#elastomeric waterproofing coating

Text

Honoring Strength, Courage, and Hope

On World Cancer Day, CAPA stands with warriors, survivors, and caregivers around the globe. Let's unite in the fight against cancer, spreading awareness, supporting research, and offering love and compassion to those affected.

Together, we can make a difference. Together, we can bring light to the darkness. Join us in honoring the resilience and determination of cancer fighters everywhere. #WorldCancerDay #CAPACares #StrengthInUnity

To know more tile adhesives and waterproofing floors, epoxy grouts visit: https://capaindia.in/product/capa-flex/, https://capaindia.in/product/capaproof-hybrid-w/

#best tile adhesive in india#top tile adhesive brands in india#top building materials companies in india#tile adhesive manufacturers#tile adhesives for fixing natural stones#high strength flooring mortars#tile adhesive companies in india#floor repairs mortars in india#tile adhesives for vitrified tiles#block jointing mortar manufacturers in india#Flooring mortar#Tile and stone adhesive#Industrial Grouts#floor repairs mortars#epoxy grouts#Powder grouts#Ready mix plaster manufacturers#Machine sprayable plaster#Thin joint mortars#Thin joint mortars for AAC blocks#Waterproofing mortar#Waterproofing system#floor repairs mortars in India#best flooring solutions in india#best waterproofing mineral mortars in india#aliphatic polyurethane waterproofing coating#elastomeric waterproofing coating#flexible waterproofing mortar for crack bridging#waterproofing solutions for crack bridging#affordable waterproofing solutions

0 notes

Text

Elastomeric Roof Coating - Metal Roof Coating

Elastomeric Roof Coating – Metal Roof Coating

How to apply elastomeric roof coating onto a mobile home metal roof.

⏱️⏱️Chapters⏱️⏱️00:00 Follow along with a handyman00:25 Using elastomeric cool seal for metal roofs01:25 We sealed the edges and penetrations with tar02:00 Probably want to do this every 4-5 years02:13 Be an American, not an American’t

🙏 Subscribe, 👍, it helps a lot!!➤❓/ 💬: [email protected]➤ Follow…

View On WordPress

#elastomeric#elastomeric paint application#elastomeric roof coating#elastomeric seal metal roof leaks#flat roof#how to apply roof coating#how to tar & seal metal roof#liquid rubber#metal roof#metal roof coating#metal roof repair#metal roofing on a house#mobile home#residential metal roofing#rogers arkansas#roof coating#roof coating application#roof coating waterproof#roof tar sealant#seal metal roof leaks#silicone roof#Straight Arrow Repair#trailer home

0 notes

Text

Comprehensive Services Offered by Waterproofing Contractors in Dubai

Dubai has a hot, dry climate with occasional heavy rains that can create unique problems for buildings. Waterproofing contractors in Dubai offer various services to protect buildings from water damage, ensuring they last longer. Here, we look at the main services these contractors provide.

1. Roof Waterproofing

One of the main services provided by waterproofing contractors is roof waterproofing. The intense heat and occasional heavy rains in Dubai can cause roofs to crack and leak. Contractors use special materials and methods, like liquid waterproofing membranes, bituminous waterproofing, and polyurethane liquid membranes, to create a strong barrier that keeps water out.

2. Basement Waterproofing

Basements can easily get water damage and flood, especially in areas with high water levels. In Dubai, contractors use methods like cementitious waterproofing, which means putting a waterproof layer on basement walls and floors. They also use cavity drainage systems to direct water away from the building, stopping damage and mold growth.

3. Foundation Waterproofing

The foundation is vital for a building's stability. Waterproofing contractors in Dubai offer services to protect the foundation from water damage. They use techniques like applying waterproof coatings and membranes, installing drainage systems, and using bentonite waterproofing, which swells when it touches water to seal any cracks or gaps.

4. Bathroom and Kitchen Waterproofing

Bathrooms and kitchens, which are always exposed to water, need special waterproofing. Contractors use waterproofing membranes and sealants to stop water from getting into walls and floors, preventing structural damage and mold growth.

5. Terrace Waterproofing

Terraces, often used as extra living spaces, need good waterproofing to stop water from leaking into the rooms below. Contractors use elastomeric coatings and other special materials to create a waterproof seal that can handle Dubai’s harsh weather.

6. Swimming Pool Waterproofing

Swimming pools need careful waterproofing to stop leaks and keep the pool strong. Contractors use special waterproofing systems, like flexible membranes and epoxy coatings, to handle constant water pressure and chemical exposure.

Conclusion

Waterproofing contractors in Dubai, like Alrayan Insulation, offer important services to handle the city's unique weather challenges. Their skill in different waterproofing methods keeps buildings safe, strong, and free from water damage. For homes, businesses, or industrial properties, using professional waterproofing services is key to keeping buildings in good shape and lasting a long time in Dubai.

#Waterproofing Contractors in Dubai#metal roof waterproofing in uae#grp linings in uae#crack injection contractor in uae#best waterproofing services in uae#water leakage repair in dubai

0 notes

Text

The Role of Construction Sealants in Modern Building Techniques

In the realm of modern building techniques, construction sealants have become indispensable. These versatile materials ensure that structures are not only aesthetically pleasing but also durable and energy-efficient. This blog will explore the various types of construction sealants and their critical roles in contemporary construction practices.

What Are Construction Sealants?

Construction sealants are materials used to seal joints, gaps, and openings in buildings, preventing the ingress of water, air, and contaminants. They are crucial for maintaining the integrity and performance of structures, ensuring that they remain weather-resistant and energy-efficient.

Types of Construction Sealants

Silicone Sealants: Silicone sealants are highly flexible and durable, making them ideal for joints that undergo significant movement. They are commonly used in glazing, curtain walls, and exterior joints.

Polyurethane Sealants: These sealants offer excellent adhesion and flexibility. They are suitable for sealing expansion joints, roofing applications, and other exterior surfaces that experience dynamic movements.

