Text

CO2 Laser Cutting Machine in Singapore

Signvec is a premier manufacturer and supplier of cutting-edge CO2 laser cutting machines in Singapore. Renowned for their precision and reliability, Signvec's laser cutting machines are at the forefront of industrial innovation. With a commitment to quality craftsmanship and advanced technology, they offer tailored solutions to meet diverse cutting needs across various industries. Trusted by businesses for their efficiency and accuracy, Signvec stands as a leader in the laser cutting machine market, delivering exceptional performance and unmatched value.

In Order To Find Out More Details Laser Cutting Machine Please Be Touch With Us Today Onwards..!

#CO2 Laser Cutting Machine#CO2 Laser Cutter#CO2 Laser Cutter Singapore#Laser Cutting Machine#Laser Cutter#Cnc Laser Cutter#Cnc Laser Cutting Machine

0 notes

Text

Laser Engraving And Laser Marking Similar Or Different Processes?

Laser etching, marking, and engraving are the most versatile modern inventions that are used in almost every industrial sector. While the difference between the laser engraving and laser marking and laser etching is quite evident, the terms laser marking and engraving are confused at times. Laser marking, is a method that leaves markings on a surface material of an object, including colour change, owing to chemical alteration.

Laser engraving is the method that is carried out by inscribing on an object surface. Laser engraving does not involve any inks or dyes, so it gains an advantage over the laser marking, wherein the replacement of tool bits like the ink heads need not be done. Laser marking has its own pros like the preservation of surface without any impact on it, since it uses colours and dyes to mark on the material surface thorough the laser techniques. Laser-sensitive polymers, metal alloys play an important role in this method. The method in general is a generic term that encompasses a variety of surfacing marking techniques like printing, hot-branding, laser attachment and so on.

On the other hand Laser engraving selectively removes minute layers of the surface material creating visibly conspicuous marks which are permanent. Different material surfaces respond to the laser in different ways. Harder surfaces primarily are responsive to ablation where the laser beam dislodges the minute particles from the surface. Engraver can create deep incisions, whereas laser marking is usually much shallower comparatively. Very short bursts of precise laser pulses or beams are done to get a clear marking, as transmit large quantity of power even without high degree of heating or melting the material surface.

Laser engraving is a part or a subsection of laser marking but however since it differs in quite a few ways it is separated from the laser marking. Mainly there are three types or categories in laser engraving, Laser ablation, deep laser engraving and laser etching. The difference in these three is the amount or the depth of engraving that is carried out depending on the requirement and the nature of the material surface. Laser ablation is the quickest way to mark on a material surface. This method is most suitable for engraving on parts that are subjected to high wear, marking serial numbers; logos, engine and chassis number engraving and so on. In laser etching, engraving is carried by the heat caused by the beam on to the surface of the material.

Nevertheless machines that are used for laser engraving and laser marking are almost similar, by virtue of the technology. But in a lot of cases these terms are confused due to the lack of awareness. Organizations like Signvec are pioneers in supply and service of laser marking machine and laser engraving machines. Located in Singapore the company has carved out a solid place for itself in the mentioned sector and has been maintaining a solid clientele, with reputed names included in it.

In Order To Find Out More Details On Laser Engraver Please Be Touch With Us Today Onwards..!

#Laser Engraver#Laser Engravers#Laser Engraving Machine#Laser Engraving Machines#Fiber Laser Marker#Fiber Laser Marking Machine#laser marking machines#laser marking machine

0 notes

Text

Laser Cutting An Innovation For Highly Accurate And Precision Cutting

Laser cutting is a methodology that uses a laser beam on the surface of the material which has to be cut. This methodology is mostly used in the industrial sector where large blocks of materials like iron and steel have to be cut to the required sizes. The process technically is similar to laser, marking and laser engraving. Even in this case, high power laser beam is directed onto the metal surface through optical devices like convergent lenses.

Computer numerical controls are used to direct the laser beams onto the material surface, which either melts or vaporises the material surface at the point of requirement, thereby living a very high quality finish at that point of cutting. Before the laser cutter or the laser cutting machine, became to be used extensively. These kinds of laser machines are mostly used to drill holes on the material surface. Advanced technology later on was used to cut material surfaces for aerospace applications, which needed a very fine finish. The disadvantages of mechanical cutting on certain material surfaces gave room to the invention of laser cutting machines. The process of laser cutting has its own advantages over the mechanical cutting like easier, cutting, more precision, accuracy, no wear and tear and so on.

