#Electric stacker

Text

Maximizing Efficiency and Safety with Semi-Electric Stackers

The effective movement and storage of items is critical in industrial facilities, distribution centers, and warehouses. This is where semi-electric stackers come into play; they provide an adaptable way to prioritize safety over operational efficiency. In this blog, we'll explore the benefits, functionality and considerations of semi-electric stackers, highlighting their role in material handling.

Understanding of Semi-Electric Stackers

Swift's Semi-electric stackers are material handling equipment designed to lift and transport loads within a facility. Semi-electric stackers use battery power for lifting functions and require manual effort for movement, compared to fully electric stackers, which rely solely on battery power for both functions.The effectiveness of electric lifting and the adaptability of manual maneuvering are combined in this hybrid design.

Key Features and Benefits

1. Efficient Lifting: With the help of electric-powered lifting mechanisms, operators of semi-electric stackers may precisely and easily move the loads. This feature allows for faster and more controlled vertical movement, which improves productivity and reduces operator effort.

2. Manual Propulsion: The manual propulsion aspect of semi-electric stackers provides operators with greater flexibility, especially in tight spaces where larger equipment may struggle to navigate. These units can quickly adjust to different work situations and manage a wide range of load sizes and forms since they let operators manually steer the stacker.

3. Compact Design: Semi-electric stackers are ideal for use in cramped settings like packed storage facilities or small aisles because of their generally compact construction.

They still have substantial lifting capabilities, but their smaller size guarantees that available space is used effectively.

4. Safety Features: In every step of material handling, safety reigns supreme. Semi-electric stackers understand this deeply, offering a human touch with features like anti-slip platforms, emergency stop buttons, and overload protection, ensuring protection for all.

5. Cost-Effective Solution: Semi-electric stackers, with their initial affordability and eco-conscious battery usage, offer a welcoming embrace to companies striving for operational excellence without financial strain. They're like trusted companions in cost-effective progress.

Applications and Considerations

different businesses such as manufacturing, retail, and warehousing, use Swift’s semi-electric stackers. For work like loading and unloading pallets, they are perfect., arranging goods on racks and moving materials across small distances. When considering the implementation of semi-electric stackers in a facility, Several things need to be considered:

Understand the heaviest load the stacker will lift, ensuring the chosen model can safely handle it, prioritizing human safety.

Operating Environment: Think of the facility like a living organism—consider its layout, aisle widths, floor conditions, and obstacles for smooth navigation.

Training Requirements: Provide sufficient instruction to operators to ensure they understand how to safely operate the stacker and adhere to best practices for load handling.

Maintenance Needs: Caring for semi-electric stackers is like tending to a trusted companion. As with physical examinations, routine maintenance guarantees that they are constantly in optimal condition and prepared to provide dependable and secure service.

Conclusion

Swift’s Semi-electric stackers bring together a beautiful harmony of efficiency, adaptability, and cost-effectiveness, enriching the fabric of contemporary material handling operations. They seamlessly merge the power of electric lifting with the finesse of human guidance, empowering operators to navigate their tasks with precision and safety in mind. Whether it's the bustling aisles of warehouses, the dynamic floors of manufacturing facilities, or the organized chaos of distribution centers, these stackers weave themselves into the very fabric of productivity, ensuring that every movement counts towards optimizing workflow and maximizing output.

#electric stacker#electric pallet stacker#semi electric stacker#electric pallet truck stacker#power stacker

0 notes

Text

Used Electric Stackers For Sale & Rental | SFS Equipments

SFS Equipments provides a wide range of high-quality secondhand electric stackers for purchase and leasing, including electric pallet stackers. These adaptable machines are intended to satisfy the different material handling requirements of warehouses and industrial facilities, delivering efficient and reliable results. They can perform a variety of lifting and stacking jobs because of their 1.5-tonne capacity and height range of 3.0-6.5 meters. SFS Equipments maintains the quality and dependability of their used stackers by thorough inspection and testing, evaluating the condition of each component. They also provide flexible rental options for short-term projects or constant operations, letting clients use high-quality stackers without making a long-term commitment. SFS Equipments delivers great service and support, assuring smooth operations and the best solution for their customers. Explore our used electric stacker selection for sale and rental today to improve efficiency in operation and production.

