Text

Powder Flame Spray Gun | Flame Powder Spray Gun

From: sand blasting hopper

Powder Flame Spray Gun

When a material is a flame-sprayed, new and complex material is produced. This is the basis that the quality of coating depends upon the quality of the powder. A slight variation in powder chemistry can greatly influence the property of the last coating. The particle size distribution in a powder can change the density plus porosity of the thermal spray coating. Our Powders meet excellent examples of chemical composition, particle shape & size, flow rate & purity.

We supply all required equipment to optimize the use of a Flame Powder Spray System, including:

Powder Flame Spray Guns

Gas Control arrangements (Mass Flow Control)

Hose

Cable

Powder feeder

0 notes

Text

Wire Flame Spray Gun Manufacturer & Supplier in India

From: sand blasting hopper

Wire Flame Spray Gun

A compressed gas stream atomized and accelerated the liquefied metal by surrounding the flame. the endless process might be adjusted by feeding the wire feedstock material at a controllable rate into the flame. We approached this problem by employing a turbine to actuated gears and drive rolls that pulled the wire into the sand blasting nozzle. The version that uses wires can spray metals that will be prepared during a wire form. The variation that uses powder has the power to feed various materials. These include normal metal alloys, oxidation-resistant metals and alloys, and ceramics. It provides sprayed surfaces of the many different characteristics. The wire is fed into the front torch of flame spray through the air-driven turbine.

We are the manufacturer of Metal Spray Gun, Flame Spray gun, Thermal Spray Gun, Metallizing Gun are the same kinds of equipment – All these are using in Coating so it’s also called as Equipment. We are the Largest Manufacturer of Wire Flame Gun.

0 notes

Text

Flame Spray Gun Supplier & Exporter in India

From: sand blasting hopper

Flame Spray Gun

The flame spray gun simplest device has based on the principle that if a wire rod were filled into an intense, concentrated flame, (the burning of a fuel gas with oxygen), it might melt. If the flame was surrounded by a stream of gas, the molten metal would become atomized and readily propelled onto a surface to make a metallic coating. Flame spray gun process variation during which the controlled explosion of a mix of fuel gas, oxygen, and therefore the powdered coating material is employed. it melts and propels the fabric to the workpiece.

We are a manufacturer of flame spray guns, Wire flame spray guns, Metal Spray Gun, Thermal Spray Gun, & Spare Parts. Flame Spray Gun Price and Metalizing gun price is low with the finest quality. Our Flame Spray Coating & Metal Spray Gun Equipments is permanent and simple to use and low maintenance. All these are using in Coating so it’s also called Flame Spray Coating Equipment. We are the Largest Manufacturer of Wire Flame Gun.

0 notes

Text

Prefilter | Prefilter for Dust Collector

From: sand blasting hopper

Prefilter

The prefilter is used to remove gaseous pollutant, odours and particulates.prefilter remove the bad odour. In several cases, this problem or bad odour is not so easy. it is timely and cost-effective too.

A Pre-filter is a device that removes unwanted large matters from the air or water. Air pre-filters include masks and respirators. Supplied air in the workplace or transport vehicles has air pre-filters to remove dust, hair, insects, pollen, fibres, etc.

Advantages of Prefilter

Easy Upgradable

Installation

Easy Maintenance

Save Power

Disposable & bio-degradable

Non-Lint fabric

Customized Size’s

Application of Prefilter

For low-velocity systems.

As a prefilter for a high-efficiency filter.

As a primary filter where medium efficiency is required.

Replaces fiberglass products.

Characteristics of prefilter

Non-allergenic.

Integrated adhesive.

Will not support microbial growth.

Unaffected by moisture.

About the company

We are the leading manufacturer of sand blasting machine, shot blasting machine, blast room, several types of dust collectors, and abrasives many other products required for the blasting operations at affordable prices. Here, customers get full technical support with the best services.

0 notes

Text

Dust Collector | Dust Collector Supplier in India

From: sand blasting hopper

Dust Collector

A Dust collector is a device that increases the quality of air by removing the impurities and other dust particles. The dust collector is designed to operate high volume dust loads. It is a collection of devices used to purify the air by removing particulate matter from the polluted air. An industrial dust collector is an air pollution control equipment and has several uses in factories, warehouses, and industries to meet environmental and workplace requirements. Its control, reduce, and remove harmful particulates and fumes from gases during the production and manufacturing. The dust collector objective is the same as the filter separate. Dust collector captures the dust in gases and after purifying release sanitized air.

