#stationary Concrete batching plants

Text

30 m3/hr Stationary Concrete Plant Installed in Aurangabad

See photos of 30 m3/hr stationary concrete plant. Atlas is an Indian manufacturer and exporter of road construction machinery. Buy 60 tph concrete batch plants.

0 notes

Text

Stationary concrete ready mix plant installation - Atlas Technologies

Installation video of Atlas stationary ready mix concrete batch mix plant.This plant is of 120 m3/hr. capacity and is with a 4500 / 3000 capacity mixing unit.

0 notes

Text

Trailer Mounted Concrete Batching Plant VS Stationary Batching Plant

Ready-mixed concrete plays a very important role in many industries as the basic material of buildings and structures. The concrete mixing plant produces ready-mixed concrete by mixing materials such as sand, gravel, cement and water in a certain proportion, and going through certain procedures. For this process, many machines and devices with different tasks need to work together in a…

View On WordPress

0 notes

Text

60 m3 Stationary Concrete Plant Near Mumbai - Atlas Equipments

Buy small concrete mixers for civil construction jobs.60 m3 stationary batching plant near Mumbai. Atlas is an Indian exporter of concrete mix plant.

0 notes

Text

youtube

ZAP-S160 Professional Stationary Asphalt Batch Mix Plant Project Starts Production

ZAP-S160 asphalt batch mixing plant combines with various advantages of western models and adopts modular design, which has compact structure, simple assembly and transport. Components of stationary asphalt mix plant adopt international famous brand, keep pace with the international advanced technology, which can guarantee high reliability and security of the equipment in long operating terms.

Besides, the stationary stype asphalt plant machine has strict trial assembly and test every equipment before delivery, so that guarantee stable quality and high standard of our equipment. Our asphalt batching mixing plant equipment also adopts human-computer interface and PLC control system and perfect human-machine exchange function for easy operating with manual, semi-auto, automatic control function; with remote fault detect and maintenance function,those can solve the problem the first time.

Excellent expansibility of ZAP-S160 asphalt batch mixing plant can be realized by adding RAP, wood fiber adding equipment etc, so that it can satisfy more requirements. Low consumption, high efficiency and environment friendly design is the ideal choice of different kinds of road construction asphalt mixing machines.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#concrete#asphalt plant#heavy equipment#asphaltplant#mobile asphalt drum mix plant#construction#asphalt mix plant#stationary asphalt mixing plant#stationary asphalt mixing plants#stationary asphalt plant#asphalt batch mix plant#asphalt batching mixing plant#asphalt batching plant#Youtube

1 note

·

View note

Text

What is a concrete batch plant? - Atlas Industries

Concrete plant is also known as stationary batching plant or batch plant. Main component of any concrete plant is the mixing unit which combines all the items together for mixing.

0 notes

Photo

Stationary Concrete Batch Plant Installed in Mumbai – Atlas

60 m3 stationary batching plant near Mumbai. Atlas is an Indian exporter of concrete mix plant. Buy small concrete mixers for civil construction jobs. We have stationary RMC plant installations in countries like Nigeria, Angola, Philippines, Bhutan, Cameroon, Myanmar and Israel.

0 notes

Text

10 Must Know Facts Before You Buy A Concrete Plant

10 Must-Know Facts Before You Buy A Concrete Plant

Many people who manage construction work take the concrete batching plant on lease and use them until they do not finish their work. However, it proves to be quite costly as you will have to pay every time you use it, compared to those who have their own concrete plant.

Buying a plant over leasing from a concrete batching plant manufacturer in India is indeed a good choice if you are engaged in construction work regularly, as leasing can prove to be expensive for the same. However, buying a Portable concrete batching plant in India should not be done without any research. In this section, we have quoted some facts that you should know before buying a concrete plant. Let's have a look at them.

10 Facts That You Should Be Aware Of Before Buying A Concrete Plant

Fix Your Budget: Concrete batching plants are available at different price ranges. You must fix a budget according to the size of your construction business and the kind of construction work you get.

Type: Another important thing that you need to know is whether you want a mobile concrete plant or a stationary. Well, you can easily buy plants for Stationary concrete batching in India from Mobile concrete batching plant manufacturers as they offer a variety of concrete plants.