#reach stacker rental#electric stacker#used electric stacker#electric reach stacker#SFS Equipments#toyota material handling equipment for rental#toyota material handling equipment for sale#material handling equipment rental#material handling equipment sale

0 notes

Text

Advantages to Get When You Buy Stainless Steel Ground Level Scissors Online

Material handling industries are one of the most crucial aspects that no one can ignore. There are different types of material handling equipment available with dissimilar functionality and features. Due to this, they offer versatile and reliable solutions for material handling, maintenance, and construction tasks. Their significance solely depends on their design combined with robustness, adaptability, and robustness. When you buy stainless steel ground-level scissors online, there are a lot of advantages to grab from. Here is all about this outstanding material handling equipment and how it helps to streamline the material handling job in various industrial setups.

Durable and Free from Corrosion

Stainless steel is preferred for its outstanding durability and corrosion resistance. This is one of the most reliable and popular features that is being used in various industrial environments where they have to deal with harassing environments. The stainless steel ground-level scissors normally operate in various harsh environments where they have to deal with moisture, chemicals, and other corrosive elements. With stainless steel construction, these scissors can easily withstand such conditions, which ensures longevity and minimal maintenance requirements. This durability helps reduce costs because it requires fewer replacements and repairs compared to any type of alternatives that are made from conventional materials.

Unmatchable Safety and Stability

The main objective of the ground-level scissors is to offer a stable platform for lifting and positioning heavy loads close to the ground level. Stainless steel construction enhances stability and safety to many extend, and needless to say, safety is a crucial factor in industries where mishaps can lead to significant injuries or damage to equipment and material. The robust design, along with the materials, helps to reduce the risk of structural failures, ensuring a safe and secure working environment for industrial operators.

Versatility to Meet Specific Requirements

Versatility is one of the biggest advantages of the stainless steel ground-level scissors. They can be easily customized to meet any specific requirements like load capacity, platform size, and lifting height. Due to this outstanding adaptability, this material handling equipment is being used in various applications across various industrial landscapes like manufacturing, warehousing, logistics, and construction. Whether it's moving heavy machinery in a factory setting or facilitating maintenance tasks in a warehouse, these scissors mainly offer different types of flexible solutions that can be tailored to meet different types of operational requirements.

Precision Control

When it comes to thorough control over the material, ground-level scissors meet this parameter in the industrial landscape. They offer unmatchable lifting and lowering operations, allowing the operators to position loads with utmost accuracy and efficiency. The stainless steel construction contributes to this precision by ensuring smooth and constant performance even under heavy loads. This kind of control is crucial in various tasks, specifically where the precise positioning is critical, like assembly lines where the components are required to be aligned thoroughly or at the construction sites where the materials need to be placed in the perfect position. In this way, it becomes the most important player in these industrial landscapes that helps to avoid any kind of delays or errors.

Environmental Sustainability

Stainless steel, with its extended lifespan and capacity for recycling, is a very sustainable material. Stainless steel ground-level scissors save waste and require fewer replacements, which helps to promote environmental sustainability. Stainless steel's eco-friendliness is further enhanced by the fact that its production procedures have less of an impact on the environment than those of many other materials.

These are the best features that you can get when you buy stainless steel ground-level scissors online. So, relying on this material handling equipment can greatly contribute to your industrial operation.