0 notes

Text

Cyclone Type Dust Collector | Dust Collector Supplier in India

From: sand blasting hopper

Cyclone Type Dust Collector

Cyclone type dust collector is the most conventional mechanical method to remove dust particles or any foreign particles using centrifugal effect due to tangential rotation. It is a type of dust collector and this method is used where the size of dust is heavy. Cyclone type dust collector is also used as pre-cleaners to high-efficiency fabric type dust collectors.

Working of Cyclone Type Dust Collector

When the dirty air enters the cyclone dust collector, a swirling movement occurs which results in a centrifugal force acting on the dust particles suspended in the air stream. The denser particles are forced to move outwards, towards the cyclone dust walls. Then they fall downwards, towards the dust exit. The clean air directed towards the Center of the cyclone and leaves through the gas exit.

0 notes

Text

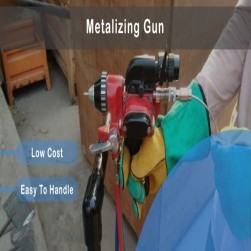

Metalizing Gun | Metalizing Gun Manufacturer in India

From: sand blasting hopper

Metalizing Gun

In Metalizing Gun a Thermal Spraying is a group of coating processes in which finely separated metallic or nonmetallic materials are placed in a molten or semi-molten condition to form a coating. The covering material may be in the form of powder, ceramic-rod, or wire. Thermal Spraying has an advantage over other processes as it is a cold process & as a result, it never spoils parent material. The thickness of the coating is controllable, no matter what the job size is. Loss of surface properties due to wear, corrosion, erosion, etc. Can be avoided in a cost-effective method by thermal spray gun coating.

Arc Spray Gun

Arc spray gun may be a coating process in which where two consumable metal wires are fed independently into the spray gun. Certain wires are then charged and an arc is produced between them. The heat of this arc melts the incoming wire, which is then entrained in an air jet of the gun. This entrained molten feedstock is when dropped on a substrate with the assistance of compressed air. In an arc spray gun, the load of coating which will be transferred per unit of your time may be a function of the electric power (amperage) of the method and therefore the frequency and freezing point of the wire. The wires usually made from electrically-conductive materials, like Aluminum, Zinc, stainless steel, and Copper.

We are a manufacturer, supplier of arc spray system, zinc spray gun, twin wire arc spray gun at a low price. Thermal Spray Gun should be used after creates a rough surface so that automized spray metal makes a good grip on the metal, then the metal life is increased by this process.

Glass Beads | Glass Beads Manufacturer in India Sandblastinghopper November 5, 2020 modify comment

From: sand blasting hopper

Glass beads

Glass beads mostly used in the abrasive blast cabinet. they are round in shape and smoothly cleans metal part with a smooth polish. pressure on which glass beads are blasted is 60-90 PSI to get the highest productivity result.

The appearance of Glass Beads are spherical and round . Glass Beads are available in all standard sizes. They are good for the environment and reliable. glass beads clean the surface without damaging them and they are recyclable. Glass Beads can perform a variety of operations. the dust level is also low and due to this reason, the cleanup maintenance is reduced. To get polished or smooth surface glass beads are shot on the surface of the object or work-piece under the pressure of compressed gas with high speed and after that, we will find a smooth and clean polished surface.

Uses of Glass Beads

Cleaning of Automotive parts.

Casting.

Deburring of rough edges.

Maintenance of Gears.

Applications

Metal preparation

surface finishing

We are a Manufacturer, Supplier, and Exporter of Sand Blasting Machine, Tumblast Shot Blasting Machine, Grit Blasting Machine, thermal spray gun, Sand Blasting Cabinet, Shot Blasting Room, Pressure blasting Cabinet, Metalizing Gun.

