#BerylliaCeramic

Text

What Makes BeO Outstanding for Electronic Packaging

In electronic packaging for RF and microwave, people are always looking for a very good insulation material with excellent properties that can be withstand the extreme strict environmental conditions in Military and aerospace applications.

Among them, BeO is standing out due to its high thermal conductivity and

excellent electrical properties. The thermal conductivity of Beryllium oxide is up to 285 W/mk, the second ceramic material next to BeO is AlN, which is 170 W/mk, and compare to most common Al2O3 material, its thermal conductivity is only 25-30 W/mk. Therefore, BeO Ceramic become the priority materials for RF Power Transistor Packages in Thermal management and the applications that require excellent electrical isolation

As an oxide ceramic, Beryllium oxide is very stable in oxygen/moisture containing

environments. The adhesion of the ceramic-to-metal joints is high and reliable. Typically, the metallization process is by Tungsten/manganese (W/Mn) coating, then plating Nickel (Ni), it can work in 800℃ at Reducing atmosphere without Nickel bubbling. BeO metallization is widely used in Microwave power circuits and Integrated Circuits (ICs).

Some misunderstandings on BeO materials is that it’s toxic, actually, only the powder of Beryllium oxide is toxic, the BeO ceramic is provided as finished product without toxic. The production workshop is strictly controlled to protect the workers’ life and safety, therefore, there is no need to worry about the health problem.

Read the full article

#BeO#BeOMetallization#BerylliaCeramic#BerylliumOxide#MicrowaveIntegratedCircuit#RFPowerTransistor#ThickFlimMetalizedBerylliumOxide

0 notes

Text

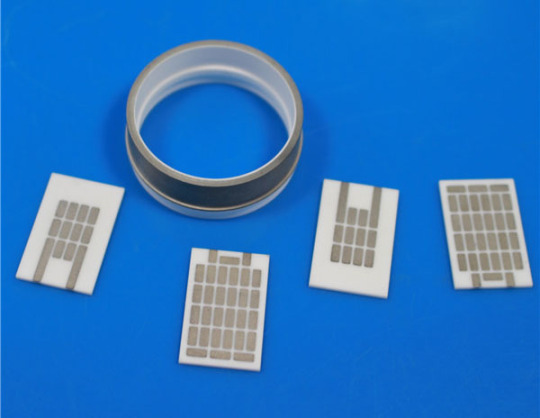

Beryllium Oxide Ceramic Substrates For Advanced LED Ceramic Modular Technology

Beryllium Oxide (BeO) Ceramics, which is commonly referred to as beryllia ceramics. BEO ceramic substrates are made of more than 99% beryllium oxide ceramics. The ceramic substrate is based on the electronic ceramic, with the membrane circuit element outside and the fitting element to form a support base for the sheet material. Beryllium Oxide Ceramic substrates thermal conductivity is more than 230 W/Mk, so it is widely used for Advanced LED Ceramic Modular Technology which requests very high thermal conductivity.

Beryllium oxide ceramic substrate advantages:

High melting point

Low dielectric constant

High electrical resistivity

Thermal shock resistance

Easy and effective metallization

More consistent heat dissipation

Low coefficients of thermal expansion

Better uniformity of crystalline structure

Superior thermal conductivity(equivalent to aluminum)

More durable in semiconductor chamber cleaning environments

Beryllium oxide ceramics are one of the most important and necessary basic materials for electric vacuum devices, power electronic modules, especially high-power microelectronic devices.

Read the full article

0 notes

Text

Beryllium Oxide Ceramic Part For Microwave Communication Systems And Microwave Ovens

As we have known, beryllia ceramics are the smart choice for protecting advanced electronics and communications technology, BEO ceramics have high thermal conductivity (more than 230 W/M.K)), good electrical resistivity, low dielectric constants and very low dielectric loss, large heat dissipation and good mechanical strength.

Due to high and low power RF and microwave radar systems require low dielectric constants and very low dielectric loss and beryllia ceramics is transparent to microwaves, so BEO ceramic is most often the material selected for these microwave communication systems and microwave ovens requirements, such as BEO ceramic part can be used as microwave communication systems and high power industrial microwave oven’s windows, radomes, and antennas and so on.

Beryllium oxide ceramic part advantages:

High melting point

Low dielectric constant

High electrical resistivity

Thermal shock resistance

Easy and effective metallization

More consistent heat dissipation

Low coefficients of thermal expansion

Better uniformity of crystalline structure

Superior thermal conductivity(equivalent to aluminum)

More durable in semiconductor chamber cleaning environments

Beryllium oxide ceramics are one of the most important and necessary basic materials for electric vacuum devices, power electronic modules, especially high-power microelectronic devices.

Read the full article

0 notes

Text

Beryllium Oxide Ceramics

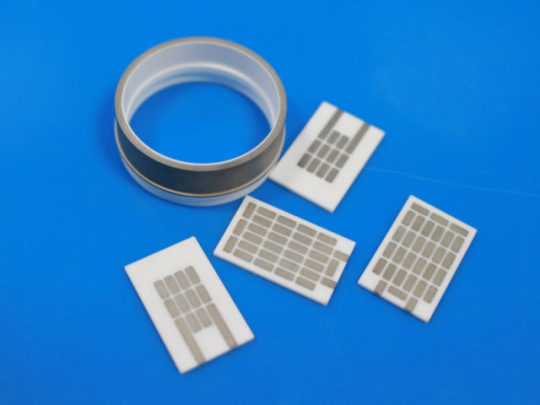

INNOVACERA widen its range of materials with Beryllium Oxide

Beryllium Oxide (BeO), which is commonly referred to as Beryllia, is endowed with a virtuously unique combination of thermal, electrical, optical, and mechanical properties which may be exploited for a diverse range of applications from thermal management systems for integrated electronics to high-temperature high-performance refractory components for nuclear reactors.

Applications of Beryllium Oxide Ceramics

Medical

Lasers

Semiconductor handling equipment

Energy

Military and Aerospace

Wireless Communications

Metallized Ceramic Joining types:

BeO Ceramic + Mo/Mn Metallized + plating Ni

BeO Ceramic + Mo/Mn Metallized + plating Ag

BeO Ceramic + Mo/Mn Metallized + plating Au

BeO Ceramic + printing Ag

Special types are available according to customer’s drawings or samples.

More detail...

Beryllium Oxide Metallization Ceramic Components for Thermal Management Solutions

Read the full article

#BeOCeramic#BeOCeramicPart#BerylliaCeramicComponent#BerylliaCeramics#BerylliumOxideCeramics#MetallizedBeOCeramicPlate

0 notes