Text

Magnets and Adaptors for Precast Windows Doors Opening

The magnetic system with clamping adaptor is greatly supportive to brace and hold the plywood forms to open the precast windows and doors. It's an application of standard switchable shuttering magnets with hanging rods. After plywood molding, just nail the bracket to the plywood forms straightly and hang the magnets onto the groove of adaptor. Once prefab concrete walls formed and demoulding, take a steel lever bar to deactive the magnet and nailed back the screws. Then the adaptor could be taken away for the next round usage.

FEATURES

1. Easy Operation, High Efficiency

2. Reusable

3. Adjustable height and supporting magnetic forces according to the solid wall specifications

APPLICATIONS

Read the full article

#PlywoodFormworkMagnet#PrecastCornerMagnets#PrecastCornerSupportingMagnet#PrecastHoldingMagnet#PrecastPlywoodForms#WindowsandDoorsFormingMagnet#WindowsOpeningMagnet

0 notes

Text

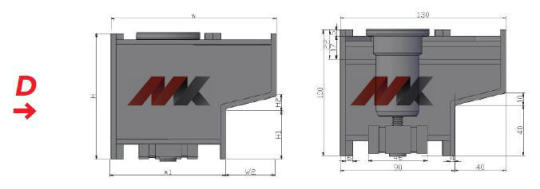

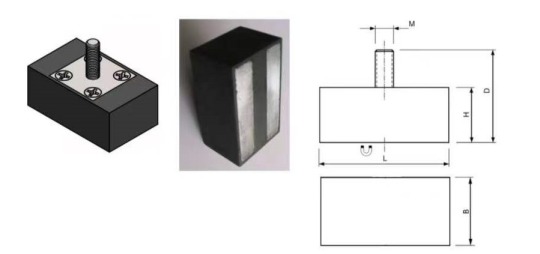

Precast Aluminum Plywood Sideforms Fixing Magnets with Adaptor

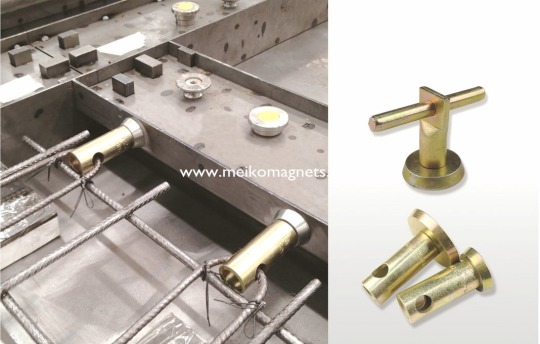

Due to the heavy dead weight of steel framework, it's cumbersom for manual operation and the robot handling equipments lead to too much investment. Therefor, more and more precast plants choose aluminum profile or plywood siderails to form the concrete, especially in those areas, which are filled with competitive cost of wooden material, like Australia, Canada and else. In order to fit customer's sideforms well, we used a special adaptor to support and fix the formwork from sliding and moving on basis of switchable shuttering magnets as a key functional part.

The adapting plates could be easliy attached to the box magnets with two small bolts. After aluminum profile placed, the magnet could be directly hanged onto it and push the button for magnet activing. When demoulding, use the lever bar to deactive the magnet and remove it for further maintenance and storage.

In some sites, when precaster only using plywood material without supporting aluminum profile, this magnet with adaptor could be workable as well. Just need to nail the additional small plate onto the plywood parallelly and then attach the magnet with hanging the particular groove on it.

Meiko Magnetics is a China-based precast concrete magnets manufacturer, mainly produce all retaining forces shutter magnets ranging from 450KG to 3000KG, adapters, precast emerged accessories holding magnets, magnetic and non-magnetic steel chamfers as well as magnetic shuttering siderails for manual or robot operating.

Thanks to our experienced and skilled technical teams, at present, we are equiped with numerous types of magnetic fixing systems and constantly innovate to process better magnetic solutions for our precasting customers.

ADAPTOR SPECIFICATION

TYPE

L(mm)

W(mm)

T(mm)

Fitting Magnet Forces(kg)

Adaptor

185

120

20

500KG to 2100KG

Read the full article

#MagneticAdaptorforPrecastAluminumForms#MagneticSystemforPrecastAluminumProfile#PrecastAluminumProfile#PrecastAluminumSideforms#PrecastConcreteMagnetsManufacturer#PrecastPlywoodProfile#SwitchableShutteringMagnet

0 notes

Text

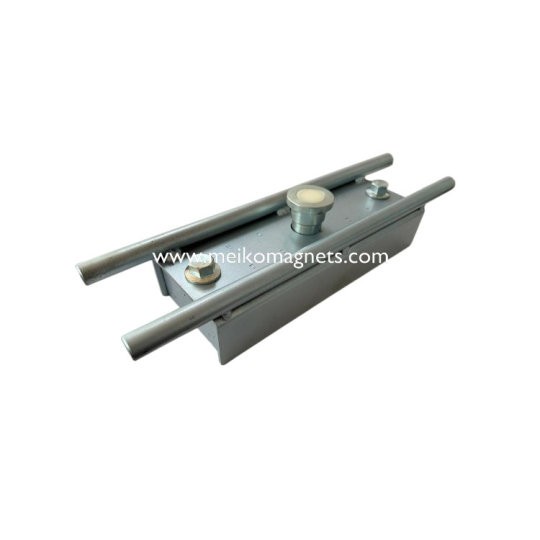

Magnetic Clamp for Precast Wooden Formwork

As an old generation magnetic fixture for precast wooden formwork mould, this type of shuttering magnetic clamp still acts a postive role in the modern precasting industry. For some countries and areas, like America, Canada & Northern Europe, wood materials could be obtained readily with low costs. Meanwhile, due to the characteristics of easy shaping and framing, it's widely applicated to make required moulds.