Acrylic Sealants: Acrylic sealants are easy to apply and paintable, making them perfect for interior applications where aesthetics are important. They are used in areas with minimal movement, such as trim and moldings.

Applications of Construction Sealants

1. Weatherproofing

Construction sealants are vital for weatherproofing buildings. By sealing joints and gaps, they prevent water and air infiltration, protecting the structure from damage caused by moisture and temperature fluctuations.

2. Energy Efficiency

Sealants play a crucial role in enhancing the energy efficiency of buildings. By preventing air leaks, they help maintain consistent indoor temperatures, reducing the need for heating and cooling and thereby lowering energy bills.

3. Structural Integrity

Sealants contribute to the structural integrity of buildings by accommodating movement between different building materials. This flexibility prevents cracks and breaks that can compromise the stability of the structure.

Importance of Roof Sealants

Roof sealants are a specialized type of construction sealant designed to protect roofs from leaks and environmental damage. They are essential for extending the lifespan of roofing systems and ensuring that they remain watertight and weather-resistant.

Types of Roof Sealants

Elastomeric Coatings: These provide a flexible, waterproof barrier that can expand and contract with the roof's movements. They are ideal for flat and low-slope roofs.

Bituminous Sealants: Used for sealing around roof penetrations and flashing, bituminous sealants offer robust protection against water infiltration.

Silicone Coatings: Known for their excellent UV resistance, silicone coatings are perfect for roofs exposed to intense sunlight. They provide a seamless, durable finish that resists weathering and leaks.

Best Practices for Using Construction Sealants

Surface Preparation: Clean and dry the surfaces to ensure optimal adhesion.

Correct Application: Follow the manufacturer's instructions for application, including recommended temperatures and curing times.

Regular Maintenance: Inspect and maintain sealed joints regularly to ensure they remain effective over time.

Conclusion

Construction sealants are a fundamental component of modern building techniques, playing a crucial role in weatherproofing, energy efficiency, and structural integrity. Whether you're working on a new build or maintaining an existing structure, choosing the right sealant and applying it correctly is essential for ensuring the longevity and performance of your project. Roof sealants, in particular, are vital for protecting against leaks and environmental damage, making them a wise investment for any building.

0 notes

Text

Elastomeric Coatings: Essential for Waterproofing and Surface Protection!

Elastomeric coatings are specifically applicable to situations in which one would want to protect surfaces from the impact of water since they act as a barrier against water. Some of the advantages that make them significant in offering civil structures permanency and flexibility. Foam Co Roofing, a roofing company in Phoenix, can be assisted by Foam Co Roofing, which operates in the following ways.

0 notes

Text

Understanding the Different Types of Roof Paint

A roof not only shelters but also defines the character and resilience of a building. So, in the sense of functionality and aesthetics, Newcastle roof painting emerges as a silent guardian, offering protection against the elements while bestowing a touch of visual appeal. Yet, amidst the options available in today’s market, navigating the diverse array of roof paint types can feel akin to unravelling a tapestry of hues and formulations.

Let’s learn more about the intricacies of various roof paint types, elucidating their features, advantages, and applications to help you decide which colour to pick for your specific building.

Acrylic Roof Paint

Acrylic roof paint emerges as a ubiquitous choice, revered for its versatility and durability. Formulated with water as its base, acrylic paint facilitates easy application and cleanup. It engenders a flexible and permeable membrane atop the roof surface, accommodating expansion and contraction in response to temperature fluctuations. Its superior UV resistance mitigates colour fading and heat absorption, thereby fostering a cooler interior ambiance. Compatible with diverse roofing materials like metal, concrete, and asphalt shingles, acrylic roof paint embodies a harmonious blend of functionality and aesthetics.

Asphalt Roof Paint

Tailored specifically for asphalt shingle roofs, asphalt roof paint, also known as bituminous paint, serves as a specialised coating imbued with protective properties. By forming a sealing layer, it fortifies the roof against water infiltration and augments its resistance to inclement weather conditions. Laden with bitumen, asphalt roof paint boasts commendable waterproofing prowess and exhibits robust adhesion to asphalt surfaces. Furthermore, it aids in rejuvenating ageing roofs by concealing minor imperfections and cracks, thereby prolonging their lifespan.

Elastomeric Roof Coating

Elastomeric roof coating emerges as a stalwart contender, characterised by its remarkable flexibility and endurance. Crafted from acrylic or silicone polymers, this coating manifests as a supple and resilient layer that ensconces the roof surface seamlessly. Its inherent ability to stretch and contract mitigates the risk of cracking or peeling, rendering it an ideal choice for flat or low-slope roofs susceptible to standing water and harsh climatic vicissitudes. Noteworthy for its superior waterproofing and weatherproofing attributes, elastomeric coatings offer respite from UV radiation and thermal fluctuations, thereby curbing energy expenditure.

Silicone Roof Coating

Synonymous with peerless durability and longevity, silicone roof coating stands as a premium option for discerning consumers. It engenders a thick, moisture-cured membrane that bestows a flawless barrier against water intrusion, UV radiation, and chemical aggressors. Possessing exceptional resistance to cracking, peeling, and fading, silicone coatings thrive in arduous climates and industrial settings. Additionally, they exhibit self-cleansing properties, impeding the accumulation of debris and grime, while also boasting eco-friendliness owing to their low VOC emissions.

Reflective Roof Coatings

Reflective roof coatings epitomise innovation in the realm of energy-efficient building solutions. Tailored to mitigate heat absorption, these coatings harness the prowess of light-coloured pigments or reflective additives to deflect solar radiation from the roof surface. Whether acrylic, silicone, or elastomeric-based, reflective coatings proffer varying degrees of reflectivity and insulation. Particularly beneficial for edifices nestled in sweltering climates or locales characterised by intense solar exposure, they facilitate the maintenance of optimal indoor temperatures, thus fostering energy conservation and prolonging the longevity of the roof substrate.

