Text

Vibration conveyors can be classified according to the type of structure

Vibrating conveyor is a continuous conveying machine without traction components. It uses the principle of mechanical resonance to transport materials.

Vibrating conveyors can be divided into various categories according to their structural types.

一 、Classification by drive device

(1) The elastic link type vibration conveyor is driven by the elastic link.

(2) Electromagnetic vibration conveyor is composed of electromagnetic exciter.

(3) Inertial vibration conveyor is composed of inertial vibration exciter.

二 、Classification by dynamic state and dynamic factors

(1)According to the dynamic state, it can be divided into non-resonant vibration conveyors (usually working in far-over resonance state) and near-resonance vibration conveyors.

(2)According to the number of vibrating masses, it can be divided into single mass vibration conveyors, dual mass vibration conveyors and multi-mass vibration conveyors.

(3)According to the linear and nonlinear characteristics of the system, it can be divided into linear vibration conveyor and nonlinear vibration conveyor.

(4)According to the balance of the two quality breaks, it can be divided into balanced vibration conveyor and unbalanced vibration conveyor.

三 、Classification by Conveying Mode

(1) Horizontal vibration conveyor.

(2) Slightly tilt the vibration conveyor up or down.

(3) Vertical vibration conveyor.

四 、Classification by material movement status

(1) Vibrating conveyor for sliding movement of materials.

(2) Vibrating conveyor for material throwing motion.

Vibration conveyor has a simple structure, low energy consumption, less lubrication points and wearing parts, and convenient maintenance. This equipment can be widely used in powder and granular material transportation in metallurgy, coal, building materials, chemical industry, glass, electric power, machinery, food and other industries.

0 notes

Text

Installation and maintenance requirements of long distance vibration conveyor

Long-distance vibration conveyors are also called horizontal vibration conveyors, high-temperature vibration conveyors, etc. They are continuous conveying machines that use a vibrator to vibrate the trough, thereby sliding or throwing the materials in the trough along a certain direction. This equipment is a highly versatile and advanced structure high temperature material vibration conveying equipment.

The working principle of the long-distance vibration conveyor is to use two vibration motors as the excitation source. Using the principle of self-synchronization, the two vibration motors rotate in the opposite direction to cause the reciprocating vibration of the balance frame at the bottom of the conveyor. The role of the drive the vibration of the upper conveying trough, so as to achieve the purpose of conveying materials.

There are two types of long-distance vibrating conveyors: open type and closed type。

Basic requirements for installation and maintenance of long distance vibration conveyors:

(1) The bottom frame and the tank of the vibration conveyor must be installed straight. It is recommended that the flatness is 10 meters and the length is not greater than 5-8 mm。Excessive deflection of the bottom frame and the tank will cause greater installation stress. , Which in turn will cause early damage to these parts。

(2) In order to meet the above requirements, the lower surface of the vibration isolation spring should have close to the same elevation, and its tolerance should not be greater than 5-8 mm.

(3) The installation angle of the guide rod of the vibration conveyor should be close to the same, the shear spring should be perpendicular to the guide rod, and the tolerance of its installation angle to its nominal installation position is + -1.

(4) The transmission shaft is perpendicular to the center line of the groove body. The two transmission links should be parallel to each other without excessive skew. The tolerance of the installation angle is + -1. After the installation, the transmission shaft should be flexible and can be moved by hand 360 or more.

(5) All screws of the vibration conveyor should be locked. Generally, spring washers should be added, and double nuts can also be used to lock. Otherwise, the bolts will loose quickly and affect the normal operation of the machine.

The long-distance vibration conveyor is mainly used for conveying materials such as powder, granular, block and mixed products. It is widely used in building materials, metallurgy, chemical industry, coal mining, machinery manufacturing, coal, tobacco, food, medicine and other industries.

0 notes

Text

Advanced Physical Extraction Technology-Supercritical fluid extraction

Supercritical fluid extraction (SFE) is the most advanced physical extraction technology in the world. At lower temperatures, when the pressure of the gas increases continuously, the gas will be converted into liquid. When the temperature increases, the volume of the liquid will increase. There is always a critical temperature (Tc) and a critical pressure (Pc) for a particular substance. When the temperature and the critical pressure are higher than the critical temperature and the critical pressure, the substance will not become liquid or gas. It's the critical point. In the range above the re-critical point, the material state is between gas and liquid, and the fluid in this range becomes supercritical fluid (SF).

