Text

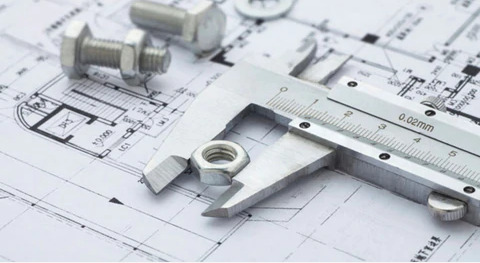

Fitting and use of bearings

Bearing fit

1. The choice of cooperation

The inner diameter and outer diameter of rolling bearings are manufactured according to standard tolerances. The tightness of the fit between the bearing inner ring and the shaft, the outer ring and the seat hole can only be achieved by controlling the tolerance of the journal and the tolerance of the seat hole. The matching between the inner ring of the bearing and the shaft adopts the base hole system, and the matching between the outer ring of the bearing and the seat hole adopts the base shaft system.

To select the fit correctly, it is necessary to know the actual load conditions, operating temperature and other requirements of the bearing, but it is actually very difficult. Therefore, in most cases, the selection is based on the use of fine grinding.

Second, the size of the load

The amount of overwind between the ferrule and the shaft or housing depends on the size of the load. For heavier loads, use a larger amount of overwind, and for lighter loads, use a smaller amount of overwind.

Precautions for use

Rolling bearings are precision parts, so it is required to be cautious when using them. Even if high-performance bearings are used, if they are used improperly, they cannot achieve the expected performance effects. Therefore, the use of bearings should pay attention to the following matters:

1. Keep the bearing and its surrounding environment clean. Even very small dust entering the bearing can increase bearing wear, vibration and noise.

2. Be careful and careful when installing, do not allow strong stamping, do not directly hit the bearing, and do not allow pressure to be transmitted through the rolling elements.

3. Use the correct installation tools, try to use special tools, and try to avoid the use of cloth and short fibers.

Fourth, to prevent the bearing from corroding and rusting, it is best not to hold the bearing directly by hand, but to apply high-quality mineral oil before operating it. In the rainy season and summer, special attention should be paid to rust prevention.

0 notes

Text

Designers need to know the design and collocation of outdoor patio tables and chairs leisure furniture

Today's busy urban life makes us always yearn for a leisurely natural pastoral life, and often lament that if we can have a small garden courtyard, then we will not deliberately pursue poetry and distance. If you want to enjoy outdoor leisure time at home, start with the design of outdoor patio tables and chairs leisure furniture!

There are many styles of courtyards large and small, different people like different styles, and different designers design different styles. However, most of the outdoor courtyards are mainly based on the integration of natural leisure, so how should the main outdoor leisure table and chair furniture in the outdoor courtyard be selected and matched? At present, no matter what the style of the outdoor patio courtyard is, most of the main outdoor leisure furniture is mainly selected with outdoor rattan furniture. Because the various colors and styles of outdoor rattan furniture can make outdoor leisure furniture better integrate into the patio garden environment.

Outdoor leisure rattan furniture is suitable for hot summer, because the rattan furniture itself is made of rattan material, weaving process, good air permeability, refreshing feel, and rain and sun protection, etc. In addition, outdoor rattan furniture is usually matched with an aluminum alloy-based frame, so outdoor rattan furniture is also very durable Pastoral style, simple and modern style, can also be naturally integrated into it.

0 notes

Text

Three-in-one socket connection method

When the three-in-one socket is connected, the zero and ground wires cannot be connected wrongly (generally, the left and right of the socket are grounded on the fire, otherwise the electrical equipment will be plugged in, and it will trip when it is turned on. In addition, what are the connection methods for the power socket? Woolen cloth?

1. First use a test pen to find the live wire.

2. Turn off the power supply of the three-in-one socket.

3. Connect the live wire to the A mark of one of the two holes of the switch, and then take a 2.5MM2 insulated wire from the other hole and connect it to the L hole of the three holes of the socket below to connect it firmly.