0 notes

Text

Arc Spray Gun | Arc Spray Gun Price in India

From: sand blasting hopper

Arc Spray Gun

Arc spray gun may be a coating process in which where two consumable metal wires are fed independently into the spray gun. Certain wires are then charged and an arc is produced between them. The heat of this arc melts the incoming wire, which is then entrained in an air jet of the gun. This entrained molten feedstock is when dropped on a substrate with the assistance of compressed air. In an arc spray gun, the load of coating which will be transferred per unit of your time may be a function of the electric power (amperage) of the method and therefore the frequency and freezing point of the wire. The wires usually made from electrically-conductive materials, like Aluminum, Zinc, stainless steel, and Copper.

We are a manufacturer, supplier of arc spray system, zinc spray gun, twin wire arc spray gun at a low price. Thermal Spray Gun should be used after creates a rough surface so that automized spray metal makes a good grip on the metal, then the metal life is increased by this process.

0 notes

Text

Zinc Spray Gun | Zinc Spray Coating in India

From: sand blasting hopper

Zinc Spray Gun

The zinc spray gun is additionally referred to as a metal spray gun, thermal spray gun, aluminum spray gun, copper coating spray. When using aluminum wire than it’s called an aluminum spray gun. and when copper is sprayed then it's called a copper spray gun. The sprayed zinc gun coating is rough and slightly porous, with a selected gravity of 6.4, related to zinc metal at 7.1. Zinc corrosion products Limitations include cost, difficulty in applying, lack of coating uniformity (particularly at corners and edges), and therefore the requirement for a clean steel surface. Zinc-rich paints should stay top coated in severe environments. The qualities of organic zinc-rich paints depend upon the solvent system. Many coats could also be applied within 24 hours without cracking. Zinc-rich paints are usually associated with retouch galvanized steel that has been damaged by welding or severe mechanical impact.

0 notes

Text

HVOF Gun | HVOF Spray Gun in India

From: sand blasting hopper

HVOF Gun

HVOF stands for High-Velocity Oxygen Fuel, and from its name, it's easy to deduce that this thermal spray process has got to do with using molten materials (or semi-molten materials) at a high speed on substrates. These uses in application Turbine engine fan blade mid-spans, compressor blades, turbine blade roots, bearing journals, stator and rotor disk snap diameters, landing gears, actuators, flap tracks, helicopter rotor joints, and sleeves. These power generation Industrial gas turbines, hydroelectric Pelton buckets, sand blasting nozzles, and blades, exhaust fans. The high-velocity oxy-fuel process was invented only 20 years ago, yet has thrust the thermal spray application range into areas that were once unobtainable. In HVOF spraying, a mixture of process gases, like hydrogen, oxygen, and air, is injected into the combustion chamber of the torch at high and ignited. The resulting gas velocities achieve supersonic speeds. The powder is injected into the flame and also accelerated to supersonic speed.

0 notes

Text

Twin Arc Spray Gun | Twin Arc Spray Gun Manufacturers

From: sand blasting hopper

Twin Arc Spray Gun

The twin wire arc spray process (TWA) utilizes metal in wire form materials. Heating and melting of the wire material occur when two electrically opposed charged wires, comprising the spray material, are fed together in such a manner that a controlled arc occurs at their intersection. The molten metal is atomized and sprayed onto the prepared workpiece by jets of compressed air or gas. The molten metal was reduced by jets of compressed gas. a device was built utilizing two aluminum wires, insulated from each other, made to advance and intersect at some point. Generally, the wires were given a difference of electrical potential of about 89 V that caused the wires to melt, and in the presence of a gas stream, the coating was produced. Two guides direct the wires to an arcing point. After this point, a sand blasting nozzle directs a stream of high-pressure air onto the arcing point where it atomizes the molten metal and sprays it to the workpiece. Power of about 450 A can spray over 50 kg/hr (110 lb/hr). Electric arc spray systems are offered that wire by either air or an electrical motor.

0 notes

Text

Metalizing Wire | Metalizing Wire Manufacturer in India

From: sand blasting hopper

The metalizing wire used in the thermal spray gun for the coating process. Coating provides over the substrate with a different method. Thermal spraying is done to increase the life of the substrate and prevent it from corrosion in even the hardest condition. The selection of metalizing wire in the thermal spray is based on the application of the substrate on which coating to be done. Metalizing wires are used in pure form as well as in alloy form also.