Supercritical fluids have strong penetration capacity similar to gases and high density and solubility similar to liquids. They have good solvent properties and can be used as solvents for extraction and separation of monomers. Supercritical fluid extraction (SFE) is a new and high technology in modern chemical separation. SFE combines traditional distillation with organic solvent extraction and effectively separates, extracts and purifies the matrix and extract by using supercritical CO2 as a solvent.

CO2 is a safe, non-toxic, cheap liquid. Supercritical CO2 has similar gas diffusion coefficient, liquid dissolving force, zero surface tension, can quickly penetrate into solid substances, extract its essence, and has the characteristics of high efficiency, no oxidation, pure nature, no chemical pollution and so on. Supercritical fluid extraction separation technology uses the solubility of supercritical fluid to be closely related to its density. By changing pressure or temperature, the density of supercritical fluid can be greatly changed. In the supercritical state, the supercritical fluid is contacted with the substance to be separated, so that the components with different polarity, boiling point and relative molecular mass can be extracted selectively.

When extracting natural products by supercritical fluid extraction, CO2 is usually used as extractant. This is because:a)

(a)The critical temperature and critical pressure are low (Tc=31.1 C, Pc=7.38MPa), the operating conditions are mild, and less damage to the effective components, so it is especially suitable for the treatment of high boiling point heat sensitive substances, such as essence, spices, oils, vitamins, etc.

(b) CO2 can be regarded as a non-toxic and cheap organic solvent similar to water;

c) CO2 is stable, non-toxic, non-combustible, safe and non-polluting in use, and can avoid oxidation of products; d) the extract of CO2 contains no nitrate and harmful heavy metal, and there is no residual harmful solvent;

e) CO2 is extracted in supercritical CO2 extraction. The extracted material can be precipitated by lowering pressure or raising temperature without repeated extraction operation, so the supercritical CO2 extraction process is simple. Therefore, supercritical CO2 extraction is especially suitable for the extraction and purification of biology, food, cosmetics and drugs.

0 notes

Text

Description:

Vibration conveyor is mainly used for conveying loose bulk or granular materials in the case of horizontal or small inclination. The structure of the vibration conveyor is simple, the energy consumption is small, and the equipment operation cost is low; there are fewer lubrication points and wearing parts, and the maintenance is convenient.

When the vibration conveyor is installed, pay attention to the following points during the trial operation:

1. No-load:

(1) The conveyor starts smoothly and quickly, and the vibration is stable, without left and right swing, jumping impact and abnormal sound;

(2) Deviations of conveyor amplitude, vibration direction angle, and vibration frequency are not more than 10% of the rated value; for vibration conveyors longer than 15m, the amplitude deviation of the front, middle, and rear sections should not be greater than 10 of the rated amplitude%;

(3) The temperature rise of rubber springs must not exceed 50 ° C, the temperature rise of metal springs must not exceed 70 ° C, and the temperature rise of bearings and motors of eccentric link-type vibration conveyors must not exceed 50 ° C; the temperature rise of electromagnet coils must not exceed 65 ° C. .

2. Load:

(1) The amplitude drop should not be greater than 10% of the rated amplitude;

(2) The material should move smoothly in the conveying trough, without obvious obstruction, running, swirling and severe material jumping;

(3) The conveying capacity should not be less than 90% of the rated conveying capacity.

Maintenance of vibration conveyor:

(1) Electrical protection devices shall be provided on the vibration conveyor.

(2) During the initial operation of the equipment, check the anchor bolts and other fasteners at least once a day to prevent loosening.

(3) The rotation direction of the motor should be correct. When the direction does not meet the requirements, it should be adjusted in time.

(4) When the bearing has been working for a certain period of time, it should be checked whether its wear is serious, and if it is serious, it should be replaced immediately.

(5) The motor should be well lubricated, and the lithium-based grease (ZL-3) should be replenished every two weeks. When refueling, add an appropriate amount of lithium-based grease through the oil cup. When using sealed bearings, the motor is not fitted with an oil cup.

(6) After running for 1500 hours, the vibration conveyor should be checked for bearings and replaced immediately if there is serious damage.

