#Carboxymethyl Cellulose (CMC) Market

Text

The Carboxymethyl Cellulose (CMC) Market is growing at a CAGR of >4.64% over the next 5 years. DuPont , Nouryon, Ashland, NIPPON PAPER INDUSTRIES CO., LTD., DKS Co. Ltd. are the major companies operating in Carboxymethyl Cellulose (CMC) Market.

#Carboxymethyl Cellulose (CMC) Market#Carboxymethyl Cellulose (CMC) Market Size#Carboxymethyl Cellulose (CMC) Market Share#Carboxymethyl Cellulose (CMC) Market Analysis#Carboxymethyl Cellulose (CMC) Market Trends#Carboxymethyl Cellulose (CMC) Market Report#Carboxymethyl Cellulose (CMC) Market Research#Carboxymethyl Cellulose (CMC) Industry#Carboxymethyl Cellulose (CMC) Industry Report

0 notes

Text

Battery Binders Market to be Worth $6.4 Billion by 2030

Meticulous Research®—a leading global market research company, published a research report titled, ‘Battery Binders Market by Type (Anode Binder, Cathode Binder), Battery Type (Lithium-ion Batteries, Ni-Cd Batteries), Material (PVDF, CMC), Application (Electric Vehicles, Consumer Electronics), Sector, and Geography - Global Forecast to 2030'.

According to this latest publication from Meticulous Research®, the global battery binders market is projected to reach $6.4 billion by 2030, at a CAGR of 8.7% from 2023 to 2030.The growth of this market is driven by the surge in demand for multitasking battery binders and the rising adoption of electric vehicles. The technological advancements in battery binders and developing infrastructure to charge electric vehicles are expected to offer significant growth opportunities for the stakeholders in the battery binders market. The growing demand for solid-state lithium-ion batteries may restrain the market's growth. Furthermore, underdeveloped infrastructure for electric vehicles is expected to pose challenges to the growth of the battery binders market.

The global battery binders market is segmented by type (anode binder, cathode binder), battery type (lithium-ion batteries, nickel-cadmium [Ni-Cd] batteries, nickel-metal hydride [Ni-MH] batteries, sodium-sulfur [Na-S] batteries, redox flow batteries [RFB], other battery types {lead–acid [PbA] batteries, and flow batteries}), material (polyvinylidene fluoride (PVDF), carboxymethyl cellulose (CMC), polymethyl methacrylate (PMMA), styrene-butadiene copolymer (SBR), other materials [materials for functional layer, and sealant for battery applications], application (electric vehicles, consumer electronics, energy storage systems, industrial devices. other applications [medical devices, & marine devices]), sector (automotive, electronics, energy & utilities, consumer goods, aerospace, marine, medical, other sectors [telecommunications and data centers]). The study also evaluates industry competitors and analyzes the market at the regional and country levels.

Based on type, the global battery binders market is segmented into anode binder and cathode binder. In 2023, the anode binder segment is expected to account for the larger share of the global battery binders market. The large market share of this segment is attributed to the growing demand for anode binders for better battery performance and the presence of industry-leading anode binder manufacturers. Moreover, this segment is projected to register the highest CAGR during the forecast period. The growth of this segment is driven by the growing demand for anode binders for lithium-ion batteries due to its significant demand in consumer electronics, electric vehicles, and energy storage systems applications.

Based on battery type, the global battery binders market is segmented into lithium-ion batteries, nickel-cadmium (Ni-Cd) batteries, nickel-metal hydride (Ni-MH) batteries, sodium-sulfur (Na-S) Batteries, redox flow batteries (RFB), and other battery types. In 2023, the lithium-ion batteries segment is expected to account for the largest share of the global battery binders market. The large market share of this segment is attributed to the increasing need for battery binders to hold the active material particles together in lithium-ion batteries and the rising demand for binders for battery cell construction and delivering a range of benefits, from safety enhancements and energy density to capacity. Moreover, this segment is projected to register the highest CAGR during the forecast period.

Based on material, the global battery binders market is segmented into polyvinylidene fluoride, carboxymethyl cellulose, polymethyl methacrylate, styrene-butadiene copolymer, and other materials. In 2023, the polyvinylidene fluoride segment is expected to account for the largest share of the global battery binders market. The large market share of this segment is attributed to the growing demand for PVDF for the development of lithium-ion batteries, efforts by companies for the development of high-performance PVDF resins and flexible copolymers, and the rising demand for electrodes for use in lithium-ion and lithium-metal polymer batteries and as a separator coating. PVDF plays an important role in powering batteries, particularly lithium-ion batteries, due to its high thermal and electrochemical stability and excellent adhesion between electrode films and collectors.

However, the styrene-butadiene copolymer segment is projected to register the highest CAGR during the forecast period. The growth of this segment is driven by the growing demand for water-based binders to prepare anode electrodes for lithium-ion batteries and the growing demand for styrene-butadiene copolymers due to their strong adhesion and high aging-retardant properties. Furthermore, it has higher flexibility, stronger binding force, and higher heat resistance. Hence, the demand for this segment is expected to grow in the coming future.

Based on application, the global battery binders market is segmented into electric vehicles, consumer electronics, energy storage systems, industrial devices, and other applications. In 2023, the energy storage systems segment is expected to account for the largest share of the global battery binders market. The large market share of this segment is attributed to the growing demand for renewable energy generation, the increasing demand for lithium-ion batteries to store electricity, and the rising demand for lithium-ion batteries due to their potential for application to grid-level energy storage systems since these batteries are known for their rapid response, modularization, and flexible installation

However, the electric vehicles segment is projected to register the highest CAGR during the forecast period. The growth of this segment is driven by the rising consumer preference for shared mobility, declining costs of high-capacity batteries, and significant investments by EV manufacturers in developing battery binders. Furthermore, supportive government policies and investment in deploying public charging infrastructure, coupled with the benefits offered by electric vehicles, are expected to create significant market growth opportunities in the coming years.

Based on sector, the global battery binders market is segmented into automotive, electronics, energy & utilities, consumer goods, aerospace, marine, medical, and other sectors. In 2023, the energy & utilities segment is expected to account for the largest share of the global battery binders market. The large market share of this segment is attributed to the growing need to build grid-level energy storage systems for power generation, the increasing popularity of portable energy storage solutions, and the growing need to implement energy storage systems with high energy density.

However, the automotive segment is projected to register the highest CAGR during the forecast period. The growth of this segment is driven by the growing deployments of lithium-ion batteries for electric vehicles, the increasing need for secure battery systems for EV charging, and the rising government initiatives to launch battery binders to support automotive battery production.

Based on geography, the global battery binders market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2023, Asia-Pacific is expected to account for the largest share of the global battery binders market. Asia-Pacific’s major market share is attributed to the growing demand for battery binders from the well-established lithium-ion batteries market across China, Japan, India, South Korea, and Australia and the growing need to develop energy storage systems across the region. Furthermore, the rising need for power generation and increasing adoption of electric vehicles, especially in China, Japan, and India, is driving the demand for battery binders, subsequently supporting the growth of the battery binders market.

In recent years, market players have been heavily investing in the production of water-based anode binders across the Asia-Pacific region, supporting the growth of this market. For instance, in May 2023, BASF (Germany) announced an investment in water-based anode binders to support the lithium-ion battery industry. The new binders will be produced at two existing dispersion plants in Jiangsu and Guangdong, China. In addition to their existing product portfolios, the two plants will produce two innovative anode binders: Licity and Basonal Power, based on modified styrene-butadiene rubber (SBR). The new range of products is expected to come on stream from mid-2023. Such initiatives by major market players are expected to support the growth of this regional market.

However, North America is projected to register the highest CAGR during the forecast period. The presence of well-established battery binders across the U.S., an increase in sales of electric vehicles, and growing investments toward the installation of batteries in the renewable energy sector drive the growth of this regional market. Furthermore, companies are increasing their efforts to develop PVDF production facilities for battery materials in the region. For instance, in November 2022, Solvay SA (Belgium) and Orbia (Mexico) announced a joint venture framework agreement to create a partnership for the production of suspension-grade polyvinylidene fluoride (PVDF). Such initiatives from major market players are expected to support the growth of this regional market.