Size and Capacity: Choose a suitable concrete batching plant as per the size and capacity you are going to need. If you want a small concrete plant, then look for Compact concrete batching plant manufacturers.

Control Panel: Look for a concrete plant with easy handling so that laborers can work on it. There are multiple concrete batching plants with complex control panels, which are quite difficult to use.

After-Sales Service: After-sales service is a very important aspect to check for in a concrete plant manufacturer so that your issue can get rapidly resolved if any problem arises at the work site. Make sure your providers offer good after-sales service.

Equipment: Check all the essential equipment needed for concrete mixing before buying the concrete mixing plant to see whether they all are functioning properly or not.

Automatic: You can buy an automatic or a manual portable concrete batching plant in India according to your requirements. Choosing automatic or semi-automatic plants will be a good pick to reduce the effort and number of the human workforce at the site.

Dry or Wet Batching Plant: Another difference that you need to consider is whether the batching plant is for the dry or wet concrete mixture. Dry batching plants are more efficient compared to other types. You can get a plant that can work for wet as well as dry batching.

Power Consumption: Different concrete plants offer different power consumption. Make sure the plant you are going to buy is power efficient.

Reputed Seller: There are multiple concrete batching plant manufacturers in India, but you can not buy from any random seller. Do some research, and then choose the trusted and popular seller to expect good service.

Gather the right knowledge and make the right choice to enjoy the considerable benefits of buying a concrete plant.

2 notes

·

View notes

Text

Exploring Mobile vs. Inline Concrete Batching Plants: A Comprehensive Guide

Exploring Mobile vs. Inline Concrete Batching Plants: A Comprehensive Guide

In the dynamic world of construction, the selection of a concrete batching plant can greatly influence the efficiency and success of a project. Mobile Concrete Batching Plants and Inline Concrete Batching Plants represent two fundamentally different approaches, each catering to specific project needs. Here's an in-depth comparison to clarify their roles and benefits, enabling professionals to make informed choices tailored to their project demands.

Mobile Concrete Batching Plants: The Epitome of Mobility and Flexibility

Mobility and Operational Flexibility Mobile concrete batching plants are engineered for ease of transport and rapid relocation. This makes them the go-to choice for projects that require movement between various sites, such as highway construction or developments in remote locations. Their key advantage lies in their ability to swiftly adapt to changing project landscapes, offering unmatched flexibility for operations with shifting timelines or locations.

Efficient Setup and Dismantling Designed for quick assembly, mobile plants typically come pre-wired and mostly assembled. This design minimizes setup times and does not necessitate elaborate groundworks or foundations, which are both costly and time-intensive. This feature is particularly advantageous for projects with stringent deadlines or temporary site use.

Cost Efficiency For projects with a limited duration or those spread across multiple sites, mobile batching plants machines are a cost-effective solution. They significantly cut down the costs associated with transporting concrete from a stationary plant to various construction sites, thereby optimizing budget allocations.

Production Capacity Although mobile batching plant excel in efficiency, their output capacity is generally lower compared to their inline counterparts. They are ideal for smaller-scale projects or in scenarios where concrete demand fluctuates.

Operational Limitations Due to their compact size, mobile plants often have limited storage for aggregates and raw materials. This constraint may affect the diversity of concrete types that can be produced, potentially requiring more frequent resupply.

Inline Concrete Batching Plants: Optimized for High Volume Production

Superior Production Capability concrete batching plants are designed for permanent installation and are well-suited for large-scale industrial and commercial projects. These plants boast a high production capacity, capable of meeting continuous, substantial demands for concrete, thus facilitating large-volume output without interruptions.

Complex Setup Requirements Setting up an inline batching plan is a more involved process. It requires extensive site preparation, including the construction of durable foundations and infrastructure. This setup demands more significant initial investments and extended preparation time but results in a more stable and robust operation.

Expanded Material Storage With a larger footprint, inline batching plants offer considerable storage capacities for materials. This capacity allows for a wide variety of concrete mixes to be produced more efficiently and decreases the need for frequent restocking. Facilities typically include large cement silos, multiple bins for aggregates, and sophisticated systems for managing admixtures and other components.