Vibration conveyor can be widely used in powder and granular materials transportation in metallurgy, coal, building materials, chemical industry, glass, electric power, machinery, food and other industries.

0 notes

Text

Points of attention for vibration conveyors during installation and construction

Description:

The vibrating conveyor is a continuous conveying machine without a traction member. It uses the principle of mechanical resonance to transport materials. The vibrating conveyor is mainly composed of a bearing member, an elastic member, an exciter, and the like. The power source of the drive mechanism of the vibrator foot vibration conveyor is used to generate an exciting force to cause continuous vibration of the bearing groove. The magnitude of the exciting force directly affects the amplitude of the load, and its alternating frequency is the operating frequency of the conveyor.

The carrier is a trough-shaped or tubular vibrating trough. During the vibration process, energy is transferred to the material to make a continuous throwing motion along the conveying direction. The carrier is a vibrating body and needs to have sufficient rigidity and strength. The vibration-damping support device is both a support device for the whole machine and a vibration-damping device.

So what are the problems that should be paid attention to during the installation and construction of the vibrating conveyor? See the following points for details:

1、 Handle gently during transportation to avoid deformation of components;

2、If problems are found during the test run, they should be stopped for treatment;

3、bracket welding should pay attention to the welding sequence, reduce welding deformation;

4、Bonding work should be carried out in a well ventilated place;

5、 tape cutting tools should have depth control fixtures;

6、disable open flames;

7、 the environment should be dustproof.

The relevant knowledge points of the vibrating conveyor introduced above are hoped to be helpful to everyone's work.

0 notes

Text

Description:

Horizontal vibration conveyor is a device for transmission and transportation. In actual operation, the vibration-damping bearings of the vibration conveyor are frequently damaged, the supporting spring is easily deformed, and the equipment vibration frequency is too fast, which seriously affects the continuous and stable operation of the device.

The company's technical department combined years of operating experience, analyzed the fault, proposed specific solutions, received practical results, and ensured the long-term stable operation of the device.

vibrating conveyor

一、Failure Analysis

1. Equipment level, vibration-absorbing bearing installation abnormal

(1) When the equipment is installed and debugged, the level is not good, and the installation standard is not reached, which causes the equipment to be polarized and unevenly stressed, which causes the material transportation trajectory to shift, the vibration-damping bearings, plate springs, and support springs to be abnormally damaged. Causes the transport body to crack.

(2) When installing vibration-damping bearings, the mounting angles of the two bearings are not consistent, the vibration period is uneven, and the excitation force distribution is uneven, resulting in abnormal wear of the vibration-damping bearings.

2. Loose anchor bolts or other fasteners

(1) There were omissions during installation and commissioning, and the anchor bolts became loose again, and they were not dealt with in time.

(2) The leaf spring is broken or the fixing bolts are loose and have not been replaced or tightened in time.

3.The equipment vibration frequency is too fast

The horizontal vibration conveyor relies on a motor to drive the crank link mechanism. The motor frequency directly determines the equipment amplitude and frequency. The motor frequency is too fast, which exacerbates the wear of spare parts and seriously affects the equipment operating cycle.

4. Support spring deformation

The device has 12 support springs to support the device body. After long-term use, individual springs are plastically deformed, causing the spring to fail, causing uneven force on the device, causing abnormal vibration of the device, and abnormal wear of the vibration-damping bearings.

horizontal vibration conveyor

二、the fault solution

(1) Adjust the level of the installation equipment so that the base of the whole machine and the base plane remain horizontal. The tolerance is 0.1 m / 1/1 000 m.

(2) All anchor bolts and components are installed and fastened as required, and the damaged leaf spring is replaced.

(3) On the premise that the equipment's conveying capacity meets the production requirements, the frequency conversion motor is used to reduce the motor frequency and reduce spare parts wear.

(4) Measure the original length of the support spring and measure the compression after installation. The deviation is less than 0.5 mm. If the deviation is too large, replace it as a whole.

The reasons for the failure of horizontal vibration conveyors are complex, sometimes the result of multiple factors. Reasonably analyzing all aspects of the equipment's failure, formulating scientific solutions, and continuously improving the operating conditions of the equipment can ensure long-term equipment operation.