Key Players:

The key players operating in the global battery binders market are Arkema (France), ENEOS Holdings, Inc. (Japan), Zeon Corporation (Japan), BASF Group (Germany), UBE Corporation (Japan), Asahi Kasei Corporation (Japan), Kureha Corporation (Japan), Mitsui Chemicals, Inc. (Japan), Solvay SA (Belgium), Sumitomo Chemical Co., Ltd. (Japan), Toray Industries, Inc. (Japan), Synthomer plc (U.K.), Trinseo PLC (U.S.), Targray Technology International Inc. (Canada), and Sicona Battery Technologies (Australia).

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5543

Key questions answered in the report:

Which are the high-growth market segments in terms of type, battery type, material, application, and sector?

What is the historical market size for battery binders across the globe?

What are the market forecasts and estimates for 2023–2030?

What are the major drivers, restraints, opportunities and challenges in the global battery binders market?

Who are the major players in the global battery binders market, and what are their market shares?

How is the competitive landscape?

What are the recent developments in the global battery binders market?

What are the different strategies adopted by the major players in the market?

What are the geographic trends and high-growth countries?

Who are the local emerging players in the global battery binders market, and how do they compete with other players?

Contact Us:

Meticulous Research®

Email- [email protected]

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

0 notes

Text

Automate to Elevate: The Growing Role of Industrial Robotics in Modern Manufacturing

Industrial robotics has emerged as a transformative force in manufacturing, revolutionizing the way goods are produced across various industries. These robots, equipped with advanced sensors, precision actuators, and sophisticated control systems, perform a wide range of tasks with high efficiency and precision. From assembly lines and welding to material handling and packaging, industrial robots have become integral to modern manufacturing processes, enhancing productivity, reducing labor costs, and improving overall product quality.

Key Applications and Market Demand for Industrial Robotics:

The demand for industrial robotics is propelled by the need for increased automation in manufacturing to address challenges such as labor shortages, rising labor costs, and the pursuit of higher production efficiency. Industries such as automotive, electronics, aerospace, and logistics heavily rely on industrial robots to carry out repetitive and complex tasks with speed and accuracy. The versatility of these robots allows for a seamless integration into diverse production lines, providing manufacturers with the flexibility to adapt to changing market demands and customize their operations.

Role of Monochloroacetic Acid (MCA) in Industrial Robotics:

Monochloroacetic Acid (MCA) is not directly linked to industrial robotics; however, it serves as an illustrative example to emphasize the diverse nature of the chemical industry. MCA finds applications in the production of carboxymethyl cellulose (CMC), which is utilized as a thickening and stabilizing agent in various industries, including those involved in the manufacturing of chemicals used in industrial robotics. While MCA and industrial robotics operate in distinct realms, they both contribute to the broader landscape of industrial efficiency and technological advancement.

Future Trends and Innovations: The demand for industrial robotics is expected to grow as technological advancements continue to enhance their capabilities. The integration of artificial intelligence, machine learning, and collaborative robotics is set to further expand the scope of industrial automation. As industries strive for increased efficiency, reduced costs, and improved safety, the adoption of robotics will likely extend to smaller and medium-sized enterprises. Innovations in human-machine collaboration, intuitive programming interfaces, and the development of more adaptable robotic systems will play pivotal roles in shaping the future of industrial robotics and meeting the evolving demands of modern manufacturing.

0 notes

Text

Carboxymethyl Cellulose (CMC) Market| Market Size, Share, Trends, Analysis, Growth and Forecast, 2023 – 2027

Originally published on Technavio: Carboxymethyl Cellulose (CMC) Market Analysis APAC, North America, Europe, Middle East and Africa, South America - US, China, India, UK, Germany - Size and Forecast 2023-2027

The Carboxymethyl Cellulose (CMC) market is poised for a comprehensive analysis and expected growth during the forecast period from 2023 to 2027. This market, integral to various industries such as food and beverages, pharmaceuticals, and oil drilling, will be examined based on regional trends in the Asia-Pacific (APAC), North America, Europe, the Middle East and Africa, and South America. Key countries, including the US, China, India, UK, and Germany, will play crucial roles in shaping the market dynamics.

In the Asia-Pacific region, particularly in China and India, the CMC market is expected to witness significant growth. The increasing demand for processed foods, pharmaceuticals, and the expanding industrial sector are driving the utilization of CMC in various applications. China, as a major global manufacturing hub, is likely to contribute substantially to the market, while India's growing population and developing industries add to the regional market expansion.

North America, led by the United States, is a prominent market for Carboxymethyl Cellulose. The region's well-established food and pharmaceutical industries, coupled with a focus on technological advancements, contribute to the consistent demand for CMC. The US, with its diverse industrial applications, is anticipated to be a key contributor to the regional market's growth during the forecast period.

In Europe, countries such as the UK and Germany are significant players in the CMC market. The region's robust food and pharmaceutical sectors, along with stringent quality standards, drive the adoption of CMC as a versatile additive and stabilizing agent. Germany, with its strong manufacturing base, is expected to be a key market for CMC applications in various industries.

The Middle East and Africa are also anticipated to witness growth in the CMC market, driven by expanding industries and increasing awareness of the benefits of CMC in diverse applications. South America, with its developing economies, is expected to contribute to the regional market's growth, particularly in industries like food and oil drilling.

To Learn deeper into this report , View Sample PDF

The forecasted period for the Carboxymethyl Cellulose market emphasizes the versatility and wide-ranging applications of CMC in multiple industries. As consumer preferences evolve and industries seek sustainable and efficient solutions, the demand for CMC is anticipated to rise globally. Manufacturers and stakeholders need to align their strategies with regional market dynamics, regulatory frameworks, and technological advancements to harness the expanding opportunities within the Carboxymethyl Cellulose market.

For more information please contact.

0 notes

Text

Carboxymethyl Cellulose Market: Global Demand Analysis & Opportunity Outlook 2035

Research Nester’s recent market research analysis on “Carboxymethyl Cellulose Market: Global Demand Analysis & Opportunity Outlook 2035” delivers a detailed competitors analysis and a detailed overview of the global carboxymethyl cellulose market in terms of market segmentation by grade, property, application, and by region.

Rising Allergies Towards Gluten-Made Products to Promote Global Market Share of Carboxymethyl Cellulose

The global carboxymethyl cellulose market is estimated to grow majorly on account of the higher adoption of gluten-free products. Around 13% of patients with celiac gluten sensitivity and 1% with autoimmune celiac disease worldwide have shifted to gluten-free food. Furthermore, around 51% of gluten-free food consumers adopt it for other reasons. Moreover, the growing demand for paper packaging is also expected to drive market growth. In paper packaging applications, carboxymethyl cellulose is used as an adhesive. It is frequently employed as a binder to unite multiple layers of paper in order to affix inscriptions and labels to packaging materials. CMC's adhesive properties serve to retain the structural integrity of the packaging and keep the contents from leaking or spilling.

Request Report Sample@

Besides this, rise in the drilling activities and the growing demand for oil and gas are also contributing to the market expansion. Polymers such as carboxymethyl cellulose are pumped into reservoirs in some modified oil recovery procedures to increase the thickness of the injected water or other displacement fluids. This increased viscosity aids in more effectively sweeping the oil towards the production wells, boosting oil recovery from the reservoir.

Some of the major growth factors and challenges that are associated with the growth of the global carboxymethyl cellulose market are:

Growth Drivers:

Expansion of the Paper Packaging Industry

Rising Need for Gluten-Free Food Items

Challenges:

Market has a variety of food additives and stabilizers as an alternative to carboxymethyl cellulose and the prices of raw materials are indefinite, these are some of the major factors anticipated to hamper the global market size of carboxymethyl cellulose. CMC is derived from cellulose, primarily sourced from wood pulp or cotton. The fluctuating cost of these raw materials can affect the overall production costs of CMC. Instability in the raw material process can lead to uncertain pricing for CC and may impact its adoption. On the other hand, the research and development of CMC takes a lot of time, which is likely to stifle market growth. Continuous research and development are essential for the expansion of CMC applications into new industries or novel formulations. The development of innovative products or processes can be time-consuming and costly, impacting the pace of market growth.

