Text

What is the reason why the chamber filter press cannot press mud?

If the chamber filter press cannot produce mud, it will have a great impact on our use. Therefore, if we want to use the chamber filter press correctly, we must strictly follow the operation. When using the chamber filter press, maintenance is required. Various components, otherwise, if they have problems, there will be very serious consequences! Then, what is the reason why the chamber filter press cannot press the mud? Let me introduce myself to you below.

1. The flocculation effect of sludge is not ideal

The chamber filter press is more dependent on conditioning. The chamber filter press is suitable for suspensions with large or almost incompressible filter residue compressibility. The solid particle concentration of suitable suspensions is generally less than 10%, and the operating pressure is generally 0.3 to 0.6 MPa, especially 3 MPa or higher. A filter press whose elastic membrane is installed between the filter plate and the filter cloth of the membrane filter press. In the process of use, after the feeding is completed, the high-pressure fluid or gas medium can be injected into the diaphragm plate, and then the whole diaphragm will bulge to press the filter cake, thereby further dehydrating the filter cake, which is usually called press filtration.

If the dosage is insufficient and the conditioning effect is not good, the capillary water in the sludge cannot be converted into free water and is removed in the gravity zone, so the sludge entering the low-pressure zone from the mold zone is still fluid and cannot be squeezed. . On the contrary, if the dosage is too large, first, the treatment cost will be increased, and more importantly, the filter belt will be blocked due to the increased viscosity of the sludge. For municipal sewage mixed sludge, when cationic PAM is used, the dosage of dry sludge is generally 1-10 kg/t, which can be determined by experiment or repeatedly adjusted during operation.

2. Low mud concentration is the main reason

The sludge concentration, often referred to as the sludge solid content, is less than 1, the direct mechanical sludge dewatering effect is not ideal, and the demand for flocculants increases. If the domestic sludge or viscous industrial sludge with a concentration lower than 1 enters the chamber filter press, it will cause sludge leakage, and the sludge cannot be pressed, and the treatment efficiency is low. The traditional practice is to increase the sludge thickening tank in civil construction. Centrifugal sludge thickener solves this problem very well. After thickening by the sludge thickener, the sludge concentration can be increased to about 3.5-11, which is very suitable for entering the chamber filter press for pressure filtration and dehydration process, avoiding the need for sludge Sludge leakage due to low concentration. It has been widely used in some sewage with a large amount of sewage and low solid content of sludge, such as domestic sewage.

3. The filter cloth is aged or improperly selected

The above is the introduction of the reasons why the chamber filter press cannot press mud, I hope it will be helpful to everyone. As a chamber filter press company, Kintep specializes in wholesale chamber filter press equipment. Our products are of good quality. If you want to know more about chamber filter press, then come and pay attention to our website.

0 notes

Text

Which chamber filter press is better?

Faced with different types of chamber filter presses on the market, you may not know how to choose them. Moreover, many processing manufacturers require the long-term use of a chamber filter press, so it is necessary to ensure its quality and performance. So how to choose the right equipment? Which brand of chamber filter press is of good quality and the price is very reasonable?

Brand equipment warranty

Because the type and performance of the chamber filter press we choose are different, the price is also different. If we want to buy the right equipment, then we still need to determine the quotation of the brand. You can first measure the functions of different devices through the network, then choose the appropriate model, and then measure the quotation, which is also guaranteed.

Moreover, the chamber filter press provided by many brands has good after-sales service. If the purchase is made through the online platform, the merchant can also provide us with services such as transportation, door-to-door installation, and maintenance. Therefore, if you want to determine the business ability of the manufacturer and the quotation, it is also guaranteed to buy a suitable chamber filter press, and the price can also be saved a lot.

Measurement of the technical level of the brand

The quality and performance of each brand of chamber filter press, as well as the level of core technology, are completely different. If we want to buy the right equipment, we must pay special attention to the specific conditions of product quality. With high-quality equipment, excellent quality guaranteed technical performance, and complete functions, such as a chamber filter press is our first choice.