Durability and Longevity Constructed for permanent operation, mini batching plants are robust and durable. They are designed to withstand prolonged usage, making them ideal for extensive projects that span several years.

Reduced Flexibility The primary drawback of inline batching plants is their immobility. Once installed, these plants cannot be easily relocated, which may pose challenges for firms undertaking projects at multiple or shifting locations.

Conclusion: Making the Right Choice

Deciding between a mobile and an inline concrete batching plant largely hinges on specific project criteria such as scope, duration, and site location. Mobile plants are preferred for their flexibility and cost-effectiveness in projects with dynamic requirements across multiple or temporary sites. Conversely, inline plants are more suitable for prolonged, large-scale projects where the higher initial investment can be amortized over time through efficient, high-volume production.

0 notes

Text

Semi Mobile Batching Plant

Semi mobile batching plant is a special type of concrete production equipment that combines the flexibility of a mobile batching plant with the stability of a stationary batching plant. The design of this type of concrete batching plant allows it to be moved or repositioned to a certain extent to suit the needs of different sites or projects, while maintaining a certain degree of stability and productivity.

Regarding the models of semi-mobile concrete batching plants, it depends on the design and specifications of different concrete batching plant manufacturers. Therefore, the specific model may vary from manufacturer to manufacturer, in Haomei Machinery, the mixing capacity of a set of semi mobile batching plant is 25-90 m3/h.

The advantages of semi-mobile concrete batching plant are mainly reflected in the following aspects:

Flexibility: Compared with fixed batching plant, semi-mobile batching plant has higher flexibility, which can be moved or repositioned according to the project requirements and adapt to the changes of different sites.

Stability: Compared with the fully mobile concrete batching plant, the semi-mobile concrete batching plant is better in terms of stability, and can withstand the impact of wind and rain and other bad weather to a certain extent, to ensure the continuity of production.

Production efficiency: Semi-mobile batching plants usually have high production capacity, which can meet the concrete demand of medium and large-scale projects, and guarantee the quality of concrete at the same time.

Semi-mobile concrete batching plant is usually suitable for projects in the following occasions:

Medium and large-scale construction projects: such as large residential areas, commercial complexes, etc. These projects require a large amount of concrete and have a long construction period, which is suitable for using semi-mobile mixing plant for production.

Infrastructure construction projects: such as highways, railroads, bridges, etc. These projects often require concrete construction in different locations, and the flexibility of semi-mobile batching plant can well meet this demand.

Temporary or short-term projects: For some temporary or short-term projects, such as disaster relief and temporary facilities construction, semi-mobile concrete batching plant can be quickly deployed and put into production to meet the emergency demand.

Overall, semi mobile batching plant is a kind of concrete production equipment applicable to many occasions, with the advantages of flexibility, stability and high efficiency, which can meet the needs of different projects.

0 notes

Text

Benefits & Types of Concrete Batching Plants for Builders

In the realm of construction, efficiency, precision, and reliability are paramount. Concrete batching plants play a pivotal role in ensuring these factors are met, contributing significantly to the success of construction projects. This blog delves into the benefits and various types of concrete batching plants, shedding light on how builders can leverage these essential tools for optimal results.

Benefits of Concrete Batching Plants:

Precision in Mixing: Concrete batching plants are engineered to precisely mix the right proportions of aggregates, cement, water, and additives, ensuring a consistent and high-quality concrete mix. This precision minimizes wastage and guarantees the strength and durability of the final product.

Increased Efficiency: These plants are designed for continuous operation, enabling a seamless workflow. Builders can achieve a higher production rate, meet project deadlines more efficiently, and handle larger volumes of concrete with ease.

Cost Efficiency: By minimizing material wastage, optimizing resource utilization, and streamlining the production process, concrete batching plants contribute to cost efficiency. The initial investment is often outweighed by long-term savings in material and labor costs.

Consistency in Quality: The automation and computerized control systems of modern batching plants ensure consistent mixing and quality control. This results in uniform concrete characteristics, reducing the risk of defects or structural issues in the finished construction.