Based on the different grades of carboxymethyl cellulose, the global market is segmented into technical grade, industrial grade, and high purity grade. The high purity grade segment is to garner the highest revenue by the end of 2035 by growing at a significant CAGR over the forecast period. High purity grade is a very pure substrate and has found application in various industries, such as cosmetics, food & beverage, pharmaceutical, and others. Furthermore, on the basis of the application of carboxymethyl cellulose, the market is further fragmented into detergent, food & beverage, paper & pulp, cosmetic, pharmaceutical, paint & coating, and oil field drilling fluid. Out of all, the food & beverage segment is anticipated to lead the market growth.

By region, the Europe carboxymethyl cellulose market is to generate notable market revenue by the end of 2035. Europe being a major hub for pharmaceutical research and production, the demand for CMC has increased significantly to meet the growing need of the industry. Moreover, the European personal care and cosmetics industry is continuously innovating and introducing new products, driving the demand for CMC as an essential ingredient. Apart from this, pet ownership increases, and pet owners become more conscious of their pets’ nutrition, the demand for premium pet food products that utilize functional ingredients like CMC has risen.

This report also provides the existing competitive scenario of some of the key players of the global carboxymethyl cellulose market which includes company profiling of Akzo Nobel N.V., J.M. Huber Corporation, USK KIMYA CORP, Amtex-Corp, Dow, DKS Co. Ltd., NIPPON PAPER INDUSTRIES CO., LTD, Daicel Corporation, Ashland., Amar Cellulose Industries, Patel Industries, SINOCMC CHEMICAL CO., LTD, and others.

Access our detailed report at:

0 notes

Text

Monochloroacetic Acid (MCAA) Market Assessment: Environmental and Regulatory Impacts

Monochloroacetic Acid (MCAA) is a vital chemical compound that finds extensive applications in various industries, including agriculture, pharmaceuticals, and chemicals. Its versatile nature, coupled with a wide range of applications, has made the Monochloroacetic Acid market a significant segment of the global chemical industry. This article delves into the Monochloroacetic Acid market, exploring the driving forces behind its growth, current trends, and future prospects.

Market Overview

Monochloroacetic Acid Market, a colorless, crystalline organic compound, is primarily used in the production of carboxymethyl cellulose (CMC), herbicides, and various drugs. The compound is also used in the manufacture of surfactants, detergents, and pesticides. The growth of these industries directly influences the demand for MCAA.

Driving Forces

Agricultural Sector Growth: With the global population continuously rising, the demand for food is increasing, leading to the growth of the agricultural sector. Monochloroacetic Acid is a crucial component in the production of herbicides, which are essential for weed control in agriculture. As a result, the increasing demand for herbicides is a significant driving force behind the MCAA market's growth.

Pharmaceutical Industry: The pharmaceutical industry relies heavily on Monochloroacetic Acid for the synthesis of various drugs and chemicals. As the healthcare sector expands globally, the demand for pharmaceutical products is also on the rise, boosting the MCAA market.

Cosmetics and Personal Care Industry: The cosmetic and personal care industry is witnessing substantial growth, driven by changing consumer preferences and an increased focus on personal grooming. MCAA is used in the production of surfactants and emulsifiers for cosmetics, further contributing to its market growth.

Environmental Concerns: Environmental regulations have become increasingly stringent, pushing the chemical industry towards the development of more environmentally friendly products. Monochloroacetic Acid manufacturers are investing in sustainable production methods, which is likely to attract environmentally conscious consumers and industries.

Current Trends

Bio-based Monochloroacetic Acid: One of the prevailing trends in the Monochloroacetic Acid market is the development of bio-based MCAA. Manufacturers are exploring greener alternatives that reduce the environmental impact of production while maintaining product quality.

Customized Formulations: Customers are increasingly seeking customized formulations of MCAA to meet their specific needs. This trend has led to increased research and development efforts by manufacturers to provide tailored solutions.

Asia-Pacific Dominance: The Asia-Pacific region, particularly China and India, has emerged as a dominant player in the global MCAA market. The presence of a strong manufacturing base, coupled with increasing industrialization and urbanization, is driving the demand for Monochloroacetic Acid in this region.

Future Prospects

The future of the Monochloroacetic Acid market demand appears promising, driven by several factors:

Innovations in Production: Continuous research and development efforts are expected to lead to more efficient and sustainable production processes for MCAA, ensuring a stable supply.

Expanding Applications: As industries evolve and diversify, new applications for Monochloroacetic Acid are likely to emerge, further expanding its market potential.

Global Sustainability Initiatives: The increasing focus on sustainability and environmental responsibility is likely to stimulate investments in eco-friendly MCAA production methods, opening up new opportunities.

In conclusion, the Monochloroacetic Acid market is poised for growth, fueled by its diverse range of applications and the ever-evolving industrial landscape. As industries continue to adapt to changing consumer demands and environmental regulations, the demand for MCAA is expected to remain robust, making it a crucial component of the global chemical industry.

#Monochloroacetic Acid (MCAA) Market Share#Monochloroacetic Acid (MCAA) Market Growth#Monochloroacetic Acid (MCAA) Market Demand#Monochloroacetic Acid (MCAA) Market Trend

0 notes

Text

Cellulose Ethers

Kima is a leading manufacturer of cellulose ether from China, and has been serving global cellulose ether market over ten years with our brand KimaCell®.

Kima offers a comprehensive range of cellulose ether products for sale to meet the requirement of global customers. KimaCell® is the unique trademark of our cellulose ether products, including 20000 tons of Hydroxypropyl Methyl Cellulose (HPMC), Hydroxyethyl Methylcellulose (HEMC).

Hydroxyethyl Cellulose (HEC), Methyl Hydroxyethyl Cellulose (MHEC), Sodium Carboxymethyl Cellulose (CMC), Redispersible Polymer Powder(RDP), Methyl Cellulose (MC), Ethyl Cellulose (EC), Hydroxypropyl Cellulose (HPC), Hydroxypropyl Starch Ether (HPS), Microcrystalline Cellulose (MCC).

Nowadays Kima's different grade of cellulose ether have been sold to more than 20 countries around the world, successfully used in building & construction, pharmaceutical, food, detergent, paints & coatings, ceramics, PVC, home care, personal care, oil drilling, cosmetics etc. Quality is well accepted among customers. KimaCell® become the reliable brand in cellulose ether market.

Buy KimaCell® cellulose ether to make product in bulk, and get the competitive wholesale price. For more information like cellulose ether viscosity, grade and formula, price per kg, please feel free to contact us.