Resource: https://superliftcanada.wordpress.com/2024/04/23/advantages-to-get-when-you-buy-stainless-steel-ground-level-scissors-online/

#stainless manlifts#Buy Stainless Steel Portable Lift Table online#Stainless Steel Triple Scissors Lift Tables#Stainless Steel Low Profile Lift Table#Stainless Steel Ergonomic Lift Table#Buy Stainless Steel Low Profile Table#Stainless Steel Pallet Lifts#Stainless Steel Lift Table#Stainless Steel Uplift Pallet Trucks#Stainless Steel Self Adjusting Pallet Positioners#Clean Room Compliant Lift Tables#Buy Stainless Steel Ground Level Scissor online#Stainless Steel Electric High Lifts#Buy Stainless Steel Powered Pallet Truck online#Buy Stainless Steel Straddle Stacker online#Stainless Steel Counterbalance Stacker#Stainless Steel Pallet Jack#Stainless Steel Hybrid Pallet Jack#Stainless Steel Reach Truck#Stainless Steel Push Stacker#Stainless Steel Walkie Stacker#Buy Stainless Steel Walkie Fork Over Stacker online#Stainless Steel Forklifts#Stainless Steel Portable Tote Tilter#Stainless Steel Straddle Tote Tilter#Stainless Steel Portable Dumpers#Stainless Steel Portable Tipper#Stainless Steel Pneumatic Tilter#Stainless Steel IBC Lift#Stainless Steel High Point Tilter

0 notes

Text

Buy Electric Golf Cart 6 Seater at Best Price

Are you ready to take your golfing game to the next level? Look no further than our top-notch 6-seater electric golf cart, now available at an unbeatable price. Discover the ultimate convenience and comfort as you navigate the greens with ease.

Unmatched Performance and Comfort

Say goodbye to long walks between holes and hello to effortless transportation. Our electric golf cart comfortably seats six players, ensuring you and your friends can enjoy every moment on the course without fatigue. With its smooth acceleration and silent operation, you'll experience golfing like never before.

Eco-Friendly and Cost-Effective

In today's world, sustainability matters. By opting for an electric golf cart, you're not only reducing your carbon footprint but also saving money on fuel costs. Enjoy guilt-free rounds of golf knowing you're contributing to a cleaner, greener environment.

Sleek Design and Durability

Crafted with precision and durability in mind, our 6-seater electric golf cart boasts a sleek design that turns heads on the course. Built to withstand the rigors of golfing terrain, you can trust its reliability round after round. Plus, with low maintenance requirements, you'll spend less time in the garage and more time on the green.

Customizable Options

Personalize your golfing experience with our range of customizable options. From deluxe seating to premium sound systems, we offer enhancements to suit every preference. Elevate your comfort and style while enjoying the convenience of our electric cart.

Exceptional Value

At we're committed to providing exceptional value to our customers. With our competitive pricing and unbeatable quality, you won't find a better deal on a 6-seater electric golf cart. Invest in your game and experience the difference today.

Conclusion

Don't let the opportunity to elevate your golfing experience pass you by. Upgrade to a 6-seater electric golf cart and enjoy unmatched performance, comfort, and eco-friendliness on the course. With our unbeatable prices and top-notch quality, there's never been a better time to make the switch.

0 notes

Text

Buy semi electric pallet stackers from stakon india website for material handling in your warehouses. The products are of high quality and affordable. Get your material handling equipment from best company.

0 notes

Text

Central to this pursuit is electric forklift and pallet stacker, revolutionizing the way businesses handle materials and streamline their operations.

Adopting electric forklifts and pallet stackers Singapore marks a significant leap forward in warehouse efficiency with their eco-friendly features, cost-effectiveness, and technology integration.

0 notes

Text

Electric Pallet Stacker | Hcforkliftaustralia.com

Discover a reliable and efficient Electric Pallet Stacker from Hcforkliftaustralia.com. Our products are designed to help you move and store pallets with ease and safety, giving you peace of mind.

https://www.hcforkliftaustralia.com/product/list/Pallet_Stackers

0 notes

Text

Why To Invest on Electric Pallet Stacker

Electric pallet stackers offer numerous advantages in various material handling industries. Whether you are talking about warehouse, manufacturing unit or any other places where material handling is the top priority, employing the electric pallet stacker would be the best thing to get best result out of these material handling requirements.