In the labyrinth of roof paint choices, selecting the apt formulation assumes paramount significance in safeguarding your investment and enhancing the visual allure of your abode. Whether your prerogative entails waterproofing, thermal insulation, or aesthetic enhancement, a myriad of options beckon, each tailored to cater to diverse requisites and preferences. Armed with a nuanced understanding of the manifold types of roof paint and their myriad attributes, you are poised to make a discerning choice that ensconces your roof in a cocoon of protection and panache.

0 notes

Text

Say Goodbye to Roof Leaks: The Importance of Waterproofing

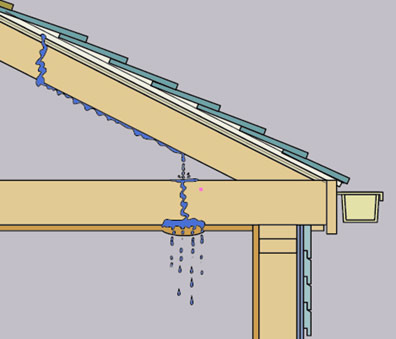

Understanding Roof Leakage:

Roof leakage occurs when water penetrates through the roofing system and enters the interior spaces of a building. Common causes of roof leaks include damaged or deteriorated roofing materials, improper installation, inadequate flashing, clogged gutters, and extreme weather conditions such as heavy rainfall or snow accumulation. Left unaddressed, roof leaks can lead to structural damage, mold growth, and costly repairs.

The Importance of Waterproofing:

Waterproofing is a proactive approach to prevent water infiltration and protect the integrity of the roofing system. By applying waterproofing materials and techniques to vulnerable areas of the roof, such as seams, joints, and penetrations, property owners can create a barrier against moisture and prolong the lifespan of their roofs. Waterproofing not only prevents roof leaks but also enhances thermal efficiency, reduces energy costs, and preserves the structural integrity of the building.

Benefits of Roof Leakage Waterproofing:

Prevents Water Damage: The primary benefit of roof leakage waterproofing is its ability to prevent water damage to interior finishes, structural components, and personal belongings. By creating a watertight seal, waterproofing membranes and coatings prevent water infiltration and protect the building's assets from moisture-related deterioration.

Preserves Indoor Air Quality: Water infiltration through the roof can promote mold and mildew growth, leading to poor indoor air quality and potential health hazards for occupants. Waterproofing helps maintain a dry and healthy indoor environment by preventing mold growth and reducing the risk of respiratory issues and allergies.

Extends Roof Lifespan: Waterproofing extends the lifespan of the roofing system by protecting it from the damaging effects of water, UV exposure, and weathering. By minimizing the risk of leaks, waterproofing helps preserve the structural integrity of the roof and prolong its service life, reducing the need for costly repairs and premature replacement.

Enhances Energy Efficiency: A properly waterproofed roof improves the thermal efficiency of the building by reducing heat loss and energy consumption. By sealing gaps and preventing air leakage, waterproofing helps maintain consistent indoor temperatures, reducing the workload on HVAC systems and lowering energy costs.

Effective Waterproofing Solutions:

Liquid Applied Membranes: Liquid waterproofing membranes, such as elastomeric coatings and acrylic sealants, provide a seamless and flexible barrier against water infiltration. These coatings adhere to various roofing substrates and can be applied with a brush, roller, or sprayer for easy installation.

Sheet Membranes: Sheet waterproofing membranes, typically made of modified bitumen or synthetic materials such as EPDM or PVC, offer superior durability and puncture resistance. These membranes are installed in overlapping layers and provide reliable protection against water intrusion.

Flashing and Sealants: Proper installation of flashing, drip edges, and sealants around roof penetrations, such as vents, chimneys, and skylights, is essential for preventing water infiltration at vulnerable points. High-quality sealants, such as silicone or polyurethane, roof waterproofing contractors provide a durable and long-lasting seal against moisture.

Roof Coatings: Roof coatings, such as acrylic, silicone, or polyurethane coatings, offer an additional layer of protection against water infiltration and UV damage. These coatings can be applied over existing roofing materials to enhance waterproofing performance and extend the lifespan of the roof.

In conclusion, roof leakage waterproofing is a crucial investment for protecting properties against

0 notes

Text

Protect Your Roof with the Best Waterproof Coating: A Comprehensive Guide

Importance of Waterproof Coatings: Roofs are constantly exposed to the elements, making them vulnerable to damage. Rainwater can seep through cracks and gaps, causing leaks and water damage to the interior of the building. Additionally, UV radiation from the sun can degrade roofing materials over time, leading to cracks and deterioration.

Best Waterproof Coatings for Roof:

Silicone Roof Coatings: Silicone roof coatings are highly durable and provide excellent waterproofing properties. They can withstand extreme temperatures and UV exposure without cracking or peeling, making them ideal for all types of roofs. Silicone coatings are also flexible, allowing them to expand and contract with the roof’s movement, preventing leaks.

Acrylic Roof Coatings: Acrylic roof coatings are popular for their affordability and ease of application. They form a seamless, protective membrane over the roof surface, preventing water infiltration and reducing the risk of leaks. Acrylic coatings are also available in a variety of colors, allowing homeowners to choose a finish that complements their building’s aesthetics.

Polyurethane Roof Coatings: Polyurethane roof coatings offer superior durability and weather resistance. They provide excellent adhesion to a variety of roofing materials, including metal, concrete, and asphalt, making them suitable for a wide range of applications. Polyurethane coatings also have excellent UV resistance, ensuring long-lasting protection against sun damage.

Elastomeric Roof Coatings: Elastomeric roof coatings are formulated with elastic polymers that allow them to stretch and contract with the roof’s movement. This flexibility helps to prevent cracking and peeling, ensuring long-term waterproofing protection. Elastomeric coatings are also highly reflective, reducing heat buildup and extending the lifespan of the roof.