Cellulose Ether Products List

Hydroxypropyl Methylcellulose (HPMC)

Hydroxypropyl Methylcellulose (HPMC), also known as hypromellose and methyl cellulose ether derivatives, is made of highly pure cotton cellulose as raw material, which is specially etherified under alkaline conditions. KimaCell® HPMC is a non-ionic cellulose ether, white powder, odorless and tasteless, soluble in water and most polar organic solvents and swell into a transparent solution in both hot and cold water. The aqueous solution has surface activity, high transparency and stable performance. CAS 9004-65-3

Hydroxyethyl Cellulose (HEC)

Hydroxyethyl Cellulose (HEC) is a non-ionic water soluble cellulose ether, which is a white or off-white, odorless, non-toxic fibrous or powdery solid polymer produced by etherification reaction of alkaline cellulose and ethylene oxide. KimaCell® HEC has good properties of thickening, suspending, dispersing, emulsifying, bonding, film-forming, water retention and protective colloid, HEC has been widely used in paints & coatings, construction, oil drilling, pharmaceutical, food, textile, paper and polymer polymerization and other fields. CAS 9004-62-0

Hydroxyethyl Methyl Cellulose (HEMC)

Hydroxyethyl Methyl Cellulose(HEMC) is methyl cellulose ether derivatives. HEMC is prepared by adding ethylene oxide substituents (MS 0.3~0.4) to methyl cellulose (MC). Its salt resistance is better than that of unmodified polymers. KimaCell® HEMC plays an important role in drymix mortar industry which can increase good workability and good water retention, excellent open time, slip resistance, impact resistance, adhesion and shear strength. HEMC is widely used in various dry-mixed mortars such as tile adhesives, protective mortars, waterproof mortars, grouting materials, detergent etc. CAS 9032-42-2

Methyl Hydroxyethyl Cellulose (MHEC)

Methyl Hydroxyethyl Cellulose (MHEC) is a non-ionic cellulose ether that is easily soluble in both hot and cold water. Compared with other cellulose ethers, methyl cellulose derivatives have slight Newtonian flow characteristics and can provide relatively high shear viscosity. Methyl Hydroxyethyl cellulose (MHEC) has the characteristics of thickening, suspending, dispersing, bonding, emulsifying, film-forming, and water retention. The water retention, viscosity stability and mildew resistance, dispersibility of MHEC is stronger than hydroxypropyl methyl cellulose (HPMC). KimaCell® MHEC has Good anti-sagging effect, long open time, high early strength, high temperature adaptability, easy to stir, easy to operate when adding to drymix mortars. CAS 9032-42-2

Methyl Cellulose (MC)

Methyl Cellulose (MC) is a cellulose methyl ether which is White or light yellow or light gray small particles, filaments or powder. It is odorless and tasteless, and about 27%~32% of the hydroxyl groups exist in the form of methoxy groups. KimaCell® Methyl Cellulose MC can be used as synthetic resin dispersant, coating film-forming agent, thickener, adhesive for building materials, sizing agent for textile printing and dyeing, film-forming agent for pharmaceutical and food industries, etc. CAS 9004-67-5

Ethyl Cellulose (EC)

Ethyl Cellulose (EC), also named as cellulose ethyl ether, is a cellulose derivative in which ethoxy groups replace the hydroxyl groups, with different molecular weights and viscosity. KimaCell® Ethyl Cellulose is white granules or powder, odorless and tasteless; easily soluble in toluene or ether, soluble in dichloromethane, slightly soluble in ethyl acetate and methanol, insoluble in water, glycerol and propylene glycol; Ethyl Cellulose is stable, resistant to alkali and salt, and is more sensitive to acid than cellulose ester. CAS 9004-57-3.

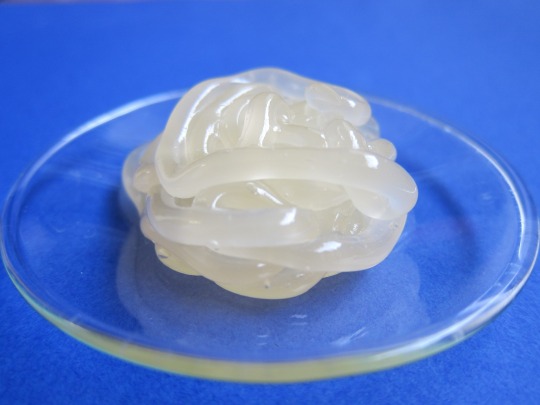

Carboxymethyl Cellulose (CMC)

Carboxymethyl cellulose (CMC), known as cellulose gum, is a high polymer cellulose ether obtained by chemically modifying natural cellulose. Sodium CMC is white or milky white fibrous powder or granules, with a density of 0.5-0.7 g/cm3, almost odorless, tasteless, and hygroscopic. CMC is easily dispersed in water to form a transparent colloidal solution, CMC can be widely used in paints & coatings, food ingredients, paper-making additives, toothpaste, oil drilling, mud conditioners, ceramics, detergent etc. CAS 9004-32-4.

Redispersible Polymer Powder (RDP)

Redispersible Polymer Powder (RDP) are water-soluble redispersible latex powders, which are divided into ethylene/vinyl acetate copolymers, vinyl acetate/ethylene tertiary carbonate copolymers, acrylic acid copolymers, etc., and the powders made after spray drying are bonded agent, with polyvinyl alcohol as a protective colloid. KimaCell® RDP powder can quickly redisperse into emulsion after contacting with water. Due to the high bonding ability and unique properties of redispersible latex powder, such as: water resistance, construction and heat insulation, etc., RDP is widely used in tile adhesives, skimcoat, drymix mortar. CAS 24937-78-8

Hydroxypropyl Cellulose (HPC)

Hydroxypropyl Cellulose (HPC) is a non-ionic water-soluble cellulose ether obtained by the reaction of cellulose and propylene oxide. HPC is odorless, tasteless, usually white to pale yellow powder. Its unique physical properties and its solubility in water and various organic solvents make it widely used in tablet bonding, release regulation, film coating and rheology regulation. HPC has been used in the pharmaceutical industry for many years, and the county has very good safety. KimaCell®HPC products comply with the US Pharmacopoeia, European Pharmacopoeia, and Japanese Pharmacopoeia. CAS 9004-64-2.

Hydroxypropyl Starch Ether (HPS)

Hydroxypropyl starch ether (HPS) is a white colorless powder with good fluidity and good water solubility. Its aqueous solution is transparent and colorless with good stability. It is stable to acid and alkali, the gelatinization temperature is lower than that of native starch, and the change of cold and hot viscosity is more stable than that of native starch. Mixing with salt, sucrose, etc. has no effect on viscosity. After etherification, the ice-thaw stability and transparency are improved. CAS 9049-76-7

Hydroxypropyl Methyl Cellulose Phthalate (HPMC-P)

Hydroxypropyl Methyl Cellulose Phthalate (HPMC-P) was originally developed as an enteric coating agent, but due to its excellent characteristics, it has expanded its use in other fields, including sustained release agents, formulations, adhesives and microcapsule components. In application, HPMCP is usually used alone or mixed with other polymers as a buffering agent. CAS 9050-31-1

Low Substituted Hydroxypropyl Cellulose (L-HPC)

Low-substituted Hydroxypropyl Cellulose (L-HPC) is a multi-purpose non-ionic cellulose derivative, which is mainly used as a solid preparation disintegration and binder. Because its powder has a large surface area and porosity, it can quickly It absorbs water and swells. When it is used in tablets, it makes the tablets disintegrate quickly. At the same time, its rough structure has a large inlay between the drug and the particles, which can significantly increase the hardness of the tablet without affecting the disintegration, thereby accelerating the drug. Dissolution, improve bioavailability. CAS 9004-64-2

Polyanionic Cellulose (PAC)

Polyanionic cellulose (PAC) is a nonionic water-soluble cellulose ether derivative obtained by chemically modifying natural cellulose. Its sodium salt is usually used. Polyanionic cellulose has a good Excellent heat stability and salt resistance, strong antibacterial properties. The mud fluid prepared by this product has good water loss reduction, inhibition and high temperature resistance. PAC is widely used in oil well drilling fluid as a mud stabilizer and fluid loss controller, it is particularly effective in saltwater brines. PAC-HV can be used in a smaller amount to increase viscosity and reduce fluid loss. PAC-LV can be used in higher amounts to reduce fluid loss with little effect on viscosity. CAS 9004-32-4

Microcrystalline Cellulose (MCC)

Microcrystalline Cellulose (MCC) is a cellulose derivatives from refined cotton or wood pulp. The particle size is generally 20-80 μm, and the limiting degree of polymerization (LODP) is 15-375. It is not fibrous and has strong fluidity. Due to its special properties such as low degree of polymerization and large specific surface area, KimaCell® Microcrystalline Cellulose MCC is widely used in medicine, food, cosmetics and other industries. Used as thickener, anti-caking agent, fat substitute, emulsifier, extender and filler in food production. The most common form is used in vitamin supplements or tablets. CAS 9004-34-6

Why Choose Kima Chemical For Cellulose Ether?