Here is why should you invest on electric pallet stacker for handling heavy stackers.

Maximizing Material Handling Efficiency

Electric pallet stackers are made to increase efficiency and productivity when handling materials. They lessen the time and effort needed for these tasks by enabling operators to move and stack pallets swiftly and easily. This effectiveness results in higher throughput and, ultimately, lower costs.

Versatility

Electric pallet stackers are very adaptable pieces of equipment. They are appropriate for a wide range of applications in sectors like transportation, manufacturing, retail, and warehousing since they can handle a variety of pallet sizes, configurations, and weights.

Electric pallet stacker suppliers are committed to improve the operator’s comfort. These characteristics include comfortable platforms, adjustable grips, and smooth braking and accelerating mechanisms. As a result, the risk of workplace injuries and operator fatigue are decreased while creating a more comfortable and secure working environment.

Added Safety Features

Safety measures on electric stackers include emergency brakes, anti-roll systems, and horn signals. The danger of injuries and property damage is decreased as a result of these safety precautions, which can minimize insurance and operational expenses. Pallet stackers powered by electricity provide precise control over raising and lowering operations. When placing loads in confined locations or moving through crowded regions, this accuracy is crucial. It contributes to preventing material damage during handling and storage.

Minimal Operating Cost

Although an electric pallet stacker may need a sizable initial investment, the decreased running costs can make this cost acceptable. Electric stackers have cheaper long-term operating expenses than their internal combustion equivalents because they are more energy-efficient. Additionally, they require less upkeep, which lowers maintenance costs. These are few things that make the electric pallet stackers much more popular among the industry leaders and this is why, they ask for the electric pallet stacker price, for investing on these units.

0 notes

Text

Informed Decision-Making: Choosing the Right Lifting Equipment, Forklifts, and Electric Pallet Stackers for Hire in Melbourne

When it comes to enhancing productivity in warehouses, construction sites, and various industrial settings, having the right lifting equipment is essential. Melbourne, a thriving hub of business and industry, offers a plethora of options for lifting equipment hire. Among these options, forklifts and electric pallet stackers are key players. Making informed choices in selecting the right lifting equipment can significantly impact your operations' efficiency and safety.

Understanding Your Needs

Before you delve into the world of lifting equipment hire, it's crucial to assess your specific needs. Take a close look at your operation's requirements, including the type and weight of materials you'll be handling, the layout of your workspace, and any special features or attachments you may need.

Forklifts for Hire in Melbourne

Forklifts hire melbourne are the workhorses of material handling, capable of lifting heavy loads and transporting them efficiently. Melbourne offers a wide range of forklifts for hire, each designed for specific tasks.

Counterbalance Forklifts: These are the most common type of forklifts, known for their stability and versatility. They're excellent for general material handling tasks.

Reach Trucks: Reach trucks are designed for use in narrow aisles and high racks. If your workspace has limited space for maneuvering, these forklifts are a great choice.

Rough Terrain Forklifts: Ideal for outdoor use and rugged terrains, these forklifts are equipped with sturdy tires and a robust design, making them perfect for construction sites.

Pallet Jacks: Also known as pallet trucks, these are excellent for moving palletized loads on a smaller scale.

Choosing the right forklift melbourne depends on your operational needs. Ensure that the forklift you select is capable of handling the weights and dimensions of the materials you typically deal with. Safety is paramount, so make sure your forklift rental comes with all necessary safety features and that your operators are properly trained.

Electric Pallet Stackers: A Versatile Option

Electric pallet stackers are another indispensable tool for material handling, particularly when it comes to moving pallets within confined spaces. These stackers are not only efficient but also environmentally friendly due to their electric power source.

Walkie Stackers: These stackers are designed to be operated by a person walking behind them, making them a versatile choice for a variety of indoor applications.