Versatility: Concrete batching plants come in various types and configurations, making them adaptable to different project requirements. Whether it’s a small residential project or a large-scale infrastructure development, there’s a batching plant suited to the task.

Types of Concrete Batching Plants:

Stationary Concrete Batching Plants: Ideal for large construction projects, stationary plants are set up at a fixed location. They offer high production capacities and are equipped with advanced features for precision mixing and control.

Mobile Concrete Batching Plants: Designed for projects requiring flexibility and mobility, mobile batching plants can be easily transported to different sites. They are compact, user-friendly, and suitable for smaller construction projects.

Transit Mixers: Also known as truck mixers, transit mixers transport pre-mixed concrete from the batching plant to the construction site. They provide flexibility in terms of delivery and are suitable for projects with tight schedules.

Central Mix Plants: Central mix plants combine all ingredients, including water, at a central location before the concrete is transported to the construction site. This process ensures thorough mixing and consistent quality.

Dry Mix Concrete Batching Plants: In these plants, all the ingredients, except water, are combined and mixed at a central point. Water is added at the construction site. Dry mix plants are known for their simplicity and ease of installation.

Conclusion:

Concrete batching plants are indispensable tools for modern builders, offering a plethora of benefits ranging from increased efficiency and cost savings to consistent quality and adaptability. By understanding the different types of batching plants available, builders can select the most suitable option for their specific project needs, ultimately contributing to the success and longevity of construction endeavors.

#Batching Plants#benefits of Concrete Batching plants#concrete batching plant#concrete batching plants#mobile concrete batching plants#stationary Concrete batching plants#types of concrete batching plants

0 notes

Text

A Simple Analysis of Concrete Batching Plant Price

In the world of construction, efficiency and cost-effectiveness are paramount. Concrete batching plants play a pivotal role in ensuring seamless operations and high-quality output. However, understanding the cost breakdown of different types of batching plants is crucial for informed decision-making. Let’s delve into the intricacies of this essential aspect.

Types of Concrete Batching Plants

1. Stationary Concrete Batching Plants: These plants are characterized by their fixed structure and are ideal for large-scale construction projects. The cost breakdown includes expenses related to land acquisition, initial setup, and maintenance.

2. Mobile Concrete Batching Plants: Offering unparalleled flexibility, mobile plants are suitable for projects requiring frequent relocation. Their cost breakdown typically comprises transportation expenses, installation costs, and ongoing maintenance.

3. Compact Concrete Batching Plants: Designed for small to medium-scale projects, compact plants combine efficiency with space-saving features. The cost breakdown involves factors such as equipment purchase, site preparation, and operational expenses.

Factors Influencing Costs

1. Capacity: The production capacity of a batching plant significantly impacts its cost. Higher capacity plants entail greater initial investment but offer economies of scale in the long run.

2. Technology and Features: Advanced technologies and additional features like automation, computerized control systems, and environmental protection measures contribute to the overall cost.

3. Maintenance and Operating Costs: Regular maintenance, spare parts availability, and energy consumption are ongoing expenses that need to be factored into the cost analysis.

Optimizing Cost Efficiency

1. Comparative Analysis: Conducting a comprehensive comparison of different types and models of batching plants helps in identifying the most cost-effective option tailored to specific project requirements.

2. Lifecycle Cost Assessment: Considering the lifecycle cost, including initial investment, operational expenses, and potential resale value, provides a holistic view of the financial implications.

3. Supplier Evaluation: Choosing a reputable supplier with a track record of delivering quality equipment and reliable after-sales support is crucial for minimizing unforeseen costs and ensuring long-term efficiency.

Understanding the cost breakdown of concrete batching plants empowers construction professionals to make informed decisions, maximize productivity, and optimize resource utilization. To explore further insights into enhancing construction efficiency and reducing costs, delve into our comprehensive guide. Read more for a deeper understanding.

0 notes

Text

The Rise of Concrete Pumping Services and Volumetric Concrete Suppliers

Two innovations that have significantly transformed the building landscape are volumetric concrete suppliers and concrete pumping services. Both technologies offer unique benefits and have revolutionized how concrete is prepared, delivered, and used in construction projects.