1. Quality Assurance

KIMA has been committed to the scientific research and development of cellulose ether and related products, and has overcome the key technical problems that restrict production.

2. Research & Development

In the process of cellulose ether research and development, KIMA company established a special technical research team to solve many industry problems from the perspectives of equipment.

3. Talent Team

Talent is the biggest core competitiveness of an enterprise. Relying on the people-oriented corporate culture and the platform advantages of listed companies.

4. Customized Products For Customer Needs

KIMA can provide customized products and services for different customer needs, which are difficult for competitors to compete.

5. Sustainable Development

To continuously contribute value to the society, our corporate culture concept is Dedicated to making human beings healthier and the environment more friendly.

1 note

·

View note

Text

Cellulose Gel Market CAGR Status, Emerging Trends and Forecast till 2030

Cellulose gel, also known as cellulose gum or carboxymethyl cellulose (CMC), is a versatile ingredient used in various industries such as food and beverages, pharmaceuticals, personal care, and others. It is derived from cellulose, a natural polymer found in the cell walls of plants.

Here is some detailed information about the cellulose gel market:

Market Overview: The cellulose gel market has experienced steady growth in recent years due to its wide range of applications in different industries. It is used as a stabilizer, thickener, binder, and emulsifier in various products.

Applications: a. Food and Beverages: Cellulose gel is commonly used in the food industry to improve texture, increase viscosity, stabilize emulsions, and prevent ingredient separation. It is found in products like ice cream, baked goods, dairy products, sauces, and dressings. b. Pharmaceuticals: In the pharmaceutical industry, cellulose gel is used as a binder in tablet formulations, a suspending agent in liquid medications, and a thickener in topical gels and creams. c. Personal Care: Cellulose gel is utilized in personal care products such as lotions, creams, shampoos, and toothpaste for its thickening and stabilizing properties. d. Other Industries: Cellulose gel finds applications in various other industries, including paints and coatings, textiles, detergents, and oil drilling fluids.

Benefits and Properties: Cellulose gel offers several advantages, including:

Water-solubility: It dissolves easily in water, making it convenient to use in various formulations.

Thickening and Stabilizing: It enhances the viscosity and stability of products, preventing separation and maintaining desired textures.

Bioavailability: Cellulose gel is considered safe for consumption and has no significant impact on human health.

Versatility: It can be used in a wide range of pH levels and temperatures.

Vegan and Gluten-free: Cellulose gel is derived from plant sources and is suitable for vegan and gluten-free products.

Market Trends: a. Growing Demand for Functional Food: The increasing consumer preference for functional foods and beverages, which offer health benefits, is driving the demand for cellulose gel as a key ingredient. b. Clean Label Products: The demand for clean label products, free from artificial additives and chemicals, is on the rise. Cellulose gel, being a natural ingredient, aligns with this trend. c. Pharmaceutical Advancements: The pharmaceutical industry's continuous development and introduction of new medications and formulations create opportunities for cellulose gel as a binder and stabilizer. d. Technological Innovations: Ongoing research and development efforts are focused on improving the functionality and performance of cellulose gel to cater to evolving industry needs.

Regional Market: The cellulose gel market is geographically diverse, with significant market players located in North America, Europe, Asia Pacific, and other regions. North America and Europe are prominent markets due to the well-established food and pharmaceutical industries, while Asia Pacific is experiencing rapid growth due to the increasing demand for convenience foods and personal care products.

Key Players: Some of the major companies operating in the cellulose gel market include Ashland Global Holdings Inc., The Dow Chemical Company, CP Kelco, AkzoNobel NV, DKS Co. Ltd., and Química Amtex.

It's important to note that market conditions and information may change over time, so it's recommended to refer to the latest reports and studies for the most up-to-date information on the cellulose gel market.

0 notes

Text

Carboxymethyl Cellulose Market Size, Share, Demand, Growth & Trends by 2032

A new research publication titled "Carboxymethyl Cellulose Market: Global Industry Analysis (2012-2016) and Opportunity Assessment (2017-2027)" by Future Market Insights focusses on various market developments, trends, growth drivers and forecasts across important regions. A detailed market segmentation is carried out that explores every angle of the carboxymethyl cellulose (CMC) market.

Request a Sample Copy of this Report @ https://www.futuremarketinsights.com/reports/sample/rep-gb-3959

Global Market for Carboxymethyl Cellulose (CMC): Growth Influencing Aspects

The demand for carboxymethyl cellulose has increased on a global scale due to a number of variables. The development of new products, economic expansion, rapid industrial growth, merger activities in the petrochemical industry, rising adoption of carboxymethyl cellulose in various applications, rising demand for carboxymethyl cellulose in the personal care and food and beverage industries, increasing focus on lowering production costs, and technological advancements are just a few of the factors driving upstream exploration for unconventional energy sources. However, the high cost of cosmetics, the drop in oil prices, and gas industry, increasing competition among local manufacturers, and stringent environmental regulations are expected to hamper market revenue growth during the forecast period.

Global Market for Carboxymethyl Cellulose (CMC): Segmental Snapshot

The global carboxymethyl cellulose market is segmented on the basis of grade type, application and region.

By grade type, high purity segment is estimated to be the largest with a high market share. This is a highly potential segment from both revenue and growth perspectives. It is projected to grow at a CAGR of 5.5% during the forecast period.

By application, food and beverages segment followed by detergent segment are expected to highly contribute to the growth of the global market. The food and beverages segment is projected to grow at the fastest pace in the coming years.

By region, the carboxymethyl cellulose market in Asia Pacific excluding Japan (APEJ) is estimated to grow at a high CAGR to reach a significant valuation during the assessment period.

Global Market for Carboxymethyl Cellulose (CMC): Competitive Landscape

The research report on the carboxymethyl cellulose market includes competition analysis. Several aspects such as SWOT analysis, product portfolio analysis, mergers and acquisitions, growth strategies, key developments, key personnel, company overview, key financials and expansion plans of the top companies are covered in this chapter. Major companies such as CP Kelco, The Dow Chemical Company, Ashland Global Holding Inc., Anqiu Eagle Cellulose Co., Ltd., Wealthy Chemical Industry (Suzhou) Co., Ltd., Shanghai Shenguang Edible Chemicals Co., Ltd., Akzo Nobel N.V., Nippon Paper Industries Co., Ltd., Lamberti S.p.A, Xuzhou Liyuan cellulose Technology Co. Ltd., Daicel Finechem Ltd., Química Amtex, S.A. de C.V., DKS Co. Ltd., Ugur Seluloz Kimya AS, Mikro Technik GmbH and Patel Industries are featured in this research report.

Global Market for Carboxymethyl Cellulose (CMC): Forecast Highlights

The research report on the carboxymethyl cellulose market reflects future market projections describing the growth direction of the market. The global carboxymethyl cellulose market is projected to grow at a high CAGR of 5.2% throughout the period of assessment and is estimated to reach a valuation of more than US$ 2 Bn by the end of the year of assessment from a value of around US$ 1.4 Bn in 2017.

A detailed market segmentation

By Application

Food and Beverage

Detergent

Paper and Pulp

Oil Field Drilling Fluid

Cosmetic and Pharmaceutical

Paint and Coating

Others (Construction, Mining, Textile etc.)