Conclusion: Investing in a high-quality waterproof coating is essential for protecting your roof and ensuring the longevity of your building. Whether you choose silicone, acrylic, polyurethane, or elastomeric coatings, be sure to select a product that is specifically designed for your roof type and climate conditions. By taking proactive measures to waterproof your roof, you can prevent costly damage and maintenance issues in the future, ultimately saving you time and money in the long run.

0 notes

Text

Energy-Efficient Roofing Options

In an era where energy conservation and environmental sustainability are increasingly important, homeowners are seeking ways to reduce their energy consumption and lower their carbon footprint. One often overlooked aspect is the roof, which can significantly impact a home's energy efficiency. In this article, we will explore some energy-efficient roofing options that can help you create a more sustainable and cost-effective home.

Cool Roofs

Cool roofs are designed to reflect more sunlight and absorb less heat compared to traditional roofs. They are typically made of materials with high solar reflectance and thermal emittance properties. Cool roofs can reduce the amount of heat transferred into your home, keeping it cooler during hot summer months. This, in turn, lowers your cooling costs and reduces the strain on your air conditioning system. Common cool roofing materials include cool asphalt shingles, metal roofs, and specially coated tiles.

Metal Roofing

Metal roofing is an excellent choice for energy efficiency. It reflects solar heat instead of absorbing it, keeping your home cooler. Metal roofs are durable, long-lasting, and recyclable, making them an environmentally friendly option. Additionally, they are often made from recycled materials and can be installed over existing roofs, reducing waste generated during the installation process.

Green Roofs

Green roofs, also known as living roofs, are gaining popularity as an eco-friendly option. They consist of a layer of vegetation and soil planted on top of a waterproof membrane. Green roofs provide insulation, reduce stormwater runoff, and help mitigate the urban heat island effect. They can effectively reduce energy consumption by providing natural insulation, keeping your home cooler in summer and warmer in winter. Green roofs also improve air quality and provide habitat for birds and insects.

Solar Roofing

Solar roofing systems harness the power of the sun to generate electricity for your home. Photovoltaic (PV) panels are integrated into the roof, converting sunlight into usable energy. Solar roofing not only reduces your reliance on traditional energy sources but also allows you to generate your own clean, renewable energy. Depending on your location and energy needs, solar roofing systems can significantly reduce your electricity bills and even provide you with a surplus of energy that can be sold back to the grid.

Insulated Roofing

Proper insulation is crucial for energy efficiency. Insulated roofing systems, such as spray foam or rigid foam insulation, can prevent heat transfer and reduce energy consumption for both heating and cooling. Insulation helps maintain a consistent indoor temperature, minimizing the need for excessive heating or cooling. This results in lower energy bills and a reduced environmental impact.

Energy-Efficient Roof Coatings

Roof coatings can improve the energy efficiency of your existing roof. Reflective coatings, such as elastomeric coatings, can be applied to roofs to increase solar reflectance and thermal emittance. These coatings help reduce heat absorption and keep the interior of your home cooler. They can be applied to various roofing materials, including asphalt shingles, metal roofs, and concrete tiles.

Conclusion

Investing in an energy-efficient roofing company in Irondequoit options not only benefits the environment but also saves you money in the long run. By choosing materials and technologies that enhance energy efficiency, you can significantly reduce your home's energy consumption and decrease your carbon footprint. Whether it's through cool roofs, metal roofing, green roofs, solar roofing, insulated roofing, or energy-efficient roof coatings, there are numerous options available to suit your needs and preferences. Consult with a professional roofing contractor to explore the best energy-efficient roofing solution for your home, and enjoy the long-term benefits of sustainability and energy savings.

Highview Roofing Company

4671 hall center rd Walworth,NY,14568

(585) 440-7663

https://highviewroofingny.com/

Find Us: https://www.google.com/maps?cid=5117176449506063978

0 notes

Text

Understanding the Benefits of EPDM Roof Coating

Flat roofs, often constructed with Ethylene Propylene Diene Monomer (EPDM) membranes, are a common sight on commercial buildings and some residential properties. While known for their durability and weather resistance, even EPDM roofs eventually succumb to the relentless effects of time and harsh weather. This is where EPDM roof coating comes in – a cost-effective solution that can significantly extend the lifespan and performance of your EPDM roof.

What is EPDM Roof Coating?

EPDM roof coating is a liquid applied product specifically formulated to adhere to and revitalize existing EPDM membranes. These coatings come in various compositions, with acrylic and elastomeric coatings being the most common. When applied correctly, they form a seamless, protective layer on the EPDM surface, offering a multitude of benefits.

Benefits of EPDM Roof Coating:

Extends Roof Lifespan: The primary advantage of EPDM roof coating is its ability to significantly extend the lifespan of your roof. By creating a protective barrier, the coating shields the EPDM membrane from harmful UV rays, ozone exposure, and extreme weather conditions. This can potentially add 15-20 years to the life of your roof, delaying the need for costly replacements.

Improved Waterproofing Performance: Over time, EPDM membranes can develop minor cracks or lose their original water-resistant properties. EPDM roof coating fills in these imperfections and strengthens the overall waterproofing capabilities of the roof. This reduces the risk of leaks, protecting your building's interior from water damage.

Enhanced Energy Efficiency: Many EPDM roof coatings are formulated with reflective properties that can help reduce your energy bills. By reflecting sunlight away from the roof during the summer months, these coatings can lower cooling costs. In colder climates, some coatings can also help retain heat within the building, improving overall energy efficiency.

Reduced Maintenance Costs: Regular maintenance is crucial for any roof, but EPDM roof coating can help minimize maintenance needs. The protective layer created by the coating reduces the frequency of inspections and repairs required, saving you time and money in the long run.

Cost-Effective Solution: Compared to a complete roof replacement, EPDM roof coating is a significantly more cost-effective solution. The application process is typically quicker and less disruptive, making it a budget-friendly way to breathe new life into your existing roof.