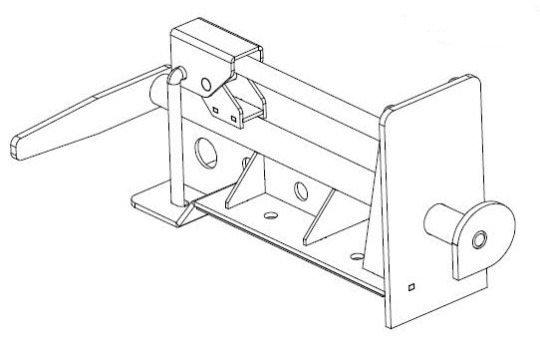

Magnetic Clamp Fixture is designed with two handles to switch the magnet and move it to whereever you need. The handle in the top is a carrying bar and an easy releasing bar. When you lift it up, the connected two feets will be put down to lever the whole magnet. Furthermore, the ending handle could be supportive to turn the oval plates around on the wood forms to help the magnet levering on the table. With advantage of lever principle, the long arm of force is great helpful for labor saving to maximize the torque.

Two factors shall be considered to fit your mold. One is the pulling force of magnet, and the other is the wooden mould height. The sampled magnetic clamp features 1800KG vertical pulling force. And the determined wooden height is 50mm. But it's available for to adjust the magnet retaining force and suitable wooden mold height. In addtion, if any requirement for table room restriction, we are also capable to short the length of magnetic fixture.

SPECIFICATION

TYPE

L(mm)

W(mm)

H(mm)

RETAINING FORCE (KG)

SUITABLE WOOD HEIGHT(mm)

VM-1800

375

100

185

1800

50

SAMPLES PICTURE

CUSTOMER'S FABRICATING SITE

Read the full article

#MagneticClamp#MagneticFixtureforPrecastSideMold#MagnetsforWooden/PlywoodSideForms#PrecastMagneticClamp#PrecastWoodenMoldMagnet#WoodenFormworkMagnet

0 notes

Text

Loaf Magnet with Adapting Accessories for Modular Wooden Shuttering System

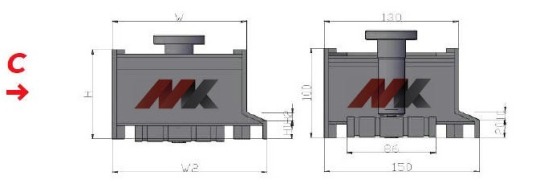

Loaf Magnet with adaptor accessory is applied for the production of precast modular components, with plywood or wooden shuttering forms. It's designed with no button, compared to standard switchable push/pull button magnet. It's quite slim and make less occupation of the steel table.

It simplies the formwork mould installation and just need to locate the shuttering magnet into the exact position by hands. Normally if there is a slight wrong position, you can use a rubber hammer to fix it. The further step is to install the adaptor accessory and adjust the tensile bar to fit your wooden mould height and make it support tightly. The bottom magnetic system could afford powerful resistance force against the forms moving under the circumstance of pouring concrete and steel platform vibrating, due to the integrated neodymium magnets. After works done, a special release bar is provided to release it and remove it for further maintain or next use. The stainless case feature soutstanding performance for anti-rust, which greatly increase the magnets using life.

MAGNET DIMENSION

Type

L(mm)

W(top)

W(bottom)

H(mm)

N.W.(KG)

Force(KG)

LF-350

125

54

45

35

1.2

350

LF-900

250

54

45

35

2.3

900

In the processing of this magnet house, we make 100% size inspection with GO/NO GO gauge to make sure it fits your current adaptor. After magnet assembling and grinding, the inspection will be done again before shipment.

Read the full article

#FormworkMagnetAccessories#FormworkMagnets#LoafMagnet#MagneticAdapterforFormwork#MagneticFormworkTechnology#MagnetsforWooden/PlywoodSideForms#ModularWoodenShutteringSystem#PlywoodSideFormsMagnet#PrecastFormworkMagnet#ShutteringMagnet#UShapeMagneticProfile

0 notes

Text

Shuttering Magnets with Adaptor Accessories for Supporting Plywood, Wooden Formwork Side Rails

Shuttering Magnets with Adapting accessories are supportive to connect the magnetic system and formwork side mould tightly. The above adapter is designed for fixing precast plywood or wooden material form rails in the thick precast solid walls production. Generally the magnets used to stand up to the side of wooden forms directly to support. But when producing thick solid walls or sandwich slabs, it requires extra supports on the top to fix the side mold. The normal single standard box magnet is hardly to work ideally. Under the circumstance, the adaptor accessory is necessary to use for the top supports.