4. Find out that the neutral wire is directly connected to the N hole of the 3 holes of the socket and connect it firmly.

0 notes

Text

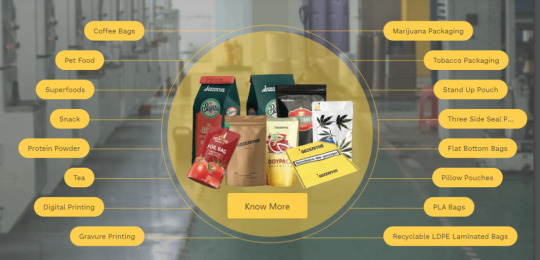

Do you know the technical principles of vacuum bags?

Do you know the technical principles of vacuum bags? Vacuum bag is a kind of packaging bag that we generally see in the market, and this kind of packaging bag is generally used in food, especially meat, instant food, and frozen food. Why is it more popular, and why are many items used for packaging? Vacuum bags have many advantages.

Whether you shop online or in supermarkets, you will often see them. Why do many manufacturers choose this kind of popular packaging bag? Let's follow the editor of the vacuum bag manufacturer "Shanghai Yuhe Packaging Products Co., Ltd." to bring you in to find out.

The main technical principle of the vacuum bag is to prevent the microorganisms of the items from growing and multiplying in the bag, and the technology inside is also adopted in a vacuum method, which is to prevent the items and food in the bag from oxidizing, that is, to prevent it from being damaged or rotted. , because generally speaking, food with more oil contains a large amount of unsaturated fatty acids. When exposed to the air for a long time, food oxidation will occur, that is, rot and odor, so that the product does not have a shelf life, and there is no external sales.

Sufficient time is guaranteed, so a vacuum bag will be used for packaging. The vacuum bag can effectively protect and protect the items in the bag from being disturbed by the air, avoid the relationship between the items in the bag and the air, and effectively suppress the bag. The shelf life of the bag is not only that, but also has many characteristics, which can maintain the color, aroma, and flavor of the food in the bag to a certain extent, the nutrition is not lost, and its original nutritional value is retained.

The above is part of the technical principle of the vacuum bag, and this is only a part of the characteristics of the vacuum bag. The vacuum bag has many characteristics, whether it is for food or other items, it has great advantages. When using the vacuum bag, of course, the main thing is It depends on what items you pack and how you use them later.

For some items, vacuum bags are not suitable for use. For some items, vacuum bags are tailor-made for them, depending on the item. decided.

0 notes

Text

Technical Questions and Answers for Diesel Generator Sets

1. What are the conditions for the parallel use of two generator sets? What device is used to complete the parallel work?

Answer: The condition for parallel use is that the instantaneous voltage, frequency and phase of the two machines are the same. Commonly known as "Three Simultaneous". Use a dedicated parallel device to complete the parallel work. It is generally recommended to use fully automatic parallel cabinets. Try not to manually parallelize. Because the success or failure of manual parallelization depends on human experience. With more than 20 years of experience in electric power work, the author dares to say that the reliable success rate of manual paralleling of diesel generators is equal to 0. Never apply the concept of manual paralleling of the large mains power supply system to the small power supply system, because the protection levels of the two are completely different.

2. What is the power factor of the three-phase generator? Can a power compensator be added to improve the power factor?

Answer: The power factor is 0.8. No, because the charging and discharging of the capacitor will cause fluctuations in the small power supply. and vibration of the unit.

3.Why do we require the customer to carry out a tightening of all electrical contacts after every 200 hours of operation of the unit? Answer: Diesel generator sets are vibration workers. Moreover, many domestically produced or assembled units are useless to use double nuts. The spring washer is useless. Once the electrical fasteners are loosened, a large contact resistance will occur, resulting in abnormal operation of the unit.

