Text

OEM/ODM Refillable Deodorant Stick Container Roll-on Bottle

Refillable deodorant stick with roller ball

1. Specifications

DB08 Roller Ball Refillable Deodorant Stick Container, 100% raw material, ISO9001, SGS, GMP Workshop, Any color, decorations, Free samples

2. Special Advantage:

(1).Special roller ball design, easy to use.

(2).Special portable design, easy to carry.

(3).Special refillable/reusable design, easy to refill.

(4).Special for deodorant stick container, sunscreen stick container, anti-itch cream stick container

3. Product Size & Material:

Item

Capacity

Material

DB08

50g

Cap:PPRefill bottle:PP

Outer bottle:PP

DB08

75g

4. Optional Decoration: Plating, Spray-painting, Aluminium Cover, Hot Stamping, Silk Screen Printing, Thermal Transfer Printing

Read the full article

#DeodorantRollonBottle#DeodorantStickContainer#EmptyDeodorantContainer#RefillableDeodorantStick#Rollonbottle#RollerBalldeodorantstick

0 notes

Text

How to Make Beauty Products to Sell

Do you want to start your own business to make beauty products? This is a great idea - there is a huge market for these products and you can be passionate about it.

Here are some of the best tips on how to make beauty products sell.

How to start a makeup line?

To start your own makeup line, follow these steps:

1) Find your niche

The first step in starting a makeup collection is finding your niche. What kind of product do you want to sell? Do you want to focus on skincare products like scrubs, or do you want to be a one-stop shop for everything from foundation to lipstick? Once you know what kind of product you want to sell, it will be easier for you to focus and create a cohesive route.

2) Develop a business plan

Now that you know what kind of product you want to sell, it's time to start thinking about the business side. What is your budget? How will you manufacture and package your product? Who is your target market? Answering these questions will help you develop a solid business plan -- essential if you want your business to be successful.

3) Find the manufacturer

Once you have a business plan in place, it's time to start looking for a manufacturer. This is an important step - you want to make sure you find a reputable manufacturer who can produce high quality products. Ask around for advice, or do some research online.

4) Create your wrapper

Your packaging matters - it makes your product stand out on the shelf. So take some time to create unique and eye-catching packaging. Consider the colors, fonts and overall design of the packaging. And make sure it reflects the brand identity you are trying to create.

Now that you know how to start a makeup collection, it's time to learn how to market your products.

Tips for Selling Products

Selling is all about developing the right marketing strategy. There are a few things you can do to market your products effectively.

Here are some tips:

1) Social Media Marketing:

Social media is a powerful tool you can use to market your products. Create social media accounts for your business and start posting about your products. Make sure to use hashtags and target relevant users.

For example, if you sell homemade sugar cosmetics, you can use the hashtag #sugarcosmetics.

2) Bring your product online:

If you want to reach a wider audience, you should put your product online. You can create an e-commerce site or sell your products on popular marketplaces like thanks for reading!

Read the full article

0 notes

Text

What is the target market for beauty products

When it comes to beauty products, there is no one-size-fits-all answer to the question of who the target market is.

Depending on the product, the target market could be young women, working mothers and retirees.

We're going to look at some of the different factors that determine who your beauty product's target market should be.

We'll also discuss how to reach your target market and which marketing strategies work best.

Beauty Products Market

The global cosmetics industry is a booming multi-billion dollar industry, and the target market for beauty products has traditionally been women. However, with the growing popularity of men's grooming products, the market is shifting towards a more gender-neutral audience.

The industry is expected to grow further in the coming years as the demand for beauty products continues to grow. Therefore, businesses and marketers looking to capitalize on this growth should focus on reaching both women and men.

Understanding what drives buying decisions and predicting future trends can create marketing campaigns that tap into this growing cosmetic market.

Why is it important to know this information?

Reaching the right target market is critical for any business, but it's especially important in the beauty industry.

People are passionate about how they look and often have strong opinions about their products.

As a result, marketing campaigns that are not up to the mark are likely to receive a lot of backlash.

On the other hand, campaigns that are well-targeted and resonate with their target audience can be very successful.

Factors to Consider When Identifying Your Target Market

There are several key factors you should consider when determining the target market for your beauty products. These include:

Your audience size and demographics

Skincare needs of the target market

Product trends in your industry

Brand awareness and positioning within the industry

supply and production capacity

Projected growth in your industry

Let's take a closer look at each of these factors in more detail.

Your audience size and demographics

The first step is to consider the size and demographics of the target market.

Are you targeting men, women, or both? What is their age range? What is their income level? where do they live?

Answering these questions will give you a better understanding of your target market and what they are looking for in beauty products.

Skincare needs of the target market

Next, you need to consider the skincare needs of your target market.