Environmentally Friendly: Many EPDM roof coating products are formulated with low-VOC (volatile organic compounds) content, minimizing their environmental impact. Additionally, by extending the lifespan of your roof and reducing the need for replacement, you contribute to a more sustainable future.

When to Consider EPDM Roof Coating:

EPDM roof coating is not a one-size-fits-all solution. Here are some indicators that your EPDM roof might benefit from this treatment:

Visible signs of wear and tear on the EPDM membrane, such as cracking, blistering, or ponding water.

Reduced water resistance, leading to leaks or moisture build-up.

Energy bills on the rise, potentially due to a compromised roof membrane.

Reaching the halfway point of the expected lifespan of your EPDM roof.

Choosing the Right EPDM Roof Coating:

With various EPDM roof coating products available, choosing the right one for your specific needs is crucial.

Consider the climate: Opt for a coating formulated for your region's specific weather conditions.

Evaluate the condition of your roof: Choose a coating suitable for addressing existing issues like minor cracks or leaks.

Warranty and lifespan: Look for a coating with a long warranty and a proven track record of extending roof life.

Professional application: Ensure the coating is applied by a qualified and experienced roofing contractor.

The Application Process:

The application process for EPDM roof coating typically involves several steps:

Roof Cleaning: The roof surface is thoroughly cleaned to remove any dirt, debris, or oils that might affect adhesion.

Minor Repairs: Any existing cracks or minor damages on the EPDM membrane are repaired.

Primer Application (optional): In some cases, a primer might be applied to further enhance the bond between the coating and the membrane.

Coating Application: The chosen EPDM roof coating is applied using spray equipment or rollers, ensuring even coverage across the entire roof surface.

Curing Time: The coating is allowed to cure completely, following the manufacturer's recommended drying time.

0 notes

Text

Comparing Traditional vs. Modern Approaches to Roof Leak Repair in Singapore

Roof leaks are a common issue faced by homeowners and property managers in Singapore. With its tropical climate characterized by heavy rainfall and intense heat, roofs are subjected to significant wear and tear over time, leading to leaks if not properly maintained. When it comes to addressing roof leaks, there are traditional methods that have been used for years, as well as modern approaches that leverage technological advancements. In this article, we will explore and compare these two approaches to roof leak repair in Singapore, highlighting their effectiveness, costs, and sustainability.

Traditional Methods of Roof Leak Repair

For decades, traditional methods have been employed to repair roof leaks in Singapore. These methods often involve manual labor and basic materials. One common traditional approach is the use of cement mortar to patch up cracks or holes in the roof. Cement mortar is applied directly onto the damaged area, filling in any gaps and creating a seal to prevent further leakage. Another traditional method involves the use of waterproofing membranes made from bitumen or asphalt. These membranes are laid over the roof surface to provide a protective barrier against water penetration.

While traditional methods have been used for many years and are relatively inexpensive, they often have limitations in terms of durability and effectiveness, especially in the long term. Cement mortar, for example, may crack and deteriorate over time due to exposure to weather elements, requiring frequent maintenance. Similarly, waterproofing membranes may degrade and lose their effectiveness over time, necessitating replacement.

Modern Approaches to Roof Leak Repair

With advancements in technology and materials science, modern approaches to roof leak repair have emerged, offering innovative solutions that address the shortcomings of traditional methods. One modern approach is the use of elastomeric coatings, which are flexible, waterproof coatings applied to the roof surface. These coatings form a seamless membrane that expands and contracts with the roof, providing superior protection against leaks.

Another modern approach involves the use of infrared thermography for leak detection. Infrared cameras are used to detect temperature differences on the roof surface, which can indicate areas of moisture infiltration. This non-invasive technique allows for precise pinpointing of leaks without the need for extensive manual inspection or dismantling of the roof structure.

Furthermore, advancements in roofing materials have led to the development of highly durable and weather-resistant options such as synthetic membranes and metal roofing systems. These materials offer superior longevity and performance compared to traditional materials like cement mortar or bitumen membranes.

Comparison of Effectiveness

When comparing the effectiveness of traditional vs. modern approaches to roof leak repair, it is evident that modern methods offer several advantages. Elastomeric coatings, for instance, provide a seamless and flexible barrier against water penetration, reducing the likelihood of future leaks. Infrared thermography allows for accurate detection and targeted repair of leaks, minimizing damage to the roof structure.

In contrast, traditional methods like cement mortar or bitumen membranes may provide temporary solutions but are prone to deterioration and may require frequent maintenance or replacement. Moreover, modern roofing materials such as synthetic membranes and metal roofing systems offer superior durability and resistance to weathering, ensuring long-term protection against leaks.

Cost Considerations

While modern approaches to roof leak repair may offer superior effectiveness and durability, they often come with a higher upfront cost compared to traditional methods. Elastomeric coatings, for example, can be more expensive than cement mortar or bitumen membranes. Similarly, infrared thermography equipment and expertise may require additional investment.

However, it is essential to consider the long-term cost implications of roof leak repair. While traditional methods may be cheaper initially, they may require more frequent maintenance and repairs over time, resulting in higher overall costs. In contrast, modern approaches that provide long-lasting solutions can offer greater cost savings in the long run by reducing the need for ongoing maintenance and repairs.

Sustainability

In addition to effectiveness and cost, sustainability is becoming an increasingly important consideration in roof leak repair. Modern approaches that utilize eco-friendly materials and techniques can help reduce environmental impact and contribute to sustainable building practices. Elastomeric coatings, for instance, are often formulated with low volatile organic compounds (VOCs) and are more environmentally friendly than traditional materials like cement mortar or bitumen.

Furthermore, the longevity and durability of modern roofing materials contribute to sustainability by reducing the need for frequent replacements and the associated consumption of resources. Metal roofing systems, for example, can last for decades with minimal maintenance, reducing the overall environmental footprint of roof leak repair activities.