The machined thread at the buttom of rod could be easily threaded into the welded nuts of the box magnet housing. And locate the standard 2100KG switchable push/pull button magnets with adaptor to the right position, push the button of magnet to active the magnetic force. Subsequently adjust the above bar to the required height against the tope of wooden side forms. Each step of installation could be easily operated by manual.

As as a leading China-based magnetic solutions factory for precast modular construction, Meiko Magnetics not only provide OEM shuttering magnets production for precasters and precast mould equipment factory, but also offer full magnetic side forming systems designs and production, with benifits of our 10 years precast project's participation.

Read the full article

#2100kgBoxMagnets#2100KGShutteringMagnets#AdaptorAccessories#MagneticAdaptors#MagneticFormworkRails#MagneticMouldForms#MagneticSideForms#MagnetsforPlywooden/WoodenMouldForms#PlywoodFormworkMagnet#PrecastConcreteAccessories#PrecastStaircaseFormsMagnets#StandardSwitchablePushButtonMagnets#SupportingMagnetsforThickSolidWalls#WoodenFormsSupportingMagnets

0 notes

Text

Shuttering Magnets with Single Rod for Locating Formwork Side Rails

Shuttering Magnets With Hanging Rod is an evoluted type magnetic system on basis of standard switchable push/pull shuttering magnet. The solid welding rod is specially produced to fix customers' formwork side rail in the precast processing. Manually hang the rod onto the groove of form rails and push down the button to active the magnet. Owing to the integrated neodymium magnet systems, it could perform over 2100kg magnetic force, which firmly hold on the steel platform from sliding under concrete pouring and vibrating.

The shorter length of magnet body could extremely reduce the occupation of your table and increase the module efficiency. It features light weight for easier operating than standard formwork button magnets.

After couple of years magnetic systems producing for precast concrete moular construction, Meiko Magnetics has grown up to be a specialized and qualified precast concrete magnets manufacturer in China. We have been committed to supply one-stop magnetic fixture solutions for precast concrete factories and precast mold equipments manufacturers of the world.

Read the full article

#FormworkSideRails#MagneticFormworkRail#PrecastConcreteMagnets#PrecastModuleRailMagnet#PrecastSideFormsMagnet#PrecastSideRails#ShutteringMagnetswithRods#StandardShutteringMagnets#SwitchableBox-OutsMagnets

0 notes

Text

Magnetic Fixture Systems for Concrete Formwork and Precast Accessories

Along with the modular construction modernizing, it has been in the teeth of the storm for the precast concrete plants to raise the productivity, reduce the labour costing and construction materials wasting. The essential factor is to accomplish the flexible and efficient precast molding and demoulding to realize the automatic, intelligent and standardized production.

Magnetic Shuttering System, as a transboundary magnetic fixture with the combination of magnetic material and precast mould, is playing a prime significant part to solve the above problems. It could extremely simplify the installation and un-installation procedures of the side formwork and precast concrete accessories in the processing of precast elements production, featuring durable, flexible and reusable characteristics, with occupying small room but perform super powerful retaining forces.

Due to the decaded experiences of tailored magnetic system production and precasting project participation, Meiko Magnetics has grown up to be a specialized and qualified formwork profile systems and magnets provider in China. We have been committed to supply one-stop magnetic fixing solutions for precast concrete factories and precast mold equipments manufacturers of the world. Currently our precast concrete magnets mainly include the following types for options.

1. Standard Shuttering Magnets

Standard shuttering magnet is the basic magnetic component for holding and positioning sided shutter molds on the steel casting bed, particularly for the tilt-up tables. It's widely suitable for steel mold, aluminum molds, wooden & plywood molds. The starndard retaining forces are 450KG, 600KG, 900KG, 1350KG, 1500KG, 1800Kg, 2100KG and 2500KG as requested.

2. Magnetic Shutter Profile Systems

It's composed with solid welded metal case or U shaped channel profile and couples of integrated push button magnetic systems for systematic production of clapping, sandwich wall, solid walls and slabs by manual operating or robot handling.

3. Inserted Magnets

The inserted magnets are ideally assemblied for fixing embedded precast concrete accessories, including lifting systems and connection systems, such as sockets, anchors,wire loop, grouting sleeves, pvc pipe, metal pipe and electrical junction boxes.

4. Steel Magnetic Chamfer Strips

Magnetic Chamfer Strip, as a necessary precast concrete accessory, is frequent to be applicated for making chamfers, beveled edges, drip molds, dummy joints, notches and reveals of precast concrete elements.

Meiko Magnetics has always kept it firmly in our mind that " innovation, quality and customer's requirements are the cornerstones of the enterprise". Hope our expertises in magnetic systems can assist you with more accurate & efficient precasting.