By Grade

High Purity Grade (99.5% +)

Technical Grade (90%-99.5%)

Industrial Grade (50%-90%)

By Region

North America

Latin America

Western Europe

Eastern Europe

Asia Pacific excluding Japan (APEJ)

Japan

Middle East and Africa (MEA)

Table of Content

1. Executive Summary

1.1. Global Market Outlook

1.2. Demand Side Trends

1.3. Supply Side Trends

1.4. Analysis and Recommendations

2. Market Overview

2.1. Market Coverage / Taxonomy

2.2. Market Definition / Scope / Limitations

3. Key Market Trends

3.1. Key Trends Impacting the Market

4. Key Success Factors

4.1. Product Adoption / Usage Analysis

5. Global Carboxymethyl Cellulose Market Demand Analysis 2012-2021 and Forecast, 2022-2032

5.1. Historical Market Volume (Tons) Analysis, 2012-2021

5.2. Current and Future Market Volume (Tons) Projections, 2022-2032

5.3. Y-o-Y Growth Trend Analysis

TO Continue TOC…

Browse Full Report: https://www.futuremarketinsights.com/reports/carboxymethyl-cellulose-market

0 notes

Text

Battery Binders Market to be Worth $6.4 Billion by 2030

Meticulous Research®—a leading global market research company, published a research report titled, ‘Battery Binders Market by Type (Anode Binder, Cathode Binder), Battery Type (Lithium-ion Batteries, Ni-Cd Batteries), Material (PVDF, CMC), Application (Electric Vehicles, Consumer Electronics), Sector, and Geography - Global Forecast to 2030'.

According to this latest publication from Meticulous Research®, the global battery binders market is projected to reach $6.4 billion by 2030, at a CAGR of 8.7% from 2023 to 2030.The growth of this market is driven by the surge in demand for multitasking battery binders and the rising adoption of electric vehicles. The technological advancements in battery binders and developing infrastructure to charge electric vehicles are expected to offer significant growth opportunities for the stakeholders in the battery binders market. The growing demand for solid-state lithium-ion batteries may restrain the market's growth. Furthermore, underdeveloped infrastructure for electric vehicles is expected to pose challenges to the growth of the battery binders market.

The global battery binders market is segmented by type (anode binder, cathode binder), battery type (lithium-ion batteries, nickel-cadmium [Ni-Cd] batteries, nickel-metal hydride [Ni-MH] batteries, sodium-sulfur [Na-S] batteries, redox flow batteries [RFB], other battery types {lead–acid [PbA] batteries, and flow batteries}), material (polyvinylidene fluoride (PVDF), carboxymethyl cellulose (CMC), polymethyl methacrylate (PMMA), styrene-butadiene copolymer (SBR), other materials [materials for functional layer, and sealant for battery applications], application (electric vehicles, consumer electronics, energy storage systems, industrial devices. other applications [medical devices, & marine devices]), sector (automotive, electronics, energy & utilities, consumer goods, aerospace, marine, medical, other sectors [telecommunications and data centers]). The study also evaluates industry competitors and analyzes the market at the regional and country levels.

Based on type, the global battery binders market is segmented into anode binder and cathode binder. In 2023, the anode binder segment is expected to account for the larger share of the global battery binders market. The large market share of this segment is attributed to the growing demand for anode binders for better battery performance and the presence of industry-leading anode binder manufacturers. Moreover, this segment is projected to register the highest CAGR during the forecast period. The growth of this segment is driven by the growing demand for anode binders for lithium-ion batteries due to its significant demand in consumer electronics, electric vehicles, and energy storage systems applications.

Based on battery type, the global battery binders market is segmented into lithium-ion batteries, nickel-cadmium (Ni-Cd) batteries, nickel-metal hydride (Ni-MH) batteries, sodium-sulfur (Na-S) Batteries, redox flow batteries (RFB), and other battery types. In 2023, the lithium-ion batteries segment is expected to account for the largest share of the global battery binders market. The large market share of this segment is attributed to the increasing need for battery binders to hold the active material particles together in lithium-ion batteries and the rising demand for binders for battery cell construction and delivering a range of benefits, from safety enhancements and energy density to capacity. Moreover, this segment is projected to register the highest CAGR during the forecast period.

Based on material, the global battery binders market is segmented into polyvinylidene fluoride, carboxymethyl cellulose, polymethyl methacrylate, styrene-butadiene copolymer, and other materials. In 2023, the polyvinylidene fluoride segment is expected to account for the largest share of the global battery binders market. The large market share of this segment is attributed to the growing demand for PVDF for the development of lithium-ion batteries, efforts by companies for the development of high-performance PVDF resins and flexible copolymers, and the rising demand for electrodes for use in lithium-ion and lithium-metal polymer batteries and as a separator coating. PVDF plays an important role in powering batteries, particularly lithium-ion batteries, due to its high thermal and electrochemical stability and excellent adhesion between electrode films and collectors.

However, the styrene-butadiene copolymer segment is projected to register the highest CAGR during the forecast period. The growth of this segment is driven by the growing demand for water-based binders to prepare anode electrodes for lithium-ion batteries and the growing demand for styrene-butadiene copolymers due to their strong adhesion and high aging-retardant properties. Furthermore, it has higher flexibility, stronger binding force, and higher heat resistance. Hence, the demand for this segment is expected to grow in the coming future.

Based on application, the global battery binders market is segmented into electric vehicles, consumer electronics, energy storage systems, industrial devices, and other applications. In 2023, the energy storage systems segment is expected to account for the largest share of the global battery binders market. The large market share of this segment is attributed to the growing demand for renewable energy generation, the increasing demand for lithium-ion batteries to store electricity, and the rising demand for lithium-ion batteries due to their potential for application to grid-level energy storage systems since these batteries are known for their rapid response, modularization, and flexible installation

However, the electric vehicles segment is projected to register the highest CAGR during the forecast period. The growth of this segment is driven by the rising consumer preference for shared mobility, declining costs of high-capacity batteries, and significant investments by EV manufacturers in developing battery binders. Furthermore, supportive government policies and investment in deploying public charging infrastructure, coupled with the benefits offered by electric vehicles, are expected to create significant market growth opportunities in the coming years.

Based on sector, the global battery binders market is segmented into automotive, electronics, energy & utilities, consumer goods, aerospace, marine, medical, and other sectors. In 2023, the energy & utilities segment is expected to account for the largest share of the global battery binders market. The large market share of this segment is attributed to the growing need to build grid-level energy storage systems for power generation, the increasing popularity of portable energy storage solutions, and the growing need to implement energy storage systems with high energy density.

However, the automotive segment is projected to register the highest CAGR during the forecast period. The growth of this segment is driven by the growing deployments of lithium-ion batteries for electric vehicles, the increasing need for secure battery systems for EV charging, and the rising government initiatives to launch battery binders to support automotive battery production.

Based on geography, the global battery binders market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2023, Asia-Pacific is expected to account for the largest share of the global battery binders market. Asia-Pacific’s major market share is attributed to the growing demand for battery binders from the well-established lithium-ion batteries market across China, Japan, India, South Korea, and Australia and the growing need to develop energy storage systems across the region. Furthermore, the rising need for power generation and increasing adoption of electric vehicles, especially in China, Japan, and India, is driving the demand for battery binders, subsequently supporting the growth of the battery binders market.

In recent years, market players have been heavily investing in the production of water-based anode binders across the Asia-Pacific region, supporting the growth of this market. For instance, in May 2023, BASF (Germany) announced an investment in water-based anode binders to support the lithium-ion battery industry. The new binders will be produced at two existing dispersion plants in Jiangsu and Guangdong, China. In addition to their existing product portfolios, the two plants will produce two innovative anode binders: Licity and Basonal Power, based on modified styrene-butadiene rubber (SBR). The new range of products is expected to come on stream from mid-2023. Such initiatives by major market players are expected to support the growth of this regional market.

However, North America is projected to register the highest CAGR during the forecast period. The presence of well-established battery binders across the U.S., an increase in sales of electric vehicles, and growing investments toward the installation of batteries in the renewable energy sector drive the growth of this regional market. Furthermore, companies are increasing their efforts to develop PVDF production facilities for battery materials in the region. For instance, in November 2022, Solvay SA (Belgium) and Orbia (Mexico) announced a joint venture framework agreement to create a partnership for the production of suspension-grade polyvinylidene fluoride (PVDF). Such initiatives from major market players are expected to support the growth of this regional market.