Rider Stackers: Rider stackers allow an operator to stand on a platform while operating the equipment, which can help increase productivity for certain tasks.

Straddle Stackers: These are suitable for handling wider loads, such as double pallets or oddly shaped items.

Electric pallet stacker are known for their ease of use and maneuverability. When considering electric pallet stacker hire in Melbourne, ensure that the equipment you choose is appropriate for your workspace's layout and the size of the loads you'll be handling.

Factors to Consider

When making an informed choice for lifting equipment hire, consider the following factors:

Budget: Determine your budget and explore options within that range. Keep in mind that while cost is important, it should not be the sole determining factor. Quality and safety should be your top priorities.

Safety: Ensure that the equipment you hire is well-maintained and equipped with necessary safety features. Also, make sure your operators are trained in the safe use of the equipment.

Maintenance and Support: Inquire about the maintenance and support services provided by the equipment rental company. Regular maintenance is essential to keep the equipment in good working condition.

Duration of Use: Determine how long you'll need the equipment. Most rental companies offer flexible rental periods to accommodate your specific needs.

Availability: Check the availability of the equipment you need, as certain types of forklifts and electric pallet stackers may be in high demand.

Conclusion

In Melbourne, making informed choices when it comes to lifting equipment, forklifts, and electric pallet stackers for hire is paramount for the success of your operations. Consider your specific needs, budget, safety requirements, and maintenance support when selecting the right equipment. By doing so, you'll ensure that your business operations run smoothly and efficiently, ultimately contributing to your overall success.

To know more ...

Contact us : All Lift Material Handling & Construction

0 notes

Text

#Hydraulic Lifts Manufacturer and Supplier in India#Hydraulic Stacker Manufacturer and Supplier in India#Pallet Scale Manufacturer and Supplier in India#Electric Stacker Manufacturer and Supplier in India#Battery Stacker Manufacturer and Supplier in India

0 notes

Text

Streamlining Operations with SWIFT’s Material Handling Equipment

Material handling equipment (MHE) is mechanical equipment used for the movement, storage, control, and protection of materials, goods and products throughout the process of manufacturing, distribution, consumption, and disposal. Material handling equipment plays a vital role in streamlining operations and ensuring smooth logistics within warehouses, distribution centers, manufacturing facilities, and other industrial settings.

This article explores some commonly used material handling equipment, including the hydraulic hand pallet truck, semi-electric stacker, high lift truck, hydraulic stacker, hydraulic floor cranes, and drum lifter & tilter.

1. Hydraulic Hand Pallet Truck

The hydraulic hand pallet truck, also known as a pallet jack, is an indispensable tool for material handling tasks. It is designed to lift and transport palletized loads within a confined area. With its hydraulic system, it enables users to easily maneuver heavy loads by manually pumping the handle to raise the forks off the ground. They are also relatively affordable, making them a good option for businesses on a budget.

2. Semi-Electric Stacker

The semi-electric stacker combines the convenience of electric power with the flexibility of manual operation. It is commonly used in settings where medium-duty lifting is required. This equipment features an electrically powered lifting mechanism, allowing operators to effortlessly lift and stack loads. They are also a good option for businesses that need to operate in tight spaces, as they are narrower than traditional forklifts.

3. High Lift Truck

A high lift truck, also known as a high-lift pallet truck or high-lift jack, is specifically designed to handle heavy loads and transport them to higher elevations. It combines the functionality of a standard pallet truck with the ability to reach raised heights, eliminating the need for additional forklift equipment. They are also used in construction sites and other industrial settings.

4. Hydraulic Stacker

Hydraulic stackers are versatile material handling equipment used for lifting and transporting loads vertically. They utilize hydraulic power to elevate the forks to desired heights, allowing for easy loading and unloading of goods. Hydraulic stackers come in different configurations, including manual, semi-electric, and fully electric models, catering to various lifting capacities and operational requirements. Hydraulic stackers are a good choice for businesses that need to store and retrieve pallets of goods in a warehouse or other facility.

