

The base of the W8 features no mention of “Vector” anywhere; instead, just the SKU is displayed: W4831.

The sides feature the text “VECTOR W8 TWINTURBO” and nothing else. Black lines streak across the back to represent the engine cover.

The rear fascia is nice, although my only real gripe is a lack of rear detail apart from the engine cover.

The front fascia is also well done, with “VECTOR” and “TWIN TURBO” on the windshield, although a lack of detail on the body apart from the side reflectors leaves me wanting more. The interior is painfully cramped so I can’t get any good photographs, but what I see are the Turbo-Hydramatic shift lever, the steering wheel, seats and molded pedals (those pedals are part of the base). The distinctive screen and CD changer are absent from the instrument panel, but of course, you can’t have everything.

Folks, I believe you may have heard of the term “One-Hit Wonder” before. This is exactly an example of that; the W8 only saw one release in the HW Boulevard series and has not been seen since. As a result, prices for the Vector have been steadily climbing on eBay and I don’t see them going down for some time; why don’t you take a look for yourself?

I hope this long writeup has given you a better idea on this turbocharged thrasher, and what is quite possibly my new favorite supercar from the ‘80s; step aside, Lamborghini Countach. As usual, I’d do something like this any day.

This article is the first in a three-part series I will call The Vector Saga. The series will document the W8, the WX-3, and the history of Vector Motors as a whole.

#hotwheels#CastingCall#vectorw8#vectorw8twinturbo#mansoncheung#thattimeforgot#vectoraeromotive#thevectorsaga

1 note

·

View note

Text

Research On World Aircraft Carbon Brake Disc [Airplane Carbon Brake Disc] Market Report 2025

Report on World Aircraft Carbon Brake Disc [Airplane Carbon Brake Disc] Market by Product Type, Market, Players and Regions-Forecast to 2025 by DecisionDatabases.com

Aircraft Carbon Brake Disc [Airplane Carbon Brake Disc] market research report provides the newest industry data and industry future trends, allowing you to identify the products and end users driving Revenue growth and profitability.

The industry report lists the leading competitors and provides the insights strategic industry Analysis of the key factors influencing the market.

The report includes the forecasts, Analysis and discussion of important industry trends, market size, market share estimates and profiles of the leading industry Players.

Browse the complete report and table of contents @ https://www.decisiondatabases.com/ip/6561-aircraft-carbon-brake-disc-industry-market-report

The Players mentioned in our report

Safran

Rubin Aviation Corporation JSC

Meggitt

Chaoma Technology

Honeywell

Hunan Boyun New Materials

Luhang Carbon Materials

Xi’an Aviation Brake Technology

SGL Group

UTC Aerospace Systems

CFC Carbon

Lantai Aviation Equipment

Beijing Baimtec Material

Mersen

Beijing Bei MO

Global Aircraft Carbon Brake Disc [Airplane Carbon Brake Disc] Market: Product Segment Analysis

Commercial Brake Disc

Military Brake Disc

Global Aircraft Carbon Brake Disc [Airplane Carbon Brake Disc] Market: Application Segment Analysis

OEM

Aftermarket

Global Aircraft Carbon Brake Disc [Airplane Carbon Brake Disc] Market: Regional Segment Analysis

USA

Europe

Japan

China

India

South East Asia

Download Free Sample Report of World Aircraft Carbon Brake Disc [Airplane Carbon Brake Disc] Market @ https://www.decisiondatabases.com/contact/download-sample-6561

There are 10 Chapters to Deeply Display the World Aircraft Carbon Brake Disc [Airplane Carbon Brake Disc] Market.

Chapter 1 About the Aircraft Carbon Brake Disc [Airplane Carbon Brake Disc] Industry

Chapter 2 World Market Competition Landscape

Chapter 3 World Aircraft Carbon Brake Disc [Airplane Carbon Brake Disc] Market share

Chapter 4 Supply Chain Analysis

Chapter 5 Company Profiles

Chapter 6 Globalisation & Trade

Chapter 7 Distributors and Customers

Chapter 8 Import, Export, Consumption and Consumption Value by Major Countries

Chapter 9 World Aircraft Carbon Brake Disc [Airplane Carbon Brake Disc] Market Forecast through 2025

Chapter 10 Key success factors and Market Overview

Purchase the complete World Aircraft Carbon Brake Disc [Airplane Carbon Brake Disc] Market Research Report @ https://www.decisiondatabases.com/contact/buy-now-6561

Other Reports by DecisionDatabases.com:

World Civil Aircraft Cleaning and Detailing Services Market Research Report Forecast 2025

World Aircraft Tire Market Research Report 2024 (Covering USA, Europe, China, Japan, India and etc)

About-Us:

DecisionDatabases.com is a global business research report provider, enriching decision makers and strategists with qualitative statistics. DecisionDatabases.com is proficient in providing syndicated research report, customized research reports, company profiles and industry databases across multiple domains.

Our expert research analysts have been trained to map client’s research requirements to the correct research resource leading to a distinctive edge over its competitors. We provide intellectual, precise and meaningful data at a lightning speed.

For more details:

DecisionDatabases.com

E-Mail: [email protected]

Phone: +91 9028057900

Web: https://www.decisiondatabases.com/

#Aircraft Carbon Brake Disc#Airplane Carbon Brake Disc#Aircraft Carbon Brake Disc [Airplane Carbon Brake Disc] Market#World Aircraft Carbon Brake Disc [Airplane Carbon Brake Disc] Market#Aircraft Carbon Brake Disc [Airplane Carbon Brake Disc] Industry#Aircraft Carbon Brake Disc [Airplane Carbon Brake Disc] Market Report

0 notes

Text

Global Aircraft Carbon Brake Disc Market 2019-2024 | Top key players are Safran,Meggitt,Honeywell,UTC Aerospace Systems,Xi’an Aviation Brake Technology,Chaoma Technology,Hunan Boyun New Materials

Global Aircraft Carbon Brake Disc Market 2019-2024 | Top key players are Safran,Meggitt,Honeywell,UTC Aerospace Systems,Xi’an Aviation Brake Technology,Chaoma Technology,Hunan Boyun New Materials

Global Aircraft Carbon Brake Disc Market Insights, Forecast to 2025

The report provides a basic overview of the industry including definitions, classifications, applications and industry chain structure. The Aircraft Carbon Brake Disc market analysis is provided for the international market including development history, competitive landscape analysis, and major regions.

The Global Aircraft…

View On WordPress

#Aircraft Carbon Brake Disc#Aircraft Carbon Brake Disc Market#Aircraft Carbon Brake Disc Market Analysis#Aircraft Carbon Brake Disc Market Industry Analysis#Aircraft Carbon Brake Disc Market Insights#Aircraft Carbon Brake Disc Market Opportunities#Aircraft Carbon Brake Disc Market Outlook#Aircraft Carbon Brake Disc Market Research Companies#Aircraft Carbon Brake Disc Market Research Company#Aircraft Carbon Brake Disc Market Segmentation#Aircraft Carbon Brake Disc Market Status#Aircraft Carbon Brake Disc Market Trend#Market Press Release#s Scope Growth In Aircraft Carbon Brake Disc#Trends In Aircraft Carbon Brake Disc Market

0 notes