4. Why must the generator room be clean and free of floating sand on the ground?

Answer: If the diesel engine inhales dirty air, its power will decrease; if the generator inhales impurities such as sand particles, the insulation between the stator and rotor gaps will be damaged, and in severe cases, it will be burned.

5. Why since 2002, our company generally does not recommend users to use neutral grounding during installation?

Answer: 1) The self-regulating function of the new generation generator is greatly enhanced; 2) In practice, it is found that the lightning failure rate of the neutral point grounding unit is relatively high; 3) The grounding quality requirements are high, and the general users cannot do it. Unsafe work grounding is worse than ungrounding; 4) The unit with neutral point grounding will cover the leakage faults and grounding errors of the load, and these faults and errors cannot be exposed under the condition of high-current power supply of mains.

0 notes

Text

What are the requirements for the selection and installation of AC sockets?

Material selection and installation requirements and related details of AC sockets: The selection of switch sockets should pay attention to: 1. The size of the AC socket panel should be consistent with the size of the embedded junction box; 2. The surface is smooth, the brand logo is obvious, and there are anti-counterfeiting signs and national The Great Wall logo of electrical safety certification; 3. The AC socket feels flexible when turned on, the socket is stable, and the copper sheet must have a certain thickness; 4. The material of the panel should be flame-retardant and firm.

The installation height of the AC socket is generally 1.2 to 1.35 meters, the distance from the door frame is 150 to 200 mm, and the height of the wall socket is generally 0.2 to 0.3 meters.

The following points should be paid attention to when choosing a switch socket: 1. Heavy brand name: brand-name products have certain guarantees in product quality and service; 2. 2. According to their own economic strength and decoration environment, choose as appropriate; When purchasing products, you should also pay attention to product quality and related details:

(1) The surface of the product should be smooth, without blistering and depression, and the structure should be refined and not rough;

(2) The wiring is bright and has no rust marks;

(3) There is no blocking feeling when the tightening screw is tightened, and the wire is not easy to loosen after tightening;

(4) When the switch and socket are fastened to the wall, there shall be no inclination or unevenness;

(5) The opening and closing positions of the switch are clearly marked;

(6) The fire, zero and ground wires of the switch and socket terminals are clearly marked;

(7) There is no crack in the back seat of the switch and socket;

(8) The switch feels light and responsive, and the on and off positions are in place;

(9) The socket can be inserted and unplugged smoothly, and there is a certain resistance when inserting, preferably with a protective door;

(10) The trademark is clearly printed or engraved, the packaging is standardized, and the certificate of conformity is attached;

(11) There are 3C certification marks;

(12) It is necessary to choose a high-quality bottom box to match it;

(13) Read the manual carefully to see if it meets your own requirements.

0 notes

Text

Do you know the advantages of automatic pipe cutting machine?

With the rapid development of the fully automatic pipe cutting machine, what are the advantages of the fully automatic pipe cutting machine? Let us share some brief introductions about the advantages of the fully automatic pipe cutting machine.

In addition, the machining accuracy is high and the noise is relatively small.

The accuracy is maintained well, and the protection is convenient.

High efficiency and low operating cost. High processing efficiency and low cost.

The energy-saving effect is better, so that the pipe does not move and saves the power required for the rotation of the pipe.

The degree of automation is high, the control function is strong, and the production automation of steel pipe cutting processing is realized.

0 notes

Text

Why use aluminum foil bags for food packaging bags?

Why do food packaging bags use aluminum foil bags? Food packaging bags are believed to be often seen in online shopping and supermarkets, and this type of packaging bag is also relatively common in the market. There are many types of food packaging bags, and different styles and materials are different. Food packaging bags Why do many food manufacturers choose aluminum foil bags? Of course, the manufacturing cost of aluminum foil bags is also much higher than that of ordinary plastic bags, and aluminum foil bags have many characteristics, so many food manufacturers use aluminum foil bags. What are the characteristics of food aluminum foil bags? Why choose aluminum foil bags? Let's follow the aluminum foil bag manufacturer "Gozeniths" to find out.

