#ControlSystem

Text

#plcprogramming#plc#automation#programming#industrialautomation#scada#automationengineering#s#hmi#siemens#electricalengineering#plcsiemens#controlsystem#siemensplc#plctraining#instrumentation#electrical#automationsolutions#tiaportal#robotics#industrialcontrol#factoryautomation#training#competitiveprogramming#engineering#programmingart#industrial#programmingclass#programmer#automatizacion

5 notes

·

View notes

Text

1 note

·

View note

Text

Optimizing Shift Transitions With Transmission Control Units

June 11, 2024

by dorleco

with no comment

Others

Edit

Introduction:

The Transmission Control Unit (TCU) is the centerpiece of the intricate dance between an automobile’s engine and transmission. This hidden hero of automotive engineering has a significant impact on the driving experience and fuel economy since he is critical to enabling smooth and effective shift transitions.

This blog post will go into the world of transmission control units, their functions, and the tactics they employ to makeshift transitions in modern automobiles as smoothly as possible.

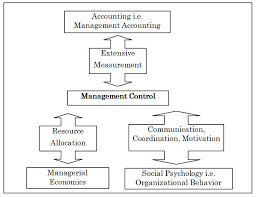

The Transmission Control Unit (TCU): An Overview

The transmission control unit is a critical component of the car’s powertrain control system. It is a sophisticated electronic control mechanism that monitors the transmission’s functionality. Its primary objective is to govern gear shifts so that the engine always delivers the proper amount of power to the wheels. TCUs accomplish this through the use of sophisticated sensors, algorithms, and feedback loops.

The Function of TCUs in Shift Transitions:

Determining shift points: TCUs monitor multiple variables, including speed, engine load, throttle position, and road conditions. They use this data to calculate the best time to start a gear shift. This assessment considers factors such as fuel economy, acceleration, and driving comfort.

Shift Actuation: After detecting that a gear change is required, the Transmission Control Units send instructions to the transmission to perform the shift. As a result, clutches must be engaged and disengaged, gears must be rotated, and hydraulic pressure within the transmission must be adjusted.

Adaptive Learning: Today’s TCU shift patterns are enhanced over time by utilizing adaptive learning algorithms. To provide a more personalized driving experience, they assess a driver’s behavior and adjust shift points accordingly.

Shift Transition Optimization:

Let’s look at the approaches TCUs employ to optimize shift changes:

Comfort and smoothness: One of TCUs’ primary goals is to ensure that shift transitions are smooth and comfortable. Shifts that are sudden or jerky can cause driver discomfort and reduce vehicle durability. TCUs use algorithms to manage clutch engagement and disengagement, minimizing torque interruption during shifts, resulting in smooth shifts. This improves the driving experience by allowing for a smooth transfer of power from one gear to the next.

Fuel efficiency: To maximize fuel efficiency, shift transitions must be effective. TCUs try to keep the engine as efficient as possible. Transmission Control Units help reduce unnecessary gear changes and improve fuel efficiency by selecting the proper gear.

Performance: TCUs are vital for improving performance in sports cars. When accelerating, they can postpone upshifts to keep the engine in its power band, resulting in quick reaction and maximum power output. They also make it easy to downshift for passionate driving or quick overtakes, allowing the driver to take full advantage of the engine’s power.

Adaptive Shifting: Many modern transmission control units feature adaptive shifting algorithms that take into account a wide range of variables, like driving behaviors, ambient conditions, and load situations. These algorithms adjust shift sequences dynamically to provide a more personalized driving experience. For example, if the driver is hauling a huge trailer, the TCU may stay in lower ratios for longer periods of time to maintain power and stability.

Temperature Management: Extreme temperatures can have an impact on transmission performance. TCUs monitor the temperature of the transmission fluid and adjust the shift patterns accordingly. In hot weather, they may prioritize cooling by reducing torque load during shifts; in cold weather, they may delay upshifts to allow the transmission to warm up.