Do they have sensitive skin? Are they looking for organic or natural products? What is their skin type?

Answering these questions will help you determine what type of product to create and how to market it.

Product trends in your industry

It is also important to stay abreast of the latest product trends in your industry.

What are people using? What do they like and dislike? What are the latest products on the market?

By keeping up with industry trends, you will be able to create products that meet the needs of your target market.

Brand awareness and positioning within the industry

You need to consider the visibility and standing of your brand in the industry.

Are you a new brand? Do you have a strong presence on social media? How do people perceive your brand?

Answering these questions will help you determine how to reach your target market and which marketing campaigns will be most effective.

Supply and production capacity

In addition to these factors, you also need to consider your supply and production capacity.

Do you have the ability to produce enough product to meet the needs of your target market? Do you have a reliable source of supply?

Answering these questions will help determine if you're ready for a marketing campaign and how to scale up production.

Projected growth in your industry

Finally, you need to consider the projected growth of your industry.

What is the expected growth in the beauty industry over the next five years? What new products or trends are expected to emerge?

By understanding the projected growth in your industry, you'll be able to create campaigns that target the right markets and take advantage of new trends.

Wrap up

The beauty product market is huge and growing. There are many different types of people who buy beauty products, so understanding your target market to sell more effectively is critical.

Knowing what motivates your target market allows you to create better marketing campaigns that directly address their needs and desires.

thanks for reading!

Read the full article

0 notes

Text

Current Situation and Development Trend of Cosmetic Bottle Recycling

For most people, cosmetics and skin care products are the necessities of life, and how to deal with the used cosmetic bottles is also a choice that everyone needs to face. With the continuous strengthening of people's awareness of environmental protection, more and more people choose to recycle used cosmetic bottles.

1. How to recycle cosmetic bottles

The lotion bottles and cream jars that we use in daily life, can be classified into many kinds of garbage according to different materials. Most of them are made of glass or plastic. And them can be recycle.

In our daily skin care or makeup process, we often use some small cosmetic tools, such as makeup brushes, powder puffs, cotton swabs, headband, etc. These belong to other garbage.

Wet wipes, facial masks, eye shadows, lipsticks, mascaras, sunscreens, skin creams, etc. These commonly used skin care products and cosmetics belong to other garbage.

But it is worth noting that some skin care products or cosmetics that have expired are considered hazardous waste.

Some nail polishes, nail polish removers, and nail polishes are irritating. They are all hazardous wastes and require special treatment to reduce their impact on the environment and land.

2. Problems encountered in the recycling of cosmetic bottles

It is well known that the recovery rate of cosmetic bottles is low.The material of cosmetic packaging is complex, so recycling cosmetic bottles will be cumbersome.For example, essential oil packaging, but the bottle cap is made of soft rubber, EPS (polystyrene foam), PP (polypropylene), metal plating, etc. The bottle body is divided into transparent glass, variegated glass and paper labels, etc. . If you want to recycle an empty essential oil bottle, you need to sort and sort all these materials.

For professional recycling companies, recycling cosmetic bottles is a complex and low-return process.For cosmetic manufacturers, the cost of recycling cosmetic bottles is much higher than producing new ones.Generally speaking, it is difficult for cosmetic bottles to decompose naturally, causing pollution to the ecological environment.

On the other hand, some cosmetic counterfeit manufacturers recycle these cosmetic bottles and fill low-quality cosmetic products for sale. Therefore, for cosmetic manufacturers, recycle the cosmetic bottles are not only an environmental protection cause but also good for their own interests.

3. Major brands pay attention to cosmetic bottle recycling and sustainable packaging

At present, many beauty and skin care brands are actively taking action to recycle cosmetic bottles. Such as Colgate, MAC, Lancome, Saint Laurent, Biotherm, Kiehl's, L'Oreal Paris Salon/Cosmetics, L'Occitane and so on.

At present, many beauty and skin care brands are actively taking action to recycle cosmetic bottles. Such as Colgate, Shulan, Mei Ke, Xiu Li Ke, Lancome, Saint Laurent, Biotherm, Kiehl's, Yu Sai, L'Oreal Paris Salon/Cosmetics, L'Occitane and so on.

For example, Kiehl's reward for cosmetic bottle recycling activities in North America is to collect ten empty bottles in exchange for a travel-size product. Any packaging of M.A.C products (including hard-to-recycle lipsticks, eyebrow pencils, and other small packages), in any counters or stores in North America, Hong Kong, Taiwan and other regions. Every 6 packs can be exchanged for a full-size lipstick.

Lush has always been an industry leader in eco-friendly packaging, and most of its products come in no packaging. The black jars of these liquid/paste products are full of three and you can change to a Lush mask.