Read the full article

#FormworkProfileMagnet#MagneticFixingSolutions#MagneticFixtureforPrecastSideMold#MagneticFixtureSystem#MagneticShutteringSystem#ModularConstructionMagnet#PrecastConcreteAccessoriesMagnet#PrecastPanelFrameworkMagnet#precasttilt-uptable#SocketHoldingMagnet#TailoredMagneticSystemforPrecastConcretePlants

0 notes

Text

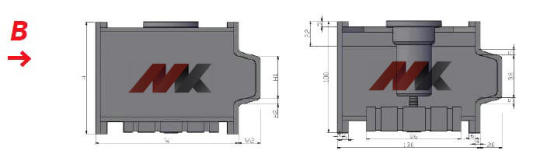

H Shape Magnetic Shutter Profile

H Shape Magnetic Shutter Profile, mainly produced with solidering weld and couples of integrated push button magnetic systems. It's a series of magnetic shuttering systems for systematic production of clapping, sandwich wall, solid walls and slabs. In the traditional magnetic applications of precasting, it used to produce switchable shuttering box magnet and precast steel side mold separately. On the precasting site, the operators locate the shuttering profile at first step, and then attach the magnet into the formwork manually, with adaptors or welding process. It wastes labor capacity and the assembling time.

After taking those overal magnetic shuttering solution, it could sharply reduce the formwork installation process and increase the productive efficiency. Meanwhile, it could be operated by manual or robot handling in optional. Compared to normal connection of side form and magnetic box, the magnetic formwork system could maximize the production space of steel platform, with benifits of occupying minimized installation area. Aparting from those features, we also are capable of producing various shapes and dimensions magnetic profiles, according to your special requirement for the precast elements, to form the concrete components at one time, like chamfers, groove and other forms.

Product Features

1. The magnetic shutter system can be operated by manual or robot handling

2. Easy operation with high productive efficiency

3. Reusable, to reduce disposable plywood forms.

4. The solidering weld is strong, durable and easy to clean

4. Varities of shapes, length, width and height for optional precast element requirements

Standard Dimensions

ITEM NO.

L

W

H

Adhesive Force

mm

mm

mm

kg

H1000

1000

130

100

2 x 1800kg

H2000

2000

130

100

2 x 1800kg

H3000

3000

130

100

2 x 1800kg

H3700

3700

1300

100

3 x 1800kg

* Other length, width, height, shapes and retaining force of each magnet are available to produce in line with customized requirements.

Read the full article

#BoxMagnet#HshapeMagneticShutterProfile#MagneticFormworkSystem#MagneticShutter#MagneticShutterProfile#MagneticShutteringProfile#MagneticShutteringSystem#MagneticSideRailSystem#PrecastConcreteMagnets#PrecastMoldMagnet#PrecastSideRailMagnet#SwitchableButtonMagnet

0 notes

Text

Rubber Magnetic Chamfer Strips

Magnetic Chamfer Strips, as necessary precast concrete accessories, are frequent to be used for making chamfers, beveled edges, drip molds, dummy joints, notches and reveals of precast concrete components. Normally they are installed onto the right position before concreting, against prefabricated formwork platform or steel framework. Due to the features of magnetic material applications, the chamfer magnets could directly hold on the steel worktop, instead of nailing or welding procession, which extremely reduce the workload of labor and improve the production efficiency.

The chamfer strips could be produced with solid steel, rubber materials with different features.

1. The steel chamfer magnet is composed of cold rolled steel profiles and emerged neodymium block magnets, featuring super strong adhesive force. We have groups of these steel chamfer magnets, containing single or double sided cathtus triangle shapes and hypotenuse magnetizing type. As well, we are stocked with trapezoid steel magnetic chamfer profiles. But owing to the solid steel material and permanent rare earth magnets, it only could be straight and a little bit heavy weight.

1) Steel Triangle Chamfer Magnet

Type

A(mm)

B(mm)

C(mm)

L(mm)

Net Weight(kg/m)

SCM01-10

10

10

14

Maximium 4000

0.43

SCM01-15

15

15

21

Maximium 4000

0.95

SCM01-20

20

20

28

Maximium 4000

1.68

SCM01-25

25

25

35

Maximium 4000

2.45

2) Steel Trapezoid Chamfer Magnet

Type

A(mm)

B(mm)

C(mm)

L(mm)

Net Weight(kg/m)

SCM02-10

30

10

10

Maximium 4000

1.68

2. Rubber Magnetic Chamfer Magnet is produced by press molding with the mixture of ceramic magnet power and rubber material. It's used for make chamfers in the situations, requiring more flexible shapes and light weight operation, like prefabricated manholes. The adhesive force of this rubber magnetic chamfer is much weaker than the neodymium magnet steel chamfer.