0 notes

Text

Advanced Physical Extraction Technology-Supercritical fluid extraction

Supercritical fluid extraction (SFE) is the most advanced physical extraction technology in the world. At lower temperatures, when the pressure of the gas increases continuously, the gas will be converted into liquid. When the temperature increases, the volume of the liquid will increase. There is always a critical temperature (Tc) and a critical pressure (Pc) for a particular substance. When the temperature and the critical pressure are higher than the critical temperature and the critical pressure, the substance will not become liquid or gas. It's the critical point. In the range above the re-critical point, the material state is between gas and liquid, and the fluid in this range becomes supercritical fluid (SF).

Supercritical fluids have strong penetration capacity similar to gases and high density and solubility similar to liquids. They have good solvent properties and can be used as solvents for extraction and separation of monomers. Supercritical fluid extraction (SFE) is a new and high technology in modern chemical separation. SFE combines traditional distillation with organic solvent extraction and effectively separates, extracts and purifies the matrix and extract by using supercritical CO2 as a solvent.

CO2 is a safe, non-toxic, cheap liquid. Supercritical CO2 has similar gas diffusion coefficient, liquid dissolving force, zero surface tension, can quickly penetrate into solid substances, extract its essence, and has the characteristics of high efficiency, no oxidation, pure nature, no chemical pollution and so on. Supercritical fluid extraction separation technology uses the solubility of supercritical fluid to be closely related to its density. By changing pressure or temperature, the density of supercritical fluid can be greatly changed. In the supercritical state, the supercritical fluid is contacted with the substance to be separated, so that the components with different polarity, boiling point and relative molecular mass can be extracted selectively.

When extracting natural products by supercritical fluid extraction, CO2 is usually used as extractant. This is because:a)

The critical temperature and critical pressure are low (Tc=31.1 C, Pc=7.38MPa), the operating conditions are mild, and less damage to the effective components, so it is especially suitable for the treatment of high boiling point heat sensitive substances, such as essence, spices, oils, vitamins, etc.

(b) CO2 can b e regarded as a non-toxic and cheap organic solvent similar to water;

c) CO2 is stable, non-toxic, non-combustible, safe and non-polluting in use, and can avoid oxidation of products; d) the extract of CO2 contains no nitrate and harmful heavy metal, and there is no residual harmful solvent;

e) CO2 is extracted in supercritical CO2 extraction. The extracted material can be precipitated by lowering pressure or raising temperature without repeated extraction operation, so the supercritical CO2 extraction process is simple. Therefore, supercritical CO2 extraction is especially suitable for the extraction and purification of biology, food, cosmetics and drugs.

0 notes

Text

Structural form of elastic connecting rod vibration conveyor

Description:

The elastic link type vibrating conveyor is a kind of highly practical vibrating conveyor. The machine has smoothness and reliability in the vibration state, and is especially suitable for long-distance transportation. The elastic link type vibration conveyor has the characteristics of low frequency and large amplitude.

The elastic flail type vibration auxiliary conveyor is composed of a conveying trough, an exciter, a transmission mechanism, a supporting component and a shock absorption system. The exciter generates a periodic vibration force under the drive of a motor, and transmits it to a conveying trough through a transmission mechanism. The conveying trough generates a periodic linear vibration at the same vibration frequency of the excitation source under the pulsation of the excitation source. At a certain throwing angle with the conveying direction of the conveying trough, the material in the trough continuously jumps and moves forward along the conveying surface of the trough under the force of forced vibration.

The elastic link conveyor is a near-resonance type vibration machine. It uses the rotation of an eccentric shaft to drive the reference tank to achieve linear reciprocating movement by driving the connecting rod and the main vibration spring to achieve the purpose of material transportation. This vibration conveyor has a wide application range and strong adaptability.

The basic structure of the elastic connecting rod vibration conveyor:

When the elastic link type vibration conveyor is used as a dual mass, its structure is composed of a slot body (upper mass), a frame (lower mass), a main vibration spring, a vibration isolation spring, a support spring, and a support pendulum (also known as a guide Connecting rod), driving connecting rod, eccentric shaft, and motor, pulley and triangle tape.

The trough body and the bracket are respectively supported by a rigid support pendulum and a support spring, and the main vibration spring, the eccentric shaft, and the driving link are connected to form an excitation force source assembly. Duplex structure.