Innisfree encourages consumers to bring empty bottles back to the store through the text on the bottles, and turn the empty bottles into new product packaging, decorative objects, etc. after cleaning. As of 2018, 1,736 tons of empty bottles have been recycled.

In the past 10 years, more and more packaging manufacturers have joined the ranks of practicing "environmental protection 3R" (Reuse recycling, Reduce energy saving and emission reduction, Recycle recycling)

In addition, sustainable packaging materials are gradually being realized.

In the cosmetics industry, environmental protection has never been just a trend, but a crucial factor in the development of the industry. It requires the joint participation and practice of regulations, enterprises and consumers. Therefore, the recycling of empty cosmetic bottles requires the joint promotion of consumers, brands and all sectors of society in order to truly achieve and sustainable development.

Read the full article

0 notes

Text

Appreciation of cosmetic packaging design in 2022

2022 Skincare Trend Insights

According to Ipsos' "Insights into New Trends in Skin Care Products in 2022", "The packaging of skin care products is an important factor in determining the purchase of products by young people. In the survey, 68% of young people are very concerned about the appearance of skin care product packaging design,72 % of young consumers say innovations in skincare packaging design make them more willing to buy the product.”

When consumers do not yet know a skin care brand and product, the packaging of skin care products is often the first to attract consumers. This is an era of winning by appearance, and various skin care product brands have invested a lot of energy to create their own unique brand appearance.

At the same time, in order to attract consumers, in recent years, merchants have put more and more efforts in cosmetic packaging, and various novel and exquisite packaging have emerged one after another. Excellent outer packaging and bottle design have indeed become the factors that make the products popular. In fact, the role of cosmetic packaging is not only to attract consumers, but also to provide essential storage space and protection functions for the material body.

The importance of packaging is also a relatively important sector for current cosmetics. Looking at all the products currently on sale in online channels, some products are unisex, and some are only for women or men, but they are as follows Several characteristics: 1. Highly competitive in the market; 2. Very sensitive to the needs of consumers; 3. Rich in trend and super trend, which can best reflect people's pursuit of aesthetic awareness.

It can be said that cosmetics is a fashionable embodiment, it is a kind of mood, compared with other products, it focuses on reflecting temperament, taste and personality, it is closer to art, it is abstract art with almost no figurative graphics, it is modern. The spiritual food pursued by consumers.

Therefore, special attention must be paid to the design of cosmetic packaging, especially for beauty products. For children, it must be caring and clean. For the elderly, it should reflect elegance, solemnity and mystery. For men, it should be generous and luxurious, as well as reflect the tension of the picture and the effect of the brand.

Cleaning supplies primarily deliver the message of being affordable and healthy. There is no clear consumer layer (except in special cases), and the choice of color tends to be simple, unified and clean. At present, there is also an environmentally friendly cleaning product, and its design generally tends to use concise copywriting as the design element of the picture.

But at the same time, the material application of cosmetic packaging cannot be ignored, it must be carefully selected and properly matched. Its production process strives to be exquisite. Among them, the products of the brand are often packaged in series or packaged with similar products.

Cosmetics generally need to store the container for a long period of time after consumers shop until the paste or liquid inside is used up. Therefore, in the design, the integrity of the cosmetic container and the outer packaging should be considered, and strive to stand out and be unique. Has a distinct personality.

The shape of cosmetic containers can be said to be ever-changing, but no matter what shape, there is always a certain basic shape, and each of these shapes has different characteristics and personalities:

Cubes, cubes give people a sense of dignified and simple, and have a certain tension. Therefore, it is more suitable for container packaging of men's cosmetics.

A sphere, a sphere is full, dynamic and full of energy. Therefore, it is more suitable for the design of cosmetic containers for young people.

Cones, cylinders, cones and cylinders have a sense of stability, uprightness, and a sense of elegance and nobility. Therefore, it is more suitable for the design of cosmetic containers used by middle-aged and cultural consumers.

Bionic body, bionic body imitates natural biological forms such as plants, animals, insects, and characters. In today's society, people are pursuing green environmental protection and nostalgia for the natural environment: Therefore, many cosmetic container packaging designs with biomimetic shapes have appeared.

Abstract forms, abstract forms are irrational and irregular forms with romantic and imaginary emotional colors. Therefore, it is more suitable for the consumer cosmetic container design that is more open-minded.

Read the full article

0 notes

Text

The Top 10 Cosmetic Packaging Suppliers

Packaging plays a huge role in product marketing and is an integral part of any business marketing strategy. To help guide your decision and give you a good starting point, we've put together a list of the top 10 cosmetic packaging suppliers today.

