#electric wire rope hoists

Text

We at S.Cranes, make Electric wire rope hoists which are crafted to precision with our well versed engineering background. Our experience in serving the clients since 1979 make us the choice of our clients in all major segments to go with us.

0 notes

Text

Founded in 2006, “Wokaite” is an acknowledged leader of China's Lifting equipment Industry.

We offer most wide range of Lifting Equipment. We are committed to manufacture the Quality Product best of its kind through advance manufacturing processes and techniques.

We specialize in every type of Overhead Cranes,Electric Hoists, Rigging, Chain Pulley Block, Monorail travelling trolley, Crane componets & all Types of Jib Cranes etc.

The management of the company has a vast experience of over Twenty Five years in the field of manufacturing and installation of electric hoist. The dedicated and professional team of management, engineers and worker are always available to share your load wherever you are.

Mobile/whatsapp:+8613989610078 Website:www.wokaitehoist.com

#electric chain hoist#electric hoist#electric wire rope hoists#chain pulley block#chain hoist#eot crane manufacturers#chain block manufacturers#electric winch machine#winch machine manual#gantry crane manufacturers#rope hoists#hydraulic manual stackers#monorail travelling trolley#beam trolley#hoist & crane manufacturers#cranes & hoists manufacturers

1 note

·

View note

Link

MIT Hoist provides its customers with effective lifting solutions. In order to guarantee the longevity, dependability, and security of its crane kits, the company only uses cutting-edge manufacturing techniques and premium components. Read more……

0 notes

Text

Electric Wire Rope Hoists: Benefits Over Chain Hoists

Electric wire rope hoists are an excellent option for lifting heavy loads, even in extreme conditions. In India, electric wire rope hoist manufacturers are used to provide all kinds of rope hoists for handling heavy loads, as they offer superior capacity and control when compared to chain hoists. Electric wire rope hoists are better than chain hoists in many ways, including higher lifting capacity, improved control, and a longer service life. If you want to learn more about the benefits of electric wire rope hoists over chain hoists, you can read about them here.

#Electric wire rope hoist manufacturer in India#Electric wire rope hoist manufacturer#Electric wire rope hoist manufacturers#Electric wire rope hoist

1 note

·

View note

Text

The Evolution of Electric Wire Rope: Innovations and Industry Impact

The evolution of electric wire rope has been a testament to human ingenuity and technological advancement, revolutionizing lifting and pulling operations across various industries. From its humble beginnings as a simple mechanical device to its modern incarnation as a sophisticated tool powered by electricity, electric wire rope has undergone significant innovations that have reshaped industrial practices and workflows. This article delves into the evolution of electric wire rope, exploring key innovations and their profound impact on industries worldwide.

Early Origins and Mechanical Design:

The origins of electric wire rope can be traced back to ancient civilizations, where ropes made of natural fibres such as hemp or cotton were used for lifting and pulling heavy objects. Over time, advancements in materials and manufacturing techniques led to the development of wire ropes made from steel wires, offering greater strength and durability. These early wire ropes were typically operated manually, with workers exerting physical force to lift or lower loads using pulleys and levers. The advent of electricity in the 19th century brought about significant advancements in the design and operation of wire ropes. Electric motors replaced manual labour, providing a more efficient and reliable means of powering lifting and pulling operations. The introduction of electric wire rope hoists, equipped with motorized drums and sheaves, revolutionized material handling in factories, warehouses, and construction sites, enabling faster, safer, and more precise lifting of heavy loads.

Innovations in Materials and Construction:

In recent decades, advancements in materials science and engineering have further enhanced the performance and durability of electric wire ropes. The development of high-strength steel alloys and synthetic fibres has led to the production of wire ropes with increased tensile strength, corrosion resistance, and fatigue life. These advanced materials enable electric wire ropes to withstand higher loads, operate in harsh environments, and endure prolonged use without compromising safety or performance. Moreover, innovations in rope construction techniques, such as compacted strands and plastic coatings, have improved the flexibility, abrasion resistance, and fatigue resistance of electric wire ropes. Compact strand technology, for example, reduces internal friction and wear between individual wires, resulting in smoother operation and longer service life. Similarly, plastic coatings provide additional protection against corrosion and abrasion, extending the lifespan of electric wire ropes in demanding applications.

Integration of Automation and Control Systems: The integration of automation and control systems has been a game-changer in the evolution of electric wire rope, enabling greater precision, efficiency, and safety in lifting and pulling operations. Modern electric wire rope hoists are equipped with advanced control systems, such as variable frequency drives (VFDs) and programmable logic controllers (PLCs), that allow for precise speed and torque control, as well as automated load monitoring and overload protection. Furthermore, the advent of digital connectivity and IoT (Internet of Things) technologies has enabled remote monitoring and management of electric wire rope systems, providing real-time data on performance, maintenance needs, and operational status. This connectivity allows operators to optimize equipment utilization, schedule preventive maintenance, and identify potential issues before they escalate into costly downtime or safety hazards.