Overcoming wear and tear: TCUs include diagnostic and preventive maintenance functions. They can detect wear and future faults in the transmission and adjust it accordingly. This proactive method can extend the transmission’s life and reduce repair costs.

Challenges and considerations:

TCUs have a lot to offer, but there are also some downsides.

Complexity: As modern transmissions become more complex, advanced TCUs are required, making diagnosis and maintenance more difficult and expensive.

Sensors and Data: Data collection by Transmission Control Units is heavily reliant on sensors. The sensitivity of these sensors to wear, damage, and environmental conditions may have an effect on TCU performance.

Software upgrades: TCUs, like any other electronic system, may require software upgrades to address problems or improve performance. The bulk of the time, trained technicians must perform these updates.

Integration: To work properly, TCUs must communicate with other vehicle systems, such as the engine control unit (ECU) and electronic stability control (ESC).

Conclusion:

The hidden heroes of modern vehicles are the transmission control units, which oversee seamless and effective gear shifts that improve driving comfort, fuel efficiency, and vehicle longevity. These sophisticated solutions optimize shift transitions based on several factors, constantly reacting to driver behavior and environmental conditions.

We should expect even more powerful transmission control units as automobile technology advances, possibly with AI and machine learning to improve shift transitions even further. The future of TCUs holds the promise of even more personalized and effective driving experiences, ensuring that every gear shift is as seamless and ideal as possible, whether you’re driving along the highway or pushing your limits on the racetrack.

“Experience Unmatched Reliability with Our Advanced VCUs!” Explore our best VCU-related products and services at Dorleco.com.

#Transmissioncontrol#TCU#evcc#ccu#evse#ProgrammableVCU#embeddedsystem#Dorleco#VCUSupplier#VCU#Controlsystem

0 notes

Text

Fireye Sb560232Aa-120Vac5/10Tfi,Uv, No Purge | PartsHnC

The Fireye SB560232AA 120Vac5/10Tfi, UV, No Purge is an innovative safety control system for HVAC equipment. This gadget makes sure that heating and cooling systems run safely and effectively by utilizing cutting-edge technology. This functions by using its ultraviolet sensors to identify the presence of flames and then initiating the necessary actions to uphold safety regulations. This product enhances energy efficiency and lowers operating costs by providing dependable flame detection without requiring an exhaust cycle, making it compatible with a variety of HVAC equipment, including boilers and furnaces. The accurate detection abilities provide comfort by preventing any risks and enhancing HVAC system performance.

0 notes

Text

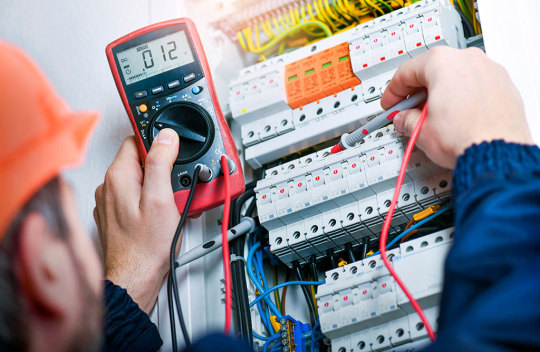

What Causes I/O Noise and Interference in PLC Systems? 8 Common Culprits Revealed!

Exploring Common Causes and Solutions for I/O Noise and Interference in PLC Systems

In the realm of industrial automation, PLC (Programmable Logic Controller) systems are indispensable, overseeing the operation of machinery and processes efficiently. However, they face a challenge: I/O (Input/Output) noise and interference. These disruptions can disrupt system stability, leading to malfunctions and downtime. In this comprehensive guide, we delve into the causes and solutions for I/O noise and interference in PLC systems, addressing 8 common culprits that engineers and technicians should understand well.

Understanding I/O Noise and Interference

Before delving into specific causes and solutions, it's crucial to understand the nature of I/O noise and interference. I/O noise refers to unwanted electrical signals or disturbances that corrupt intended signals in PLC systems. Interference includes external factors like electromagnetic radiation, radio frequency interference (RFI), and electromagnetic interference (EMI) disrupting communication between PLC components.