1. Petro Packaging Company Inc.

2. Paper Mart

3. SKS Bottle & Packaging

4. APC Packaging

5. Cosmopak

6. Topfeelpack Co., Ltd.

7. Cosmetic Packaging Now!

8. Berlin Packaging

9. The Packaging Company

10. Kaufman Container

Read the full article

0 notes

Text

Lotion bottle

Lotion bottles come in many different sizes, shapes and materials. Most of them are made of plastic, glass or acrylic. There are several different types of lotions for the face, hands, and body. The composition of lotion formulations also varies widely. So there are many types of lotion bottles. Of course, the wide variety of lotion bottles also provide consumers with more and better choices. Included below are some of the different options for storing lotion.

Some lotions are kept in tubes. These tubes are usually made from plastic and depending on their size, can hold quite a bit of lotion. The plastic tube aren’t always the best choice though when it comes to lotion bottles. Whether it’s hand lotion, face lotion ,body lotion or otherwise, the lotion can sometimes cause build up and cake around the spout that it comes out of. If application isn’t done carefully, and lotion gathers on the spout or in the cap, it’s wasteful and causes a bit of a mess. Another problem that some may have with capped tubes is if they always forget to close the cap, the lotion then becomes exposed. This can dry out lotion and decrease it’s effectiveness over time.

Secondly, There are lotion bottle have pump dispensers instead of capped tops. They also made of plastic.It is more convenient to use. Pump dispensers come in a wide variety of options. There are the smooth pumps, the up lock pumps, the down lock pumps and the foam pump. This is a good option for those that have problems with the strength in their hands. There is a trouble that, depending on how much lotion you need, you may have to pump more than a few times. That can get a bit annoying, especially if the pump doesn’t dispense a lot each time.

Lastly, another efficient and a good choice is store lotion in the glass bottle. These type of lotion bottles are great because they come in virtually every type and size, and they easily dispense the amount of lotion that you need. You can choose to use a pump with a glass bottle, or you can simply twist off the pump and pour as much lotion into your hand as you require. Lotion bottles come in many different styles , it just depends on your personal preference.

Read the full article

0 notes

Text

The Importance of Cosmetic Packaging in the Cosmetic Industry

When it comes to cosmetics, image is everything. The beauty industry excels at creating products that make consumers look and feel their best. It is well known that product packaging can have a major impact on the overall success of a product, especially for cosmetic products. Consumers want their cosmetics to look good inside and out, and product packaging plays a big role in that. This article briefly explores the importance of product packaging in the cosmetic industry, and the various ways in which packaging influences consumers’ cosmetic purchasing patterns.

1. Protective Effect

At the most basic level, product packaging is designed to protect the product and prevent it from being tampered with. This is a very important factor for cosmetics, as these products are often placed near the eyes, nose and mouth. Therefore, tampering with a product in any way can pose significant health risks to consumers. Therefore, many cosmetic brands package their products in tamper-proof packaging. Durable product packaging also helps keep the product from being damaged in transit. Appearance is very important in this industry, so products must be pristine when they arrive in stores.

2. Display Effect

Often, the first thing consumers look for when buying cosmetics is color. Therefore, product packaging should represent the color of the product as accurately as possible. Packaging cosmetics in clear plastic folding cartons allows consumers to clearly see the product before purchasing. The color of the product will be displayed accurately, making it easy for consumers to choose the right color for their style or skin tone.

3. Brand Marketing

The cosmetics industry relies heavily on branding. Consumers tend to be very loyal to the cosmetic brand of their choice, and once they find a brand they like, they are very reluctant to switch to other brands. Therefore, product packaging should be designed so that it is immediately recognizable. This helps the company retain its loyal customer base, while also making it easier to market to new customers who might only be marketing to a company through word of mouth. The quality of packaging materials also plays an important role in cosmetic marketing. High-quality product packaging is often associated with high-quality products. When customers see beautiful product packaging, they are more likely to trust the company and the product and are more likely to make a purchase. Packaging with high-quality cosmetic products assures consumers that the product is reliable and well-constructed.

Read the full article

0 notes

Text

30ml Crystal Lantern Special Dropper Bottle

30ml PETG Blowing Bottle for Make-up

Item

Capacity

Parameter

Material

PB01

30ml

H85.5 x 33 x44.5mm

Lid:PP Plug:PP Bottle:PETG 304 Stainless steel beads

Since this bottle made of PTEG material, its material has very good chemical resistance and it is Durable for cosmetic products.

It can be any color, like transparent, black, blue, orange, matte, shiny or any your pantone color.

When it is made into a transparent, it can show inner ingredients. At the same time, as this lid is design in double layer, both visual and tactile are great with top quality.

It is suitable for liquid foundation, primer, makeup base, sunblock and other color cosmetic products, like

30ml liquid foundation bottle

30ml primer bottle

BB cream Bottle

empty Primer bottle

Essential CC cream Bottle

foundation bottle

liquid foundation bottle

More details

The design of this pre-makeup foundation bottle PB02 and PB01 are very similar, but they have two differences.