Type

A(mm)

B(mm)

C(mm)

RCM01-10

10

10

14

RCM01-15

15

15

21

RCM01-20

20

20

28

RCM01-25

25

25

35

Read the full article

#10x10mmTriangleChamferStripMagnet#15x15mmMagneticChamferStrip#20x20mmChamferMagnets#ChamferingMagnet#MagneticChamfer#MagneticChamferProfile#MagneticChamferStrip#MagneticChamferringStrips#MagnetictrapezoidalChamferStrips#Magnetictriangularchamferstrips#RubberChamferMagnet#RubberMagnet#RubberMagneticChamferStrip#RubberTriangleChamferMagnet

0 notes

Text

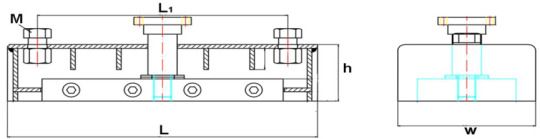

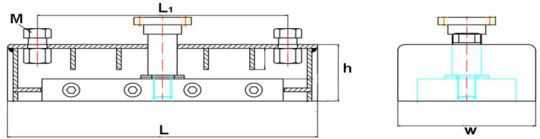

Precast Concrete Push Pull Button Magnets with Sided Rods, Galvanized

Precast Concrete Push/Pull Button Magnet is the standard magnetic fixing solution for holding precast framework on the steel table. It's widely used for steel, wooden/plywood frames with or without extra adaptors. This type button magnets with two sided rods could be put into the steel frame directly, no extra adaptors required. It's produced with steel casing with welded steel rods, and switchable spring button integrated magnetic system. Profiting by the emerged super neodymium magnet block, it could afford powerful and incessancy retaining force against the framework from silding and moving issues.

Owing to maximize the performance of magnetic force, the critical point is to clean out any small crushed concrete or ferrous nails and stuffs under magnet before installation. In front of pushing down the spring button, put the magnets into the right position and make the sided rods hanging on the framework grooves, no more extra welding or bolting needed. The follow-up operation is only to depress the button and it works now. After demoulding, better to use a special lever tool to release the button.

As a professional shuttering magnets manufacturer in China, Meiko Magnetics are serving and participating in hundreds of precasting projects by outputting our professional knowledge and qualified products on magnetic system concerning on precast filed. Here you can find all required magnets for your easier and more efficient fixing solutions in the modular construction.

Standard Dimensions

ITEM NO.

L

W

h

L1

M

Adhesive Force

Net Weight

mm

mm

mm

mm

kg

kg

SM-450

170

60

40

136

M12

450

1.8

SM-600

170

60

40

136

M12

600

2.0

SM-900

280

60

40

246

M12

900

3.0

SM-1350

320

90

60

268

M16

1350

6.5

SM-1500

320

90

60

268

M16

1500

6.8

SM-1800

320

120

60

270

M16

1800

7.5

SM-2100

320

120

60

270

M16

2100

7.8

SM-2500

320

120

60

270

M20

2500

8.2

Advantages

-High Forces from 450KG to 2500KG in small body, save the space of your mold extremely

-Integrated automatic mechanism with steel springs for easier operation

-Welded threads M12/M16/M20 to adapt required form-work fixture

-Multi-functions magnets for different purpose

-Various type of adapters are equipped to match your side rail profile, no matter wooden, plywood, steel, aluminum mold.

Read the full article

#PrecastBoxMagnets#PrecastButtonMagnets#PrecastConcreteMagnets#PrecastMoldMagnet#PrecastPushPullButtonMagnets#PrecastPushPullMagnets#PrecastSwitchableButtonMagnet#PrecastSwitchablePull/PushMagnet#ShutteringMagnets#ShutteringMagnetswithAdaptor#SideRodsPrecastMagnets