When a vibrating conveyor with a dual mass structure works, the two masses move in opposite directions; the two inertial forces can be relatively balanced, and in actual design and production applications, the mass of the two masses is constantly changing and it is difficult to be completely equal . In material transportation, the mass of the upper mass continuously changes and cannot be balanced with the mass of the lower mass. It will still cause most of the unbalanced inertial force to be transmitted to the foundation. Therefore, the bearing capacity of the foundation should be further balanced to reduce vibration The use of lower masses and weights to balance the inertial force, or the rigid treatment and structural arrangement of the vibration isolation springs, reduces the dynamic load transmitted to the foundation, and balances the vibration of the entire mechanism. The mass should be slightly greater than the sum of the mass of the tank and the weight of the material, so that the operation of each vibration conveyor mechanism is normal.

The vibration conveyor has a simple structure, low energy consumption, less lubrication points and wearing parts, and convenient maintenance. This equipment can be widely used in powder and granular material transportation in metallurgy, coal, building materials, chemical industry, glass, electric power, machinery, food and other industries.

0 notes

Text

Understand the installation and commissioning method of motor vibration conveyor

Description:

DZS motor vibration conveyor uses the vibration of the trough in order to achieve the rapid transportation of the material from the entrance to the port of discharge. It can be used to transport block, granular or powder materials under normal temperature or high temperature. The feeding end and discharge end can also be made into a few of types according to requirement of customer, such as one feed to one discharge, one feed to multi - port discharge, Multi- port feed to one discharge。

DZS motor vibration conveyor Through driving the vibrating motor or two motors,it engenders a specific exciting force,which drives vibrating frame to make periodic linear and reciprocal vibrationalong the inclined direction. When the vibrating accelerated speed of vertical component of vibrating frame is larger than gravity accelerated speed, materials are throwed up and move forward along a parabolic path,throwing up and falling down are completed in a flash。

Motor vibration conveyor features:

1. Feeding capacity is adjustable。

2. Small volume, light weight, simple structure。

3. Easy installation and convenient maintenance 。

4. Long service life of feeding trough。

5. Flow stability, low noise and small power consumption。

Installation and commissioning method of motor vibration conveyor:

1. The vibrating conveyor can be installed horizontally or in the range of 0~-12° (the “-” sign indicates that the discharge end is lowered).

2. The connection between the vibration motor and the trough should be firm.

3. Before starting the machine, check whether the angle between the adjustable eccentric block of the two vibration motors and the fixed eccentric block is the same. If it is inconsistent, adjust it to the same and tighten the fastening bolts.

4. Test start to observe whether the two vibration motors are turning in opposite directions. If the steering is not reversed, replace any two-phase wiring of any vibration motor.

5. After starting the machine, observe that the body should not have lateral swing, the motor current should meet the requirements, and the whole machine has no abnormal sound.

0 notes

Text

Description:

The PSL fully balanced vibrating conveyor is a new balanced connecting rod vibrating conveyor developed on the basis of the dual mass resonance type. By using the balance body as the transport tank body, the upper and lower tanks can be transported at the same time, and the effect of using two conveyors can be produced without increasing equipment and space. A screen is installed in the conveying tank to realize the classification of the material while conveying.

Features:

In addition to the advantages of the double-body resonance type, the PSL fully balanced vibration conveyor has the most outstanding advantage that the inertial vibration force (dynamic load) transmitted to the foundation is very small and the noise is low. It is suitable for longer distances and wider slots. Wide conveyor requirements, when installed on floor slabs or steel frame supports, have the unmatched damping advantages of other types of vibrating conveyors.

Structure:

1. Conveying trough; 2. Balance frame; 3. Underframe; 4. Eccentric linkage drive; 5. Resonant spring; 6. Elastic pendulum device; 7. Damping spring; 8. Damping seat.

Principle:

The fully balanced vibrating conveyor adopts a unique elastic support type, which makes the conveying trough body and the balance body form a double-mass resonance system with completely balanced mass. The two mass bodies are connected by a resonant coil spring and an elastic guiding pendulum. Under the action of the vibration exciter, a resonance system is formed with the balance body, and the inertial vibration force generated by the resonance system is substantially canceled in the system; the equipment support chassis is coupled with the installation foundation through the spring isolation system, and can be reduced again due to the tank body. Unbalanced vibrations caused by changes in material flow, so the dynamic load on the equipment is very small.