Basically, there are three types of laser cutting machines in which the carbon dioxide laser is the best suited for cutting, drilling, and engraving. The ND lasers are used where very high power is needed in case of cutting very thick sheet metal materials. However, both carbon dioxide lasers and ND lasers can be used for the purpose of welding. While carbon dioxide lasers are used for the industrial cutting of many materials, including titanium and stainless steel, the ND lasers are primarily used for cutting ceramics. The laser cutting machine are dependent on the type of a gas flow that is used in it.

The usual types of gases that are used in these machines are carbon dioxide, helium, nitrogen, or a mixture of any of these. A laser cutting machine generates a good amount of heat within itself and hence requires a proper cooling process also. In most of the cases, water is commonly used as a coolant and is circulated during the process. A micro jet of water is integrated at a low pressure, which is used to perform laser cutting functions, which is also helpful in removing the debris and cooling the material.

Another advanced type of laser cutting machine is the fiber laser which is a solid state laser. Here the fiber technology is used to produce a laser beam which is then amplified and is known as fiber with a suitable wavelength. These lasers are very much suitable for cutting metals and metal sheets which reflect the light which is the main advantage of fiber laser cutting machine. Signvec is an organization that deals with laser cutting and engraving machine, known to have a number of advantages like less energy consumption, higher reliability, and performance, less maintenance, very low, operational cost and so on.

In Order To Find Out More Details On Laser Cutter Please Be Touch With Us Today Onwards..!

#Fiber Laser Cutting Machine#Laser Cutting Machine#Laser Cutter#Cnc Laser Cutter#Cnc Laser Cutting Machine#Laser Cutter Singapore

0 notes

Text

3D Fiber Laser Marker in Singapore

Signvec is a leading manufacturer and supplier in Singapore, renowned for high-quality 3D fiber laser marker solutions. Our expertise lies in crafting precision-engineered fiber laser marker machines that excel in marking applications. With cutting-edge technology and meticulous craftsmanship, Signvec ensures superior performance and reliability for diverse industrial needs. Trusted globally, we offer comprehensive support and customization options, making us the preferred choice for businesses seeking top-tier fiber laser marker solutions.

In Order To Find Out More Details Fiber Laser Marker Please Be Touch With Us Today Onwards..!

0 notes

Text

Laser Engraving The Magical Invention For Metal Surface Marking

Laser engraving and laser marking are quite known factors in the field of surface marking technologies. The theory and technology behind it is quite simple and straightforward but a talk about its applications would not end in a single discussion. The scope of this magical invention and the significance in various applications is amazing. Laser marking and laser engraving are those technologies which make use of a focused beam of light to the desired point on the surface of the material. While this converged beam of light is scientifically known as light amplification of stimulated emission of radiation, has an extraordinary power of making a permanent and consistent marking on any metal surface. Depending on the intensity of light, the amount of time it is in contact with the medical surface, and nature of the metal surface. These laser beams actually make a deep incision like markings, which is conspicuously visible from a distance.

Although laser marking machine and laser engraving machine is usually done on hard metal surfaces, it is also employed in creating or inscribing on other surfaces, which are comparatively weak and soft Depending on the metal surface and its nature, the amount of laser beam, the time of exposure and similar relevant aspects, the intensity, the focal point and other allied things are set up to carry out the necessary actions. Although these laser beams are used to engrave or mark an almost all solid surfaces, there are certain metals which are best suited for laser engraving and laser marking.

although there are other various means of writing and marking on metal surfaces, laser technology is the most preferred method because the marking has an exceptionally good capacity to remain legible and clear even under very hard conditions. The next important point that makes lasers marking machines and laser engraving machines stand above the rest is the time taken for the whole process. Laser marking and laser engraving hardly takes up any time in comparison to its other competitors where in the engraving is done using physical force like a rotor, or chipping of the unwanted material, and similar, physically, strenuous and mechanical methods whereas, in case of laser engraving and laser marking not much of physical strain is needed, on the contrary, only the laser beam must be moved in accordance with the inscription, text, image, symbol or other similar which have to be marked engraved. The same way in certain mechanisms the laser beam remains fixed while the platform on which the metal surface is placed is moved accordingly. In either of the cases, the marking is 100% accurate and precise and as per the necessity and requirement.

Signvec Technology is the pioneer in engraving and signage industry located in Singapore specialist in laser, rotary engravers, marking, and allied products that range from high-end laser marking and engraving machines to affordable budget, range machines.

In Order To Find Out More Details On Laser Engraver Please Be Touch With Us Today Onwards..!

#engraver#engravers#laser engraving machine#laser engraver#laser engravers#engraving machine#engraving machines#laser engraving machines#fiber laser marking machine#fiber laser marker

0 notes

Text

Top Quality CO2 Laser Marker in Singapore

CO2 laser commonly used for non-metallic materials marking such as rubber, leather, wood, PVC, bamboo, acrylic sheet. Also it can be used for cutting some soft materials such as leather, garment, paper. Many wedding or greeting card factories adopts CO2 laser for making hollow out designs on cards. Also CO2 laser marker is wide applicable in production date making on packing industries.