Impact on Industries and Applications:

The evolution of electric wire rope has had a profound impact on industries and applications worldwide, transforming the way lifting and pulling operations are conducted in various sectors. In manufacturing facilities, electric wire rope hoists facilitate the movement of heavy machinery, materials, and finished products with precision and efficiency, enhancing productivity and throughput. In construction sites, electric wire rope cranes enable the lifting and positioning of structural components, equipment, and building materials, accelerating project timelines and ensuring safety. Moreover, electric wire rope plays a crucial role in mining and extraction operations, where it is used for hoisting ore, transporting equipment, and supporting underground infrastructure. In marine and offshore applications, electric wire rope winches and capstans are employed for mooring, towing, and cargo handling on ships, oil rigs, and offshore platforms, ensuring safe and efficient operations in challenging maritime environments.

Evolutionary Innovations: The transformative journey of electric wire rope has not only revolutionized lifting and pulling operations but has also brought forth innovative features and technologies that significantly impact industries and applications. The continuous evolution of electric wire rope is driven by a quest for enhanced performance, increased efficiency, and improved safety standards across diverse sectors.

Advanced Materials and Construction: As electric wire rope evolves, advancements in materials and construction techniques play a pivotal role in enhancing its durability and performance. The integration of high-strength alloys, precision engineering, and innovative manufacturing processes results in wire ropes that offer superior tensile strength, corrosion resistance, and fatigue durability. These improvements contribute to prolonged service life and increased reliability in challenging industrial environments.

Smart and Connected Technologies: The incorporation of smart and connected technologies represents a significant leap forward in the evolution of electric wire rope. IoT (Internet of Things) sensors and monitoring systems are now integrated into wire ropes, providing real-time data on load conditions, stress levels, and overall performance. This connectivity enables predictive maintenance, early detection of potential issues, and optimized operational efficiency, reducing downtime and enhancing safety.

Variable Speed Control and Precision: Evolutionary advancements in electric wire rope technology include variable speed control mechanisms and precision handling capabilities. Electric wire rope hoists equipped with state-of-the-art control systems allow operators to precisely control lifting and lowering speeds, ensuring smooth and accurate movements. This level of control is particularly crucial in applications that demand precision, such as delicate material handling or intricate construction tasks.

Customization and Application-Specific Solutions: The evolution of electric wire rope extends to providing more customizable and application-specific solutions. Manufacturers now offer a diverse range of configurations, capacities, and accessories, allowing businesses to tailor electric wire rope systems to their unique operational requirements. Whether it's lifting heavy machinery in a manufacturing plant, hoisting materials on a construction site, or supporting offshore operations, electric wire rope can be customized for optimal performance.

The Role of Electric Wire Rope Hoist Manufacturers: As electric wire rope continues to evolve, the role of manufacturers becomes increasingly crucial. Electric wire rope hoist manufacturers play a pivotal role in driving innovation, ensuring product quality, and meeting the diverse needs of industries. Their expertise in designing and manufacturing hoists that incorporate the latest technologies contributes to the overall evolution and impact of electric wire rope in lifting and pulling operations.

Conclusion:

In conclusion, the evolution of electric wire rope has been characterized by continuous innovation and technological advancement, resulting in safer, more efficient, and more reliable lifting and pulling solutions for industries worldwide. From its humble origins as a manual lifting device to its modern incarnation as a sophisticated electrically powered tool, electric wire rope has undergone significant transformations that have reshaped industrial practices and workflows. As industries continue to evolve and embrace digitalization, electric wire rope is poised to remain a cornerstone of material handling operations, driving productivity, safety, and efficiency across diverse applications.

0 notes

Text

Electric Wire Rope Hoist Manufacturers in India

3Tech Cranes & Lifts stands as a beacon of excellence among electric wire rope hoist manufacturers in India. Our meticulously crafted hoists combine cutting-edge technology with robust design, ensuring reliable and efficient lifting solutions. Trust our electric wire rope hoists to meet the diverse demands of various industries with precision and durability.

0 notes

Text

In the dynamic world of cargo transportation, ratchet lashings are considered a reliable and efficient solution for securing loads.

https://prasunenterprises.com/ratchet-lashings/

0 notes

Text

Precision Construction Winches for Superior Performance

In the dynamic world of construction, where efficiency and precision are paramount, the role of cutting-edge equipment cannot be overstated. Among the myriad tools that contribute to seamless project execution, precision construction winches stand out as indispensable for achieving superior performance. These sophisticated devices play a crucial role in various construction applications, ensuring not only the successful completion of projects but also enhancing safety and reliability.

