Text

NOX Scrubber Manufacturer & Supplier in India

A NOx scrubber is a device used to remove nitrogen oxides (NOx) from industrial emissions. NOx is a harmful air pollutant that is produced by combustion processes in industries such as power plants, refineries, and chemical plants.

NOx scrubbers work by converting NOx into less harmful compounds, such as nitrogen and water vapor, through a chemical reaction. This process is called selective catalytic reduction (SCR) and typically involves the use of a catalyst, such as vanadium oxide, to facilitate the reaction.

NOx scrubbers are an important technology for reducing air pollution and improving air quality. They are commonly used in large industrial facilities, particularly those that burn fossil fuels, to comply with environmental regulations and reduce their environmental impact.

In addition to reducing NOx emissions, NOx scrubbers can also help reduce other harmful pollutants, such as particulate matter and sulfur dioxide, from industrial emissions. However, NOx scrubbers can be expensive to install and maintain, which can be a barrier to their widespread adoption.

#NOX Scrubber#NOX Scrubber Manufacturer#NOX Scrubber Manufacturer in india#NOX Scrubber Manufacturer & Supplier

0 notes

Text

SOX Scrubber Manufacturer & Supplier in Gujarat, India

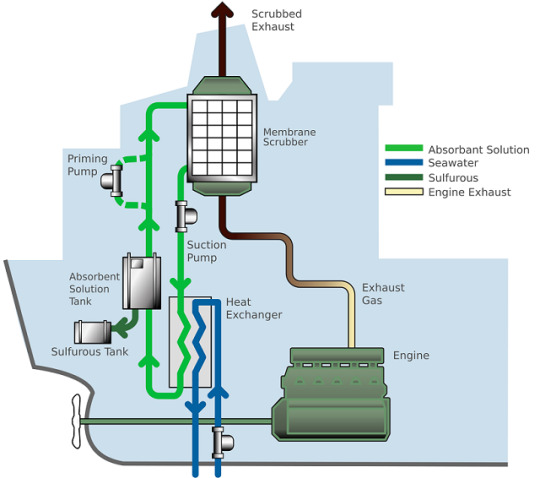

SOX scrubber is a term used to describe a technology or process that is designed to remove sulfur oxides (SOx) from industrial emissions, particularly those produced by burning fossil fuels such as coal or oil. SOx scrubbers are also known as flue gas desulfurization (FGD) systems.

Sulfur oxides are a major contributor to air pollution and can have harmful effects on human health, wildlife, and ecosystems. SOx scrubbers work by removing these harmful pollutants from the emissions before they are released into the atmosphere. There are several different kinds of SOx scrubbers, including wet, dry, and hybrid scrubbers.

Although dry scrubbers utilise a solid sorbent material to catch the pollutants, wet scrubbers employ a liquid, usually water, to capture and remove the sulphur oxides from the emissions. To maximise the removal of SOx, hybrid scrubbers use both wet and dry scrubbing techniques. In industrial environments, such as power plants, refineries, and other production facilities, SOx scrubbers are frequently utilised. They are regarded as a crucial technological advancement for lowering air pollution and raising air quality.

#SOX Scrubber#SOX Scrubber Manufacturer#SOX Scrubber Manufacturer in india#SOX Scrubber Manufacturer in gujarat

0 notes

Text

H2S Scrubber System | Manufacturer & Supplier in | Gujarat, India

Airpoll Technologies Manufacturer & Supplier Of H2S Scrubber in Gujarat, India

An H2S scrubber system is a type of equipment used to remove hydrogen sulfide (H2S) from gas streams, typically in industrial or commercial settings. H2S is a toxic and flammable gas that can be produced during a variety of industrial processes, including oil and gas production, refining, wastewater treatment, and chemical manufacturing. The scrubber system typically consists of a vessel filled with a chemical solution that reacts with the H2S gas to neutralize it. The most common chemical used in H2S scrubbers is sodium hydroxide (NaOH), which reacts with H2S to produce water and sodium sulfide (Na2S). The gas stream containing H2S is passed through the scrubber vessel, where it comes into contact with the chemical solution.

The H2S reacts with the NaOH, and the resulting sodium sulfide solution is collected and disposed of or recycled, depending on the specific application. H2S scrubber systems are often used as a safety measure to protect workers and equipment from the harmful effects of H2S gas. They can also be used to comply with environmental regulations that limit the amount of H2S that can be released into the atmosphere.

#H2S Scrubber#H2S Scrubber System#H2S Scrubber System Manufacturer in gujarat#H2S Scrubber System Manufacturer in india#H2S Scrubber System Supplier in gujarat

0 notes

Text

WET Electrostatic Precipitators Manufacturer & Supplier in Gujarat, India

Airpoll Technologies Manufacturer & Supplier Of WET Electrostatic Precipitators in Gujarar, India

Air streams with a relative humidity of 100% are used to power wet electrostatic precipitators (also known as wet ESPs or WESPs). WESPs are often used in industrial process gas streams to remove liquid droplets, such as sulfuric acid mist. Additionally, the WESP is typically used when the gases contain high levels of moisture, combustible particles, or sticky-type particles.

A device for lowering air pollution that is used to remove solid particles from contaminated air streams is called an electrostatic precipitator. When contaminated air enters an ESP chamber, corona electrodes, also known as electron emission electrodes, ionise it. After being charged by the electron field, the charged suspended particles migrate to a collection plate. Rapping or rapping against the collection plates with rappers removes accumulated particle matter on a regular basis (mallets type hammers). When large particles fall to the ESP's base, hoppers catch them and store them there for later disposal.