Power Supply Issues: The Silent Saboteur

A stable power supply is crucial for any PLC system. However, fluctuations or disturbances can introduce noise, jeopardizing performance. Issues like voltage spikes, dips, and harmonics can arise, impacting power quality and increasing I/O noise.

Grounding Problems: Unearthing the Root Cause

Proper grounding is vital in mitigating I/O noise and interference. However, inadequate practices can amplify noise within the system. Ground loops and poor connections can create pathways for unwanted currents, resulting in signal distortion and ground noise.

Electromagnetic Interference (EMI): Taming the Invisible Beast

EMI originates from various sources like nearby motors and power lines, inducing unwanted voltages in nearby cables and components. Shielding cables, using twisted pair wiring, and relocating sensitive components can mitigate EMI.

Radio Frequency Interference (RFI): Navigating the Airwaves

RFI, found in industrial environments bustling with wireless devices, poses a threat to PLC systems. Employing frequency filtering techniques and shielding can mitigate RFI.

Crosstalk: When Signals Collide

Crosstalk occurs when adjacent conductors induce voltages in neighboring cables, leading to signal interference. Shielding, spacing, and wiring techniques can mitigate crosstalk.

Environmental Factors: Nature's Influence

External factors like temperature fluctuations and humidity can impact PLC systems. Extreme temperatures and humidity levels accelerate corrosion and compromise signal integrity, while contaminants can lead to short circuits.

Component Aging: The Silent Deterioration

Over time, components within PLC systems deteriorate, impacting performance and reliability. Regular maintenance and component inspection are essential to mitigate aging's impact.

FAQs (Frequently Asked Questions)

1. How do I identify I/O noise in PLC systems? Signal integrity tests using oscilloscopes help pinpoint irregularities in waveforms indicative of noise interference.

2. Can inadequate shielding contribute to I/O noise? Yes, it allows external electromagnetic fields to penetrate cables. Proper shielding minimizes noise ingress.

3. What role does firmware/software play in mitigating I/O noise? Updates may include optimizations or algorithms to filter noise, reducing its impact.

4. Are there industry standards for mitigating I/O noise? Yes, standards like IEC 61000 provide guidelines for EMC.

5. How can ground loops be prevented? Ensuring all ground connections are made at a single point eliminates potential differences and minimizes ground loop currents.

6. What measures mitigate environmental factors' impact? Installing PLCs in controlled environments and using protective enclosures safeguard components from environmental hazards. For more information visit here👉PujaControls

#PLCInterference#EMIandRFI#IndustrialAutomation#ElectricalNoise#PLCTroubleshooting#SignalInterference#ElectricalEngineering#AutomationTechnology#IndustrialControl#NoiseFiltering#ControlSystem#EMIProtection#RFISuppression#FactoryAutomation

0 notes

Text

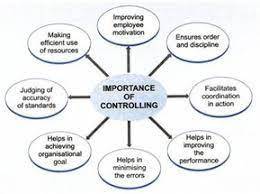

Control Mechanisms and Gaining a Competitive Advantage

The Importance of Control

Types of Controls

Control Systems in Operations

ORGANIZATIONAL CONTROL AND STEPS IN THE CONTROL PROCESS

1 note

·

View note

Text

youtube

I wrote a simple program for Scene2. I implemented states using a word in memory to hold the state id and then compare and movp to change between the states. I also added timers to each state to generate a fault if the state does not complete without the expected time specified. I did not create any logic to handle the error so for now the PLC just flags and continues. Next I would add the routines for error handling and also the EMO logic. I will leave it for now and continue to the next simulation.

https://href.li/?https://github.com/grimmonkey52/Mitsubishi_PLC_projects/blob/main/FIO_SCENE2/SCENE2.pdf

0 notes

Text

Delve into the Core Components of Dust Collection Systems. Discover the Power Source, Particle Separators (Vessels), and System Control, and Elevate Your Workplace Cleanliness to New Heights!