Application:

PSL fully balanced vibrating conveyor is suitable for many industries including biomass, recycling, pellet manufacturing, sawmill, plywood, OSB, food processing, and agricultural industries.

0 notes

Text

Understand the installation and use points of the inertial vibration conveyor

Description:

A vibrating conveyor is a continuous conveying machine that uses a vibrator to vibrate a trough so that the material in the trough slides or is thrown in a certain direction. It is mainly composed of a vibration exciter, a bearing groove, a main vibration spring and a frame. Can be used to transport a variety of loose materials horizontally, gently or vertically.

The vibrating conveyor is used for material conveying by means of reciprocating vibration of the conveying trough. It is a continuous conveying equipment of non-flexible traction members. It can transport granular or block loose materials horizontally or obliquely, and can also be used to transport powder.

The inertial vibration conveyor is driven by the inertial excitation force generated by the inertia exciter. The inertia exciter is mainly composed of an eccentric block, a main shaft, a bearing, a bearing seat, a chute, etc., and a centrifugally varying inertial force generated by the eccentric block rotating periodically excites the chute vibration. This centrifugal inertial force is the excitation force.

The eccentric block of the inertia exciter generates a large inertia force when rotated, and the structure is simple and compact. According to the number of spindles, it can be divided into a single-axis inertial vibration conveyor and a two-axis inertial vibration conveyor.

Note on the installation and use of inertial vibrating conveyor:

1. Before the empty running test, check the bolts of each part, especially the anchor bolts of the vibration motor. After 4 hours of continuous operation, the bolts of each part should be tightened once again, and tightened 2-3 times within one week.

2. The rotation direction of the two vibration motors should be opposite when working.

3. When the air test is running, check whether the conveyor is running smoothly, and pay attention to the temperature rise of the vibration motor bearing. After 4 hours of continuous operation, the maximum temperature of the bearing must not exceed 75 °C.

Inertial vibrating conveyor has the advantages of simple structure, light weight, low noise, reliable operation, no dust pollution, convenient installation and maintenance, etc. It has been widely used in metallurgy, mining, coal, building materials, chemical, food and other industries.

0 notes

Text

Characteristics and debugging methods of motor vibration conveyor

Description:

Motor vibratory conveyor is used to feed lump, grain and powder material to receiving device from storage bin or hopper at a continuous and even flow during production.

The motor vibration conveyor has below features:

1. Easy adjustment, stable flow。

2. Low noise, low power consumption, good performance of regulator, no material clashing。

3. Reliable running, convenient adjustment and installation, light weight, samll voume, easy maintenance。

Installation and commissioning method of motor vibration conveyor:

1. The conveyor can be installed horizontally or in the range of 0~-12° as required.

2. The connection between the vibration motor and the trough should be firm.

3. Before starting the machine, check whether the angle between the adjustable eccentric block of the two vibration motors and the fixed eccentric block is the same. If it is inconsistent, adjust it to the same and tighten the fastening bolts.

4. Test start to observe whether the two vibration motors are turning in opposite directions. If the steering is not reversed, replace any two-phase wiring of any vibration motor.

5. After starting the machine, observe that the body should not have lateral swing, the motor current should meet the requirements, and the whole machine has no abnormal sound.

The motor vibration conveyor has the advantages of simple structure, light weight, low noise, reliable operation, no dust pollution, convenient installation and maintenance. Motor vibration conveyors are widely used in metallurgy, mining, coal, building materials, chemicals, food, glass, ceramics and other industries.

0 notes

Text

Describe the working principle and characteristics of long-distance vibrating conveyor

Description:

The long-distance vibrating conveyor adopts two vibration motors as the excitation vibration source. Using the self-synchronization principle, the two vibration motors rotate in the opposite direction, so that the balance frame at the bottom of the conveyor produces reciprocating vibration, which is driven by the main vibrating spring and the guide leaf spring. The upper conveying trough vibrates to achieve the purpose of conveying the material.The long-distance vibrating conveyor has two types: open type and closed type, and the cross section of the trough can be made into various types such as a circle, a rectangle and a trapezoid.