Key Players:

The key players operating in the global battery binders market are Arkema (France), ENEOS Holdings, Inc. (Japan), Zeon Corporation (Japan), BASF Group (Germany), UBE Corporation (Japan), Asahi Kasei Corporation (Japan), Kureha Corporation (Japan), Mitsui Chemicals, Inc. (Japan), Solvay SA (Belgium), Sumitomo Chemical Co., Ltd. (Japan), Toray Industries, Inc. (Japan), Synthomer plc (U.K.), Trinseo PLC (U.S.), Targray Technology International Inc. (Canada), and Sicona Battery Technologies (Australia).

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5543

Key questions answered in the report:

· Which are the high-growth market segments in terms of type, battery type, material, application, and sector?

· What is the historical market size for battery binders across the globe?

· What are the market forecasts and estimates for 2023–2030?

· What are the major drivers, restraints, opportunities and challenges in the global battery binders market?

· Who are the major players in the global battery binders market, and what are their market shares?

· How is the competitive landscape?

· What are the recent developments in the global battery binders market?

· What are the different strategies adopted by the major players in the market?

· What are the geographic trends and high-growth countries?

· Who are the local emerging players in the global battery binders market, and how do they compete with other players?

Contact Us:

Meticulous Research®

Email- [email protected]

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

0 notes

Text

Carboxymethyl Cellulose Market Size, Growth Analysis Report, Forecast to 2032

The global carboxymethyl cellulose market is currently expected to be around US$ 1835.10 million in 2022 and is expected to progress at a constant CAGR of 4.8% between 2022 and 2032 to reach a valuation of USD to be reached 2,932.7 million by 2032.

Increasing demand for carboxymethyl cellulose from the food, paint, coating, paper and pulp, construction and textile industries is a factor , driving the growth of the market. A detailed market segmentation is carried out that explores every angle of the carboxymethyl cellulose (CMC) market.

Several factors have contributed to the growth of the global carboxymethyl cellulose market. Increase in the upstream exploration for unconventional sources of energy, growth in end use industries to fuel demand, new product development, economic growth, high industrial growth and merger activities in the petrochemical sector.

Rising adoption of carboxymethyl cellulose in different applications, rising demand for carboxymethyl cellulose in the personal care and food and beverages industry, increasing focus towards reduction in production costs, technologically advanced manufacturing infrastructure.

Global Market for Carboxymethyl Cellulose (CMC): Competitive Landscape

The research report on the carboxymethyl cellulose market includes competition analysis. Several aspects such as SWOT analysis, product portfolio analysis, mergers and acquisitions, growth strategies, key developments, key personnel, company overview, key financials and expansion plans of the top companies are covered in this chapter.

Major companies such as CP Kelco, The Dow Chemical Company, Ashland Global Holding Inc., Anqiu Eagle Cellulose Co., Ltd., Wealthy Chemical Industry (Suzhou) Co., Ltd., Shanghai Shenguang Edible Chemicals Co., Ltd., Akzo Nobel N.V., Nippon Paper Industries Co., Ltd., Lamberti S.p.A, Xuzhou Liyuan cellulose Technology Co. Ltd., Daicel Finechem Ltd., Química Amtex, S.A. de C.V., DKS Co. Ltd., Ugur Seluloz Kimya AS, Mikro Technik GmbH and Patel Industries are featured in this research report.

Get a Sample Copy of the Report @

https://www.futuremarketinsights.com/reports/sample/rep-gb-3959

A Detailed Market Segmentation

By Application:

Food and Beverage

Detergent

Paper and Pulp

Oil Field Drilling Fluid

Cosmetic and Pharmaceutical

Paint and Coating

Others (Construction, Mining, Textile etc.)

By Grade:

High Purity Grade (99.5% +)

Technical Grade (90%-99.5%)

Industrial Grade (50%-90%)

Global Market for Carboxymethyl Cellulose (CMC): Segmental Snapshot

The global carboxymethyl cellulose market is segmented on the basis of grade type, application and region.

By grade type, high purity segment is estimated to be the largest with a high market share. This is a highly potential segment from both revenue and growth perspectives. It is projected to grow at a CAGR of 5.5% during the forecast period.

By application, food and beverages segment followed by detergent segment are expected to highly contribute to the growth of the global market. The food and beverages segment is projected to grow at the fastest pace in the coming years.

By region, the carboxymethyl cellulose market in Asia Pacific excluding Japan (APEJ) is estimated to grow at a high CAGR to reach a significant valuation during the assessment period.

Browse latest Market Reports@

https://www.futuremarketinsights.com/category/chemicals-and-materials

0 notes

Text

0 notes

Text

Chemical Chameleon: Unveiling the Many Faces of Monochloroacetic Acid (MCA)

Monochloroacetic Acid (MCA) is a vital chemical compound widely used in the production of various industrial and consumer goods. It is a carboxylic acid with a chlorine atom attached to the acetic acid molecule. MCA is a versatile chemical intermediate with applications in the manufacturing of herbicides, agrochemicals, pharmaceuticals, and surfactants. Its ability to undergo various chemical reactions makes it a key component in the synthesis of numerous organic compounds, contributing significantly to diverse industries.

Key Applications and Market Demand for Monochloroacetic Acid (MCA):

The demand for Monochloroacetic Acid is primarily driven by its role as a precursor in the production of carboxymethyl cellulose (CMC), a crucial ingredient in the food, pharmaceutical, and cosmetic industries. CMC is widely used as a thickening and stabilizing agent in a variety of products, including food items, pharmaceuticals, and personal care products. Additionally, MCA is a key building block in the manufacturing of herbicides, ensuring its relevance in the agriculture sector. The growing global population, coupled with increased urbanization and industrialization, contributes to the rising demand for MCA across various end-use industries.

Industry Trends and Growth Drivers:

The Monochloroacetic Acid market is influenced by several factors, including trends in the agrochemical, food, and pharmaceutical industries. The increasing demand for specialty chemicals, coupled with advancements in chemical synthesis techniques, contributes to the growth of the MCA market. Regulatory initiatives emphasizing sustainable and eco-friendly practices also impact the industry, leading to innovations in production processes and the development of bio-based alternatives. Moreover, the continuous evolution of pharmaceutical and personal care formulations drives the demand for high-quality raw materials, further boosting the market for Monochloroacetic Acid.

Future Outlook and Innovations:

As industries continue to evolve, the demand for Monochloroacetic Acid is expected to grow steadily. Innovations in production methods, including the development of more sustainable and cost-effective processes, are likely to shape the industry's future. The adoption of green chemistry principles and the exploration of bio-based alternatives may become significant trends, aligning with the global focus on sustainability. With its diverse applications and integral role in various value chains, Monochloroacetic Acid remains a key contributor to the chemical industry, adapting to the changing landscape of modern manufacturing.

0 notes

Text

0 notes

Text

Cellulose Ether Derivatives Market Size, Market Industry, Market Share, Market Growth, Market Segmentation Market Revenue Market Forecast 2030

A New Market Study, Titled “Cellulose Ether Derivatives Market Upcoming Trends, Growth Drivers and Challenges” has been featured on fusionmarketresearch.

Description

This global study of the Cellulose Ether Derivatives Market offers an overview of the existing market trends, drivers, restrictions, and metrics and also offers a viewpoint for important segments. The report also tracks product and services demand growth forecasts for the market. There is also to the study approach a detailed segmental review. A regional study of the global Cellulose Ether Derivatives industry is also carried out in North America, Latin America, Asia-Pacific, Europe, and the Near East & Africa. The report mentions growth parameters in the regional markets along with major players dominating the regional growth.

Request Free Sample Report @ https://www.fusionmarketresearch.com/sample_request/(COVID-19-Version)-Global-Cellulose-Ether-Derivatives-Market/5049

The report offers detailed coverage of Cellulose Ether Derivatives industry and main market trends with impact of coronavirus. The market research includes historical and forecast market data, demand, application details, price trends, and company shares of the leading Cellulose Ether Derivatives by geography. The report splits the market size, by volume and value, on the basis of application type and geography.

First, this report covers the present status and the future prospects of the global Cellulose Ether Derivatives market for 2016-2025.