Food aluminum foil is a flat metal aluminum tool that can be used in the kitchen to cook, hold food, or make some materials that can be easily cleaned.

Food aluminum foil bags on the market are generally heatable and storable. Most of the aluminum foil used in food processing is bright on one side and dull on the other. Food can be wrapped in aluminum foil on both sides. It is usually recommended to wrap it with a bright surface to improve the thermal conductivity.

Aluminum foil is used in food packaging bags because of its good barrier properties. The oxygen permeability of aluminum foil is extremely low, which can effectively block the gas in the air that easily deteriorates food, such as oxygen. And aluminum foil is opaque and has good shading properties, which can prevent some foods from discoloring or deteriorating due to light. The corrosion resistance of aluminum foil itself is extremely poor, and it is easily corroded by acidic or alkaline substances.

Food aluminum foil bags are not only made of aluminum foil, but also of composite materials. The composite is made of aluminum foil and nylon, some of which are made from four layers of co-extruded film. When packaging some food products, it is often multi-layer composite materials.

The reason for using multi-layer composite materials is to package food and maintain the quality of food. Another reason is that rich colors and patterns can be printed on food packaging bags, which is a way for food to be recognized by the market and a necessity for food promotion Way.

0 notes

Text

The application prospect of mangosteen extract is broad

mangosteen

Mangosteen is known as the "Queen of Fruits". It is a fruit with fresh and sweet taste, tender pulp and delicate taste. Its sweet taste is loved by people all over the world. In addition, mangosteen is rich in protein and lipids. It has a good nourishing effect on the body, and has a good nourishing effect on the frail, malnourished, and after illness. People in Southeast Asia have always had a tradition of using mangosteen for medicinal purposes. Then, further research found that a kind of histamine in the extract of mangosteen plays the role.

Active ingredient: α-mangostin, one of the most biologically active xanthone compounds contained in mangosteen extract. An active and natural substance rarely found in fruits and vegetables, and a very powerful antioxidant.

Efficacy

Improve immune system health

Studies have shown that mangosteen peels or rinds are rich in alpha-mangostin, which not only has antioxidant properties, but also helps improve immune system health.

prevent cardiovascular disease

Alpha-mangostin can help the body reduce the absorption of bad cholesterol, thereby preventing atherosclerosis and other cardiovascular diseases. This antioxidant also scavenges the body of harmful toxins and free radicals, which combined with bad cholesterol can cause certain heart diseases.

good for skin health

All antioxidants are good for the skin. And the benefits of alpha-mangostin don’t stop there, this type of antioxidant can treat skin conditions like seborrhea, eczema, and psoriasis. Mangosteen shells are also miraculous in healing wounds, making them heal faster.

application

Health food development: make various nutritional supplements, effervescent tablets, drug research and development, etc.

Food and beverage development: mangosteen solid beverage, mangosteen jelly, mangosteen canned food. The red pigment in mangosteen peel can be developed and used as a natural ideal food coloring.

Daily chemical development: The extract of mangosteen is harmless to the skin and has no side effects on the skin. The mangosteen shell extract is put into the ingredients of various products that are interested in the cosmetics and skin cleansing industries. Such as: remove body odor, relieve skin diseases and treat acne mangosteen shell soap, mangosteen facial cleanser, facial mask, lotion and other skin care products. It works great and is loved by today's consumers.

other:

Development of biological pesticides: The mangosteen peel extract has good insecticidal and antibacterial activities, so it can be used as an alternative material for the development of new botanical pesticides.

Studies have shown that mangosteen flavonoids extract can be used in cigarettes after purification, which can effectively modify smoke and reduce irritation, and has broad development prospects.