The capacity of PB01 is 30ml, and the PB02 is 40ml. PB01 has a smooth, curved surface, and the cap and bottle of this PB02 have a facet forms.

Other Recommended Foundation Bottle

PB01 Sunblock Bottle

PB03 Sunblock & Primer Bottle

PB04 Makeup Base Cream Bottle

Factory

GMP work shop

ISO 9001

1 day for 3D drawing

3 days for prototype

Read more

Quality

Quality standard confirmation

Double quality inspections

3rd Party testing services

8D report

Read more

Service

One-stop cosmetic solution

Value-added offer

Professional and Efficiency

Read more

Frequently Asked Questions

What is your MOQ?

Our have different MOQ requirements based on different items due to the molds and production difference. The MOQ range usually from 5,000 to 20,000 pieces for a customized order. Also, we have some stock item that with LOW MOQ and even NO MOQ requirement.

What is your Price?

We will quote the price according to the Mold item, capacity, decorations (color and printing) and order quantity. If you want a exactly price, please give us more details!

Can I get samples?

Of course! we support customers to ask samples before order. The sample ready in office or warehouse will be provided to you for free!

What Other Are Saying

To exist, we must create classics and convey love and beauty with unlimited creativity! In 2021, Topfeel have undertaken nearly 100 sets of private molds. The development goal is “1 day to provide drawings, 3 days to produce the 3D protype”, so that customers can make decisions about new products and replace old products with high efficiency, and adapt to market changes. If you have any new ideas, we are glad to help you achieve it together!

Beautiful, recyclable, and degradable cosmetic packaging are our unremitting goals

Call us today at +86 18692024417 or email [email protected]

Please tell us your inquiry with details and we will get back to you as soon as possible. Due to time difference, sometimes the response may be delay, please wait patiently. If you have an urgent need, please call to +86 18692024417

Contact Us!

Read the full article

#30mlDropperBottle#essentialoildropper#Exquisitedropperbottle#LanternshapedDropper#serumdropper#SpecialDropperBottle

0 notes

Text

Packaging Surface Treatment Process: Water Transfer Printing

Slowly immerse the sneaker in the water with "paint", and then move it quickly, the unique pattern will be attached to the surface of the shoe. At this point, you have a pair of DIY original global limited edition sneakers. Car owners also usually use this method to DIY their car, like tires to show their uniqueness.

This DIY method favored by many brands and consumers is a "water transfer printing" process that is widely used in the packaging industry. The processing of the common beautiful and complex cosmetic packaging container is made by water transfer printing.

What is water transfer printing?

Water transfer technology is a printing method that uses water pressure to transfer the color patterns on the transfer paper/plastic film to the printed matter. Water transfer printing technology is divided into two categories: one is water mark transfer technology, and the other is water coating film transfer technology.

Watermark transfer technology is a process to completely transfer the graphics and text on the transfer paper to the surface of the substrate, mainly to complete the transfer of text and photo patterns.

Water coating film transfer technology refers to the decoration of the entire surface of the object, covering the original face of the workpiece, and capable of pattern printing on the entire surface of the object (three-dimensional), which tends to perform a complete transfer on the entire product surface.

What are the processes for water transfer printing?

Coating film. Pre-print the water-soluble film with a pattern.

Activation. Use a special solvent to activate the pattern on the film into an ink state

Drape. Use water pressure to transfer the pattern onto the printed material

Water wash. Rinse the remaining impurities on the printed workpiece with water

Dry. Dry the printed workpiece

Spray paint. Spray PU transparent varnish to protect the surface of the printed workpiece.

Dry. Dry the surface of the object.

What are the characteristics of water transfer printing?

1. Pattern richness.

Using 3D printing + water transfer technology, photos and graphics files of any natural texture can be transferred onto the product, such as wood texture, stone texture, animal skin texture, carbon fiber texture, etc.

2. The materials to be printed are diverse.

All hard materials are suitable for water transfer printing. Metal, plastic, glass, ceramics, wood and other materials are suitable for water transfer printing. Among them, the most common are metal and plastic products.

3. Not limited by the shape of the substrate.

Water transfer printing technology can overcome the problems that traditional printing, thermal transfer, pad printing, silk screen printing, and painting cannot produce complex shapes.