Types of metalizing wire

Zinc wire

Zinc Wire is present in a variety of diameter and mostly used in small, voids and uncoated areas which are not readily accessible. Zinc wire coating has more resistance in hard water and less in soft water. Zinc wire is mostly used in pH range 6 to 12. Zinc coating has poor resistance in any water above 60 degrees Celsius. Zinc wires coating has poor resistance to almost all organic and inorganic acids. Zinc is mostly used as a primer on surfaces to form electrically conductive surfaces on glass and ceramics. Zinc wire also used in alloy form depends upon the application.

Applications

Atmospheric and immersion corrosion protection on large steel or iron structures like bridges, roadway barriers, posts and poles, offshore structures, and marine structures.

Corrosion protection on steel or iron substrate such as tanks and gas bottles.

0 notes

Text

Thermal Spray Gun | Thermal Spray Gun Price

From: sand blasting hopper

Thermal Spray Gun

The thermal spray gun is used for coating purposes in this technology thickness of 22 microns to several mm thick coating is sprinkle and it depends on feedstock.

Product Details:

Air Pressure: 70-100 psi

Nozzle Size: 3.15 mm

Form: Wire

Item Weight: 15 Kg

Air Consumption: 8 to 9 cfm

Air Inlet: 3/8"

Sound Pressure: 115 dB

Usage/Application: Flame

Thermal Spray Gun is used for coating processes in which melted materials are sprayed on the surface to provide better polishing and remove foreign particles. Thermal spray guns provide thick coatings up to several mm depending on the application. Thermal Coating materials available for thermal spraying include metals, alloys, ceramics, plastics abrasives, and composites. The coal thermal spray guns are used for coating processes in which melted materials are sprayed on the surface to provide better polishing and remove foreign particles.

Thermal spray guns are used to improve the metal surface. The main purpose of using a thermal spray gun is the expansion the rotating shaft and increasing the life of sand blasting machines. The thermal spraying method can come up with a thick coating over a large area at a high deceleration rate as compared to more coating processes. The thermal spray gun melts the material which results in molten droplets accelerated in a gas stream which is projected against the surface to be coated. Molten material helps in adhering to the particles, overlapping, and interlocking.

Types of the thermal spray gun

Flame spray gun

Wire flame spray gun

Arc spray gun

The main feature of the thermal spray gun

Increase the life of machines

Provide excellent finish

Resist corrosion

Reliable and efficient

Economic and long-lasting

Performance is high

Thermal Spray Gun Price

We are the manufactures of the best-designed models for thermal spray guns as per their applications. The prices of thermal spray guns are within the budget of the customers, they can afford them easily. From ordering to delivering, We give assurance of providing the best service. The thermal spray guns available here are capable of working on any type of work-piece geometry.

0 notes

Text

Sand Blasting Machine | Sand Blasting Machine Manufacturer in India

From: sand blasting hopper

Sand Blasting Machine

Sand blasting machine is used for the blasting operations so, that any dust or contaminants from the metal surface can be removed easily. It is used in many industries for surface preparation.

Product Details:

Power Consumption: 30

Automation Grade: Possible

Usage/Applications: Surface Preparation

Portable: Yes

Sand blasting Machine

A Sand Blasting machine is mainly used to remove rust, corrosion, and contaminants from the metal surface with the help of abrasive media. In the sand blasting machine, silica sand is used as an abrasive for sand blasting operation. A Sand blasting machine is also used to mold and to clean the surface of the metal. For this blasting process, compressed air at high velocity and pressure is imparted on the blast wheel. The sand blasting machine is the strongest method among all the other blasting methods.

Types of Sand blasting machine

Pressure blasting machine

Suction blasting machine

Wet blasting machine

Working of Sand blasting machine

In the sand blasting machines, compressed air with abrasive is used for surface preparation. It is one of the most efficient and fast methods of blasting. The sand blasting machine involves the operation of forcibly propelling a stream of abrasive material against a rough surface. Here, compressed air or pressurized liquid is used as the propellant. Sand blasting is also known as abrasive blasting. Operators are advised to use safety wears while operating sand blasting machines for their safety purpose. There a few more variants of the sand blasting process such as shot blasting, soda blasting, and bead blasting, etc.

We are the manufacturer, supplier & exporter of Portable sand blasting machines, shot blasting machines, vacuum blasting machines, Sand Blasting Cabinet, Sand Blasting Room, Sand Blasting Nozzle, and many other products required for the blasting operations at affordable prices. Here, customers get full technical support with the best services.