#Construction winch#Crane Limit Switch#Electric chain hoist#Crane Limit Switches#Electric Wire rope hoist#Crane Joystick Control

1 note

·

View note

Link

Krishna Crane Engineer is one of the leading electric wire rope hoist manufacturers in ahmedabad. Request a FREE Quote today!

0 notes

Link

Leading Electric Wire Rope Hoist Manufacturer In India. 24/7 Customer Service.Serving Since 1979, ISO 9001 Certified.

0 notes

Text

We at S.Cranes, make Electric wire rope hoists which are crafted to precision with our well versed engineering background. Our experience in serving the clients since 1979 make us the choice of our clients in all major segments to go with us.

We have a speciality of understanding the needs of our client based on which our engineers provide solutions which are technically proven to match their requirements.

0 notes

Text

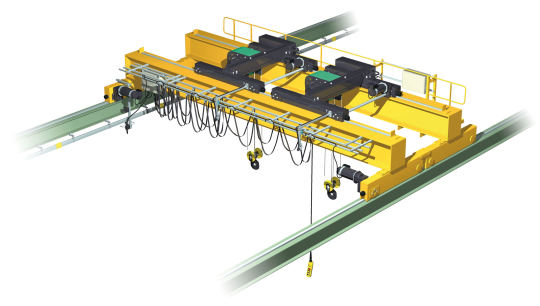

#crane#cranes#EOT Crane#jib crane#jib cranes#jib#jib cranes for sale#wire rope#overhead cranes#gantry crane#gantry cranes#jib crane manufacturer#gantry#eot cranes#goliath crane#transfer trolleys#electric hoist#double girder cranes#double girder crane#single girder crane#overhead crane#bridge crane#cranes manufacturers#EOT cranes

0 notes

Link

For your winching and handling requirements, purchase a high-quality snatch block! To view the selection of Lifting Clamps and Snatch Blocks from Taizhou Etalon Machinery Co. Ltd., contact us today.

0 notes

Text

Professional Crane Manufacturer in India

Ambica Engineering is a reliable and largest crane manufacturer in India With years of experience. Our extensive material handling equipment includes EOT cranes, hoists, lift magnets, goods lifts, and crane spares. Select Ambica Engineering for your crane supplier today!

#jib crane#cranes#jib crane manufacturers#electric wire rope hoist manufacturers#crane manufacturer in india

1 note

·

View note

Text

Exploring the Versatility of Electric Wire Rope: Applications and Advantages

Electric wire rope, also known as electrically powered wire rope, is a versatile and indispensable tool used in various industries for lifting, pulling, and moving heavy loads. With its robust construction, flexibility, and high strength-to-weight ratio, electric wire rope offers numerous advantages over traditional lifting methods. This article explores the wide-ranging applications and advantages of electric wire rope, highlighting its importance in modern industries.

Applications of Electric Wire Rope:

Construction Industry: Electric wire rope finds extensive use in the construction industry for lifting and moving heavy materials and equipment. Cranes equipped with electric wire rope hoist are commonly used for lifting steel beams, concrete panels, and other construction materials to various heights. Moreover, electric wire rope winches are utilized for pulling and positioning heavy machinery and components during construction projects, enhancing efficiency and safety on job sites.

Manufacturing and Warehousing:

In manufacturing facilities and warehouses, electric wire rope plays a vital role in material handling and logistics operations. Overhead cranes equipped with electric wire rope hoist are used for lifting and transporting raw materials, finished products, and heavy machinery within production facilities. Additionally, electric wire rope hoist are employed in storage and distribution centres for loading and unloading cargo from trucks and containers, streamlining warehouse operations and optimizing space utilization.

Mining and Extraction:

The mining and extraction industry relies heavily on electric wire rope for various applications, including shaft hoisting, material handling, and personnel transport. Electric wire rope hoist and winches are used in underground mines for hoisting ore, equipment, and personnel to the surface. Moreover, electric wire rope cranes are deployed in open-pit mining operations for lifting and moving heavy machinery, excavators, and trucks, facilitating efficient extraction and transportation of minerals.

Marine and Offshore:

In the marine and offshore industry, electric wire rope is utilized for a wide range of applications, including mooring, towing, and lifting operations. Electric wire rope winches and capstans are commonly installed on ships, offshore platforms, and oil rigs for anchoring, docking, and positioning vessels. Additionally, electric wire rope cranes are employed for loading and unloading cargo, as well as for lifting and lowering equipment and personnel between the vessel and the offshore structure.

