#stainlesssteelcasting

Text

Driving Precision: Unveiling the Crucial Role of Stainless Steel Casting in Automotive Components

Precision of components is critical in determining the durability, efficiency, and overall performance of cars in the dynamic arena of automotive manufacture. Stainless steel casting, a sophisticated production process that propels the automobile industry to new heights of excellence, is at the heart of this precision.

Stainless Steel Casting Unveiled:

Stainless steel casting is a metallurgical marvel that uses the precision of a steel foundry to mold complicated automotive components with unrivaled precision. Pouring molten stainless steel into painstakingly formed molds results in components with remarkable strength, corrosion resistance, and dimensional correctness.

Applications in Engine Components:

The automotive engine, frequently referred to as the "heart" of any vehicle, is heavily reliant on stainless steel casting for crucial components. Precision stainless steel casting ensures that components such as exhaust manifolds and turbine housings can endure high temperatures, corrosive exhaust gasses, and harsh working conditions.

Light weighting for Fuel Efficiency:

The car industry is continually pursuing light weighting technologies in order to improve fuel efficiency and environmental sustainability. In this domain, stainless steel casting emerges as a vital participant, offering the strength and durability required for safety-critical components while also contributing to vehicle weight reduction.

Corrosion Resistance for Chassis Components:

The chassis is an automobile's structural backbone, and stainless steel casting excels in providing corrosion-resistant components for this vital structure. The corrosion resistance inherent in stainless steel assures the durability and structural integrity of the vehicle, from suspension components to frame parts.

Customization Tailored to Design Needs:

Stainless steel casting allows for a degree of personalization that is in sync with the different designs and specifications of current automobiles. Manufacturers use this flexibility to produce bespoke components that meet the distinct design and performance needs of various vehicles.

Ensuring Precision in Oil Seals:

The precision of stainless steel casting benefits oil seals, which are critical for preventing leakage in engines and transmissions. This process's dimensional accuracy assures a flawless fit, improving the efficiency of oil seals and contributing to the overall reliability of automotive systems.

Sustainability and Environmental Impact:

The use of stainless steel casting is consistent with the automotive industry's commitment to sustainability. The technique reduces material waste, and stainless steel's inherent recyclability helps to environmentally beneficial production processes. Because of this environmental sensitivity, stainless steel casting is positioned as a responsible choice in automobile component production.

Quality Assurance in Every Pour:

The automotive industry's strict quality standards necessitate a manufacturing process that provides dependability and safety. With stringent quality assurance standards, stainless steel casting meets this demand. Each pour is meticulously tested to ensure that every component meets or exceeds industry requirements.

Conclusion

The precision seen in crucial automobile components is being driven by stainless steel casting. Stainless steel casting plays an important role in boosting engine performance, helping to light weighting programs, and ensuring the longevity of chassis components. As the automobile industry evolves, stainless steel casting precision will surely remain a cornerstone of innovation, propelling the industry to new heights of quality and efficiency.

0 notes

Text

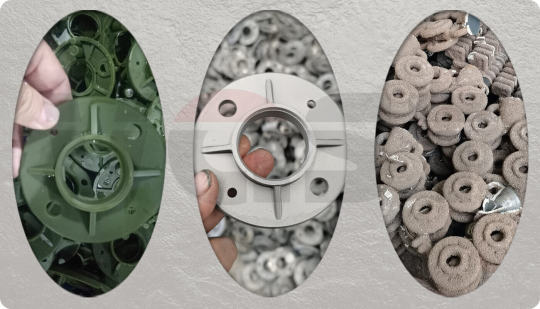

#vastcasting#stainlesscasting#precisioncasting#lostwaxcasting#industrialparts#valveparts#pump#bottleopener#beeropener#stainlesssteelcasting#castings#oemcasting#fishfork#harpoon#fluidcontrol#foundry#buildinghardware#flatware#candleholder#oildrillingtool#meatgrinderparts#wheel

1 note

·

View note

Text

Elevate Durability with Stainless Steel Casters in Turbhe, Navi Mumbai

Unlock the power of durability with Stainless Steel Casters in Turbhe, Navi Mumbai! Swiift Caster presents a premium selection of stainless steel casters designed to withstand the toughest environments. From corrosive substances to heavy loads, our casters ensure longevity and reliability in every application. Whether for industrial equipment, food service carts, or medical furniture, our stainless steel casters provide smooth, quiet operation and exceptional maneuverability. Upgrade your mobility solutions today with Swiift Caster!

0 notes

Text

Difference between lost wax casting and sand casting

Do you know difference between lost wax casting and sand casting? and lost wax casting advantages and disadvantages?

#metalcasting #stainlesssteelcasting #alloycasting #carbonsteelcasting

2 notes

·

View notes

Photo

forged blank hot treatment,welcome you visit our factory #stainlesssteelthreadedfittings #stainlesssteelfittings #stainlesssteelforged #stainlesssteelcasting #stainlesssteelballvavles #stainlesssteelbsptnptthreaded #304316threadedfittings #investmentcastingfittings wechat/whatsapp:+8613383373010 https://www.instagram.com/p/B-vpgHuDbx6/?igshid=2ohxqv3jp7w7

#stainlesssteelthreadedfittings#stainlesssteelfittings#stainlesssteelforged#stainlesssteelcasting#stainlesssteelballvavles#stainlesssteelbsptnptthreaded#304316threadedfittings#investmentcastingfittings