And in this report, we analyze global market from 5 geographies: Asia-Pacific[China, Southeast Asia, India, Japan, Korea, Western Asia], Europe[Germany, UK, France, Italy, Russia, Spain, Netherlands, Turkey, Switzerland], North America[United States, Canada, Mexico], Middle East & Africa[GCC, North Africa, South Africa], South America[Brazil, Argentina, Columbia, Chile, Peru].

At the same time, we classify Cellulose Ether Derivatives according to the type, application by geography. More importantly, the report includes major countries market based on the type and application.

Finally, the report provides detailed profile and data information analysis of leading Cellulose Ether Derivatives company.

Leading players of Cellulose Ether Derivatives including:

DOW Chemical Company

Akzonobel

Shin-Etsu Chemical

Ashland

Daicel Finechem Ltd

Lotte Fine Chemicals

DSK Co. Ltd.

China Ruitai International Holdings Co. Ltd

Fenchem Biotek Ltd

J. Rettenmaier & Sohne GmbH + Co.Kg (JRS)

Reliance Cellulose Products Ltd

CP Kelco

Shandong Head Co. Ltd

Sichem LLC

Zhejiang Kehong Chemical Co. Ltd

SE Tylose GmbH & Co. Kg

Cellulose Ether Derivatives Market split by Type, can be divided into:

Methyl Cellulose (MC)

Hydroxypropyl Methylcellulose (HPMC)

Hydroxymethyl Methylcellulose (HMC)

Carboxymethyl Cellulose (CMC)

Hydroxyethyl Cellulose (HEC)

Ethyl Cellulose (EC)

Hydroxypropyl Cellulose (HPC)

Cellulose Ether Derivatives Market split by Application, can be divided into:

Foods & Beverages

Construction

Paints & Coatings

Pharmaceuticals

Personal Care

Mining

Cellulose Ether Derivatives Market Report Scope

Report AttributeDetails

Base year of estimation2021

Historical data2017 – 2020

Forecast period2022 – 2030

Quantitative unitsRevenue in USD million/billion and CAGR from 2022 to 2030

Segmentation

By Type

By Application

By Region/Country

By Type Methyl Cellulose (MC), Hydroxypropyl Methylcellulose (HPMC), Hydroxymethyl Methylcellulose (HMC), Carboxymethyl Cellulose (CMC), Hydroxyethyl Cellulose (HEC), Ethyl Cellulose (EC), Hydroxypropyl Cellulose (HPC)

By Application Foods & Beverages, Construction, Paints & Coatings, Pharmaceuticals, Personal Care, Mining

Report coverageRevenue forecast, company market share, competitive landscape, growth factors, and trends

Key companies profiledDOW Chemical Company, Akzonobel, Shin-Etsu Chemical, Ashland, Daicel Finechem Ltd, Lotte Fine Chemicals, DSK Co. Ltd., China Ruitai International Holdings Co. Ltd, Fenchem Biotek Ltd, J. Rettenmaier & Sohne GmbH + Co.Kg (JRS), Reliance Cellulose Products Ltd, CP Kelco, Shandong Head Co. Ltd, Sichem LLC, Zhejiang Kehong Chemical Co. Ltd, SE Tylose GmbH & Co. Kg

Regional scope

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Spain etc.)

Asia-Pacific (China, Japan, Korea, India, Australia and Southeast Asia etc.)

South America (Brazil, Argentina and Colombia etc.)

Middle East & Africa (South Africa, UAE and Saudi Arabia etc.)

Table of Contents

Part 1 Market Overview

1.1 Market Definition

1.2 Market Development

1.2.1 Current Situation

1.2.2 Aspects of COVID-19 Impact

1.3 By Type

Table Type of Cellulose Ether Derivatives

Figure Global Cellulose Ether Derivatives Market Share by Type in 2021

1.4 By Application

Table Application of Cellulose Ether Derivatives

Figure Global Cellulose Ether Derivatives Market Share by Application in 2021

1.5 By Region

Figure Global Cellulose Ether Derivatives Market Share by Region in 2021

Figure Asia Cellulose Ether Derivatives Market Share by Region in 2021

Part 2 Key Companies

2.1 DOW Chemical Company

2.1.1 Company Profile

Table DOW Chemical Company Overview List

2.1.2 Products & Services Overview

2.1.3 Sales Data List

Table Cellulose Ether Derivatives Business Operation of DOW Chemical Company (Sales Revenue, Sales Volume, Price, Cost, Gross Margin)

2.2 Akzonobel

2.3 Shin-Etsu Chemical

2.4 Ashland

2.5 Daicel Finechem Ltd

2.6 Lotte Fine Chemicals

2.7 DSK Co. Ltd.

2.8 China Ruitai International Holdings Co. Ltd

2.9 Fenchem Biotek Ltd

2.10 J. Rettenmaier & Sohne GmbH + Co.Kg (JRS)

2.11 Reliance Cellulose Products Ltd

2.12 CP Kelco

2.13 Shandong Head Co. Ltd

2.14 Sichem LLC

2.15 Zhejiang Kehong Chemical Co. Ltd

2.16 SE Tylose GmbH & Co. Kg

Part 3 Global Market Status and Future Forecast

3.1 Global Market by Region

Table Global Cellulose Ether Derivatives Market by Region, 2017 – 2020 (Million USD)

Figure Global Cellulose Ether Derivatives Market Share by Region in 2021 (Million USD)

Table Global Cellulose Ether Derivatives Market by Region, 2017 – 2020 (Volume)

Figure Global Cellulose Ether Derivatives Market Share by Region in 2021 (Volume)

Table Price List by Region, 2017 – 2020

3.2 Global Market by Company

Table Global Cellulose Ether Derivatives Market by Company, 2017 – 2020 (Million USD)

Figure Global Cellulose Ether Derivatives Market Share by Company in 2021 (Million USD)

Table Global Cellulose Ether Derivatives Market by Company, 2017 – 2020 (Volume)

Figure Global Cellulose Ether Derivatives Market Share by Company in 2021 (Volume)

Table Price List by Company, 2017 – 2020

3.3 Global Market by Type

Table Global Cellulose Ether Derivatives Market by Type, 2017 – 2020 (Million USD)

Figure Global Cellulose Ether Derivatives Market Share by Type in 2021 (Million USD)

Table Global Cellulose Ether Derivatives Market by Type, 2017 – 2020 (Volume)

Figure Global Cellulose Ether Derivatives Market Share by Type in 2021 (Volume)

Table Price List by Type, 2017 – 2020

3.4 Global Market by Application

Table Global Cellulose Ether Derivatives Market by Application, 2017 – 2020 (Million USD)

Figure Global Cellulose Ether Derivatives Market Share by Application in 2021 (Million USD)

Table Global Cellulose Ether Derivatives Market by Application, 2017 – 2020 (Volume)

Figure Global Cellulose Ether Derivatives Market Share by Application in 2021 (Volume)

Table Price List by Application, 2017 – 2020

3.5 Global Market by Forecast

Figure Global Cellulose Ether Derivatives Market Forecast, 2022-2030 (Million USD)

Figure Global Cellulose Ether Derivatives Market Forecast, 2022-2030 (Volume)

Part 9 Market Features

9.1 Product Features

9.2 Price Features

9.3 Channel Features

9.4 Purchasing Features

Part 10 Investment Opportunity

10.1 Regional Investment Opportunity

10.2 Industry Investment Opportunity

PART 11 Coronavirus Impact

11.1 Impact on Industry Upstream

11.2 Impact on Industry Downstream

11.3 Impact on Industry Channels

11.4 Impact on Industry Competition

11.5 Impact on Industry Obtain Employment

Part 12 Conclusion

Related Reports :

System of Insight Market :https://www.newstrail.com/system-of-insight-market-size-share-growth-trends-regional-outlook-and-forecast-2022-2030/

System Integrators in Aerospace and Defense Market : https://www.newstrail.com/system-integrators-in-aerospace-and-defense-market/

Synthetic Textile Flooring Market : https://www.newstrail.com/synthetic-textile-flooring-market/

0 notes

Link

0 notes