0 notes

Text

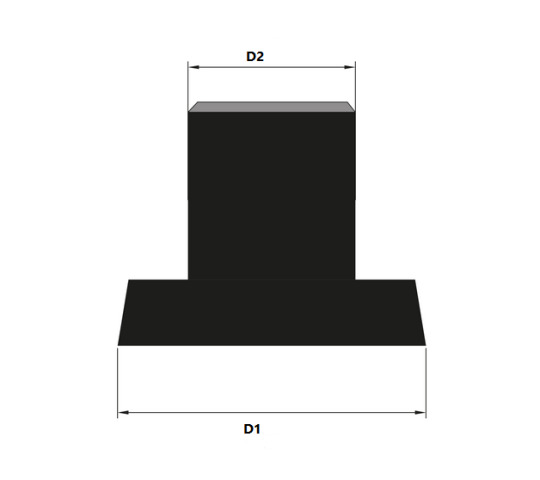

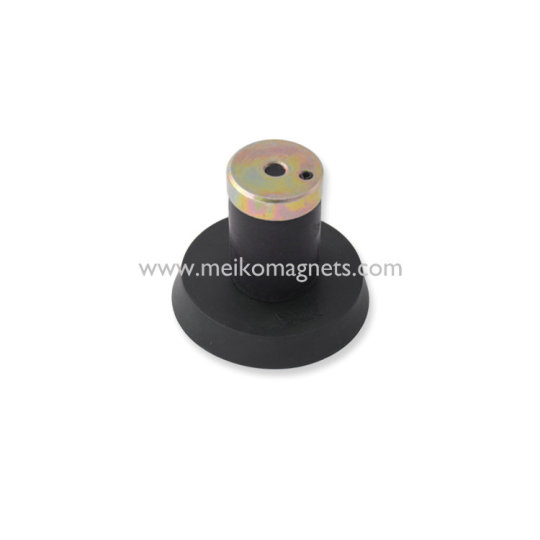

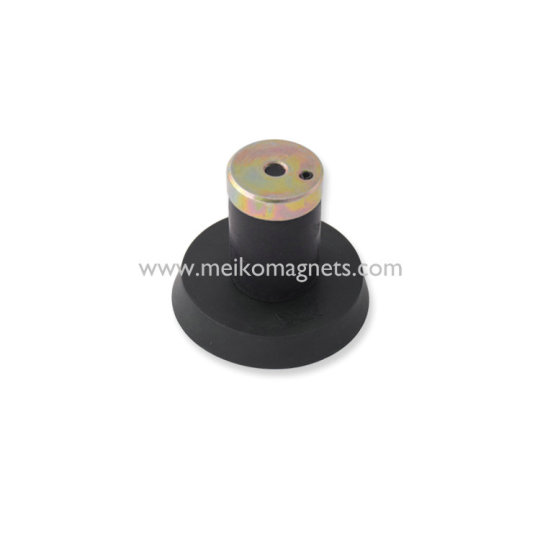

Magnetic Holder for Corrugated Metal Pipe

Corrugated Metal Pipe Magnetic Holder is the combination of steel inserted magnet and a rubber cover. With benifit of outer compressible rubber and inserted powerful neodymium magnets, this pipe magnet could tighten the metal pipe greatly and hold the pipe/tube stabliy on the steel framework in the processing of precast production.

Pipe Magnet consist of

• A magnet

• A magnet cover

• A compressible rubber part

• A metal fixing plate

Type

D1(mm)

D2(mm)

Force(KG)

RPM27

70

27

80

RPM37

70

37

80

RPM47

70

47

80

RPM57

95

57

120

RPM77

95

77

120

Read the full article

0 notes

Text

Magnetic Holder for Corrugated Metal Pipe

Corrugated Metal Pipe Magnetic Holder is the combination of steel inserted magnet and a rubber cover. With benifit of outer compressible rubber and inserted powerful neodymium magnets, this pipe magnet could tighten the metal pipe greatly and hold the pipe/tube stabliy on the steel framework in the processing of precast production.

Pipe Magnet consist of

• A magnet

• A magnet cover

• A compressible rubber part

• A metal fixing plate

Type

D1(mm)

D2(mm)

Force(KG)

RPM27

70

27

80

RPM37

70

37

80

RPM47

70

47

80

RPM57

95

57

120

RPM77

95

77

120

Read the full article

0 notes

Text

Magnetic Holder for Corrugated Metal Pipe

Corrugated Metal Pipe Magnetic Holder is the combination of steel inserted magnet and a rubber cover. With benifit of outer compressible rubber and inserted powerful neodymium magnets, this pipe magnet could tighten the metal pipe greatly and hold the pipe/tube stabliy on the steel framework in the processing of precast production.

Pipe Magnet consist of

• A magnet

• A magnet cover

• A compressible rubber part

• A metal fixing plate

Type

D1(mm)

D2(mm)

Force(KG)

RPM27

70

27

80

RPM37

70

37

80

RPM47

70

47

80

RPM57

95

57

120

RPM77

95

77

120

Read the full article

0 notes

Text

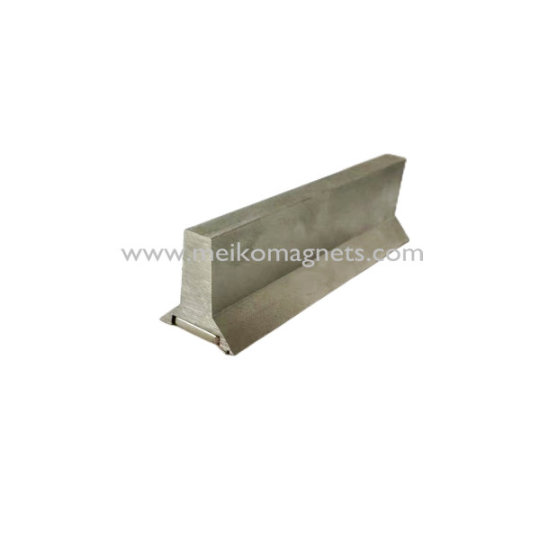

Trapezoid Steel Chamfer Magnet for Pre-stressed Hollow Core Panels

Trapezoid Steel Chamfer Magnet makes groove opening on the faces of pre-stressed hollow core panels. Due to the powerful inserted neodymium magnets, the magnetic trapezoid strip profile could hold tightly in position on the steel plateform. Several meters chamfer strips are put in a line to form a steel trapzoid barrier for opening a straight groove after precast hollow slabs demolding.

It provides fast and accurate placement of the chamfer strips in steel formwork construction, which is helpful for significant labor and material savings.