In Order To Find Out More Details CO2 Laser Marker Please Be Touch With Us Today Onwards..!

#CO2 Laser Marker#CO2 Laser Marker Singapore#CO2 Laser Markers#CO2 Laser Marking Machine#CO2 Laser Machines

0 notes

Text

Types of Laser Engraving And Laser Marking Machines

Laser engraving and laser marking have got its own applications and scope. These are one of the complex mechanisms that are used in various industrial sectors. Initially this method was being widely used in the automotive industry to mark the engine numbers which had to be consistent and long lasting. Later on this method slowly started to spread to other sectors like medical, toys, electronics, manufacturers of Fancy, glass panel, House-hold electronic devices and so on. Basically it’s laser beam that is focused to a precise point and then subjected to on the material surface where the marking has to be done. Depending on the intensity of the beam, the material surface undergoes changes which may be physical and to some extent chemical.

The laser beam accurately burns out the area of focus, thereby leaving a marking which either is a grove contrasted with the surrounding material service, which other words is a long, lasting mark left on the material surface, which is conspicuously visible. Laser marking and laser engraving are two Technically similar, but giving a different result. Laser engraving is that method where the laser beam is usually of a stronger intensity, strong enough to create a grove whereas laser marking is a comparatively low intensity, laser beam marking, which is also quite long lasting but without any grove on the material surface. Categorically there are three main types of laser engraving machines that can be mentioned. The carbon dioxide laser marking machine, the fiber laser marking machine and the crystal laser marking machine. In a carbon dioxide, leisure engraving machine, a mixture of carbon dioxide undergo electrical treatment giving rise to a precise laser beam.

Talking about the fibre, laser engraving machine, it can be called as a solid state laser which has a very short wavelength and a smaller focal diameter due to which the intense intensity of the laser beam. The third type of laser engraving machine is the crystal laser machine, which is a highly complex device which involves the use of diodes in it. Since these diodes wear out in Due course, they need to be replaced with new diodes. In comparison to the other engraving machines, crystal laser engraving machine happens to be more intricate and needs more maintenance than the other two. However, due to this intricacies, crystal lasers are used to engrave on plastic ceramics and glass.

However, all the above three laser engraving machines can be employed to laser mark metal surfaces like aluminium, steel, magnesium, lead and stainless steel. Different material surfaces respond in their own way when they are subjected to the laser. Organisations like Signvec technology, Located in Singapore are skin and expert in manufacturing, installing, servicing and maintenance of laser marking machine and laser engraving machines. With a special expertise in Rotary engraving, laser cutting, The Company, manufactures, customised laser engraving machines to reputed clients. With a dedicated intention to offer and deliver best services in this sector, Signvec has been providing first quality as engraving and blazer marking machines.

In Order To Find Out More Details On Laser Engravers Please Be Touch With Us Today Onwards..!

#engraver#engravers#laser engraving machine#fiber laser marking machine#laser engraver#fiber laser marker#laser engravers#engraving machine#engraving machines#laser engraving machines#laser marking machine#laser marking machines

0 notes

Text

Laser Engraving And Marking: Metals That Are Mostly Preferred For The Job

The process of laser engraving or marking is one of the most preferred ways of inscribing on metal surfaces, where in a focussed beam of laser light is used to carry out the process. While this process can be implemented on various materials surfaces, there are certain materials that may not be so suitable as well. Material surfaces that are fragile and sensitive to lasers cannot be subjected to lasers. However material surfaces that are durable and tolerant to lasers can be successfully used to carry out the task of laser engraver and marking. Naming a few material surfaces that are commonly used, Aluminium both anodized and non-anodized, Stainless Steel are the ones that are extensively preferred, but all the same magnesium and lead also can be categorised as the metal surfaces that are suitable for the job.

A deeper review reveals why these metal surfaces are considered as ideal surfaces for laser engraving and marking. Aluminium is such a metal that is very widely used in fabricating vehicle crankcase and body parts in the automobile sector. With a comparatively high thermal conductivity, aluminium metal can sustain substantially high temperature variations and due to the naturally light colour of the metal surface laser engraver can make remarkable contrast markings which are quite conspicuous and visible easily. Stainless steel is the other metal that can be categorised as a metal that is one of the strongest materials, and can hence withstand the laser treatments to a great extent without the loss of properties or getting disfigured easily.

Along with the process of laser etching and engraving, the process of annealing laser on the material surface of steel also offers corrosion resistance, when we consider rust as one of the biggest killer of steel surfaces or the material as a whole. Steel tubes, sheets and other steel items can effectively endure to the process of laser engraving.