As a chamber filter press manufacturer, Kintep specializes in the production of chamber filter presses with guaranteed product quality. If you want to know more about chamber filter press, then come and pay attention to our website.

0 notes

Photo

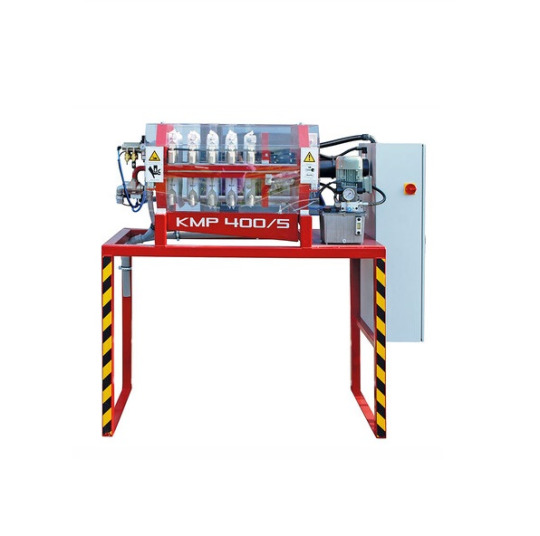

Chamber filter presses are widely used in organic chemistry and metallurgical industry processing. So do you know the relevant knowledge of chamber filter press filter plates?

0 notes

Text

Precautions for the use of chamber filter press

0 notes

Photo

Explain the reasons and treatment methods for leakage of chamber filter press, which can help customers deal with problems in time and improve production capacity.

#chamber filter press#the reasons for the leakage of the chamber filter press#chamber filter press enterprise

0 notes

Photo

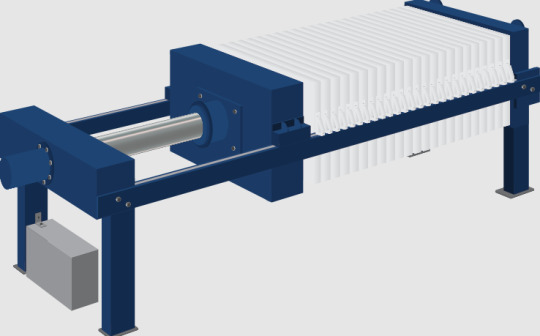

The filter press is an important sludge treatment equipment with a wide range of applications. The following describes the working process of the filter press.

0 notes

Photo

The damage of the filter plate of the filter press will affect the working efficiency of the filter press, so the filter plate of the filter press is very important.

0 notes

Text

What should be paid attention to when installing screw type filter press?

The following issues should be paid attention to when installing screw type filter press:

1. There should be enough operation and maintenance space around the screw type filter press. The hydraulic filter press should be equipped with a hydraulic station in a suitable position to ensure that the hydraulic station can work normally.

2. Place the filter plate according to the work needs, and arrange the feeding, cleaning and drainage pipes. Equipped with a pressure display gauge and a return channel to control the filtration pressure. If it is a diaphragm extrusion type, configure the compressed air pipeline.

3. Hydraulic filter press, inject 20#-40# hydraulic mechanical oil into the hydraulic station, the operating temperature is >-5℃; when the ambient temperature is too low, the hydraulic oil with similar viscosity and low point can be selected. The hydraulic pressure oil volume is 80, and a 100-mesh filter is added.

4. The screw type filter press should be installed on a horizontal concrete foundation. The bottom bolt of the thrust plate machine at the feeding end is fixed on the base, without the need for anchor bolts, or after the anchor bolts are positioned, they are locked with two nuts and nut washers. There is a proper gap between the machine foot and the machine foot base, so that the machine foot can be slightly stretched. The installer should correct the large plane perpendicularity of the beam and thrust plate before positioning.

5. For mechanical or hydraulic presses, the motor should work normally when the power is turned on. The hydraulic pressure gauge should rise smoothly on the pressure gauge, the hydraulic system should not overflow, and the working pressure of the hydraulic station should be adjusted correctly according to the model size. If the oil storage tank is found to be insufficient after the test machine, it should be replenished in time.