As a leading magnetic fixing solution manufacturer in China, Meiko Magnetics has always been serving and participating in hundreds of precasting projects by outputting our professional knowledge and qualified products on magnetic system concerning on precast filed. Here you can find all your magnetic solutions to make your precast concrete elements production more efficient and economic.

Read the full article

#MagneticChamfer#MagneticChamferStrip#MagneticProfile#MagneticStripProfile#MagneticStrips#PrecastHollowPanels#PrefabricatedHollowCore#SteelChamfer

0 notes

Video

youtube

Precast Concrete Magnets 2100KG Vertical Adhesive Force | Meiko Magnetics

0 notes

Text

Shuttering Magnets, Precast Concrete Magnets, Magnetic Formwork System

The On/Off Switchable Precast Box Magnet is a typical shuttering magnet type of precast magnetic solutions, applied for positioning and fixing shuttering side mold on the steel casting bed in the field of precast element productions, such as precast concrete interior/exterior wall panel, stairs, balconies for the most molds, as steel mold, aluminum molds, wooden & plywood molds. It plays a new critical role for featuring higher productivity, easier operating method of precast production, compared to traditional bolting or welding on the steel tables, especially for the tilt-up table.

As long as the framework settled down, the shuttering magnets could freely move into the right position. It’s essential to check the surface of magnet and bed on this step, cleaning up the adsorbed ferrous stuffs on the outward magnet as well as remaining concrete on the platform, to make sure the magnets tightly hold the table, without any gap.

Subsequently, the unique designed button can be pushed to make magnets attracted on the steel plate firmly, which will generate extremely multi magnetic circles between emerged magnetic block and steel table, through the outputting magnetic flux. The integrated super powerful permanent sintered neodymium magnets (NdFeB) are being constantly and strongly supportive to fix the side rail profile against removing and sliding, under the processing of concrete pouring and vibrating inside of frame mold.

Once prefabricated components accomplished and side mold de-attached, an extra professional steel lever could be used for pulling up the button to release the magnet by manual operation. After magnet works done, it should be taken away and stored regularly for further maintenance, like cleaning up, anti-rusty lubricating to keep a durable performance in the next round of use.

Advantages

-High Forces from 450KG to 2500KG in small body, save the space of your mold extremely

-Integrated automatic mechanism with steel springs for easier operation

-Welded threads M12/M16/M20 to adapt required form-work fixture

-Multi-functions magnets for different purpose

-Various type of adapters are equipped to match your side rail profile, no matter wooden, plywood, steel, aluminum mold.

Read the full article

#2100kgFormworkMagnets#MagneticFormworkSystem#MagneticShutteringSystem#MagneticSiderailSystem#PrecastConcreteMagnets#PrecastMagneticClamp#PrecastMoldMagnet#ShutteringMagnets

0 notes

Text

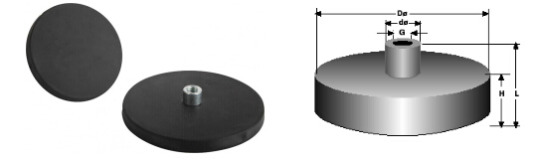

Rubber Coated Magnets

The Introductions to Rubber Coated Mounting Magnets

Rubber Coated Magnet, also named as rubber covered neodymium pot magnets & rubber coated mounting magnets, is one of the most common practical magnetic tool for indoors & outdoors. It's generally regarded as a typical sustained magnetic solution, especially for storage, hanging, mounting and other fixing functions, which require powerful attraction force, waterproof, durable lifetime, anti-rusty, free of scratches and slide resistance. In this article, let's try to figure out the component, characteristics, features and applications of rubber coated magnets family together.

1. What is rubber coated magnet?

Rubber coated magnets are normally composed with super powerful permanent sintered neodymium (NdFeB) magnet, backup steel plate as well as durable rubber (TPE or EPDM) covering. With the characteristics of emerged neodymium magnets, it could afford powerfully strong adhesive forces in very small size to use. Several pieces small round or rectangular magnets will be mounted into the backup steel plate with glue. A magic multi-poles magnetic circle and steel plate basement will be generated from "N" and "S" pole of magnet groups through each other. It brings out 2-3 times of strengths, compared to the regular magnets by themselves.

Regarding the backup steel plate basement, it's stamped into shapes with pressing holes for positioning and installing magnets. Also it requires kind of glues to enhance the connection of magnet and steel bed.

To provide a durable, stable and multi-shaped protection for inside magnets and steel plate, the Thermo-Plastic-Elastomer material is chosen to use under the processing of vulcanization or injection molding technology. The injection molding technology is much more conventional in the rubberized procession, due to its high productivity, material and manual cost saving and flexible color options, rather than vulcanization technology. However, vulcanization technology is preferably taken for those operational environment, featuring superior durability of wearing quality, weather ability, seawater corrosion resistivity, oil proof, broad temperature compatibility, such as wind turbine applications.

2. Categories of Rubber Coated Magnets Family

With benefits of rubber shapes flexibility, the rubber covered mounting magnets could be in various shapes as round, disc, rectangular and irregular, according to users' demand. The internal/external thread stud or flat screw as well as colors are optional for production.