The metal magnesium is one such metal where the industrial sector mostly makes use of in the fabrication of auto parts that have to be lighter I weight. Generally spares like the gearbox parts, steering wheels of cars, engine casings and similar are those parts which contain a known percentage of magnesium to render the parts light in weight. Laser engraving works best in this metal surface thereby making it one of the preferred metals for laser marking and engraving. Lead is another metal that is subjected to laser engraving and etching or marking, in the industry.

Since the metal lead has a comparatively lesser thermal conductivity amongst the other preferred metals, heat generated during the process does not disassociate to the atmosphere or the surrounding, on the other hand it remains on the material surface, making it the fastest of the metal surfaces that can go on with the laser marking, etching and laser marking process. Companies like Signvec technology, with more than two decades of rich professional experience in the manufacture of laser marking machines, laser etching and laser engraving machines, provide second to none services in the mentioned sector.

In Order To Find Out More Details On Laser Marking Machine Please Be Touch With Us Today Onwards..!

#engraver#engravers#fiber laser marking machine#laser engraving machine#fiber laser marker#laser engraver#laser engravers#engraving machine#engraving machines#laser engraving machines#laser marking machines#laser marking machine#uv laser marker#fiberlasermarkingmachine

0 notes

Text

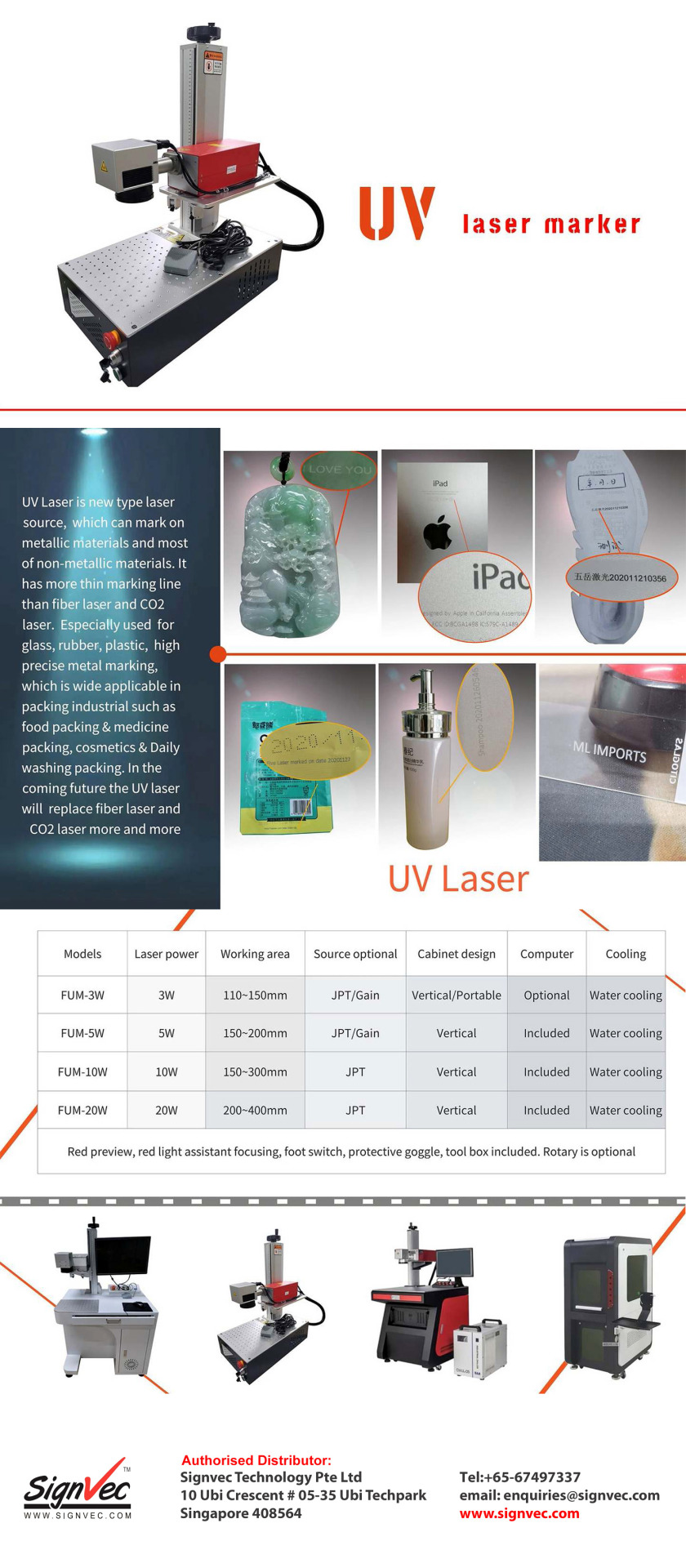

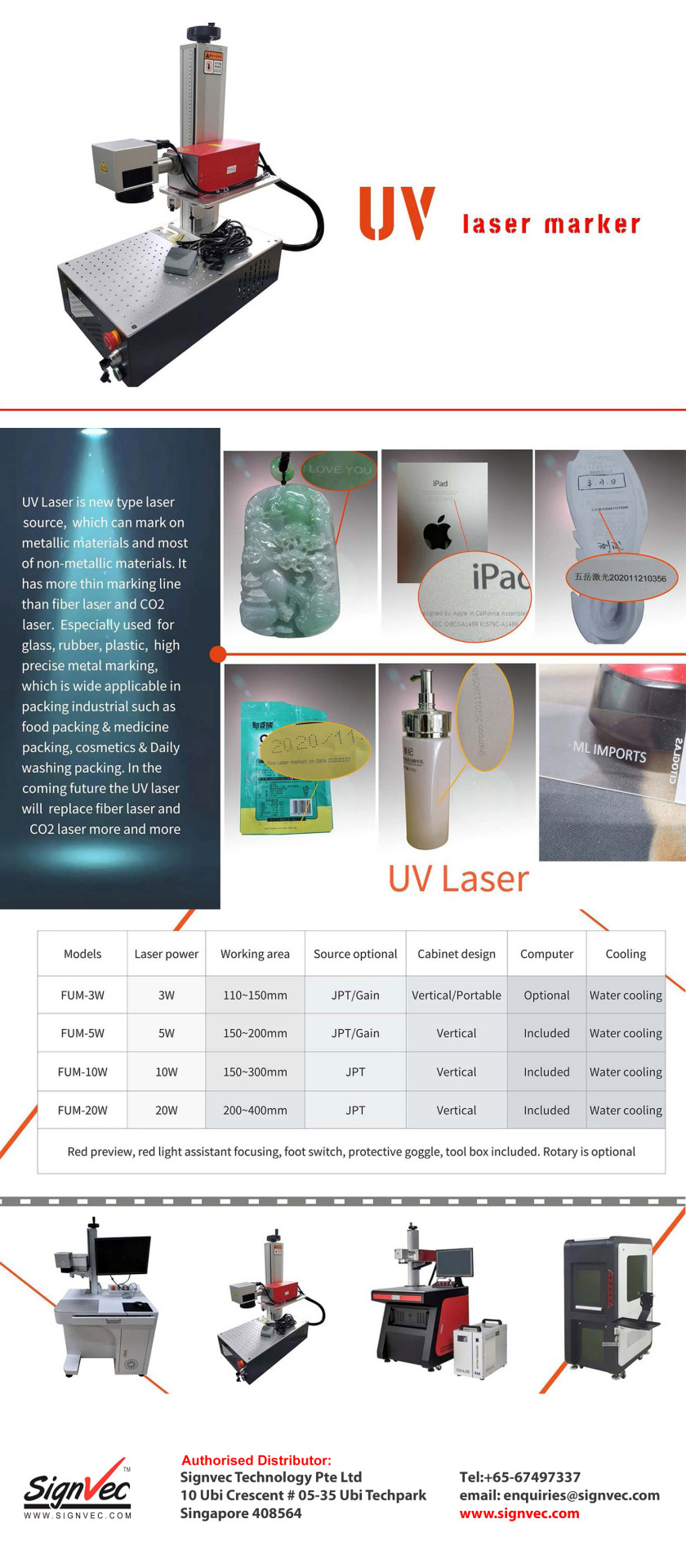

UV Laser Marking Machines in Singapore

UV Laser marker machine is new type laser source, which can mark on metallic materials and most of non-metallic materials. It has more thin marking line than fiber laser and CO2 laser. Especially used for glass, rubber, plastic, high precise metal marking, which is wide applicable in packing industrial such as food packing, cosmetics & Daily washing packing. In the coming future the UV laser marker will replace fiber laser marker and CO2 laser more and more.

0 notes

Text

UV Laser Marking Machines in Singapore

UV Laser marker machine is new type laser source, which can mark on metallic materials and most of non-metallic materials. It has more thin marking line than fiber laser and CO2 laser. Especially used for glass, rubber, plastic, high precise metal marking, which is wide applicable in packing industrial such as food packing, cosmetics & Daily washing packing. In the coming future the UV laser marker will replace fiber laser marker and CO2 laser more and more.

In Order To Find Out More Details UV Laser Marking Machines Please Be Touch With Us Today Onwards..!