Long-distance vibration conveyor features:

1. The equipment starts and stops quickly, the operation is stable, the vibration isolation performance is good, the noise is small, and the tank body wear is extremely small.

2. Large conveying capacity, light weight and good heat insulation effect. And the power consumption is less, only 20-50% of the general conveying equipment.

3. The load characteristics are good. The amplitude of the slot is affected by the fluctuation of the power supply voltage and the amount of the transmission. It can start normally under full load and overload conditions.

4. Simple structure, easy debugging and long service life.

5, easy to install, no need for special foundation and anchor bolts, easy to move position, less variety of wearing parts, easy maintenance.

6, good isolation performance, easy to feed and discharge multiple points, especially suitable for cement clinker and slag storage top.

7. The inlet and outlet ports can be different from the site, and can be fed in multiple ports, one-out discharge; multi-port feeding, multi-port discharging and other forms. It is suitable for cement clinker and slag bottom and top storage.

8, can be fully enclosed transport, eliminate dust, but also open transport. In special cases, different types of materials can be transported at the same time.

The long-distance vibrating conveyor is a highly versatile and advanced structure high-temperature material vibrating conveying equipment, which is generally used for long-distance transportation of powdery and granular materials. The vibration conveyor is widely used in building materials, metallurgy, chemical industry, coal and other industries.

0 notes

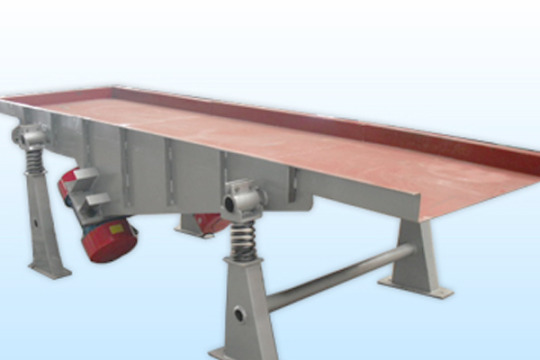

Photo

Description:

A vibrating conveyor is a continuous conveying machine that uses an exciter to vibrate a chute, thereby sliding or throwing materials in the chute along a certain direction. The vibration conveyor is mainly composed of an exciter, a bearing groove, a main vibration spring and a frame. Except for some parts of the vibration mechanism, there are few relative rotating parts.

The motor vibration conveyor is suitable for uniformly and continuously feeding block, granular and powdery materials from the storage bin or hopper to the receiving device. The motor vibration conveyor uses the vibration of the hopper to quickly transfer the materials in the hopper from the inlet to the outlet. It can be used to transport various materials in the form of blocks, granules or powders, room temperature or high temperature.

When the vibration conveyor is installed, what should be paid attention to during the test run:

1. No-load:

(1) The conveyor starts smoothly and quickly, and the vibration is stable, without left and right swing, jumping impact and abnormal sound。

(2) Deviations of conveyor amplitude, vibration direction angle, and vibration frequency are not more than 10% of the rated value; for vibration conveyors longer than 15m, the amplitude deviation of the front, middle, and rear sections should not be greater than 10 of the rated amplitude. %;

(3) The temperature rise of rubber springs must not exceed 50 ° C, the temperature rise of metal springs must not exceed 70 ° C, and the temperature rise of bearings and motors of eccentric link-type vibration conveyors must not exceed 50 ° C; the temperature rise of electromagnet coils must not exceed 65 ° C.

2. Load:

(1) The amplitude drop should not be greater than 10% of the rated amplitude;

(2) The material should move smoothly in the conveying trough, without obvious obstruction, running, swirling and severe skipping.

(3) The conveying capacity should not be less than 90% of the rated conveying capacity.

The motor vibration conveyor has the advantages of simple structure, light weight, low noise, reliable work, no dust pollution, and convenient installation and maintenance. Widely used in metallurgy, mining, coal, building materials, chemical, food, glass, ceramics and other industries.

0 notes

Photo

Characteristics and debugging methods of motor vibration conveyor

Description:

Motor vibratory conveyor is used to feed lump, grain and powder material to receiving device from storage bin or hopper at a continuous and even flow during production.