5. Hydraulic Floor Cranes

A hydraulic floor crane is a type of material handling equipment that is used to lift and move heavy loads. Hydraulic floor cranes are commonly used in workshops, construction sites, and manufacturing plants to lift engines, machinery, or other heavy components. Their maneuverability, compact design, and adjustable boom make them an indispensable tool for efficient material handling in challenging environments.

6. Drum Lifter & Tilter

Drum lifters and tilters are specialized equipment designed for handling drums or barrels safely and efficiently. Drum lifter & tilters are often used in warehouses and other facilities where drums need to be moved around. They are also used in manufacturing plants and other industrial settings. Drum lifters and tilters help prevent accidents and injuries associated with manual handling of heavy drums, making them ideal for industries dealing with chemicals, pharmaceuticals, food processing, and other sectors that involve frequent drum handling.

Conclusion

Material handling equipment plays a crucial role in enhancing operational efficiency, reducing manual labor, and ensuring the safety of workers. Swift Technoplast Provides wide range of Material Handling Equipment such as hydraulic hand pallet trucks to drum lifters and tilters, each type of equipment serves a specific purpose in the material handling process. By leveraging the right equipment for the job, businesses can streamline their operations, improve productivity, and maintain a safe working environment. Investing in reliable material handling equipment is a wise choice.

#material handling equipment#material handling#swifttechnoplast#SwiftTechnoplastPrivateLimited#plastic pallets#plastic industry#hdpeplastic#hand pallet truck#electric stacker#Hydraulic Stacker

0 notes

Text

Discover High-Quality Electric Stackers at SFS Equipments

SFS Equipments offers high-quality electric stackers that enhance efficiency and productivity in warehouses and industrial facilities. These versatile tools are suitable for a wide range of material handling tasks, including pallet stacking, loading and unloading trucks, and transporting goods over short distances. Their compact design allows for efficient use in confined spaces and narrow aisles. The stackers are user-friendly with ergonomic features, ensuring precise handling and positioning of loads. Safety features like overload protection, emergency stop buttons, and anti-rollback systems prevent accidents and injuries. The stackers operate quietly, producing minimal vibrations, and creating a conducive working environment for employees. SFS Equipments offers a cost-effective solution for material handling needs, whether renting or buying. Their team of experienced professionals provides exceptional customer support, from helping select the right stacker to providing training and maintenance services. Contact SFS Equipments to learn more about their electric stackers and find the perfect solution for your operational needs.

#used electric stacker#electric stacker#SFS Equipments#material handling equipment rental#material handling equipment for sale#toyota material handling equipment for rental#toyota material handling equipment for sale#Electric Pallet Stacker

0 notes

Text

What Is the Purpose of Electric Pallet Jack and Stacker?

A Pallet Jack is just Utilized to lift a pallet just a few inches off the ground level, move it to another place, and then place it back into the ground. The utmost lift height of a pallet truck is generally about 8” to 10”.

Lifting heavy pallets high into the air makes a tipping danger which requires that pallet stackers have either an outrigger (legs with rolls at the end that extend outward in front of the unit) for steadiness or a weighted counter-balance in the back of the unit to stop it from tipping over.

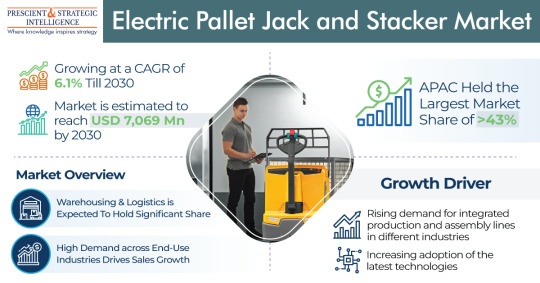

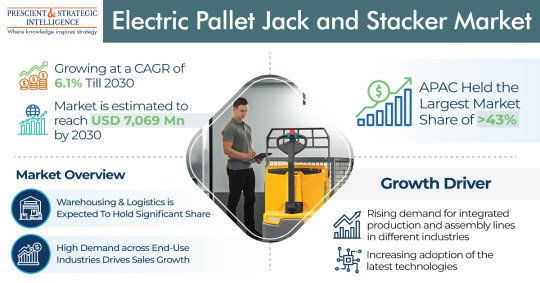

The electric pallet jack and stacker market is experiencing growth and is projected to reach USD 7,069 million by 2030.