0 notes

Text

Grit Blasting Machine | Grit Blasting Machine Manufacturer in India

From: sand blasting hopper

Grit Blasting Machine

The Grit Blasting Machine is used to harness the abrasive qualities of the material to clean components. There are different sizes and styles are available to make abrasive blasting. This is the best solution for companies for repairing industries.

Product Details:

Tank Capacity: 250 liters

Material: Mild Steel

No. of Wheels: 3

Height:1500 mm

Portable:Yes

Nozzle Size: 5-10 mm

Grit Blasting Machines are used to remove foreign particles from the metal surface. Grit Blasting Machine is a particle size sand process, also known as Sand Blasting Machine. It is a process in which abrasives are sprayed out at very high pressure through a grit blasting nozzle using compressed air on the surface which needs to be re-engineered and provide a desirable surface finish. Grit blast machines can also enhance the surface of components by removing scratches, casting, and mold marks. The operation of the grit blasting machine depends on different applications such as:

Loading of abrasives into the cylinder.

Throwing pressurized air through the nozzle on the surface.

A grit blasting machine consists of two hoses, one of which is connected to the bottom of the handle, and another one is connected with the lower side of the barrel. it has a repository of loose sand which helps in forming a vessel or bucket. When the gun is fired, the air creates suction which pulls the sand into the gun and this sand can be reused.

Grit blasting machines can be categorized as:

Portable Grit Blasting Machine: They are used for small and medium-size industries such as; automobile industry, paint transformer, manufacturing companies, pipe manufacturer, casting manufacturers, powder coating industry, and many more. Portable grit blasting machines may use any type of abrasives.

Cabinet type Grit Blasting Machine: They are used for medium and small-sized jobs such as; stainless steel, glass handicrafts, wood, casting, and mold.

Grit Blasting Machines are most suitable for preparing the surface before welding and afterward to enhance the adhesion of coatings. Moreover, grit blasting can be used to remove sand and scale formed in the fettling of castings. Due to the effect of compression in the grit blasting machine, it can be used to prevent corrosion also.

Grit Blasting Cabinet is used where no dust is needed to create in the working environment. The component which is treated is inserted into the cabinet and sealed until the pressurized abrasive is forced through nozzles into the chamber. The grit blasting machine can be operated with the help of a foot-pedal by the operator. It can be turn on and off with the foot-pedal and rubber glove hand inserts operators to pick the components up and move them around as they are being blasted. The operator works inside the blasting room, wearing the operator’s suit.

Grit Blasting Machine Manufacturers

Grit Blasting Machine supplies effective services and solutions for many manufacturing industries based on their demands.

We are the leading manufacturer and exporter of Sandblasting Machine, portable Shot blasting Machine, Grit blasting Machine, Sand Blasting Cabinet, Shot Blasting Room, Pressure Blasting Cabinet, and different abrasives.

0 notes

Text

Shot Blasting Machines | Shot Blasting Machine in India

From: sand blasting hopper

Shot Blasting Machine

The Shot Blasting Machine uses a method call propelling abrasive media with the help of a radial wheel to remove the damage or contaminants from the surface of metal and steel. The Shot Blasting Machine basically cleans and remove the loose scales from the surface of metal and steel.with the help of this machine we can also clean the rough surface edges of automobile parts that have uneven or sharp surface.

Shot Blasting Machine is used as a mechanical method for the surface treatment by using an abrasive with the help of a centrifugal wheel at high speed to obtain excellent surface and remove impurities for secondary operations.

Shot blasting is used for the following main purposes:

It provides a better texture to enhance paint adhesion.

It increases the coating life of a machine by reducing its maintenance cost.

For cleaning and preparing the surface before painting, coating, metalworking.

It also used for making non-slipping surfaces and providing surface homogenization.

Shot blasting is done after heat treatment and also for mechanic descaling.

The shot blasting is done in two ways:

Wheel blasting: It is a common and economical method. In this process, the electric motor energy is converted into kinetic energy by rotating a turbine wheel. This is mostly used for treating heavy equipment. The turbine wheel works here as a centrifugal pump and it delivers the abrasive by centrifugal force on the surface.