For more details, visit- https://www.acmeairequipments.com/product/dust-collection-system/

0 notes

Text

#plcprogramming#plc#automation#programming#industrialautomation#scada#automationengineering#s#hmi#siemens#electricalengineering#plcsiemens#controlsystem#siemensplc#plctraining#instrumentation#electrical#automationsolutions#tiaportal#robotics#industrialcontrol#factoryautomation#training#competitiveprogramming#engineering#programmingart#industrial#programmingclass#programmer#automatizacion

0 notes

Text

VTT is a dependable static time delay relay ideal for tasks needing frequent operations and steady precision, often in industrial processes with minimal maintenance.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐮𝐬 𝐨𝐧 +91 7021624024 𝐨𝐫 𝐠𝐞𝐭 𝐢𝐧 𝐭𝐨𝐮𝐜𝐡 𝐰𝐢𝐭𝐡 𝐮𝐬 𝐚𝐭 [email protected]

#alstomrelay#industrialtech#relaytech#precisionrelay#industrialcontrol#automation#electricalengineering#reliabletech#controlsystems#powermanagement

0 notes

Text

User Interface and User Experience in eMobility Controls

June 10, 2024

by dorleco

with no comment

eMOBILITY CONTROLS

Edit

Introduction

When developing controls for eMobility systems like electric automobiles (EVs) and electric scooters, the user interface (UI) and user experience (UX) are critical components. These features are critical to ensuring that users can engage with and operate these cars efficiently and effectively. In this introduction, we’ll go over the key concepts and variables to consider when designing a user interface and user experience for eMobility controls.

UI: user interface.

Clarity and Simplicity: Ensure that the user interface is clear and simple. Users should be able to understand the vehicle’s controls without confusion.

Touchscreen and Physical Controls: The user interface (UI) of an eMobility device may have physical buttons, knobs, touchscreen displays, or some mix of these. Make sure the controls are easy to use and conveniently located.

Visual Feedback: When users interact with controls, provide visual feedback. For example, display the battery level on a screen or change the color of a button when pressed.

Consistency: Maintain consistency in the UI element designs. All buttons, icons, and labels in the interface should have a consistent design.

Accessibility: Ensure that a wide range of users, including those with disabilities, can use the user interface. Use screen readers and voice commands to increase inclusiveness.

UX (User Experience)

UX encompasses the entire set of interactions a user has with eMobility controls. It includes not only the aesthetics but also utilitarian and emotional aspects. Important UX elements include:

Efficiency: Make it simple for users to do critical actions such as starting, halting, and controlling the vehicle’s speed. Reduce the number of steps required.

Safety: Put safety first when designing UX. Ensure that the controls are designed to prevent unintentional acceleration and other unintentional actions that could lead to an accident.

Feedback and Alerts: Provide users with clear feedback on key events or difficulties, such as low battery warnings or system failures, via sounds, vibrations, or images.

Customization: Allow customers to tailor settings to their tastes, such as changing the acceleration sensitivity or creating energy-saving modes.

User Testing: The user interface and user experience will be improved repeatedly based on user feedback. Consider running usability tests to identify issues and potential solutions.

Multi-Platform Integration: For a consistent user experience across many platforms, ensure that the UI and UX of the mobile app match those of the vehicle’s controls, provided the eMobility system supports them.

Data and analytics: Collect information about user interactions and behaviors to better understand how they use the controls and find areas for improvement.

The Importance of User Interface and Experience in eMobility Controls

It is impossible to overstate the significance of User Interface (UI) and User Experience (UX) in eMobility controls. These characteristics influence how people interact with and perceive EVs, electric scooters, and other eMobility technology. Here are some significant reasons why UI and UX are important in eMobility controls:

User Acceptance: A well-designed UI and UX can significantly influence how well users embrace eMobility solutions. More people are likely to prefer electric transportation if the controls are simple, easy to use, and enjoyable.