0 notes

Text

Steel Casting Manufacturers in India

Fortune Foundries Pvt Ltd is one of the reliable Steel Casting Manufacturers in India. We are manufacturer, supplier and exporter of steel casting, stainless steel casting, Duplex Steel Casting, Super Duplex Steel Casting, Alloy Steel Casting. We provide end to end solutions from patterns to machined steel casting parts.

https://www.fortunefoundries.com/steel-casting-manufacturers-india-duplex-steel-casting.php

#fortunefoundries#steelcastingmanufacturers#steelcastingsuppliers#steelcastingexporter#stainlesssteelcastings#stainlesssteelcastingsuppliers#stainlesssteelcastingexporter

0 notes

Text

Stainless Steel Casting in Automotive Manufacturing: Enhancing Performance and Safety

In the production of automobiles, stainless steel casting is crucial, greatly boosting both performance and safety. Control links are one of the crucial parts created by stainless steel casting.

1. Durability and Strength:

Sand casting, in particular, provides unmatched strength and durability for stainless steel. The strength of stainless steel benefits control linkages, which are in charge of conveying motion and force in various vehicle systems. They are capable of withstanding the harsh circumstances seen in the vehicle environment, such as collisions and vibrations.

2. Corrosion Resistance:

Corrosion is a major worry since automotive components are frequently exposed to moisture and salt from the road. Because stainless steel is naturally resistant to corrosion, control linkages are kept free of rust and wear, extending the life of the car.

3. Precision Engineering:

Control links can have complex and accurate designs thanks to sand casting. Vehicle performance and safety depend heavily on this accuracy because even little variations can have an impact on the steering, suspension, and braking systems.

4. Weight Reduction:

To increase fuel efficiency and lower emissions, weight reduction is a major concern in contemporary car design. Casting in stainless steel makes it possible to produce control linkages that are both light and durable, which helps reduce the overall weight of the vehicle.

5. Vibration Dampening:

Stainless steel control linkages have better vibration dampening capabilities. This is essential for a smooth, comfortable ride since it prevents the driver and passengers from being overly affected by excessive road vibrations.

6. Safety Enhancement:

The robustness and dependability of the control linkages directly affect the safety of the vehicle. They affect stability and responsiveness as essential parts of the steering and suspension systems. Control linkages comply with strict safety regulations thanks to high-quality stainless steel casting.

7. Customization and Adaptability:

Control links can be modified via sand casting to satisfy unique vehicle needs. Control link designs can be modified by manufacturers to meet different vehicle types and sizes, assuring compatibility and top performance.

8. Cost-Effective Solutions:

Stainless steel casting not only offers great quality, but it also offers affordable alternatives for automakers. Control links' robustness and lengthy lifespan cut down on maintenance and replacement expenses.

9. Environmental Considerations:

Given the increased emphasis on sustainability in the automotive sector, stainless steel is a recyclable material. For control linkages and other automobile components, stainless steel casting is an environmentally favorable option because it can be recycled.

Conclusion

Particularly important in the production of control linkages for automobiles, stainless steel casting is a type of sand casting. It is the perfect option for crucial automotive components due to its durability, corrosion resistance, precision engineering, weight reduction, and safety benefits. The benefits of stainless steel casting not only improve vehicle performance but also increase the dependability and safety of moving vehicles. Stainless steel casting is a cornerstone of innovation and development in the industry as automotive technology develops further.

0 notes

Text

#vastcasting#stainlesscasting#precisioncasting#lostwaxcasting#industrialparts#valveparts#pump#bottleopener#beeropener#stainlesssteelcasting#castings#oemcasting#fishfork#harpoon#fluidcontrol#foundry#buildinghardware#flatware#candleholder#oildrillingtool#meatgrinderparts#wheel

0 notes

Link

Stainless steel casting by design

0 notes

Text

#vastcasting#stainlesscasting#precisioncasting#lostwaxcasting#industrialparts#valveparts#pump#bottleopener#beeropener#stainlesssteelcasting#castings#oemcasting#fishfork#harpoon#fluidcontrol#foundry#buildinghardware#flatware#candleholder#oildrillingtool#meatgrinderparts#wheel

0 notes

Text

#vastcasting#stainlesscasting#precisioncasting#lostwaxcasting#industrialparts#valveparts#pump#bottleopener#beeropener#stainlesssteelcasting#castings#oemcasting#fishfork#harpoon#fluidcontrol#foundry#buildinghardware#flatware#candleholder#oildrillingtool#meatgrinderparts#wheel

0 notes

Text

#vastcasting#stainlesscasting#precisioncasting#lostwaxcasting#industrialparts#valveparts#pump#bottleopener#beeropener#stainlesssteelcasting#castings#oemcasting#fishfork#harpoon#fluidcontrol#foundry#buildinghardware#flatware#candleholder#oildrillingtool#meatgrinderparts#wheel

0 notes

Text

#vastcasting#stainlesscasting#precisioncasting#lostwaxcasting#industrialparts#valveparts#pump#bottleopener#beeropener#stainlesssteelcasting#castings#oemcasting#fishfork#harpoon#fluidcontrol#foundry#buildinghardware#flatware#candleholder#oildrillingtool#meatgrinderparts#wheel

0 notes

Text

#vastcasting#stainlesscasting#precisioncasting#lostwaxcasting#industrialparts#valveparts#pump#bottleopener#beeropener#stainlesssteelcasting#castings#oemcasting#fishfork#harpoon#fluidcontrol#foundry#buildinghardware#flatware#candleholder#oildrillingtool

0 notes