Air blasting: In this method compressed is used and sprayed out through nozzles on the surface. This is mostly used for smaller equipment. Air blasting is comparatively expensive due to the use of steel frames and weldments.

After the process of shot blasting, shots are removed by the air washing process.

The shot blasting machine works on the projectile motion of an abrasive on the metal surface to get a better surface finish. So, this mechanical method depends on the abrasive. For this, mostly metal abrasive should be used.

Metal abrasives can provide the following benefits:

They can increase productivity by reducing maintenance costs.

Waste generation can be reduced to get better quality of work.

They cause less environmental pollution and also there is no risk to the operator’s health by using metal abrasive.

The main components of the shot blasting are:

Blast wheel: The efficiency of a shot blasting machine depends on the quality of wheels used. So one used to use a better quality of the wheel.

Cabinet: Cabinet consists of dust and abrasive. The shot blasting cabinet is made up of steel material to secure strength. A dust collector is mounted on the machine to prevent dust from entering the shop environment.

Work handling mechanism: Handling of parts depends on the quantity of the parts. Tumblast Shot Blasting Machines are used for large quantities and spinner hangers are used for heavier parts.

Elevator: After the metallic shots hit the surface they fall into the hopper under the machine from which the elevator carries them to the separator at the upper part of the machine.

Separator: The separator, separates contaminates, and the cleaned abrasive is fed into the shot turbine.

Dust collector: A dust collector system is used to release clean air. A properly designed and sized dust collector is preferred for shot blasting machines.

Control and instrumentation: The starting and stopping of all operations depend on the controls and instrumentation features of the shot blasting machines.

The shot blasting machine is mostly used in chemical industries, petroleum industries, Aerospace, Automobile industry, Heavy engineering industry, Railways, Defence.

We are the leading Manufacturer, Supplier, and Exporter of different kinds of Sand Blasting machines and blasting equipment, Shot Blasting Machines, Sand Blasting Cabinet, Shot Blasting Cabinet, pressure blasting cabinet, Shot Blasting Room, Automatic Sand Blasting Machine, thermal spray gun, Metalizing Gun in India at a low price for Sale.

0 notes

Text

Ps Balls | Ps Ball Manufacturer in India

From: sand blasting hopper

Ps Balls

It gives a perfect atomizing of elements size, density, hardness, and durability. Therefore, the effectiveness of abrasive reduces the consumption rate and increases productivity as well as non-toxic environment status. PS Ball is a cheap material when compared to other mineral substances. PS Ball can be reused up to 3-4 times based on its surface roughness.

Product Details:

Color: Black

State: Grains

Hardness: 7.5 mohs

Types of Cutting: Sand blasting

Density: 3.64 g/㎤

Fe2O3: 43.5%

SiO2: 19.5%

Ps Balls

PS Ball stands for Precious Slag Ball. PS Ball is the great product of the slag atomizing process. We named it precious since it is turned from valueless waste into newborn material with good value-added. It is an environment-friendly substance with a stable status of spinet structure by rapid air & mist cooling system, proven by professionals. PS Ball is designed by supercooling molten steel slag. it's an exciting and versatile product that's highly stable, hard, and extremely tough. Its superior features make it suitable for an outsized range of applications and its most typical usage is as an abrasive for the surface preparation of steel before the application of paint coatings. As PS Ball doesn't contain Free Silica, it's non-toxic and in compliance with environmental regulations the world over. As compared to copper slag, it's superior compressive strength, hardness, and anti-weathering characteristics.

Advantages of Ps Balls

Excellent hardness for blasting.

Improve the efficiency of work.

Less dust during the sand blasting machine work than silica or garnet.

Reuse available (2~3 times) by recycling equipment.

Good intensity of illumination.

Uses of Ps Balls

Abrasive Blasting Material.

Filter Media.

Casting Sand.

Weight Material.

Industrial Uses

Shipbuilding.

Steel Bridges.

Heavy Steel Structure.

Storage Tanks.

We provide steel shot, SS shot, copper slag, steel grit, garnet sand, quartz shot, aluminum oxide, glass beads, etc. We provide a large range of products and are checked on various parameters, such as density, physical and chemical properties, microstructure, hardness, durability. We are focused on our quality products and customer satisfaction.

0 notes