Conclusion

In conclusion, while traditional methods of roof leak repair have been used for many years, modern approaches offer several advantages in terms of effectiveness, durability, and sustainability. Elastomeric coatings, infrared thermography, and advanced roofing materials provide innovative solutions that address the shortcomings of traditional methods, offering long-lasting protection against leaks and minimizing environmental impact.

While modern approaches may entail higher upfront costs, their long-term benefits in terms of reduced maintenance and repairs, as well as environmental sustainability, make them a worthwhile investment for homeowners and property managers in Singapore. By embracing modern technologies and materials, we can ensure that roof leak repair activities are not only effective but also sustainable for the future.

Let’s Get Connect

Name: NASAX ROOFING CONSTRUCTION

Address: 845 Geylang Rd, #02-04, Complex 400845

Call: +6590837264

Map: https://goo.gl/maps/LtyDkaJu5LV9Junm6

0 notes

Text

Experience the Power of Aplicacer PU Flex

Designed for versatility, Aplicacer PU Flex offers unparalleled adhesive strength for a wide range of surfaces. Whether it's interior or exterior, dry or wet conditions, this multipurpose adhesive delivers superior performance every time. Say goodbye to challenges with its remarkable bonding ability on various substrates. Elevate your projects with Aplicacer PU Flex today! To know more about best waterproofing mineral mortars in india visit: https://capaindia.in/product/

#top tile adhesive brands in india#tile adhesive manufacturers#top building materials companies in india#best tile adhesive in india#tile adhesives for fixing natural stones#tile adhesives for vitrified tiles#high strength flooring mortars#block jointing mortar manufacturers in india#tile adhesive companies in india#floor repairs mortars in india#best waterproofing mineral mortars in india#elastomeric waterproofing coating#epoxy grouts in india#epoxy adhesive manufacturers#epoxy adhesives manufacturers#affordable waterproofing solutions#Flooring mortar#Tile and stone adhesive#Industrial Grouts#floor repairs mortars#epoxy grouts#Powder grouts#Ready mix plaster manufacturers#Machine sprayable plaster#Thin joint mortars#Thin joint mortars for AAC blocks#Waterproofing mortar#Waterproofing system

0 notes

Text

Presenting CeraChem's cementitious Waterproofing Solutions: Trusted, Effective, and Innovative!

At CeraChem, we understand the importance of protecting your structures from water damage. That's why we've developed a range of advanced waterproofing solutions to meet your diverse needs. Our products are engineered to provide superior protection, durability, and ease of application, making them the ideal choice for professionals and homeowners alike.

1. Ceralastic: The Ultimate Elastomeric Waterproofing Solution

Ceralastic is a two-component, elastomeric, cementitious waterproofing coating that offers exceptional flexibility and adhesion. Its unique formulation combines synthetic resins, cement, and well-graded aggregates, creating a seamless, waterproof barrier that can withstand thermal movements and crack bridging.

2. Cera Elastocrete: Acrylic Based Polymer Additive for Cementitious System

CERA ELASTOCRETE is an acrylic based polymer system which can be used as an additive to cement composites in waterproofing and structural repair applications. It also imparts durability to the structure and improves the aesthetics of the exterior finishes.

3. Cera Fibrolastic: Fiber-Reinforced Waterproofing Excellence

Cera Fibrolastic is a two-component, elastomeric, fiber-reinforced waterproofing coating that combines synthetic resins, cement, well-graded sand, and high-performance multi-dimensional synthetic fibers. This unique formulation provides exceptional flexibility, crack-bridging ability, and resistance to weathering and abrasion.

At CeraChem, we pride ourselves on delivering innovative solutions that cater to the diverse waterproofing needs of our customers. Our products are easy to apply, environmentally friendly, and backed by extensive research and testing, ensuring long-lasting protection for your structures.

Discover the CeraChem difference and experience the peace of mind that comes with trusted, effective, and innovative waterproofing solutions.

📞 Call us at: 98404 80307

📧 Email: [email protected]

#cerachem #Concrete #ConstructionSolutions #EfficientCuring #concreterepair #buildingmaterials #constructionchemical #ConstructionChemicals #concrete #epoxy #epoxygrout #decorative #protective #coating #ironprotection #waterproofing #wallprotection #NonShrinkGrout #windmills #grouting #waterproofing #CementitiousWaterproofing #ceralastic #cerafibrolastic #ceraelastocrete

0 notes

Text

Liquid Rubber: Versatility in Protective Coatings and Sealants

Introduction

In the realm of materials science, few substances offer the versatility and utility of liquid rubber. A synthetic elastomer, liquid rubber exhibits remarkable properties that make it invaluable in various industries, from construction and automotive to marine and aerospace. Its ability to form a flexible, impermeable barrier has led to its widespread use as a protective coating, sealant, and adhesive. This article explores the characteristics, applications, and benefits of liquid rubber in modern engineering and manufacturing.

Characteristics of Liquid Rubber

Liquid rubber is typically derived from synthetic polymers, primarily silicone or polyurethane. These polymers undergo a curing process to transform from a liquid state to a solid elastomeric material. One of the most notable characteristics of liquid rubber is its flexibility. Even when cured, it retains its elasticity, allowing it to withstand movements and deformations without cracking or losing its integrity. This flexibility makes it ideal for applications where traditional rigid materials would fail.

Additionally, liquid rubber exhibits excellent adhesion properties. It can adhere to a wide range of substrates, including metals, concrete, wood, and plastics, forming a strong bond that enhances durability and longevity. Its ability to adhere to both porous and non-porous surfaces makes it suitable for sealing joints, seams, and cracks in various structures.

Moreover, liquid rubber is highly resistant to water, chemicals, UV radiation, and extreme temperatures. These properties make it an ideal choice for outdoor applications where exposure to harsh environmental conditions is inevitable. Whether used as a protective coating for roofs, pipelines, or industrial equipment, liquid rubber provides reliable protection against corrosion, leaks, and degradation.