Electrostatic precipitators are used to remove one micron or smaller particles from gas streams. This technique is also used by desalters to filter salt and silt from the crude oil feeds.

#WET Electrostatic Precipitators#WET Electrostatic Precipitators Manufacturer & Supplier#WET Electrostatic Precipitators Manufacturer in gujarat#WET Electrostatic Precipitators supplier in gujarat

0 notes

Text

Flue Gas Desulfurization Plant Manufacturer Supplier in Gujarat, India

Airpoll Technologies | Flue Gas Desulfurization (FGD) Plant | Manufacturer in Gujarat, India

What is flue gas desulfurization process?

Flue gas desulfurization, a procedure, removes sulphur compounds from the exhaust emissions of fossil-fueled power plants. To do this, absorbents are added, which can remove up to 95% of the sulphide from the flue gas.

How does Flue Gas Desulfurization Works ?

The basis of the FGD technology is the chemical reaction that happens when limestone and warm exhaust gases from a coal-fired boiler come into contact. With this reaction, In addition to converting the limestone into calcium sulphite, it also eliminates 92% of the sulphur dioxide in the flue gas. Actually, an absorber tower receives the flue gas by forcing it via the FGD ductwork after being forced into it by a booster fan from the boiler.

Because of our strict environmental regulations, E.ON does not use limestone from national parks. A mixture of limestone slurry inside the absorber tower then comes into touch with the gas. Slurry is sprayed from banks of nozzles positioned at the top of the tower.

Sulphur dioxide (SO2) present in the hot gas and the limestone slurry interact chemically when they come into contact. During this reaction, the limestone is changed into calcium sulphite, and SO2 is also removed from the flue gases. When compressed air is supplied, this calcium sulphite and limestone slurry sinks to the base of the absorber. The oxidation of compressed air changes calcium sulphite into calcium sulphate, which is frequently referred to as gypsum.

Email : [email protected]

Phone : +91-9712942756

#Flue Gas Desulfurization#Flue Gas Desulfurization plant#FGD Plant Manufacturer in gujarat#FGD Plant

0 notes

Text

Venturi Scrubber Manufacturer Supplier In Gujarat, India

Airpoll Technologies Supplier & Manufacturer of | Venturi Scrubber | in Gujarat, India

The head, which is the narrowest part of the venturi tube, the diffuser, and the converging portion make up a venturi scrubber. In the area of the throat, the dust/gas mixture passes through the venturi tube most quickly. The speed is again decreased as the mixture moves into the diffuser after that. The gas flow is liquid-injected either before or during the throat segment. The gas and liquid are evenly distributed in the venture tube's throat region. Due to the high velocity that the gas and liquid can reach, water is expelled as tiny water droplets.

Venturi scrubbers can be used to remove tiny particles from a gas stream that are smaller than 1 mm in size. But it takes an extraordinarily large amount of energy to do that. They can handle bigger particles as well. Even at pressure decreases that are exceedingly large, some types of dust are unable to separate. To handle various flow volumes while maintaining a good yield, certain venturis include a throat section width that can be adjusted.

What is venturi scrubber ?

Particulate scrubbers, also known as venturi scrubbers, are air-control devices that are particularly effective at removing particulate matter (PM 2.5) emissions from industrial exhaust produced by both batch- and continuous-type process applications. Compared to filters and other dust-gathering tools, venturi scrubbers have a number of advantages. They have the ability to manage gas streams that are hot, humid, or include a lot of particles, which is an advantage. The fact that the equipment is often smaller overall is an additional benefit.

#venturi scrubber#venturi scrubber manufacturer supplier#venturi scrubber manufacturer in gujarat#venturi scrubber system manufacturer supplier in gujarat

0 notes

Text

Airpoll Technologies Supplier & Manufacturer of | Venturi Scrubber | in Gujarat, India

The head, which is the narrowest part of the venturi tube, the diffuser, and the converging portion make up a venturi scrubber. In the area of the throat, the dust/gas mixture passes through the venturi tube most quickly. The speed is again decreased as the mixture moves into the diffuser after that. The gas flow is liquid-injected either before or during the throat segment. The gas and liquid are evenly distributed in the venture tube's throat region. Due to the high velocity that the gas and liquid can reach, water is expelled as tiny water droplets.

Venturi scrubbers can be used to remove tiny particles from a gas stream that are smaller than 1 mm in size. But it takes an extraordinarily large amount of energy to do that. They can handle bigger particles as well. Even at pressure decreases that are exceedingly large, some types of dust are unable to separate. To handle various flow volumes while maintaining a good yield, certain venturis include a throat section width that can be adjusted.

#venturi scrubber#venturi scrubber manufacturer supplier#venturi scrubber manufacturer in gujarat#venturi scrubber system manufacturer supplier in gujarat

0 notes

Text

AirPoll Technologies is the leading pollution control and process Improvement Company

AirPoll Technologies has created the open environment that encourages the creation of high-quality products and services. Our staff takes great pleasure in delivering results in a way that is based on integrity and is differentiated by a total commitment and solutions provided to our clients. We are dependent on the diversity of our workforce for the growth and success of our business.

A rectangular or circular flow channel can be found on a venturi scrubber. This is set up to filter out fine particles from gas streams including challenging-to-handle solid items, toxic, flammable, or corrosive gas streams. The venturi throat receives water injection from a bank of nozzles on either side of the throat. Along the direction of the airflow, the water creates a curtain. The gas stream's high velocity atomizes the liquid added to it. In order to speed up the liquid droplets and boost liquid atomization, this is done. Because they use high pressure fans, these have a low performance efficiency. When there is a lot of dust present, they are used. Since they get constant moisture, they are resistant to clogging and plugging.

1 note

·

View note