Safety: Safety is prioritized in ineffective UI and UX designs by reducing distractions and ensuring that users can confidently operate eMobility cars. Well-designed controls reduce the likelihood of accidents caused by confusion or user mistakes.

Efficiency: A smooth user experience facilitates interactions with a vehicle. The overall user experience may be enhanced as a result of faster and easier access to critical tasks such as starting, stopping, and speed modification.

User Satisfaction: Higher user satisfaction is the result of a positive user experience. Satisfied users are more likely to use eMobility goods again and promote them to others, allowing the sector to grow.

Reduced Learning Curve: A well-designed UI and UX can help users who are new to eMobility get up to speed faster. This is critical for encouraging the usage of electric vehicles, especially among people who are transitioning from traditional gasoline-powered cars.

Brand Image and Loyalty: The quality of the user interface and user experience reflect the brand and manufacturer. Users are more likely to choose products from trusted brands; therefore, a positive experience with eMobility controls can improve brand image and increase brand loyalty.

Accessibility and Inclusivity: Well-thought-out UI and UX designs incorporate accessibility elements that cater to a diverse spectrum of users, including those with disabilities. Inclusionary design demonstrates a commitment to serving a diverse audience.

Data Gathering and Insights: UI and UX can help collect critical user information. Manufacturers

Drawbacks of the User Interface and Experience in eMobility Controls

Although the design of the User Interface and User Experience is an important aspect of eMobility controls, there may be disadvantages or issues. To properly address these potential concerns and improve the overall user experience, it is critical to be aware of them. The following are some common drawbacks:

Technology complexity: electric vehicles (EVs) and eMobility systems are becoming increasingly complex in terms of functionality and technology. It can be difficult to design a user-friendly interface for a complex system since it may result in information overload or a crowded interface.

Over-engineering: There is a risk of over-engineering the user interface (UI) to provide more features and functionalities, making it difficult for people to navigate. This could lead to a frustrating and confusing scenario.

Costs: Creating a well-designed UI and UX may require a significant amount of resources. The costs associated with design, user testing, and software development may be significant, raising the overall price of e-mobility devices.

Compatibility issues: Different eMobility devices may use different operating systems and hardware configurations. Ensuring compatibility across multiple platforms and devices can be difficult, potentially leading to inconsistent user experiences.

Challenges with accessibility: It may be challenging to ensure accessibility for all users, especially those with disabilities. It may be essential to make additional design and development efforts to meet accessibility requirements and regulations.

Localization: Setting up the UI and UX for multiple languages and localities can be challenging and time-consuming. It is critical to take cultural differences in user preferences and expectations into consideration.

User Resistance to Change: Users who are accustomed to driving traditional gasoline-powered vehicles may be hesitant to accept e-mobility solutions. Manufacturers must work to eliminate customer aversion to an unfamiliar UI/UX.

Legal and regulatory compliance: It may be challenging to keep up with the ever-changing rules governing eMobility controls. Failure to comply with the ever-changing legal standards can result in legal difficulties and fines.

Conclusion:

To summarize, user interface and user experience are critical components of eMobility controls, with a substantial impact on the success and adoption of electric vehicles (EVs) and other electric mobility solutions. A well-designed UI/UX can be an effective catalyst for beneficial outcomes such as safety, user acceptance, efficiency, and brand loyalty. However, to create a seamless and user-centric experience, potential downsides and problems such as complexity, cost, and compatibility must be acknowledged and addressed.

Manufacturers and developers must stress simplicity, clarity, accessibility, and efficiency when designing UI and UX for eMobility controls. They should invest in user testing, data analysis, and continuous improvement efforts to improve the user experience. Furthermore, compliance with regulatory standards and cybersecurity measures must not be disregarded.

Finally, the success of eMobility solutions is dependent on a harmonic collaboration between cutting-edge technology and user-centered design. By prioritizing consumers’ requirements, preferences, and safety, eMobility providers can shape a future in which electric mobility is not only ecologically sustainable but also user-friendly and widely adopted.