0 notes

Text

Laser Engraving, Marking And Etching: An Overview Of Associated Aspects

The word Laser is an abbreviation which marks the process that is carried out by using a highly focused beam of light that is created by the stimulated emission, which is amplified to the desired extent where in the beam thus generated will leave a mark on the surface of a material. When this highly focused beam gets in contact with the material’s surface, it changes the material’s physical property and appearance.

While this focused beam aims at a specific area, a precise, contrasted mark is formed. Laser marking process makes it ideal for material surfaces which require accuracy and permanency. With the advancement of science and technology, the recent technically progressive cutting-edge fiber laser technology has been on the trend, belonging to the solid-state lasers category, they have a shorter wavelength due to which a smaller focal diameter beam is created or formed the point of impact on the material surface. In this case the intensity is many folds greater than the carbon di oxide laser technology. Owing to the high power beam and a considerably smaller wavelength, they are almost maintenance-free providing a service life of about 25000 hours.

Another category of lasers, the crystal lasers, too have their place in the same class, as of the solid state laser systems. In this type the diodes generate crystal laser beams, essentials present in these diodes are usually carrier crystals of neodymium. Even in this case the wavelength is quite convenient to mark on metals and plastics as well. But the main difference in this crystal lasers are the deterioration of the diodes over a period of time, rendering it not 100% maintenance free but requires some maintenance of the system, mainly the replacement of diodes.

These crystal lasers are efficient on coated metals, with an extended performance on other metals too. As mentioned crystal lasers can be used to mark and engrave on plastics, ceramics and other delicate and fragile material surfaces also. The topic of laser engraving and marking goes never ending, likewise the applications of these systems also is quite wide ranged. Lasers and its applications are applied in almost all the products ranging from an automobile spare part to laser printing on packing materials like wrappers, boxes and other similar containers.

Automobile engines and other critical parts are laser etched or laser marked or laser engraved for their unique and authentic engine and chassis numbers. These markings are permanent and deep so that they cannot be tampered easily. Organizations like Signvec, in Singapore manufacture, service and supply laser marking machine of supreme quality and performance. Specifically specialised in laser rotary engraving machine, laser cutting and laser marking machines, the organization delivers products ranging from the high end to the affordable range.

In Order To Find Out More Details On Laser Engravers Please Be Touch With Us Today Onwards..!

#laser engraving machine#fiber laser marking machine#fiber laser marker#laser engravers#engraving machine#engraving machines#laser engraver#engraver#engravers#laser engraving machines

0 notes

Text

Metal Surfaces That Are Desirable For The Purposes of Laser Marking

Laser marking and engraving are undoubtedly unique methods for marking on different surfaces. But all the same not all material surfaces respond in the same way. They have different properties and structure and react to the process in dissimilar ways. All the same the power and process that has to be employed for different metal surfaces are also different. While hard surfaces require more power and techniques, softer and delicate surfaces require much gentle processes. So in order to accomplish the desired effect and finish, a precise metal surface has to be selected and likewise an accurate powered device as well.

Amongst the surfaces that is laser marked, aluminium has been found to be the most suitable surface. Aluminium is that metal that is widely used in manufacturing crankcases of automobiles. Due to high thermal conductivity, aluminium has a high capacity to give out an excellent finish and response to the laser engraving and marking processes. Especially the fibre laser engraving products can sculpt aluminium and can produce contrast markings of high quality.

Another strong material is stainless steel and on this metal surface laser engraving is reasonably challenging. In this case the speed and power must be increased by adjusting, which usually is done by observing the marking done and the intensity of engrave, on the basis of the light and dark marks. While steel tubes, pipes and similar items are common that undergoes laser engravers, there are also other shapes that are subjected to laser engraving and laser marking in accordance to their necessities. Laser marking or engraving on anodized aluminium can be carried in ways, either it can be engraved or marked on the surface of the metal in the absence of the oxide layer or can be done above the oxide layer. However in either of the cases the resistance magnitude of the metal rests intact.

Magnesium is another metal which the industries prefer to manufacture lighter parts like gearbox, steering wheel and engine casing. While the process of laser engraving and marking can be used for such light parts, the part needs a solid grip. Owing to this reason, it cannot be considered as the best technique, since lighter parts may tend to break while applying force and too much grip. Since the engine can be called as the most essential part of any vehicle, it is important to engrave in such a way that it includes the necessary codes and identifications as well.

Signvec Technology formed in 1997 to cater to the needs of clientele has accomplished within the span of about two and a half decades. Specialised in laser and rotary engraver and cutting, machines that are manufactured are the best in the sector, with their product ranging from high end to the more affordable range. Not only has the company made a name in supplying laser engraving and laser marking machines, but also has a reputation of delivering the beast and timely aftersales services also.