Advantages of Using Pallet Stackers

The benefits of using pallet stackers include:

Pallet stackers have a little entrance barrier as they are made to be simple to use. Huge mechanical products will need dedicated training to function, while a stacker operative can be trained by other staff or by a dedicated in-house team. Operators can be trained in a single session, removing knowledge loss because of staff turnover.

To receive free sample pages of this report@ https://www.psmarketresearch.com/market-analysis/electric-pallet-jack-stacker-market/report-sample

Flexible and effective: Stackers are made to be sprightly and can be used in an extensive variety of professional settings. This means they'll be able to stay on if your business pivots or deals with an extensive variety of products. Pallet stackers are therefore virtually future-proof, and an expenditure in one can reap benefits for numerous years to come.

Simple work such as lifting and sorting things take a long time in factories or warehouses. Time is saved, and heavy products are efficiently carried and organized, thanks to superior pallet trucks of numerous sizes and weight carrying capacities.

#Electric Pallet Jack and Stacker Market#Electric Pallet Jack and Stacker Market Size#Electric Pallet Jack and Stacker Market Share#Electric Pallet Jack and Stacker Market Growth#Electric Pallet Jack and Stacker Market Outlook#Electric Pallet Jack and Stacker Market Trends

0 notes

Text

Founded in 2006, “Wokaite” is an acknowledged leader of China's Lifting equipment Industry.

We offer most wide range of Lifting Equipment. We are committed to manufacture the Quality Product best of its kind through advance manufacturing processes and techniques.

We specialize in every type of Overhead Cranes,Electric Hoists, Rigging, Chain Pulley Block, Monorail travelling trolley, Crane componets & all Types of Jib Cranes etc.

The management of the company has a vast experience of over Twenty Five years in the field of manufacturing and installation of electric hoist. The dedicated and professional team of management, engineers and worker are always available to share your load wherever you are.

Mobile/whatsapp:+8613989610078 Website:www.wokaitehoist.com

#electric chain hoist#electric hoist#electric wire rope hoists#chain pulley block#chain hoist#eot crane manufacturers#chain block manufacturers#electric winch machine#winch machine manual#gantry crane manufacturers#rope hoists#hydraulic manual stackers#monorail travelling trolley#beam trolley#hoist & crane manufacturers#cranes & hoists manufacturers

1 note

·

View note

Text

Electric Pallet Jack and Stacker Market Will Reach USD 7,069 Million by 2030

The total value of the global electric pallet jack and stacker market was USD 4,402 million in 2022, and it will rise at a growth rate of above 6.1% shortly, reaching USD 7,069 million by 2030, according to P&S Intelligence.

Electric pallet jacks and stackers are mainly utilized for loading and transporting pallets in manufacturing facilities, distribution centers, and warehouses. Hence, the…

View On WordPress

#Electric Pallet Jack and Stacker Market#Electric Pallet Jack and Stacker Market Growth#Electric Pallet Jack and Stacker Market Outlook#Electric Pallet Jack and Stacker Market Research Report#Electric Pallet Jack and Stacker Market Share#Electric Pallet Jack and Stacker Market Size#Electric Pallet Jack and Stacker Market Trends

0 notes

Text

To efficiently move and raise pallets and other heavy loads in a warehouse, distribution center, or factory, material handling equipment such as electric pallet stackers are indispensable. They use a hydraulic system powered by an electric motor to raise and transport heavy objects.

0 notes