6. The foundation structure should be designed according to the load condition of the equipment, the construction personnel should design the foundation structure, and the anchor bolt should adopt the reserved hole position of twice grouting.

After the above operations are completed, there will be basically no problems in the installation of the screw type filter press. As long as you pay attention to the maintenance and maintenance of the screw type filter press in daily use, the working status and work efficiency of the screw type filter press can be guaranteed.

As a screw type filter press manufacturer, Kintep produces high-quality screw type filter presses, which are widely praised by customers. If you want to know more about screw type filter press, then come and pay attention to our website.

#screw type filter press#screw type filter press installation precautions#screw type filter press manufacturer

0 notes

Text

Why use spiral sludge dewatering machine to reduce costs?

1. Reduce construction costs

The spiral sludge dewatering machine has a compact design and is easy to adapt to local adjustments, which can reduce the space occupied and the construction cost of the dewatering machine itself. Due to the sludge thickening function, no thickening storage unit is required, reducing the total space and construction cost of the sewage treatment facility.

2. Reduce design cost

The spiral sludge dewatering machine has various specifications and complete series. According to different processing scales, suitable models can be selected to avoid over-qualification. Compact body design, integration of concentration and dehydration, electronic control cabinet, sludge flocculation mixing tank and other auxiliary devices, strong compatibility with supporting equipment, and simple design.

3. Reduce maintenance costs

The spiral sludge dewatering machine is durable, with low maintenance frequency and fewer replacement parts. With a small design, maintenance and replacement operations are easy to learn and less time-consuming.

4. Reduce operating costs

The main body of the spiral sludge dewatering machine has the function of self-cleaning, without using a large amount of cleaning agent to prevent the sludge from clogging. Using low-speed screw extrusion technology, low energy consumption. The electric control cabinet is equipped with an automatic control device, which can transport sludge, inject liquid, concentrate and dehydrate, and discharge sludge cake to realize 24-hour automatic and continuous unattended operation and reduce labor costs.

Environmental protection is one of the main starting points for current development, and we are also constantly optimizing new standards. For example, the requirement for sludge reduction in recent years is a key requirement for secondary pollution. We should also consider the environment when dealing with or optimizing the existing environment. Whether it will cause secondary pollution, as a spiral sludge dewatering machine.

Reasons why spiral sludge dewatering machine can avoid secondary pollution:

1. The spiral sludge dewatering machine is a kind of mechanical equipment, which will not cause any pollution to the environment. For example, it does not burn gasoline and oil, nor does it produce harmful gases and liquids.

2. Equipment cleaning, such as the equipment we used before, such as plate and frame filter presses, belt filter presses, these equipments are filter cloth extrusion dehydration, the effect is not very ideal, the need for high-pressure water gun cleaning will lead to secondary pollution, spiral The sludge dewatering machine has baffles, which greatly eliminates this possibility.

3. The equipment is sealed, the spiral sludge dewatering machine can be completely sealed, so that the taste of sludge treatment is sealed, the emission of harmful gases is reduced, and the surrounding environment is improved.

The above is about the advantages of using the spiral sludge dewatering machine. We are a professional sales company of the spiral sludge dewatering machine. If you are interested in the spiral sludge dewatering machine, please pay attention to our website.

#spiral sludge dewatering machine#advantages of spiral sludge dewatering machine#spiral sludge dewatering machine company

0 notes

Text

Advantages of screw sludge dewatering machine

The spiral sludge dewatering machine has gradually become indispensable and important equipment in people's life and work. The spiral sludge dewatering machine is also widely used in medicine, municipal engineering, chemical factory, leather factory, pharmaceutical factory, wineries, and other fields. What are the advantages of spiral sludge dewatering machines?