Focusherb

Focusherb is a reliable global supplier of botanical extracts and plant extracts. We are committed to providing quality raw materials and solutions to customers in the health food, Nutraceutical, Cosmetics and Pharmaceutical industries.

0 notes

Text

Why Diesel Generator Sets Difficult to Start in Winter?

The temperature in winter is low, compared with the difficulty of starting diesel generator sets in winter in summer, the following is the reason why diesel generator sets are difficult to start in winter by gogopower.

The viscosity of lubricating oil increases greatly at low temperature, or even solidifies, which increases the starting resistance of the engine, and cannot reach the minimum speed + (generally above 100r/min (revolution/min) required for starting the engine).

Due to the decrease of the starting speed, the leakage of compressed air increases, and the heat dissipation of the cylinder wall increases, which greatly reduces the temperature and pressure of the air at the end of compression, which increases the delay period of diesel ignition, and even can not burn in severe cases.

The viscosity of diesel oil at low temperature increases, which reduces the injection speed. In addition, the swirl speed, temperature and pressure of the air at the end of compression are relatively low, so that the atomization quality of the diesel injected into the cylinder is poor, and it is difficult to form quickly with the air. A good combustible gas will ignite and burn in time, or even fail to catch fire, resulting in difficulty in starting.

The above content is why diesel generator sets are difficult to start in winter, and I hope to be helpful to everyone.

0 notes

Text

PDU power socket features

1. The installation and maintenance of the PDU power socket is very convenient. The PDU power socket can be installed and fixed in a variety of ways.

2.The PDU power socket has local or network online detection of current and voltage and other power consumption environment and early warning functions, and has protection functions such as leakage prevention, lightning protection, overload, and surge.

3. Because PDU power sockets are safer and more reliable than ordinary power sockets. The PDU power socket fundamentally eliminates the frequent power failures, burns, fires and other safety hazards caused by poor contact and small load of ordinary power sockets.

4. The PDU power socket fundamentally eliminates the frequent power outages, burns, fires and other safety hazards caused by poor contact and small load of ordinary power sockets.

5. The kit material of the PDU power socket is made of phosphorous copper material, which is finely processed.

6. PDU power sockets are produced and designed in accordance with the international general structure, and are widely used in various standard and non-standard cabinets. Compared with ordinary power sockets, PDU power sockets can be applied to sensitive equipment system installations. The PDU power socket has the advantages of PDU technology, high work efficiency, strong anti-interference ability and reliable performance.

7. The reliable contact of PDU power sockets is far greater than that of ordinary power sockets, and the life of single-pole unplugging and plugging is more than 5,000 times, which is much higher than that of ordinary power sockets.

PDU power outlets have very good connectivity and electrical continuity. The difference between PDU and ordinary socket

1. In terms of load power: the cable configuration load of ordinary sockets is relatively weak, most of which are nominally rated at 10A; when using 1.5mm2 cables, a few manufacturers will have a nominal 16A4000W. According to the national cable wire standard, no matter which one is used. In this configuration, the rated carrying power of ordinary sockets is difficult to truly reach more than 4000W. It can be seen that it is difficult to meet the requirements of the computer room that is growing rapidly. PDU (POWER DISTRIBUTION UNIT) undoubtedly solves this problem to a large extent, because any of its components can be customized, which can fully meet the safety of the power environment in the computer room. At present, industrial plugs are more and more widely used in PDUs, and their current numbers can meet the needs of 16A, 32A, 65A, 125A, etc., so it is very wrong to use ordinary non-professional sockets in cabinets.

2. In terms of materials: ordinary ones are generally plastic, while PDUs are all metal. If the load is too large, the PDU has the function of fire protection, while the ordinary outlet does not. Since the PDU is a metal enclosure, it has an anti-static function, which protects sensitive electronic equipment from electrostatic hazards. So as to protect the stable operation of the equipment.