#UserInterface#UserExperience#evcc#ccu#evse#ProgrammableVCU#embeddedsystem#Dorleco#VCUSupplier#VCU#Controlsystem

0 notes

Text

Elevate industrial automation with #PLC and #SCADA solutions! 🏭✨ Discover how our cutting-edge technologies enhance efficiency and control in manufacturing processes.

Reach Us: 8807148869

PLC SCADA

#PLC#SCADA#AutomationTech#ControlSystems#PLCProgramming#IndustrialAutomation#SCADASystems#SmartFactory#Industry40#ProcessControl#PLCSCADA#AutomationEngineer#IoTinIndustry#SmartManufacturing#FactoryAutomation#PLCTechnology#DigitalTransformation#SCADAControl#AutomationSolutions#TechInnovation

0 notes

Text

Applications of Control Systems Engineering in Everyday Life

Control Systems Engineering, often hailed as the backbone of modern technology, plays a vital role in shaping the functionality of various systems encountered in our daily lives. From regulating the temperature of our homes to optimizing the performance of our vehicles, control systems quietly work behind the scenes, ensuring efficiency and precision in numerous applications.

0 notes

Text

Startek Industrial is an industrial contracting company located in Edmonton, Alberta, Canada. They specialize in mechanical, electrical, and instrumentation services for the oil & gas, refining, petrochemical, power generation, and infrastructure industries.

Some of the specific services they offer include:

Mechanical installations, maintenance, and turnaround support for rotating equipment, pressure vessels, heat exchangers, piping systems, and more

Electrical and instrumentation contracting services covering motor control centers, switchgear, variable frequency drives, control systems, and field device installation

Fabrication capabilities for skids, modules, pipe spooling, and custom equipment

Scaffolding and insulation services

Staff augmentation to supplement client project teams

Startek Industrial employs over 60 staff and has been operating for over 25 years. They have a strong safety record and focus on building long-term relationships with clients through consistent, quality work. The company services projects across Western Canada.

#industrialcontracting#mechanicalservices#electricalservices#instrumentation#oilandgas#refining#petrochemical#powergeneration#infrastructure#rotatingequipment#pressurevessels#heatexchangers#pipingsystems#motorsystems#switchgear#drives#controlsystems#fabrication#skids#modules#spooling#customfabrication#scaffolding#insulation#staffaugmentation#safetyleaders#technicalservices#westerncanada#YEGbusiness#madeinedmonton

1 note

·

View note

Text

Industrial Control and Factory Automation Market Size 2024 Research Report by Global Growth Rate, Development Strategy, Recent Trends, and Regional Demand till 2030

The qualitative report published by Exactitude Consultancy research on the “Industrial Control and Factory Automation Market offers an in-depth examination of the current trends, latest expansions, conditions, market size, various drivers, limitations, and key players along with their profile details. The Industrial Control and Factory Automation market report offers the historical data for 2018 to 2023 and also makes available the forecast data from the year 2024 to 2030 which is based on revenue. With the help of all this information research report helps the Market contributors to expand their market positions. With the benefit of all these explanations, this market research report recommends a business strategy for present market participants to strengthen their role in the market. This report analyzes the impact of the Covid 19 pandemic on the Industrial Control and Factory Automation Market from a Global and Regional perspective.

The Industrial Control and Factory Automation Market Is Expected to Grow At 10.5% CAGR From 2022 To 2029. It Is Expected to Reach Above USD 297.51 Billion By 2029 From USD 129.1 Billion In 2023.

For The Full Report Click here:

https://exactitudeconsultancy.com/reports/24982/industrial-control-and-factory-automation-market/

#FactoryAutomation#ManufacturingAutomation#IndustrialAutomation#AutomationTechnology#ControlSystems#ProcessAutomation#SmartManufacturing#IndustrialIoT#Industry40#SmartFactory#DigitalFactory#AutomatedManufacturing#PLC#SCADA#RoboticsAutomation#IoTinManufacturing#ProductionControl#MachineAutomation#FactoryFloor

0 notes