The spiral sludge dewatering machine has a stable structure and stable operation. The whole machine occupies a small area and can achieve continuous dehydration work efficiency. The dewatering rate of the spiral sludge dewatering machine can reach 95%. The fixed ring is combined with the floating ring to form a filter press mode. The service life of spiral sludge dewatering machines can reach more than ten years. Because the screw shaft adopts surfacing welding technology, the maintenance cost is relatively low, all of which are 304 stainless steel, which is wear-resistant and corrosion-resistant. The spiral sludge dewatering machine has an automatic spray system, which can automatically clean the screw shaft and prevent clogging. These advantages of spiral sludge dewatering machines make more users use and love it.

The spiral sludge dewatering machine can not only process high-concentration sludge but also directly concentrate and dewater low-concentration sludge. It is suitable for a wide range of sludge concentrations, up to 3000mg/L-50,000mg/L. After Wanjie's own rotating disc pre-concentration device is configured, it is better at dealing with low-concentration sludge, with stable treatment and large treatment capacity.

Concentration: When the screw push shaft rotates, a plurality of stationary laminations arranged around the push shaft moves relatively. Under the action of gravity, water is filtered out from the relatively moving lamination gap to achieve concentration.

Dewatering: The thickened sludge moves forward with the rotation of the screw shaft; along the outlet direction of the mud cake, the pitch of the screw shaft gradually decreases, the ring gap gradually shrinks, and the volume of the spiral cavity shrinks; under the action of the outlet back pressure plate, the internal pressure gradually increases. Driven by the continuous operation of the screw shaft, the moisture in the sludge is extruded and discharged, and the solid content of the filter cake increases continuously, realizing the continuous dewatering of the sludge.

Self-cleaning: The rotation of the screw shaft promotes the continuous rotation of the swimming ring. The equipment relies on the movement between the fixed ring and the moving ring to realize a continuous self-cleaning process, which cleverly avoids the common clogging problem of traditional dehydrators. The existing gravity concentration characteristics can achieve low concentration sludge concentration, complete flocculation concentration, reduce the subsequent dewatering pressure into the sludge concentration, and stabilize the sludge concentration.

As a supplier of spiral sludge dewatering machines, Kintep has exported a large number of spiral sludge dewatering machines to overseas countries and won wide acclaim from customers. If you want to know more about the spiral sludge dewatering machine, then come and pay attention to our website.

#spiral sludge dewatering machine#advantages of spiral sludge dewatering machine#spiral sludge dewatering machine supplier

0 notes

Text

Why did the filter press suddenly stop working?

Regarding the filter press, we are now a relatively common equipment in our lives, which brings great convenience to our life. If the filter press is used for a long time, it will suddenly stop working or have some failures. This is What is the reason, the following small series will explain the specific reasons to you.

Reasons why the filter press suddenly stops working:

Errors in the filter press control system can cause the filter press equipment to stop working. We all know that when the filter press equipment is working, it needs a control system to control the hydraulic system and control its expansion and contraction range, so as to control the power generated by the hydraulic system to the filter plate, and the power received by the filter plate can be transmitted to the filter plate. The filtrate has the ability to penetrate the filter cloth directly displayed by the pressure, so the control system of the filter press equipment directly affects the filtration of the filtrate.

When there is an error in the control system, or the control system cannot be understood, or the control system cannot sense the condition of the hydraulic system, naturally the filter press equipment cannot work, and it is very dangerous even if it runs reluctantly, so It is necessary to stop the work of the equipment in time.

The reason why the filter press stops working may be that the flow path channel in the equipment is blocked. When some of the water channels in the filter press are blocked, it will cause the filtrate to not enter the equipment or be excluded from the equipment, so that the filter press equipment will suddenly stop running and stop flowing out of the drain by manpower. of liquid. In the case of this blockage, even if the filtrate is in contact with the filter cloth, since there is no pressure difference, the filter separation effect cannot occur, so at this time, the filter press will naturally stop working.

As an exporter of filter presses in China, Kintep has a professional manufacturing team. Our products have stable performance and long service life. If you want to know more about filter presses, then come and pay attention to us.

0 notes

Text

How to clean the chamber filter press?