3. In terms of function: ordinary power sockets only have the functions of power supply overload and master control, and the output of the jack is also very monotonous; while PDU not only has many functions (with lightning protection function, master control switch, overload protection, current and voltage display) , remote monitoring function, smoke sensor temperature and humidity online detection, etc.) and the standard of the output module can be reasonably matched and selected according to the specific situation. (There are national standard, American standard, international IEC, German standard, etc.)

4. In terms of service life: ordinary sockets are generally 2-3 years. Plug and unplug about 4500-5000, and the PDU socket is made of super conductive metal material - tin (phosphor) bronze. It has good wear resistance and electrical conductivity, and the temperature rise is only 20 degrees after full load for one hour, which is far lower than the national standard of 45 degrees, effectively preventing the components from heating. More than 10,000 hot plugs, and the service life is as high as 10 years, which is more than 5 times that of ordinary sockets.

0 notes

Text

What is the difference between 3D printing and CNC?

First of all, 3D printing is an additive technology, and CNC machining is a subtractive technology, so they are very different in terms of materials.

1. Differences in materials

3D printing materials mainly include liquid resin (SLA), nylon powder (SLS), metal powder (SLM), gypsum powder (full color printing), sandstone powder (full color printing), wire (DFM), sheet (LOM) and many more. Liquid resins, nylon powders and metal powders account for the vast majority of the market for industrial 3D printing.

The materials used for CNC machining are all pieces of plates, that is, plate-like materials. By measuring the length, width, height and wear of the parts, the corresponding size plates are cut for processing. There are more choices of CNC machining materials than 3D printing. General hardware and plastic sheets can be CNC machined, and the density of molded parts is better than 3D printing.

2. Differences in parts due to molding principles

As we mentioned earlier, 3D printing is a kind of additive manufacturing. Its principle is to cut the model into N layers/N multi-points, and then pile them up layer by layer/bit by bit in order, just like building blocks Same. Therefore, 3D printing can effectively process parts with complex structures, such as hollow parts, while CNC is difficult to process hollow parts.

CNC machining is subtractive manufacturing. Through various tools running at high speed, the required parts are cut out according to the programmed tool path. Therefore, CNC machining can only process rounded corners with a certain radian, but cannot directly process inner right angles, which must be realized by wire cutting/sparking and other processes. Outside right angle CNC machining is no problem. Therefore, parts with inner right angles can be considered for 3D printing.

There is also the surface. If the surface area of the part is relatively large, it is recommended to choose 3D printing. CNC machining of the surface is time-consuming, and if the programming and operator experience is not enough, it is easy to leave obvious lines on the parts.

3. Differences in operating software

Most of the slicing software for 3D printing is easy to operate, even a layman can operate the slicing software proficiently in a day or two with professional guidance. Because the slicing software is currently very simple to optimize, and supports can be automatically generated, which is why 3D printing can be popularized to individual users.

CNC programming software is much more complicated and requires professionals to operate it. People with zero basic knowledge generally need to learn about half a year. In addition, a CNC operator is required to operate the CNC machine.

Because the programming is very complicated, a component can have many kinds of CNC processing solutions, while 3D printing only has a small impact on the processing time and consumables because of the placement position, which is relatively objective.

4. Differences in post-processing

There are not many post-processing options for 3D printed parts, generally grinding, oil injection, deburring, dyeing, etc.

There are various post-processing options for CNC machined parts, in addition to grinding, oil injection, deburring, electroplating, silk screen printing, pad printing, metal oxidation, laser engraving, sandblasting and so on.

0 notes

Text

There are three main points in the design of food packaging bags that cannot be ignored

I believe that many people will be fascinated by the shape, color or meaning of the food packaging bag, which will lead to the impulse to buy. This also directly shows the importance of food packaging bags, and also shows that the shape, color and meaning of food packaging are important considerations that cannot be ignored in packaging design.