Read the full article

0 notes

Text

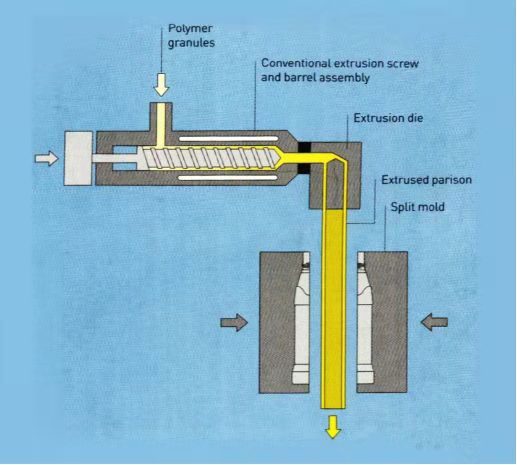

From the Molding Process to See How to Make Cosmetic Plastic Bottles

The plastic packaging material molding process in the cosmetics industry is mainly divided into two categories: injection molding and blow molding.

Injection Molding

What is the injection molding process?

Injection molding is a process of heating and plasticizing the plastic (heating and melting into a fluid, plasticity), and then applying pressure to inject it into a closed mold space, allowing it to cool and solidify in the mold, to produce a product with the same shape as the mold. It is suitable for mass production of parts with complex shapes.

Characteristics of injection molding process:

1. Fast production speed, high efficiency, high degree of operation automation

2. The product has high precision, and the appearance error is very small

3. Able to produce parts with complex shapes

4. High mold cost

Most our airless bottle, double-wall lotion bottle are produced by injection process.

Blow molding

Characteristics of blow molding process:

Drawing lessons from the traditional glass blowing process, blow molding uses compressed air with a certain pressure to inflate and cool the preform (semi-finished tubular plastic body) in the mold into a molding process for hollow products. It is suitable for mass production of hollow plastic containers.

What are the characteristics of the blow molding process?

1. Simple production method, high production efficiency and automation

2. Low dimensional accuracy

3. There are certain restrictions on the shape of the product

4. Low mold cost

According to different production steps and processes, blow molding can be divided into three types: extrusion blowing, injection blowing, and injection stretch blowing.

The first is squeezing and blowing. As the name suggests, extrusion blow has two major steps: extrusion and blow molding.

The first step is to extrude the parison-mold closure. The extrusion device continues to squeeze to form a hollow tubular parison. When the parison is extruded to a predetermined length, the top of the parison is cut to a length suitable for a single piece, and the molds on the left and right sides are closed.

The second step, air introduction-trimming. Compressed air is injected into the preform through the mandrel to inflate. The parison closely adheres to the inner wall of the mold to cool and shape, and the product is removed from the mold, and the second trimming is performed. The cost of extrusion and blowing equipment and molds is relatively low, and the production cost is also relatively low.

However, flashing occurs during the production process, and the mouth and bottom of the bottle need to be trimmed mechanically or manually, and sometimes the mouth of the bottle needs to be polished and trimmed.

Extrusion-blow molded plastic bottles have a parting line (a linear protrusion) at the bottom, and the mouth of the bottle is rough and not smooth, so some have the risk of liquid leakage. Such bottles are usually made of PE material and are used in cosmetics such as foam bottles, body lotions, shampoos and conditioners.

The second type is injection blowing, which has two major steps: injection-blow molding.

Step 1: Preform injection-mold closure.

Use the injection molding process to produce a bottomed parison, and the console rotates 120° to the blow molding link.

The mold is closed, and compressed air is introduced into the parison through the mandrel pores for blow molding.

Step 2: Preform inflation-cooling and demoulding.

After the blow-molded product is completely cured and molded, the console rotates 120° to demold the product. No need for secondary trimming, so the degree of automation and production efficiency are high. Because the bottle is blown from an injection-molded parison, the mouth of the bottle is flat and the bottle has better sealing properties, such as the TB07 blowing bottle series.

The third type is note pulling and blowing. It is divided into three steps: injection-stretching-blow molding.

Different from the turntable type of injection blowing, injection stretch blowing is an assembly line production.

Step 1: Preform injection-mold closure

Put the preform produced by injection into the blow mold

Insert the stretch rod and close the mold left and right

Step 2: Stretching-Blowing-Cooling and demoulding

The stretching rod is longitudinally stretched, while air is injected through the stretching rod for lateral stretching

Cooling and shaping, demoulding and taking out the product

Injection stretch blowing is the one with the highest quality, precision and cost in the blow molding process.

At present, there are two production methods in the injection stretch blowing process, called: one-step method and two-step method. Injection molding and blow molding are completed together in a one-step method, and the two steps are completed independently as a two-step method.

Compared with the two-step method, the one-step method is completed in one-step equipment from the raw materials to the finished product. The production process is simple and no secondary heating is allowed, so the energy consumption is lower.

The two-step method requires first preform injection, and then secondary processing on the blow molding machine. Blow molding requires secondary heating of the cooled preform, so the energy consumption is high.

Most of the information comes from the CiE beauty supply chain

Read the full article

0 notes

Text

Types of Cosmetics

Cosmetics have many types and different functions, but in terms of their external shape and suitability for packaging, there are mainly the following categories: solid cosmetics, solid granular (powder) cosmetics, liquid and emulsion cosmetics, cream cosmetics, etc. .