Applications of Liquid Rubber

The versatility of liquid rubber lends itself to a wide array of applications across different industries:

1. Roofing: Liquid rubber coatings are commonly used in commercial and residential roofing systems to provide a seamless and waterproof barrier. Applied as a spray or brush-on coating, liquid rubber forms a monolithic membrane that effectively seals joints, seams, and penetrations, preventing water ingress and extending the lifespan of the roof.

2. Automotive: Liquid rubber sealants and adhesives find extensive use in the automotive industry for various purposes, including gasketing, weatherproofing, and vibration damping. Whether sealing windows and doors or adhering trim components, liquid rubber offers superior performance and durability compared to traditional rubber gaskets and adhesives.

3. Marine: In the maritime sector, liquid rubber coatings are utilized to protect ships, boats, and offshore structures from corrosion, fouling, and abrasion. Applied as an anti-fouling barrier on hulls or as a protective layer on decks and equipment, liquid rubber helps maintain the structural integrity of marine vessels and infrastructure in harsh marine environments.

4. Construction: Liquid rubber is indispensable in construction for waterproofing basements, foundations, tunnels, and retaining walls. Its seamless application and excellent adhesion ensure effective moisture protection, preventing water infiltration and structural damage in below-grade structures.

5. Electrical: Liquid rubber coatings are employed in electrical insulation applications to provide moisture resistance and electrical insulation for wires, cables, and electrical components. The flexible nature of liquid rubber allows it to conform to irregular shapes and provide a protective barrier against moisture, chemicals, and electrical hazards.

Benefits of Liquid Rubber

The widespread adoption of liquid rubber can be attributed to several key benefits:

1. Seamless Application: Liquid rubber can be applied seamlessly to surfaces of any shape or size, eliminating the need for seams or joints that can serve as potential weak points. This seamless application ensures uniform coverage and consistent protection against leaks and corrosion.

2. Flexibility: The inherent flexibility of liquid rubber allows it to accommodate movements and vibrations without cracking or deteriorating. This flexibility is particularly advantageous in dynamic environments where structural elements are subjected to thermal expansion, contraction, or mechanical stress.

3. Longevity: Liquid rubber coatings and sealants offer long-lasting protection against environmental degradation, extending the lifespan of the underlying substrate. With proper preparation and maintenance, liquid rubber can provide decades of reliable performance, reducing the need for frequent repairs or replacements.

4. Environmentally Friendly: Many liquid rubber formulations are solvent-free and low in volatile organic compounds (VOCs), making them environmentally friendly alternatives to traditional solvent-based coatings. These eco-friendly properties make liquid rubber suitable for use in green building projects and sustainable development initiatives.

5. Cost-Effectiveness: While the initial cost of liquid rubber may be higher than that of conventional materials, its long-term benefits, such as reduced maintenance and energy savings, often outweigh the upfront investment. Additionally, the seamless application and ease of maintenance can contribute to lower installation and lifecycle costs over time.

Conclusion

Liquid rubber stands as a testament to the ingenuity of materials science, offering a versatile and reliable solution for a myriad of engineering and manufacturing challenges. Its unique combination of flexibility, adhesion, and durability makes it an indispensable component in protective coatings, sealants, and adhesives across various industries. As technology advances and new formulations emerge, the potential applications of liquid rubber are likely to expand, further solidifying its position as a cornerstone of modern materials engineering.

0 notes

Text

RV Roofing: Choosing the Best Coating for Your Mobile Home and Travel Trailer

When seeking the ideal coating for your RV roof, it's crucial to consider factors such as weather resistance, durability, and ease of application. Explore reputable brands and consult fellow RV owners for their recommendations.

Understanding the Basics of RV Roof Repair

Maintaining and repairing your RV roof is essential for a seamless travel experience. Here are key steps and tips for DIY RV roof repair:

Assessment: Inspect the roof for cracks, scratches, or holes, common issues in RV roofing.

Cleaning: Begin by thoroughly cleaning the roof to ensure proper adhesion of repair materials.

Materials: Consider using reliable products like Eternabond RV Rubber Roof & Leak Repair Tape for patching and Dicor for overall coating.

DIY Guide: Follow comprehensive guides for step-by-step instructions, costs, and common questions related to RV roof repair.

Community Advice: Seek advice from online communities like Reddit and Good Sam, where fellow RV owners share their experiences and recommendations.

Remember, proactive maintenance and timely repairs can extend the life of your RV roof, ensuring worry-free travels.

Exploring Roof Coating Options for Mobile Homes

When considering best rv roof coating options for mobile homes, several choices cater to different needs and budgets:

Elastomeric Roof Coating: A popular and cost-effective choice, elastomeric coatings provide flexibility, durability, and efficient UV protection.

Silicone Roof Coating: Silicone coatings offer excellent waterproofing, UV resistance, and durability. They are suitable for various climates.

Cool Roof Coatings: Options like Cool guard and Siliconizer are designed to reflect sunlight, keeping mobile homes cooler and potentially reducing energy costs.

When exploring these options, consider factors like climate, budget, and application ease for the best choice in mobile home roof coatings.

Avoiding Common Mistakes: Camper Roof Coating Tips

When applying camper roof coatings, it's crucial to avoid common mistakes to ensure optimal protection and longevity:

Inadequate Cleaning: Properly clean the roof before coating to remove dirt and debris, preventing adhesion issues.

Weather Considerations: Avoid applying coatings in rainy conditions, as it can compromise the effectiveness of the coating.

Understanding Purpose: Different coatings serve varied purposes; ensure you choose the right one for your specific camper roof needs.

Roof Repair First: Address any existing issues like leaks or damage before applying coatings for a comprehensive solution.

Avoiding Harsh Chemicals: Refrain from using harsh chemicals or abrasive cleaners that can damage the roof sealant.

By steering clear of these common mistakes, you can maximize the effectiveness of camper roof coatings and enhance the overall durability of your camper.