When designing the shape of a food packaging bag, the consumer and the product will be considered. For consumers, the packaging designs on the market are becoming more and more convenient, such as easy to carry, easy to use, etc. Therefore, flexible packaging design and diversified size design have become one of the mainstream trends in packaging design. From the product point of view, packaging design generally starts from the source of raw materials, product functions and other characteristics. For example, the design of the wildly successful Nongshanquan natural mineral water bottle was inspired by the falling of water droplets.

In many commodity packaging designs, they can attract consumers' attention in the fastest, most eye-catching, and most pleasing way. Rich colors convey a variety of different interests, showing different quality styles and decorative charms.

The choice and combination of colors are very important in packaging design and are often the key to determining the quality of packaging design. Under the influence of minimalism, get rid of the shackles of traditional colors due to their attributes, combine modern packaging design theory and commodity attribute requirements, and use non-colored gold, silver, black, white, and gray to design packaging, which will display the goods. Eternal beauty. The special nature of the colorless system provides a stage for the packaging design of many commodities to show its charm.

In addition to the uniqueness of shape and color, packaging that can express special meaning is always more likely to resonate with consumers. Vibrant packaging often incorporates specific cultural connotations or cultural heritage. The author believes that this culture should include brand culture, corporate culture, technology culture, historical culture, etc.; with culture, it will naturally show "taste". The so-called "Chinese poetry and calligraphy spirit" has no special moral integration. Gorgeous packaging may appear pale due to lack of cultural support, lack of affinity and attractiveness, and it is difficult to arouse people's psychological resonance, so it is difficult for consumers to identify with the brand psychologically.

Food packaging bag design is not only a means to enhance consumers' desire to buy, but also a reflection of brand culture. Unique packaging is not only a symbol of the brand, but also a silent spokesperson for the product. It not only promotes products and brands, but also affects consumers' desire to buy, which can be said to kill two birds with one stone.

0 notes

Text

Market prospect and application of fruit and vegetable powder

With the growing maturity of fruit and vegetable powder processing technology, fruit and vegetable powder can not only be used as a substitute for fresh fruits and vegetables in special environments to ensure the nutritional needs of the human body, but also meet people's daily life requirements for diversification and convenience of fruits and vegetables , so fruit and vegetable powder processing will develop rapidly. At present, the international advanced fruit and vegetable powder processing is developing in the direction of low temperature and ultra-fine grinding, and makes full use of the roots, stems, leaves, skins, cores, etc. of fruits and vegetables to achieve full utilization of fruits and vegetables and production without skin residue .

fruit and vegetable powder

Fruit and vegetable powder is a kind of processing of fresh fruits and vegetables through more than 10 processes such as pretreatment, quick-freezing, vacuum drying, and ultraviolet sterilization. Effectively retain all the nutrients of the fruit, which is 20 times higher than similar products, and maintain 100% of the natural taste of the fruit. Its nutritional value is very high, containing a variety of minerals, trace elements, dietary fiber. Moderate consumption of some can play a laxative, lower blood pressure, beauty and beauty effect. It has now become a healthy ingredient for the taste and flavor of food.

The main technology of fruit and vegetable powder - spray drying: It is mainly made of fruit juice, concentrated juice, and slurry through instantaneous high temperature spray drying. The production energy consumption is moderate and the production capacity is large. Spray-dried fruit and vegetable powder is currently a mainstream product and is more and more recognized by the market.

application

Around 2000, fruit powder began to gradually enter the food ingredient market, mainly used in convenience foods, and then gradually used in functional solid beverages, tablet candies and seasonings. By around 2010, functional solid beverages such as probiotic powder , Enzyme powder, protein powder, meal replacement powder, etc., most of them start to use fruit and vegetable powder for seasoning. The advantages are natural health, convenient application, reduced seasoning research and development time, and relatively stable product properties. The processed fruit and vegetable powder can be applied to almost all fields of food processing. Not only is there less nutritional loss, but it is also very helpful for improving the nutritional content of products and improving the color and flavor of food. Until today, fruit and vegetable powder has become an indispensable ingredient for natural seasoning, and it can be used in unlimited quantities without any safety risks. And gradually increase the demand for functional fruit and vegetable powder, such as: strawberry powder, apple powder, cranberry powder, blueberry powder, lemon powder, etc.

solid drink

*Protein-based solid drink: used to enrich the taste of products, or correct the fishy smell of fish collagen. Commonly used flavors are: strawberry, banana, blueberry, sweet orange, etc.