In the process of using the chamber filter press, after long-term use, there will be a lot of contamination inside the chamber filter press, so how to clean the contamination of the chamber filter press is what we often do, then, the following Let's take a look at the cleaning of the lower chamber filter press.

The cleaning of the chamber filter press is mainly the cleaning of the bearing. The cleaning of the bearing is divided into rough washing and fine washing, and a metal mesh frame can be placed at the bottom of the container in use. During rough cleaning of the chamber filter press, use a brush, etc. to remove grease or sticking matter in the oil. At this time, if the bearing is rotated in oil, be careful that the rolling surface may be damaged by foreign matter or the like. During fine cleaning, the bearings are slowly rotated in the oil, which must be done carefully.

Generally, the cleaning agent used in the chamber filter press is neutral non-hydrous diesel or kerosene, and sometimes warm lye is also used as needed. No matter which cleaning agent you use, filter it frequently to keep it clean. After the van filter press is cleaned, the imported bearings should be coated with anti-rust oil or anti-rust grease immediately. In this way, the service life of our chamber filter press can be extended.

In the chamber filter press, if the hydraulic power system of the equipment cannot work normally, it will directly lead to the failure of the entire chamber filter press equipment to work normally. So how do we protect the hydraulic system of the chamber filter press equipment?

1. Check the components of the hydraulic system.

Therefore, we need to regularly clean and inspect the hydraulic system. During the cleaning, we pay attention to observe the links of each part to see if there are signs of leakage. Once found, make up for it, so as not to cause greater damage to the equipment system. destroy.

2. The hydraulic oil needs to be replaced regularly. The hydraulic oil moves cyclically in the whole system, and often the hydraulic oil is under the action of strong pressure, and its impact force is relatively strong, so the hydraulic oil is in the process of moving.

We have been using the chamber filter press equipment for a period of time, and we need to replace the hydraulic oil to ensure the clarity of the hydraulic oil, which is also an effective protection for the hydraulic system.

3. Ensure the supply pressure range of the hydraulic system. In fact, the hydraulic system can change the power range. In fact, in order to protect it, we try to reduce the number of changes to it.

The above is the relevant knowledge about the cleaning of the chamber filter press. As a supplier of chamber filter press, Kintep specializes in selling filter press equipment. Our products are of good quality. If you want to know more about chamber filter press, then come and pay attention to our website.

0 notes

Text

What are the effects of excessive temperature on the chamber filter press?

Chamber filter presses overheat for two reasons: one is the hydraulic system and the other is the filter press. The hydraulic system of a filter press is closely related to temperature. It can control the hydraulic system through the heat release device of the equipment, so that the filter press can operate normally. Excessive temperature in the hydraulic station is especially important because it affects the hydraulic system and the system will not work properly. The filter plate is made of polypropylene material to avoid overheating, slow down the temperature rise and the application cycle of the filter plate. Reduce filter plate damage, increase productivity and achieve higher profitability.

If the filter press is overheated, it will not only have a great impact on the operation of the staff, but also have a certain impact on the filtrate during the operation, which will cause the filtrate to change, thus affecting the separation effect, so you should pay attention to the operation.

1. If the bearing of the van filter press is found to be damaged, please replace it in time. Very strict standards are required when installing new bearings. Be careful not to be random.

2. Prevent the bearing from bringing strong impact, prevent scratches, indentations, and cracks.

3. In the process of using the box filter press, it is necessary to pay attention to the anti-rust treatment of the bearing regularly, so as not to stain the water. Clean the perimeter of the housing, apply lubricant and maintain.

High temperature affects the chamber filter press

1. The influence of temperature on the working state of the chamber filter press is the temperature of the filtrate. The temperature of the filtrate directly affects the filtration efficiency of the chamber filter press and whether the filtration can operate normally. When the temperature of the filtrate exceeds the temperature of the chamber filter press and exceeds the temperature of the filter press plate, it will directly cause the deformation of the chamber filter press, or reduce the acid and alkali resistance of the filter press plate, or accelerate the damage of the filter plate.