Volumetric concrete from Volumetric concrete suppliers near me involves the use of mobile concrete batching plants, known as volumetric concrete mixers. These units are effectively mobile factories that carry all the necessary ingredients for concrete—cement, water, sand, and aggregates—and mix them on-site. This approach provides a stark contrast to traditional methods where concrete is mixed at a central batching plant and transported in a drum mixer.

Benefits of Volumetric Concrete

Fresh Concrete on Demand

Volumetric mixers produce concrete on-site, ensuring the mixture is fresh and has not begun to cure or set during transportation. This leads to stronger, more durable concrete.

Customization and Flexibility

Since the concrete from Readymix concrete supplier near me is mixed on the spot, adjustments can be made to the mix design according to specific project needs without waste or additional costs.

Increased Efficiency

The ability to produce concrete by Readymix concrete supplier near me on demand means no delays due to under ordering or waiting for additional deliveries. Projects can proceed faster and more smoothly.

The Role of Concrete Pumping Services

Concrete pumping is a method used to transport freshly mixed concrete to specific locations on a construction site, unreachable by conventional means. Concrete pumps come in various types including boom pumps, line pumps, and stationary pumps, each serving different purposes.

Advantages of Concrete Pumping

Access Hard-to-Reach Areas

Concrete pumping services can deliver concrete to high-rise locations or sites with limited access without compromising the quality or workability of the concrete.

Speed and Efficiency

Pumping concrete is much faster than traditional methods of transportation and placement. This reduces labor costs and accelerates the construction timeline.

Reduced Labor Intensity

Manual labor for concrete placement is significantly reduced, minimizing human error and fatigue, and enhancing safety on the job site.

Consistent Quality

Concrete pumps deliver a steady flow of concrete, which can be critical for certain applications like laying foundations, ensuring a uniform and consistent finish.

Combining Volumetric Mixers with Concrete Pumps: A Construction Game-Changer

Integrating volumetric concrete delivery by Volumetric concrete suppliers near me with pumping services streamlines the construction process even further. Concrete can be mixed precisely to specifications and then pumped immediately to where it's needed. This synergy not only improves logistical efficiency but also enhances the overall integrity and quality of the structure.

#readymix concrete supplier near me#concrete pumping services#volumetric concrete suppliers near me#concrete suppliers near me

0 notes

Text

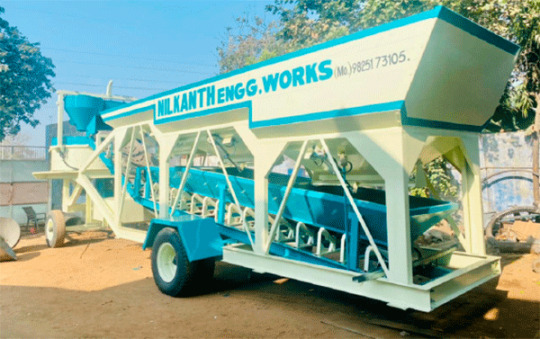

MOBILE CONCRETE BATCHING PLANT

Fully Automatic Stationary Concrete Batching & Mixing Plant.

Available in 75/90/120 Cu.M. Per Hour Capacity.

Reversible Non Tilting Heavy Drum Mixer

Inline Bins.

Hardened Steel Ring Gear, Twin Rollers Guide & Pinion

Easy & fast installation, commissioning & erection.

Flexible in adopting to different design mix.

Dual/Double conveyor Belts reduces cycle time and helps in achieving maximum output.

Tyres & tow bar provides mobility to the plant.

Built on single Frame Structure/Chasis.

High accuracy weighing system.

Less Foundation required.

Consistent & uniform mixing.

Plant only require power supply.

Plant only require power supply.

Easily movable.

0 notes

Text

60 m3 Stationary Concrete Plant Near Mumbai - Atlas Equipments

Buy small concrete mixers for civil construction jobs.60 m3 stationary batching plant near Mumbai. Atlas is an Indian exporter of concrete mix plant.

0 notes

Text

stationary concrete batch mixing plant, India - Atlas Technologies

See video of Atlas make 60 m3/hr. stationary concrete plant installed in Mumbai, India. It is a very rugged design machine suitable for rough applications.

0 notes