1. Packaging of liquid, emulsion cosmetics and cream cosmetics.

Among all cosmetics, the types and quantities of these cosmetics are the largest, and the packaging forms are very complicated. They mainly include: tubes and plastic bottles of various shapes and specifications; composite film bags of plastic bags; glass bottles of various shapes and specifications (including wide-mouth Bottles and narrow-mouth bottles are generally used for packaging of cosmetics that are volatile, permeable, and contain organic solvents, such as essence, nail polish, hair dye, perfume, etc.). For the packaging of the above products, the advantage is also to match the color printing box. Together with the color box, it forms the sales package of cosmetics to improve the grade of cosmetics.

2. Packaging of solid granular (powder) cosmetics.

This type of cosmetics mainly include powder products such as foundation and talcum powder, and the commonly used packaging methods include paper boxes, composite paper boxes (mostly cylindrical boxes), jars, metal boxes, plastic boxes, plastic bottles, etc.

3. Spray packaging of cosmetics.

The spray bottle has the advantages of being accurate, effective, convenient, hygienic, and quantified on demand. It is often used in toners, perfumes, sunscreen sprays, dry shampoos, hair styling and other products. Commonly used spray packages include aluminum can sprayers, glass spray bottles, and plastic spray bottles.

In the future, with the development of technology, more cosmetic packaging will emerge as the times require. Just like the current reusable moisturizing bottles, essence bottles and some cream jars.

Read the full article

0 notes

Video

youtube

Scale Design Available 50ml PCR Airless Pump Bottle Manufacturer

0 notes

Text

Chapter 2. How to Classify Cosmetic Packaging for a Professional Purchaser

2. Glass bottles are divided into wide mouth containers and narrow mouth containers. Solid paste (cream) is generally used for wide mouth container/jars, which should be equipped with electrochemical aluminum cap or plastic cap. The cap can be used for color injection and other effects; Emulsion or liquid generally used narrow bottle, suitable match with pump head. People should pay attention to prevent spring and ball rust. Most of the pump is equipped with glass beads, usually we need to make material applicable test. If we matching the cover with internal plug, liquid formula need match a small internal plug, thicker emulsion usually match with a big hole plug.

3. The glass bottle has more consistent material selection, more shapes, rich processing technology and diversified matching with the bottle cap. The common bottle types are cylindrical, oval, flat, prismatic, conical, etc. the factory often develops a series of bottle types. The bottle body processes include spraying, transparent, frosting, translucent color matching, silk screen printing, bronzing, etc.

4. If the glass bottle is made by manual mold, there will be a little deviation in capacity. During selection, it shall be tested and correctly marked. The of the automatic production line is relatively uniform, but the shipment requirements are large, the cycle is relatively long, and the capacity is relatively stable.

5. Uneven thickness of the glass bottle may easily lead to damage, or it may be easily crushed by the contents under severe cold conditions. The reasonable capacity shall be tested during filling, and it is recommended to use # outer box for transportation. Skin care products in glass bottles should be equipped with color boxes. If there are inner brackets and medium boxes, they can play a role in earthquake prevention and have higher safety.

6. Common types of glass bottles are usually in stock. The production cycle of glass bottles is longer, 20 days faster, and some are as long as 45 days. For normal glass bottle processing technology, such as customized spraying color and silk screen printing of essential oil bottles, its minimum order quantity is 5000 pcs or 10000 pcs. The smaller the bottle type, the greater the required MOQ, and the cycle and minimum order quantity will be affected by the low season and peak season. Some brown/amber oil bottles and lotion bottles can be shipped on a low MOQ basis, as the supplier has prepared regular stock.

7. Mold opening cost: about $600 for manual mold and about $1000 for automatic mold. A mold with 1 to 4 ot 1 to 8 cavities mold is costs US $3000 to US $6500, depending on the manufacturer's conditions.

8. The bottle cap process can be used for electrochemical aluminum lettering, gilding and line engraving. It can be divided into matte surface and bright surface. It needs to be equipped with gasket and inner cover. It is best to match with sub sensitive film to strengthen the sealing effect.

9. The essential oil bottle usually uses brown, frosted and other colored to avoid light and protect the ingredients. The cover has a safety ring and can be equipped with an inner plug or dropper. Perfume bottles are usually matched with fine mist pumps or plastic caps.