In Order To Find Out More Details On Fiber Laser Marking Machine Please Be Touch With Us Today Onwards..!

#engraver#laser engraving machine#laser engraver#fiber laser marking machine#engravers#laser engravers#engraving machine#fiber laser marker#engraving machines#laser engraving machines

0 notes

Text

Laser Marking And Engraving - Skill is Used Across A Wide Range of Industries

Laser marking and laser engraving are two exceptionally advanced, but yet based on a simple scientific principle technological inventions. These methods are used in a variety of industries like the automotive industry, electronic parts manufacturing, medical & scientific parts manufacturers and so on. In the recent aerospace research sector laser marking has been the most preferred method to make markings on vital and critical components of the equipment and space vehicles as well. While discussing about laser marking machine, the most common methods of execution are annealing, carbon migration, engraving, etching and coloration. In order to understand how this technology works on different material surfaces, it is very much necessary to know the principle on which it is based.

To put it in a very simple sense, it works by focusing a beam of light amplified by the stimulation and emission of radiation, which is focused and fixed towards a particular area on the material surface. Since a laser beam is enthused to discharge elements of light, this beam carries a certain amount of energy that is released which is assessed in wavelengths .The greater the wavelength, the more potent the laser beam will be.

When the beam thus released comes in contact with the material surface, it apparently modifies the material surface properties and to some extent its appearance as well. The main advantage in this laser beam is that it targets only a specific area, enabling the laser beam to create a precise and high quality marks virtually on all surfaces, barring some materials which are delicate and sensitive to high temperature. Due to this wide range of applications on a variety of material surfaces, laser marking is considered as an ideal technology where the aspects of precision and durability are needed.

Although the science involved in the technology of lasers and laser marking machines, is quite straight and simple, because of the fact that at their concentrated point, a considerable amount of heat that is generated, that is at the point of contact it may not be the preferred method for certain softer and heat sensitive material surfaces, in such cases, a reformed type of laser machine the UV laser or cold laser beam that practically emits less energy and heat they are a the most preferred solutions for marking many soft products and heat sensitive materials.

Signvec is a company that has been manufacturing laser marking and laser engraving machines in Singapore. The company has a reputation of being one of the leading laser equipment manufacturer and supplier. The main advantage of Signvec is that it not only sells this equipment but also undertakes the service, maintenance and repairs of the laser marking machines, laser engravers and allied equipment.

In Order To Find Out More Details On Fiber Laser Marking Machine Please Be Touch With Us Today Onwards..!

#fiber laser marking machine#laser engraver#fiber laser marker#laser engravers#laser engraving machine#laser engraving machines#engraving machines#engravers#engraver#engraving machine#laser marking machines#laser marking machine

0 notes

Text

Cylindrical And Flat Max S5 Engraver Machine For Sale

The MAX Engraver is Vision's original multi-axis rotary engraving machine. With engraving speeds of up to 10" per second and a removable 8" x 12" flat engraving table, the MAX can engrave cylindrical items up to 11" in diameter and flat items up to 11" thick. You can engrave text and logos on jewelry, mugs, steins, bowls, cups, and many other items. The MAX is also ideal for heavy-duty work, including marking industrial items such as tools, cylinders, pipes, and gauges.

In Order To Find Out More Details Cylindrical And Flat Max S5 Engraver Please Be Touch With Us Today Onwards..!

#engraver#Cylindrical And Flat Max S5 Engraver#Vision Max S5 Engraver#Flat Max S5 Engraver#engravers#laser engraver#laser engravers#engraving machines#engraving machine#laser engraving machines#laser engraving machine#fiber laser marking machine#fiber laser marker

0 notes

Text

The Virtuosity of Laser Engraving And Laser Marking And Etching

As a general perception and method the laser marking process simply is a precisely focused beam of light that is amplified to several times by stimulation of particular radiations to mark on any specific surface of a known material. While the beam of radiated light focused interacts or hits the material surface, apparently the material and its surface properties and physical appearance gets altered there by creating a marking on the surface. Nevertheless this ray of concentrated light aims only at a particularly specified area on the surface hence enabling the laser beam to create precise, superior quality, contrasted marks that can be easily read or scanned. It is this feature of the laser that makes marking via laser beam an ideal method where in accuracy and permanencies are very much needed. Another method in close reference to Laser marking is the laser engraving technology that is normally used in the process of engraving metal surfaces of different kinds.