The temperature of the filtrate also affects the filtration quality and filtration efficiency of the filter cloth. As the temperature of the filtered liquid increases, the mobility of the water molecules increases, so water is more likely to flow out of the filter cloth. In addition, the temperature of the filtered liquid is also transferred to the filter cloth in contact with it. The pores of the filter cloth also have certain direct changes at different temperatures. When the temperature is higher, the fiber temperature in the filter cloth is also lower. As it increases, the pore size will also increase slightly, so the degree of increase, the filtration efficiency will also increase.

2. Excessive humidity may cause a short circuit in the line, and may also reduce the sensitivity of the sensor, resulting in a slight delay in the operation of the chamber filter press, especially when the chamber filter press changes its working conditions. Therefore, in this case, it is necessary to adapt to the working state of the chamber filter press and prolong the control time of the filter press as much as possible.

3. When the chamber filter press is working, the temperature of the hydraulic oil will increase. If the ambient temperature is too high, it may affect the generally sensitive parts of the hydraulic system of the chamber filter press and cannot adapt to such a temperature in a short time. Poor, resulting in half of the hydraulic oil in the chamber filter press hydraulic oil is high temperature hydraulic oil, half is low temperature hydraulic oil, which may also cause the pressure of the hydraulic oil to be unstable. .

To sum up, the high temperature will not only affect the working efficiency of the chamber filter press, but also greatly reduce the life of the equipment. Therefore, you can learn more about the appropriate temperature by actively interacting with the manufacturer and reduce the operation time. in trouble.

As a filter press supplier, Kintep has a professional manufacturing team. Our products have a long service life. If you want to learn more about filter presses, then come and pay attention to our website.

#chamber filter press#causes of overheating of chamber filter press#effects of overheating of chamber filter press

0 notes

Text

What is the difference between sludge thickening and sludge dewatering?

In the process of sewage treatment, water-containing sludge of different properties is generally produced, and sludge treatment and disposal is a new problem in the process of sewage treatment. Sludge is composed of solid matter in wastewater and solid matter produced during wastewater treatment. The purpose of sludge treatment, on the one hand, is to reduce the moisture content of the sludge as much as possible to facilitate transportation through concentration and dehydration; dispose of.

Because the sludge contains a large amount of harmful substances, such as parasites, pathogenic microorganisms, bacteria, synthetic organic matter, etc., the organic matter content is high, unstable, and easily corrupted. Improper disposal will adversely affect the surrounding environment. Generally, the sludge discharged by the biological usually has a water content of 99%. The sludge thickening machine and the sludge dewatering machine need to be used for sludge treatment. The purpose of the two is the same, but the results are different.

The sludge thickening machine can continuously and stably concentrate sludge, and increase the concentration of sludge with a concentration of about 1% to 3-4%. It is often used for solid-liquid separation and is widely used in sludge reduction and concentration pretreatment of various projects. , Urban domestic sewage, engineering drainage and wastewater treatment of pulp industry, chemical industry, etc. Using the sludge thickening machine, the sludge volume can be effectively reduced after thickening, and the moisture content can reach about 80%, which meets the transportation standard.

After the sludge is thickened by the sludge thickening machine, the volume is larger, and it must be dewatered to increase the solid content of the sludge cake to reduce the footprint of the sludge. Sludge dewatering machine is a continuously operating sludge treatment equipment, which is dewatered by mechanical methods after the sludge is concentrated by gravity. In the sewage treatment system of other industries. After treatment, sludge can be used as soil fertilizer, sludge brick making, incineration treatment, etc. for secondary use to achieve different utilization values.

As an exporter of sludge thickening machines and sludge dewatering machines, Kintep has exported a large number of sludge thickening machines and sludge dewatering machines to overseas countries and won wide acclaim from customers. If you want to know more about sludge thickening machine and sludge dewatering machine, then come and pay attention to our website.

#sludge thickening machine#sludge thickening and sludge dewatering difference#sludge thickening machine exporter

0 notes

Text

How to maintain the sludge thickener machine?