10. Description of process cost: there are usually two kinds of glass screen printing. One is high-temperature ink screen printing, which is characterized by not easy decolorization, dull color and difficult purple color matching. The other is low-temperature ink screen printing, which has bright color and high requirements for ink, otherwise it is easy to fall off. Buyers and sellers need to pay attention to the disinfection methods of such bottles. The cost of silk screen printing is US $0.016 per color. Cylindrical bottles can be used as monochrome plan, and special-shaped bottles are calculated according to the cost of two-color or multi-color. As for spraying, the cost of spraying is generally US $0.1 to US $0.2/color, depending on the area and the difficulty of color matching. The cost of gold and silver stamping is $0.06 per pass.

Send Inquiry to [email protected]

Read the full article

0 notes

Text

01 How to Classify Cosmetic Packaging for a Professional Purchaser

Cosmetic packaging materials are divided into main container and auxiliary materials.

The main container usually includes: plastic bottles, glass bottles, tubes, and airless bottles. Auxiliary materials usually include color box, office box, and middle box.

This article mainly talks about plastic bottles, please find the following information.

1. The material of cosmetic plastic bottle is usually PP, PE, PET, AS, ABS, PETG, silicone, etc.

2. Generally used in cosmetics containers with thicker walls, cream jars, caps, stoppers, gaskets, pumps, and dust covers are injection molded; PET bottle blowing is two-step molding, the preform is injection molding, and the finished product is packaged as blow molding.

3. The PET material is an environmentally friendly material with high barrier properties, light weight, not fragile, and chemical resistance. The material is extremely transparent and can be made into pearlescent, colored and porcelain color. It is widely used in daily chemical products and skin care products. Bottle mouths are generally standard #18, #20, #24 and #28 calibers, which can be matched with caps, spray pumps, lotion pumps, etc.

4. Acrylic is made of injection molding bottle, which has poor chemical resistance. Generally, it cannot be directly filled with formula. It needs to be blocked by an inner cup or inner bottle. The filling is not recommended to be too full to prevent the formula from entering between the inner bottle and the outer bottle to avoid cracks. The packaging requirements are high during transportation. It looks particularly obvious after scratches, has high permeability, and the sensory upper wall is very thick, but the price is very expensive.

5. AS\ABS: AS has better transparency and toughness than ABS. However, AS materials are prone to react with some special formulations and cause cracking. ABS has good adhesion and is suitable for electroplating and spraying processes.

6. Mold development cost: The cost of blowing molds ranges from US$600 to US$2000. The cost of the mold varies according to the volume requirements of the bottle and the number of cavities. If the customer has a large order and requires a faster delivery time, they can choose 1 to 4 or 1 to 8 cavity molds. The injection mold is 1,500 US dollars to 7,500 US dollars, and the price is related to the required weight of the material and the complexity of the design. Topfeelpack Co., Ltd. is very good at providing high-quality mold services and has rich experience in completing complex molds.

7. MOQ: The custom-made MOQ for blowing bottles is generally 10,000pcs, which can be the color that customers want. If customers want common colors such as transparent, white, brown, etc., sometimes the customer can provide stock products. Which meet the requirements of low MOQ and fast delivery. It is worth noting that although the same color masterbatch is used in one batch of production, there will be a color difference between the colors of the bottle and the closure due to the different materials.

8. Printing: Screen printing has common ink and UV ink. UV ink has better effect, gloss and three-dimensional effect. It should be printed to confirm the color during production. Silk-screen printing on different materials will have different performance effects.

9. Hot stamping and other processing techniques are suitable for the completion of hard materials and smooth surfaces. The soft surface is unevenly stressed, the effect of hot stamping is not good, and it is easy to fall off. At this time, the method of printing gold and silver can be used. Instead, it is recommended to communicate with customers.

10. The silkscreen should have a film, the graphic effect is black, and the background color is transparent. The hot-stamping and hot-silvering process must produce positive film, the graphic effect is transparent, and the background color is black. The proportion of text and pattern should not be too fine, otherwise the effect will not be printed.

Read the full article

0 notes

Text

Oval Flat Empty Primer Liquid Foundation Bottle 50ml

The 50ml flat-shoulder bottle is matched with a double-lid diamond face design. After electroplating, the visual texture of the product becomes better.. The body is made of PETG material, which has the advantages of high impact resistance, temperature resistance and long life. Accept color customization. The sample in the picture is a bright gold and silver cap, matched with white and highly saturated orange injection molding

Read the full article

#50mlfoundationbottle#50mlprimerbottle#foundationbottle#liquidfoundationbottle#primerbottle#primertube#Sunblockbottle

0 notes

Text

Facet Forms Sunblock Bottle Orange Bule Make Up Base Tube Bottle

This is a 40ml blown plastic bottle with a natural gloss on the surface. The cap and bottle body are in facet form design, with a pointed mouth plug fitting. The body is made of PETG material, which has the advantages of high impact resistance, temperature resistance and long life. It is suitable for high-end liquid foundation, primer, makeup base, sunblock and other color cosmetic products.

Read the full article

0 notes