#warning tape for underground cable exporters in India

Text

The Importance of Quality Control in Underground Warning Mesh

Underground warning mesh plays a pivotal role in ensuring the safety of underground utilities like pipelines and cables. These warning systems are designed to provide a visual indicator to prevent accidental damage during excavation or construction activities. However, the effectiveness of these warning systems largely depends on their quality. This article delves into the importance of quality control in underground warning mesh and highlights the contributions of leading Warning mat in pipeline manufacturers in Ahmedabad and warning tape for underground cable exporters in India.

The Role of Underground Warning Mesh

Before diving into the significance of quality control, it's essential to understand the role of underground warning mesh. These warning systems are typically made of durable materials like high-density polyethylene (HDPE) and are designed to withstand varying environmental conditions. They serve as a protective barrier, alerting excavation crews and construction workers to the presence of buried utilities. This early warning helps prevent accidental strikes, which can lead to costly repairs, service disruptions, and even safety hazards.

Quality Control: A Critical Aspect

Quality control is a critical aspect of manufacturing underground warning mesh. Ensuring that these warning systems meet the required standards is essential for their effectiveness and reliability. Poor-quality warning mesh can lead to false alarms, premature degradation, and ultimately, failure to provide adequate protection.

Importance for Warning Mat in Pipeline Manufacturers in Ahmedabad

Ahmedabad is a hub for manufacturing high-quality warning mats for pipelines. These manufacturers play a crucial role in supplying robust and durable warning systems that meet industry standards. Quality control measures, such as rigorous testing and inspection, are implemented to ensure that the warning mats are capable of withstanding the demands of underground environments.

In India, the demand for warning tape for underground cables is on the rise. Warning tape for underground cable exporters in Ahmedabad are at the forefront of meeting this demand by supplying top-notch warning tapes that adhere to international quality standards. Quality control practices, including material testing and quality assurance, are integral to ensuring the reliability and longevity of these warning tapes.

Conclusion

Quality control plays a pivotal role in ensuring the effectiveness and reliability of underground warning mesh. Whether it's warning mat in pipeline manufacturers in Ahmedabad or Warning tape for underground cable exporters in India, adhering to stringent quality control measures is essential for delivering reliable warning systems. By prioritizing quality, manufacturers and exporters can contribute to safer excavation and construction practices, ultimately protecting underground utilities and preventing costly and potentially dangerous accidents.

Frequently Asked Questions

What are the key factors to consider when choosing underground warning mesh?

When choosing underground warning mesh, it's crucial to consider factors such as material durability, visibility, and compliance with industry standards. High-quality warning mesh should be made of durable materials like HDPE and should be highly visible to ensure effective warning.

How often should underground warning mesh be inspected?

Regular inspections are essential to ensure the ongoing effectiveness of underground warning mesh. It's recommended to inspect these warning systems at least once a year or after any significant excavation or construction activity.

What are the consequences of using poor-quality warning mesh?

Using poor-quality warning mesh can lead to false alarms, premature degradation, and failure to provide adequate protection. This can result in costly repairs, service disruptions, and safety hazards.

How do warning mat manufacturers in Ahmedabad ensure quality?

Warning mat manufacturers in Ahmedabad employ rigorous quality control measures, including material testing, production inspections, and compliance with industry standards, to ensure the quality and reliability of their products.

What sets warning tape for underground cable exporters in Ahmedabad apart?

Warning tape exporters in Ahmedabad prioritize quality and reliability by adhering to international standards and implementing robust quality control practices. Their commitment to excellence ensures that their warning tapes provide reliable protection for underground cables.

#warning mat in pipeline manufacturers in Ahmedabad#warning tape for underground cable exporters in India#warning tape for underground cable exporters in Ahmedabad

0 notes

Text

#geogrid fabric exporters in Ahmedabad#underground cable warning tape manufacturers in Gujarat#underground warning tape manufacturers in India#UNDERGROUND WARNING MESH

0 notes

Text

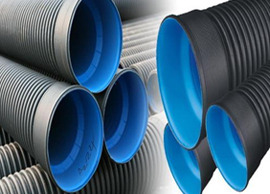

HDPE Corrugated Pipes for Cable Protection & Sewer Drainage Systems

Jagannath Industries is a renowned corrugated pipe manufacturer, exporter and supplier company in India offering a wide range of HDPE pipes including single wall corrugated and double wall corrugated pipes for cable protection, sewer drainage and structural post-tensioning applications. Apart from being a well-established corrugated pipe exporter, Jagannath Industries is also into manufacture of duct accessories like pipe couplers, push fit coupler, end plug, end cap and duct cable sealing plug, warning tape, luminaire and street light pole, electrical panel, safety helmets, safety shoes, safety cones and safety jackets in India. We can supply the finest range of high density polyethylene pipe polymers in various sizes according to the needs of our customers.

Whether it is for underground installation in drainage system or for above the ground electrical fitting requirements, durable pipes are required which are easy to install and as well can show excellent resistance to corrosion and toxic chemicals. Previously, the galvanized metal and cast iron ducts and pipes were used in city wire distribution networks and drainage systems. However, these CI and GI systems did not show the best resistance to corrosion and were usually bit hard to install. Hence, the HDPE sheathing duct systems came into play. The HDPE corrugated pipes offer the best air and water tightness properties and are the best replacement for conventional galvanized metal ducts or pipes. They are the best ducts offering additional advantages over conventional prestressing properties of the galvanized iron pipes.

Here are a few types of HDPE pipes offered by us for the best protective casing and sewer system applications.

Corrugated HDPE Pipe

HDPE corrugated pipes are the most flexible, long lasting and sturdy pipes made from polyethylene, a tough material that can withstand high chemical and environmental stress. These pipes are usually lighter in weight and easier to install due to their flexible structure. They are known for their high strength and best resistance to shocks and extreme pressures.

There are mainly two categories of corrugated HDPE pipes which we offer, the regular single wall corrugated pipe and the extra robust one called the double wall corrugated pipe. While the single wall HDPE corrugated sheathing duct pipe is the best replacement for metallic galvanised ducts, our DWC pipes are tough, extra layered pipes that come with extra rib strength that allows them to take heavy loads and pressures. These pipes are chemically inert, highly stiff yet flexible enough to take bends and curves easily. They are built to be environment friendly and are easy to handle and install with least weight and easy joining abilities. Our HDPE DWC pipe is manufactured according to the set industry standards and makes up for the best water transport pipe to be used in drainage systems, sewer lines and residential pipeline connections, treatment plants, and irrigation and industrial applications.

HDPE Corrugated Perforated Pipe

HDPE corrugated pipe is the best for the drainage and sewer systems. These are the high strength corrugated pipes that show excellent physical and chemical properties that are most suitable for the liquid as well as solid waste transportation. One of the main strengths of our HDPE perforated pipes is that they are heat resistive and come with extraordinary leak proof abilities. With maximum compressive strength, corrosion and frictional resistance, this is the best pipe for the underground installations.

HDPE Sewer Pipe

HDPE corrugated sewer pipe is a highly flexible and sturdy pipe that comes with unique ability to support and distribute live and dead loads. They are made out of high-density polyethylene and hence offer excellent chemical inertness and significant long-term advantage over conventional sewer pipes. With a unique flexible design, these pipes have maximum load bearing strength and come with a maximum service life that can extend up to 50 or more than 50 years. Our corrugated drain pipes can perform the best in both high cover and low cover applications and come in a environment friendly design with no leaks or cracks. They are available in longer lengths and hence, make up for easy, fast and cost effective drainage system installations.

0 notes