* Sports solid drink/tea drink: used to increase the taste of the product, mask or correct the odor of vitamins or minerals, commonly used flavors are: grapefruit, orange, peach, etc.

Nutritious food and baby food

* Meal replacement powder: including fruit meal replacement powder, cereal meal replacement powder, milkshake meal replacement powder and other categories, commonly used flavors are: banana, pineapple, kiwi, etc.

* Probiotic powder: used to adjust the taste of products, commonly used flavors are: apple, blueberry, pineapple, kiwi, cherry, cranberry, etc.

* Enzyme powder: Most of the sources of enzymes are fruits and vegetables, which are used to enrich the taste of products and increase the flavor characteristics of fruits. Commonly used flavors are: blueberry, pineapple, kiwi, dragon fruit, etc.

* Baby rice noodles/pasta, mainly with sweet taste, adjust the taste of rice noodles, commonly used flavors are: orange, apple, banana, blueberry, etc.

Snacks & Sweets

* Tablet candies: including chewable tablets, effervescent tablets, milk tablets, etc., to enhance the taste of juice, commonly used flavors are orange, lemon powder, peach powder, strawberry, mango, tropical fruits;

* Puffed food/baked products: including potato chips, popcorn, roll core crisp, used as flavor base for seasoning powder, common flavors are: mango, cucumber, lemon, blueberry, strawberry, pineapple, etc.;

* Chocolate food: sandwich biscuits, coated biscuits, chocolate coating raw materials, white chocolate, etc., add fruit and vegetable powder to increase color and taste, commonly used flavors are: strawberry, mango, blueberry, kiwi, lemon, etc.;

meat products

The antioxidant components in fruits and vegetables are mainly flavonoids (proanthocyanidins, quercetin, catechins) and water-soluble vitamins (VC). Many fruits and their extracts can be used as antioxidants in meat products. For example, cranberry fruit powder contains high concentrations of phenolic compounds, which have potential effects on inhibiting fat oxidation in turkey and ground pork.

Advantage

Derived from freshly picked fruit, finely ground

The original taste of the ingredients is preserved, and the color and taste are mellow and natural

Zero additives: no artificial colors, artificial flavors, preservatives

Wide range of uses and good market prospects

The powder is fine and uniform, easy to knead, and the color is clear and bright without smearing

0 notes

Text

Where does the excess electricity from diesel generators go?

The generator is driven by a diesel engine. When an electrical appliance is connected, the internal coil of the generator and the external electrical appliance form a loop, which will generate current. When there is current, electromagnetic force resistance torque will be generated, and energy is conserved. For a generator with a stable speed, more electromagnetic resistance does more work, which means that the resistance torque is large.

When there is no electrical appliance, there is no current inside the generator coil, and the coil generates an electromagnetic resistance torque.

However, the bearing and belt of the generator will have resistance torque, which also consumes the power of the diesel engine. In addition, the diesel engine itself is a four-stroke, only one of which is a power stroke, and it also requires fuel consumption to maintain its idle operation. The efficiency of the diesel engine as a heat engine of an internal combustion engine is also limited.

When the generator power is large and the consumer power is small, these power losses may be larger than the consumer power. Diesel engine power is difficult to make small, so the minimum power of diesel generator is a few kilowatts. For a power tool of several hundred watts, this load is negligible. The above confirms what you said, with or without electrical appliances, the fuel consumption is similar.

0 notes