The sludge has a high water content and cannot be directly processed and transported effectively. Now the environmental protection industry chooses to use a sludge thickening machine for sludge thickening to facilitate transportation and processing. When using the sludge thickening machine, it is necessary to do the corresponding maintenance work, then how should the maintenance work? Today, the editor will introduce in detail the maintenance methods of the sludge thickening machine.

1. Only the normal filter press can be used for feeding work, and the whole machine must be inspected comprehensively before each shift. The mechanical compression transmission components and the reduction box must be filled with enough lubricating oil; the hydraulic compression rechecks the oil tank storage capacity and the hydraulic station working pressure. The hydraulic oil is generally replaced once a year. The hydraulic system should be thoroughly cleaned when the hydraulic station is replaced. The working pressure of the hydraulic station should be less than The working pressure of the oil cylinder is high, but it should not be lower than the allowable value of the filter pressure.

2. It is forbidden to start working in the factory when the sludge thickening machine filter plate is less than the specified number, so as to avoid damage to the machine parts. Check the arrangement of the filter plates before feeding. The filter cloth should not be folded to prevent large leakage; after unloading the cake, the filter plates must be tightly pressed and arranged neatly.

3. After everything is normal, the filter plate can be compressed and filtered. The filter pressure and filter temperature must be within the specified range. If the filter pressure is too high, it will cause leakage. If the filter temperature is too high, the plastic filter plate is easy to deform. The concentration of the suspension should be uniform. There must be no impurities; the filter cloth and filter plate must be rinsed after unloading the cake. Residues are not allowed to stick to the sealing surface or the feed channel, otherwise it will affect the smooth flow of the feed and the tightness of the filter plate, which will cause the two sides of the filter plate. Unbalanced pressure causes deformation and damage to the filter plate.

4. The choice of sludge thickening machine must meet the technical requirements of the filter paddle. The new filter cloth should be shrunk before production. The opening diameter should be smaller than the filter plate aperture. When the filter plate is matched, the cloth hole and the plate hole should be relatively concentric. The hole cloth should be close to the wall of the cylinder, otherwise it will cause unclear filtration, low filtration rate, rupture of the cloth cylinder, and the effect of failing to achieve the expected filtering purpose.

5. In the initial stage of sludge thickening machine, the filter is turbid. When a layer of filter cake is formed on the filter cloth, the filtrate will become clear. If the filtrate has been turbid or mixed, it may be that the filter cloth is damaged or the cloth holes are different from the plate holes. At this time, close the valve or stop feeding to replace the filter cloth. A small amount of leakage caused by the capillary phenomenon of the filter cloth is allowed between the filter plates.

6. When moving the filter plate of the sludge thickening machine, the force should be even and appropriate, and no collision or beating is allowed to avoid damage to the sealing surface and the filter handle. After a period of time, the filter cloth will become hard and its performance will decrease. For this reason, regular inspections are required. If changes are found to affect the filtration rate, the corresponding low-concentration weak acid and weak alkali can be used to neutralize and clean the filter cloth to restore its function. If it cannot be restored, replace it in time.

Kintep, as a sludge thickening machine manufacturer, we produce sludge thickening machines with good quality and long service life. If you want to know more about sludge thickening machine, please follow our website.

#sludge thickening machine#sludge thickening machine maintenance method#sludge thickening machine manufacturer

0 notes

Text

Do you know the maintenance measures of the filter press?

We should all know that the different seasons also have a great impact on the work of the filter press, so in order to ensure the normal use of the filter press, we must understand the maintenance measures for the filter press in winter.

1. Hydraulic oil:

In winter, the hydraulic oil is the most affected by the low temperature of the filter press. When the temperature is low enough for it to condense into a solid, we need to pay special attention. We should open the hydraulic station every time before starting the equipment to check whether the hydraulic oil is in normal liquid state. The filter can be started. Therefore, we must try our best to ensure that the equipment hydraulic station is in a mild environment, and the injection valve must be closed tightly to maintain a relatively stable environment inside the hydraulic station.