DIY RV Roof Repair: The Power of Liquid Roof Sealant

Embarking on a DIY RV roof repair journey? Harness the effectiveness of liquid roof sealants with these key steps:

Inspection: Begin by inspecting the RV roof for holes, cracks, leaks, and rips.

Cleaning: Clean the roof surface around identified issues to ensure optimal adhesion of the sealant.

Choice of Sealant: Opt for quality liquid roof sealants like Liquid Rubber or Liquid RV Roof, known for their durability and ease of application.

Application: Apply the liquid roof sealant to problem areas, such as using Liquid Rubber tape for targeted repairs.

Cost Consideration: Understand the DIY RV roof sealing cost, which depends on the chosen sealant quality.

Environmentally Friendly: Consider eco-friendly options like Liquid Rubber RV Roof Coating for a DIY solution with leak-free results.

By following these steps and utilizing the power of liquid roof sealants, DIY enthusiasts can effectively repair and protect their RV roofs.

Benefits and Usage Guide: RV Roof Coatings

RV roof coatings offer numerous benefits, enhancing the protection and longevity of your recreational vehicle:

Protection from UV Rays: RV roof coatings shield the roof from damaging UV rays, preventing deterioration and extending the lifespan of the roof material.

Waterproofing: An essential feature, RV roof coatings act as a waterproof barrier, preventing leaks and water damage to the interior of your vehicle.

Energy Efficiency: Some coatings contribute to energy efficiency by reflecting sunlight, reducing the interior temperature, and easing the strain on your RV's cooling systems.

Easy Application: RV roof coatings are designed for easy application, providing a hassle-free maintenance solution for RV owners.

Improved Appearance: Beyond protection, a roof coating can enhance the aesthetic appeal of your RV, giving it a refreshed and newer look.

Usage Guide:

Inspect the RV roof for any existing damage or issues before applying the coating.

Clean the roof surface thoroughly to ensure proper adhesion of the coating.

Make sure to follow manufacturer instructions for the specific coating product you choose to ensure optimal results.

Conclusion:

When considering RV roof coatings, the conclusion drawn from various sources is that silicone roof coatings, such as those offered by RV Roof Magic, are recommended for their immense benefits. These benefits include superior protection against the elements, extended lifespan, chemical resistance, and versatile application possibilities. BUS-KOTE™ is also highlighted as a coating that provides a wide range of benefits for RV, bus, camper, or trailer roofs, offering protection from the elements and contributing to energy efficiency.

Additionally, understanding the lifespan of RV roof coatings is crucial. Regular maintenance, inspection, and recoating, as suggested by experts, contribute to prolonging the effectiveness of the coating and ensuring continued protection against leaks and environmental factors.

In conclusion, selecting a high-quality silicone roof coating and adhering to a proper maintenance schedule can significantly enhance the durability and performance of an RV roof.

0 notes

Text

Beat the Heat: Exploring Heat Reflective Paint and Coatings

Feeling the heat? You're not alone. With rising temperatures, many are seeking ways to stay cool and reduce their energy bills. Heat reflective paint and coatings offer a promising solution, and understanding their differences can help you choose the right option for your needs.

Heat Reflective Paint:

Imagine a shield for your surfaces, deflecting the sun's rays like a mirror. That's essentially what heat reflective paint does. Formulated with special pigments that reflect solar radiation, this paint helps keep surfaces cooler, reducing the amount of heat transferred to the interior.

Benefits of Heat Reflective Paint:

Cooler Homes and Buildings: By reflecting sunlight, heat reflective paint can significantly lower surface and interior temperatures, leading to a more comfortable living or working environment. This can translate to reduced reliance on air conditioning, ultimately decreasing energy consumption and costs.

Energy Efficiency: As mentioned, lower cooling needs lead to less energy use. This not only benefits your wallet but also contributes to a more sustainable lifestyle by reducing your carbon footprint.

Improved Roof Lifespan: Heat can take a toll on roofs, causing cracks and shortening their lifespan. Heat reflective paint helps protect roofs from excessive heat, potentially extending their longevity and reducing the need for costly replacements.

Versatility: Heat reflective paint can be applied to various surfaces, including roofs, walls, and even outdoor furniture. This versatility allows for targeted cooling solutions in different areas.

Heat Reflective Coatings:

Similar to paint, heat reflective coatings offer a protective layer that reflects solar heat. However, they differ in composition and application. Coatings can be made from a variety of materials, including elastomeric, silicone, and ceramic. They are often applied in thicker layers compared to paint, offering additional benefits like waterproofing and insulation.

Benefits of Heat Reflective Coatings:

Enhanced Durability: Compared to paint, heat reflective coatings often boast superior durability and weather resistance. This makes them a good choice for exposed surfaces like roofs and exterior walls.

Improved Insulation: Certain coatings offer additional insulation properties beyond just reflecting heat. This can further contribute to maintaining a comfortable indoor temperature.

Waterproofing and Leak Protection: Some coatings offer waterproofing capabilities, protecting your surfaces from rain and moisture damage. This can be particularly beneficial for roofs and balconies.

Choosing the Right Option:

Both heat reflective paint and coatings offer valuable benefits, but the best choice depends on your specific needs and priorities. Consider the following factors:

Surface type: Different paints and coatings are formulated for specific surfaces. Ensure you choose a product compatible with the material you're planning to apply it to.

Desired benefits: Are you primarily looking for cooling or do you also need waterproofing or added insulation?

Budget: Heat reflective coatings often come at a higher cost compared to paint. Weigh the initial investment against the potential long-term benefits like energy savings and extended durability.

By understanding the differences between heat reflective paint and coatings, you can make an informed decision and reap the benefits of cooler spaces and potentially lower energy bills. Remember to consult with professionals for specific recommendations based on your individual situation.

Contact : +91 9011958800Visit : https://www.protexion.in/heat-reflective-coating.php

0 notes