The motor vibration conveyor has below features:

1. Easy adjustment, stable flow。

2. Low noise, low power consumption, good performance of regulator, no material clashing。

3. Reliable running, convenient adjustment and installation, light weight, samll voume, easy maintenance。

Installation and commissioning method of motor vibration conveyor:1. The conveyor can be installed horizontally or in the range of 0~-12° as required.2. The connection between the vibration motor and the trough should be firm.3. Before starting the machine, check whether the angle between the adjustable eccentric block of the two vibration motors and the fixed eccentric block is the same. If it is inconsistent, adjust it to the same and tighten the fastening bolts.4. Test start to observe whether the two vibration motors are turning in opposite directions. If the steering is not reversed, replace any two-phase wiring of any vibration motor.5. After starting the machine, observe that the body should not have lateral swing, the motor current should meet the requirements, and the whole machine has no abnormal sound.

The motor vibration conveyor has the advantages of simple structure, light weight, low noise, reliable operation, no dust pollution, convenient installation and maintenance. Motor vibration conveyors are widely used in metallurgy, mining, coal, building materials, chemicals, food, glass, ceramics and other industries.

0 notes

Photo

Description:

A vibrating conveyor is a continuous conveying machine that uses a vibrator to vibrate a trough so that the material in the trough slides or is thrown in a certain direction.

Simply put, a vibrating conveyor is a device that continuously transports material by means of vibration. It is mainly composed of a vibration exciter, a bearing groove, a main vibration spring and a frame. Can be used for horizontal, gentle tilting or vertical transport (rising along the spiral groove) of various loose materials.

The vibrating conveyor can be divided into two types: horizontal conveyor and vertical conveyor according to the direction of conveying materials. According to the different driving methods, it can be divided into three types: electromagnetic vibrating conveyor, inertial vibrating conveyor and eccentric connecting rod vibrating conveyor.

Frequent maintenance and maintenance of the vibrating conveyor can increase the service life and reduce the failure rate. Specific requirements are as follows:

1. Due to the vibration transmission of the vibrating conveyor, the coupling may be loosened. Although elastic washers are added during installation, in order to avoid loosening, the operator should always check the equipment and tighten it if it is loose.

2. Operating parts, such as bearing housings and tie rod housings, with grease fittings on the outside. Each class should be filled with calcium-based or lithium-based grease to ensure lubrication and normal operation of the running parts. 3. If an operator finds an abnormality during work, he should stop the inspection in time to eliminate the fault.

4. Always check the bearing for damage. If it is found damaged, replace the new bearing of the same type in time.

5. There is a safety cover at the size of the V-belt drive. After the inspection, the protective cover should be installed in time to prevent danger.

The vibrating conveyor has the advantages of simple structure, convenient installation and maintenance, low energy consumption, no dust overflow and low noise. It is widely used in the transportation of powder and granular materials in metallurgy, coal, building materials and other industries.

0 notes

Text

Section bending machine classification

Description:

Section bending machine is divided into two types:

Flat bending and vertical bending. It is a new machine for bending flat steel, square steel, round steel, angle steel, I-shaped steel, H-shaped steel, square tube, rectangular tube, round tube and other profiles.

Different molds can be customized according to user requirements.

The three rollers are all active rollers and are driven by three independent hydraulic motors.

The winding speed is fast and the efficiency is high.use

Application:

Section bending machine is a relatively advanced profile forming equipment at home and abroad, and is widely used in the production of various round flanges in petroleum, chemical, steel, machinery and other industries.

Feature:

The section bending machine can complete the pre-bending, rounding and rounding process of the profile at one time; the profile bending machine has advanced structure and full functions, and can be placed or placed horizontally according to the user's use.

operating:

Before using the profile bending machine, the profile bending machine should be inspected thoroughly and the no-load test run should be carried out.

The fuselage of the profile bending machine should be grounded. The power supply is not allowed to be directly connected to the button. The switch box should be installed separately.

The placement of the steel bars should be matched with the direction of the iron retaining shaft and the working disk, and do not reverse.

Not straight steel bars, it is forbidden to bend on the profile bending machine to prevent accidents.

After the operation of the profile bending machine, pay attention to cleaning the on-site maintenance equipment and power off, and the cleaning site and maintenance equipment must be working after the power is cut off.

0 notes