Advantages of Electric Wire Rope:

High Strength and Durability: Electric wire rope is constructed from high-strength steel wires wound together to form a robust and durable cable. This construction provides exceptional tensile strength, allowing electric wire rope to withstand heavy loads and harsh operating conditions without compromising performance or safety. Moreover, electric wire rope is resistant to corrosion, abrasion, and fatigue, ensuring long-term reliability and durability in demanding industrial environments.

Flexibility and Maneuverability: Unlike rigid lifting structures such as beams and chains, electric wire rope offers greater flexibility and manoeuvrability, making it suitable for lifting and moving loads in confined spaces and complex environments. Electric wire rope can be easily routed around obstacles, through sheaves and pulleys, and over long distances, enabling precise positioning and control of loads with minimal effort. This flexibility enhances productivity and efficiency in various industrial applications, reducing downtime and labour costs.

Variable Speed and Control: Electric wire ropes and winches are equipped with variable speed drives and control systems that allow operators to adjust lifting and lowering speeds according to the specific requirements of each task. This capability enables smooth acceleration and deceleration of loads, precise positioning, and safe handling of delicate or sensitive materials. Moreover, electric wire rope offers multi-speed options, allowing operators to optimize lifting speeds for different load capacities and operating conditions, enhancing overall efficiency and safety. Versatility and Adaptability are hallmark characteristics of electric wire rope, making it an indispensable asset across diverse industries for a myriad of lifting and pulling applications. With its wide array of configurations, capacities, and accessories, electric wire rope stands out as a customizable solution tailored to meet the unique demands of each task and industry.

Custom Configurations: Electric wire rope can be tailored to suit various requirements, whether it's the length, diameter, or strength capacity. This customization allows businesses to select the ideal configuration that aligns with their specific lifting needs, ensuring optimal performance and safety.

Specialized Capacities: From lightweight applications to heavy-duty lifting, electric wire rope comes in a range of capacities to accommodate varying load requirements. Whether it's lifting heavy machinery in a manufacturing plant or hoisting materials on a construction site, electric wire rope can be customized to handle the desired weight with precision and reliability.

Versatile Accessories: Electric wire rope can be enhanced with a multitude of accessories to further augment its functionality and adaptability. Accessories such as hooks, shackles, and pulleys expand the capabilities of electric wire rope, allowing for versatile applications across different industries and environments.

In essence, the versatility and adaptability of electric wire rope, coupled with the reliability and precision of electric wire rope hoist, make them indispensable tools in various industries. Whether it's lifting heavy machinery, transporting materials, or anchoring vessels, electric wire rope solutions offer unparalleled performance and flexibility, driving efficiency and productivity in diverse industrial settings.

Conclusion:

In conclusion, electric wire rope is a versatile and indispensable tool used in numerous industries for lifting, pulling, and moving heavy loads. From construction and manufacturing to mining and marine applications, electric wire rope offers unmatched strength, flexibility, and control, making it an ideal choice for a wide range of lifting and material handling tasks. With its high strength-to-weight ratio, durability, and adaptability, electric wire rope continues to play a vital role in modern industries, driving efficiency, productivity, and safety across diverse applications.

0 notes

Text

Get the Perfect Electric Wire Rope Hoist from the Most Respected Firms

An electric wire rope hoist is a type of materials management tool used for raising, descending, and transporting goods. They have an electric generator that propels them overhead. Electric chain hoists and electrical wire rope hoists are the two primary varieties of electric hoists.

A roof tile elevator for sale can persist for generations rather than just a few decades because of its great resistance to damage from water, cold, fire, wind, and insects. A correctly built tile roof is the last roof a building owner will ever need to purchase, which has a significant positive impact on resale value.

The Utilisation of an Electric Rope Hoist

Winches are electrical devices that rely on mechanical advantages to sustain hanging weights and move items upward. By spreading weight with the use of pulleys or gears, mechanical hoist equipment converts reduced power over long distances into huge forces over small distances.

Technology for elevating is used for lifting generally as well as in mobile and stationary applications. They may also be utilised for specific tasks like removing automotive engines, among other things. They operate by fastening a hook to the load's fixed end, connecting it to a motor and crane, then attaching a second hook to the movable end, engaging the load.

How to Select the Perfect Rope Hoist for your Purpose

Ask your team whatever load needs to be published on the website before you start lifting loads. Choose an electric parachute cord hoist with a capacity of more than what you need on a daily basis. This increases the Hoist's resilience and lowers the possibility of mishaps.

It is also important to examine how many lifts are anticipated per day. As important as other parameters, tensile strength is needed for various weights and turn counts. Therefore, before purchasing a machine, it is important to consider the anticipated quantity of lifts and select the appropriate kind. Get in touch with the experts to know more.

Source

0 notes