1) Rubber Coated Magnet with Internal Screwed Bush

This screw bushing rubber coated magnet is ideal for inserting and attaching equipment to the targeted ferrous substance where it is crucial to protect the paint surface from damage. A threaded bolt will be inserted into this screwed bushing, rubber coated, mounting magnets. The screwed bush point will also accept a hook or handle for hanging ropes or manual operating. Several of these magnets bolted onto a three-dimensional promotional product or to decorative signage can make it suitable to be displayed on cars, trailers or food trucks in a non-permanent and non-penetrative way.

Item No.

D

d

H

L

G

Force

Weight

mm

mm

mm

mm

kg

g

MK-RCM22A

22

8

6

11.5

M4

5.9

13

MK-RCM43A

43

8

6

11.5

M4

10

30

MK-RCM66A

66

10

8.5

15

M5

25

105

Mk-RCM88A

88

12

8.5

17

M8

56

192

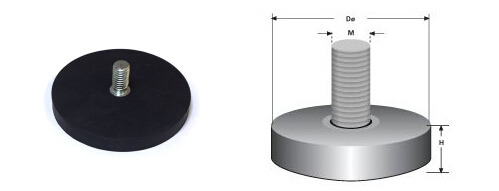

2) Rubber Coated Magnet with External Threaded Bush/Threaded Rod

Item No.

D

d

H

L

G

Force

Weight

mm

mm

mm

mm

kg

g

MK-RCM22B

22

8

6

12.5

M4

5.9

10

MK-RCM43B

43

8

6

21

M5

10

36

MK-RCM66B

66

10

8.5

32

M6

25

107

Mk-RCM88B

88

12

8.5

32

M6

56

210

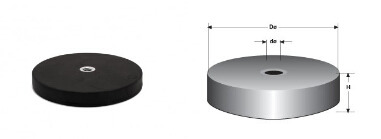

3) Rubber Coated Magnet with Flat Screw

Item No.

D

d

H

G

Force

Weight

mm

mm

mm

kg

g

MK-RCM22C

22

8

6

M4

5.9

6

MK-RCM43C

43

8

6

M5

10

30

MK-RCM66C

66

10

8.5

M6

25

100

Mk-RCM88C

88

12

8.5

M6

56

204

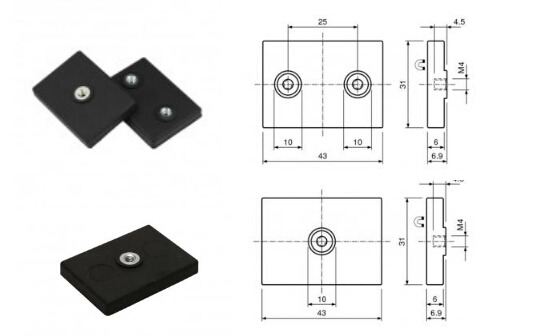

4) Rectangular Rubber Coated Magnet with Single/Double Screw Holes

Item No.

L

W

H

G

Force

Weight

mm

mm

mm

kg

g

MK-RCM43R1

43

31

6.9

M4

11

27.5

MK-RCM43R2

43

31

6.9

2 x M4

15

28.2

5) Rubber Coated Magnet with Cable Holder

Item No.

D

H

Force

Weight

mm

mm

kg

g

MK-RCM22D

22

16

5.9

12

MK-RCM31D

31

16

9

22

MK-RCM43D

43

16

10

38

6) Customized Rubber Coated Magnets

Item No.

L

B

H

D

G

Force

Weight

mm

mm

mm

mm

kg

g

MK-RCM120W

85

50

35

65

M10x30

120

950

MK-RCM350W

85

50

35

65

M10x30

350

950

3. The Main Advantages of Rubber Coated Magnets

(1) Diverse optional rubber coated magnets in different shapes, working temperature, adhesive forces as well colors on the demands.

(2) The special design brings out 2-3 times of strengths, compared to the regular magnets by themselves.

(3) Rubber coated magnets features a superior waterproof, durable life time, anti-rusty, free of scratches and slide resistance, compared to regular magnetic assemblies.

4. The Applications of Rubber Coated Magnets

These rubber coated magnets are functionally used to create a connection joint for the items to the ferrous plate or wall, mounted on the steel surface of vehicles, doors, metal shelves and machine types with sensitive touching surfaces. The magnetic pot can create a permanent or temporary fixing point avoid a borehole and damage the painted surface.

The fixing points are also used to fix sheets of ply or similar protecting openings in buildings under construction from thieves and inclement weather, attached to metal door and window frames. For truckers, campers and emergency services, these devices effect a secure fixing point for temporary containment lines, signs and flashing lights while protecting highly finished painted vehicle finishes via the rubber coating.

In some critical environment, like Wind Turbine nearby seawater, it requires seawater corrosion resistivity and broad temperature compatibility strictly for all the working equipment. In this case, the rubber coated magnets are perfect to use for fixing bracket, equipment on the wind turbine tower wall, instead of bolting and welding, like lighting, ladder, alert labels, pipe fixing.

Read the full article

0 notes