However this laser engraving best works with metals like stainless steel and aluminium irrespective of whether the metal surfaces are anodized or not. While discussing about the key aspect of this process, it obviously is its capability to engrave codes that still maintain very high levels of clarity even after chemical treatments that are done post to the process of engraving. Likewise, laser etching is another associated process because of its high-speed and non-dependence on the other factors to a great extent. Laser etching can be carried out on a variety of material surfaces which include stainless steel, aluminium both anodized and non-anodized types, and also on metals like lead, magnesium, and zinc. The process of laser etching literally fluxes the metal surface to transform into its variance, whereas laser engraving process sublimates the metal surface and creates abysmal fissures, making the metal surface instantly captivate enough energy to transform from solid state to gaseous state without even converting into a liquid state.

But however in order to achieve the state of sublimation directly, the laser engraver system may have to produce considerable power and energy for the metal surface to touch its vaporization temperature in a very short time probably within a few milliseconds. Since extreme temperatures are obviously required for this process of sublimation, laser engraver machines must be very powerful. This apart a method which is called laser annealing is also employed to mark on metal surfaces like stainless steel and aluminium.

Organizations like the Signvec Technology have currently made a big name in the engraving and signage industry. Specialised exceptionally in the manufacture and installation of laser, rotary engravers, cutting and laser marking machines, it ranges from high end to affordable range of variety of laser machines.

In Order To Find Out More Details On Laser Engravers Please Be Touch With Us Today Onwards..!

#engraver#laser engraving machine#fiber laser marking machine#engravers#laser engraver#engraving machine#engraving machines#laser engraving machines#laser engravers#fiber laser marker#laser marking machines#laser marking machine

0 notes

Text

Laser Marking And Laser Engraving: Equipment And Techniques

Laser is that process where the stimulated emission of particles of light is generated. Wherein, this generated light when converged and focused towards any surface, leaves a mark at the point of contact and this is referred to as a laser mark. Generated with a complex laser marking machine, laser marking technique finds usage in a range of various applications. While automatically processed at very high swiftness, these laser beams have a capacity of leaving long-lasting marks on a range of materials, like aluminium, copper, ceramics, plastics, wood, paper and much more.

In comparison to the different marking techniques that are carried out, out of which most of them are not permanent, laser marking stands out among all of them in terms of durability and maximum productivity. Different types of marking can be carried out with the help of different equipments, and each of the apparatus operates differently. While the performance of the machine depends on various other factors, the main one is based on the material surface. The process of laser marking can be carried out by comparatively low powered laser devices in which the beam generated is of low intensity, and hence does not increase the temperature of the metal surface. Whereas the laser engraving machines operates at relatively high temperatures, and extracts the material surface layers to a considerable extent.

However both the procedures result in permanent markings. While increase in temperature disperses the surface of the material it is a process that takes place more rapidly creating deep depressions. All the same laser engraving method is not always suggested for surfaces that are delicate and fragile. Surfaces like wood, glass, ceramic, plastic, natural and artificial leather can efficiently be marked. Likewise, the method of laser etching is also very much similar to the laser engraving.

Even here the laser light beam is converged into a narrow beam or ray and the material surface is engraved with a variable depth. But since this process often changes the surface behavior and sensitivity of the substrate, it is best suited in cases of plated metal surfaces, ceramics and other kinds of polymers. While the technology of laser engraving is to an extent complex the machinery involved in it also happens to be sophisticated and advanced in terms of its technical aspect.

In order to deliver these state of the art machinery, the industry as to be a dynamic and technically experienced one. Signvec Technology a well-known organization in the engraving and signage industry offers sales of top quality laser engraver and marking machines. Also with a dedicated expertise in laser and rotary engraver, cutting and marking machines, it caters to high end clients requiring high precision and superior quality laser marking and laser engraving machinery.

In Order To Find Out More Details On Laser Engravers Please Be Touch With Us Today Onwards..!

#engraver#engravers#laser engraving machine#laser engraving machines#laser engraver#fiber laser marker#fiber laser marking machine#laser engravers#engraving machine#engraving machines#laser marking machine

0 notes

Text

Cylindrical And Flat And Glass MAX Pro S5 Engraver Machine

The MAX Pro S5 Engraver was developed to be Vision's most versatile machine to date, allowing for engraving of flat, deep, round or odd-shaped items in one compact, easy-to-use machine. The system is frequently used as a glass engraving machine, but its automatic surface-sensing feature allows for flat and curved surface engraving on a wide range of other materials as well, such as plastic, brass, coated and non-coated metals, artificial stone, crystal, and more. The system includes Vision’s Auto Laser Layout feature, which sends the engraving area and position directly to the software without measuring.

In Order To Find Out More Details Vision MAX Pro S5 Engraver Machine Please Be Touch With Us Today Onwards..!

#Vision Max Pro S5 Engraver#Max Pro S5 Engraver#Engravers#Engraver#Engraving machine#Engraving machines#Engraving product#Engraving products#Engraving system#Engraving systems

0 notes