2. Filter channel:

In winter, we must prevent the residual liquid in the filter press from freezing and blocking the filter channel. Since there is a complicated filtrate flow channel in the filter press, when the filter press stops working, these liquids will remain in the equipment. After a period of freezing, the flow channel of the filter press will be Blockage, so that the filter press can not work next time. Therefore, at this time, we must discharge the liquid in the filter press to create good conditions for the next work.

3. Filter cloth:

In winter, when the filter press is working, the filter cloth will be dampened, so that the filter cloth will contain a lot of liquid. When the temperature is relatively low, the liquid on the natural filter cloth will also become solid, which will block the filter cloth. Therefore, we need to replace the filter cloth and store the filter cloth separately in a mild environment so that it can be used next time.

4. Control box:

Since the working environment of the general filter press is relatively harsh, it is often in contact with high-humidity air. When the temperature drops sharply, some dry substances must be placed in the filter press control box for suction Air moisture in the filter press control box.

The above is the detailed introduction of the maintenance measures of the filter press in winter. I believe that through the above introduction, after entering the winter, everyone will keep the filter press warm, and it will not be affected by the low temperature in winter, which will affect the work of the filter press. .

As a filter press manufacturer, Kintep has a professional production and manufacturing team. Our products have a long service life. If you want to learn more about filter presses, please pay attention to our website.

0 notes

Text

Do you know how to use the filter press?

The filter press has become an indispensable important equipment and has played an irreplaceable role in industrial production. Nowadays, the figure of the filter press can be seen anytime and anywhere in our daily life, but do we really understand how to use the filter press? What should I pay attention to when using the filter press?

Filter press operation method:

1. It is forbidden to start working in the factory when the number of filter plates is less than the specified number, so as to avoid damage to the machine parts. Check the arrangement of the filter plates before feeding. The filter cloth should not be folded to prevent large leakage; after unloading the cake, the filter plates must be tightly pressed and arranged neatly.

2. Only the normal filter press can be used for feeding, and the whole filter press must be inspected before each shift. The mechanical compression transmission components and the reduction box must be filled with enough lubricating oil; the hydraulic compression review the oil tank storage capacity and the hydraulic station working pressure. The hydraulic oil is generally replaced once a year. The hydraulic system should be thoroughly cleaned once during the replacement, and the hydraulic station working pressure It is less than the maximum working pressure of the oil cylinder, but the minimum can not be lower than the allowable value of the filter pressure.

3. After the filter press is normal, the filter plate can be compressed and filtered. The filter pressure and filter temperature must be within the specified range. Excessive filtration pressure will cause leakage. If the filtration temperature is too high, the plastic filter plate is easy to deform and add materials. The concentration of the suspension should be uniform. There must be no impurities; the filter cloth and filter plate must be rinsed after unloading the cake, and residues are not allowed to stick to the sealing surface or in the feeding channel, otherwise it will affect the smooth flow of the feed and the tightness of the filter plate, which will cause the two sides of the filter plate. Unbalanced pressure causes deformation and damage to the filter plate.

4. The filter cloth selection of the filter press must meet the technical requirements of the filter paddle. The new filter cloth should be shrunk before production, and the opening diameter should be smaller than the filter plate aperture. When the filter plate is matched, the cloth hole and the plate hole should be relatively concentric. The feed hole cloth should be close to the wall of the cylinder, otherwise it will cause unclear filtration, low filtration rate, rupture of the cloth cylinder, and failure to achieve the expected filtering purpose.

5. In the initial stage of filter press, the filter is turbid. When a layer of filter cake is formed on the filter cloth, the filtrate will become clear. If the filtrate has been turbid or mixed, it may be that the filter cloth is damaged or the cloth holes are different from the plate holes. At this time, close the valve or stop feeding to replace the filter cloth. A small amount of leakage caused by the capillary phenomenon of the filter cloth is allowed between the filter plates.

Kintep has high-level production and processing technology and equipment, stable product performance, convenient operation, and professional after-sales service. If you want to learn more about filter presses, please pay attention to our website.

0 notes